Custom Components for

Emobility solutions

Experience the power of precision components for emobility solutions. Our expertly engineered components deliver exceptional performance, reliability, and efficiency. Drive the future of transportation with our precision components tailored for emobility applications.

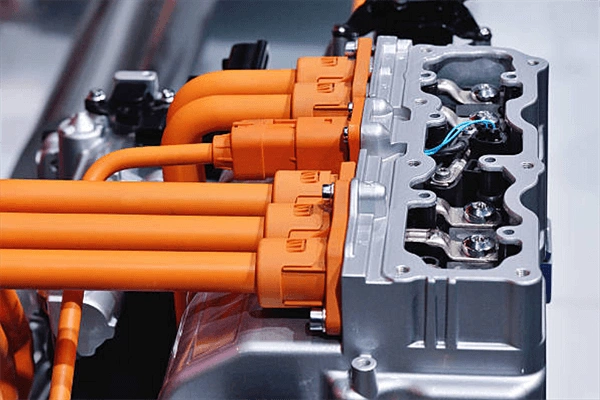

Battery Component Solutions for Advanced Electric Mobility

Safe and efficient battery management is crucial for electric vehicles. Our precision manufacturing processes, including CNC machining, plastic injection molding, insert molding, and precision casting, produce high-quality battery pack frames, housings, connectors, and cooling components. These ensure efficient thermal management, secure battery protection, reliable electrical connectivity, and durability, optimizing battery performance and safety across electric cars, scooters, and e-bikes.

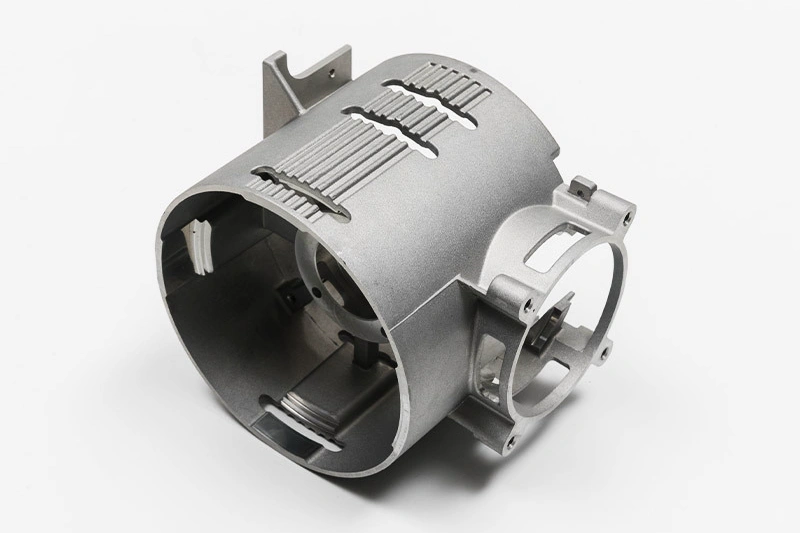

Precision Motor Component Manufacturing for Electric Vehicles

High-efficiency electric motors require precision-crafted components for optimal performance. Utilizing processes such as metal injection molding, powder pressing molding, CNC machining, and precision casting, we produce high-density magnetic cores, rotor components, and stators. These components significantly enhance motor efficiency, torque, durability, and thermal management, crucial for reliable operation in electric cars, scooters, e-bikes, and other e-mobility solutions.

