MIM-Fe-3Si

Magnetic Alloy MIM-Fe-3Si Injection Molding

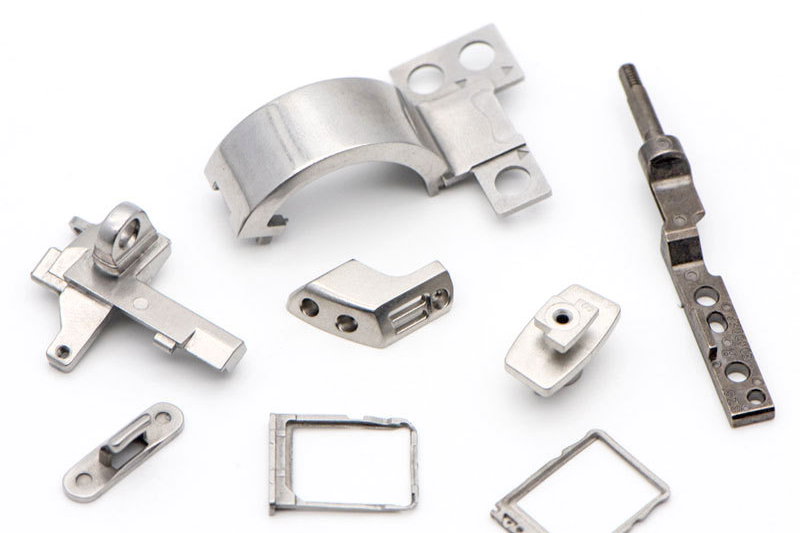

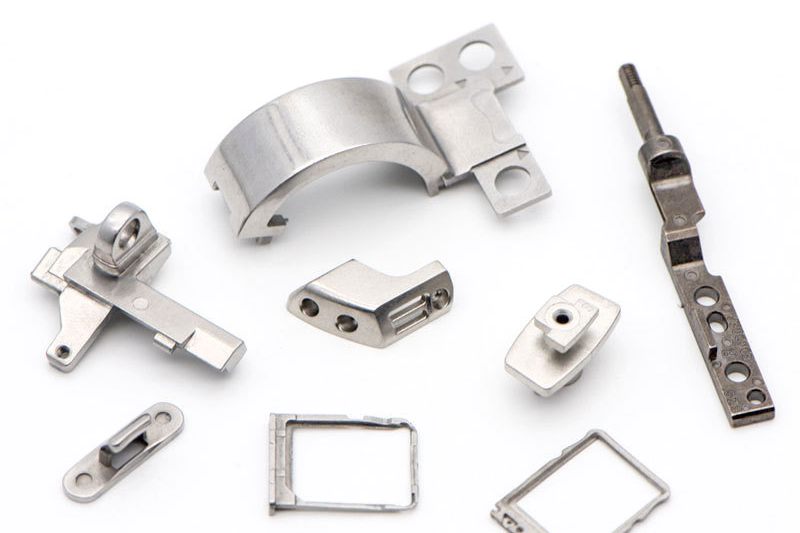

Magnetic Alloy MIM-Fe-3Si MIM Sintering Parts

Magnetic Alloy MIM-Fe-3Si MIM sintering parts exhibit exceptional magnetic performance that sets them apart. With specific properties like high saturation magnetization and low coercivity, these parts are pivotal in creating efficient electromagnetic devices. Their precision allows for intricate designs, ensuring optimal performance of consumer electronics, telecommunication, and power tools. Moreover, their magnetic stability over a wide range of temperatures makes them invaluable in applications where consistent performance is critical, such as in lighting solutions and locking systems.

Secondly, the MIM-Fe-3Si MIM sintering parts offer outstanding durability and resistance to corrosion, enhancing their longevity even in demanding environments. This resilience is particularly advantageous in aerospace, where components must withstand extreme conditions.