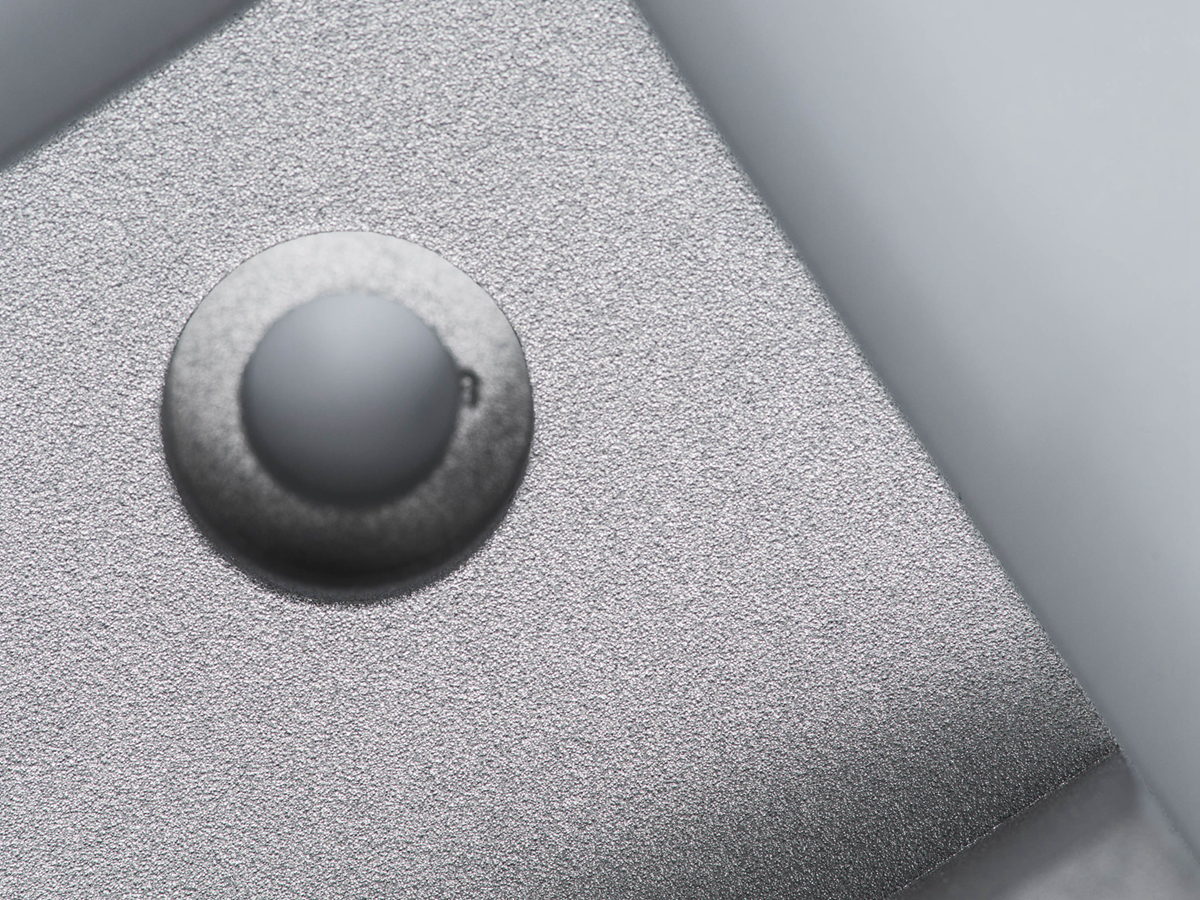

Lightweight Structural Solutions for Enhanced Electric Mobility

Reducing vehicle weight is key to maximizing range and performance in electric mobility. We specialize in aluminum die casting, sheet metal stamping, plastic injection molding, and precision metal bending to manufacture lightweight, durable battery housings, motor casings, structural frames, and protective enclosures. These components improve energy efficiency, structural integrity, crashworthiness, and overall vehicle dynamics for EVs, scooters, and e-bikes.

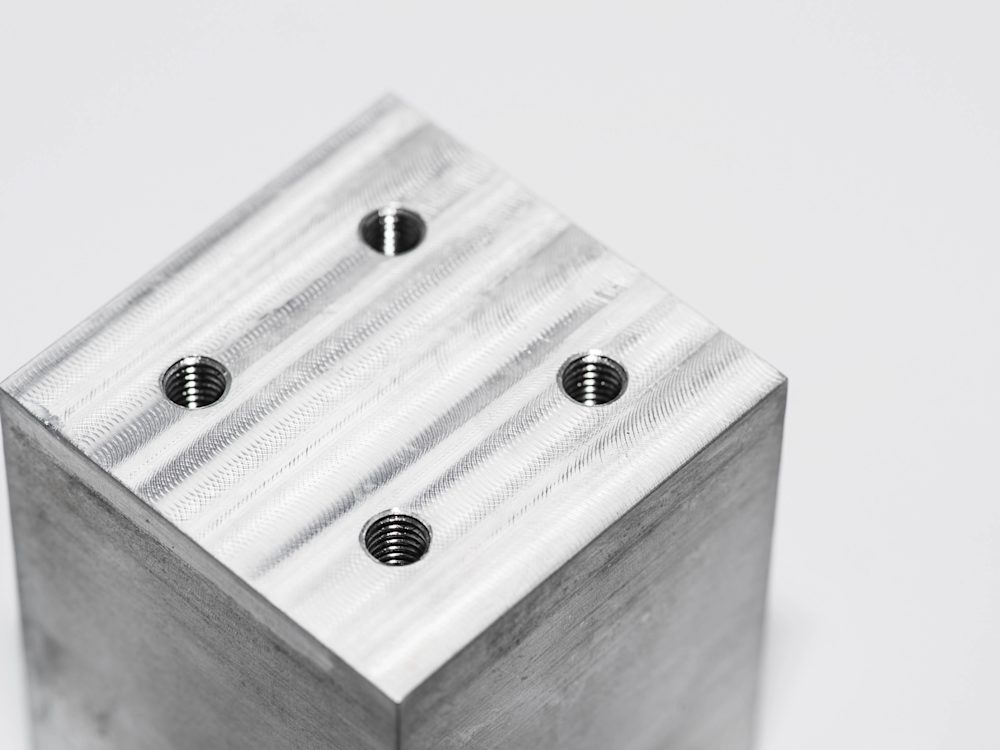

Accelerated E-Mobility Prototyping & Component Verification

Accelerate e-mobility development cycles with our rapid prototyping services. Using CNC machining, 3D printing, and rapid molding, we quickly produce prototypes of motor casings, battery housings, electronic enclosures, and structural elements. These rapid prototyping capabilities enable extensive functional testing, accurate validation, and quicker market entry, helping manufacturers efficiently optimize designs, reduce risks, and meet stringent quality standards required in electric mobility.

Case Study

Let's Start A New Project Today

Explore Related Resources

Solutions

Copyright © 2026 Neway Precision Works Ltd.All Rights Reserved.