Typical Applications:

Wireless Earphone Parts

Signal Amplifiers

Magnetic Ballasts Parts

Magnetic Lock Parts

Typical Properties Of MIM-Fe-3Si Magnetic Alloy

Chemical Composition Of MIM-Fe-3Si Magnetic Alloy

Element | Composition (Percentage by Weight) |

|---|---|

Iron (Fe) | 97.5% |

Silicon (Si) | 2.5% |

MIM-Fe-3Si Physics and Mechanical Properties

Property | Status | Tensile Strength (MPa) | Yield Strength (MPa) | Impact Strength (J/cm²) | Hardness (HRC) | Young's Modulus (GPa) | Poisson's Ratio | Elongation (%) | Density (g/cm³) |

|---|---|---|---|---|---|---|---|---|---|

MIM-Fe-3Si Magnetic Alloy | As Sintered | 580 | 360 | 30 | 35 | 175 | 0.29 | 5 | 7.8 |

Applications of MIM-Fe-3Si MIM Sintering Parts

MIM-Fe-3Si MIM Sintering Wireless Earphone Parts

MIM-Fe-3Si MIM sintering parts are exceptionally well-suited for applications in wireless earphones due to their unique blend of properties. Firstly, their high precision manufacturing allows for intricate and compact designs, crucial in the miniaturized components of wireless earphones. These parts can be crafted precisely down to the micrometer level, ensuring a snug fit within the earphone's casing, which is especially vital for the earbuds' comfortable and ergonomic design.

Secondly, the magnetic properties of MIM-Fe-3Si play a pivotal role in the functionality of wireless earphones. These parts can create micro-sized speakers and drivers, offering superior acoustic performance. The alloy's high saturation magnetization and low coercivity ensure efficient sound generation and clarity. Additionally, their durability ensures long-lasting earphone performance, making them an ideal choice for the demanding requirements of the consumer electronics industry.

MIM-Fe-3Si MIM Sintering Signal Amplifiers

MIM-Fe-3Si sintering parts offer exceptional advantages for signal amplifiers in various industries, including Telecommunication and Consumer Electronics. These parts are crafted through Metal Injection Molding (MIM), a precision manufacturing process that Neway excels at. MIM ensures the production of intricate and high-precision components, making it ideal for signal amplifier applications where precision is paramount.

MIM-Fe-3Si components exhibit low magnetic permeability in signal amplifiers, a critical attribute for minimizing electromagnetic interference. Their magnetic properties contribute to signal integrity and overall amplifier performance. Moreover, their excellent thermal conductivity and stability ensure reliable long-term operation, even in demanding conditions.

Magnetic Alloy MIM-Fe-3Si MIM Sintering Magnetic Ballasts Parts

Firstly, MIM-Fe-3Si parts exhibit outstanding magnetic properties, including high magnetic permeability and low coercivity. Magnetic ballasts must ensure efficient energy transfer and reduce power losses during operation. The precise control over material composition and sintering process parameters allows for attaining specific magnetic characteristics and optimizing ballast performance.

Secondly, these sintered parts can be produced with remarkable dimensional accuracy and tight tolerances down to micrometer levels. In the lighting solutions industry, where precision is paramount, MIM-Fe-3Si components provide the exacting specifications for consistent and reliable ballast operation. This precision ultimately translates into improved overall efficiency and longevity of lighting systems.

Magnetic Alloy MIM-Fe-3Si MIM Sintering Magnetic Lock Parts

MIM-Fe-3Si sintering parts offer remarkable advantages, making them an ideal choice for magnetic lock components in various industries, including Locking Systems and Consumer Electronics. These parts exhibit exceptional precision, with a sintering tolerance often reaching up to ±0.3%, ensuring the seamless operation of locking mechanisms. This high-precision attribute is crucial in lock components, where even the slightest deviation can affect performance.

Furthermore, MIM-Fe-3Si sintering parts possess excellent magnetic properties. With a coercivity of approximately 15 Oe and a saturation magnetization of 15 emu/g, these parts can generate strong magnetic forces, providing reliable and secure locking solutions. Their corrosion resistance and durability are additional benefits, ensuring long-term functionality in diverse environments.

Neway Custom Manufacturing Capability

Neway has gradually improved the production system of basic hardware, plastic, and ceramic non-standard parts after 30 years of growth from the original CNC workshop. As well as polishing, PVD, and simple assembly lines. Provide one-stop, non-standard manufacturing services to our customers.

More MIM Materials Optional

Neway has a comprehensive selection of metal injection molding materials. We have a mature metal powder supply chain. At the same time, we can configure the powders according to specific MIM part requirements.

Common MIM Materials We Use: