History

1993

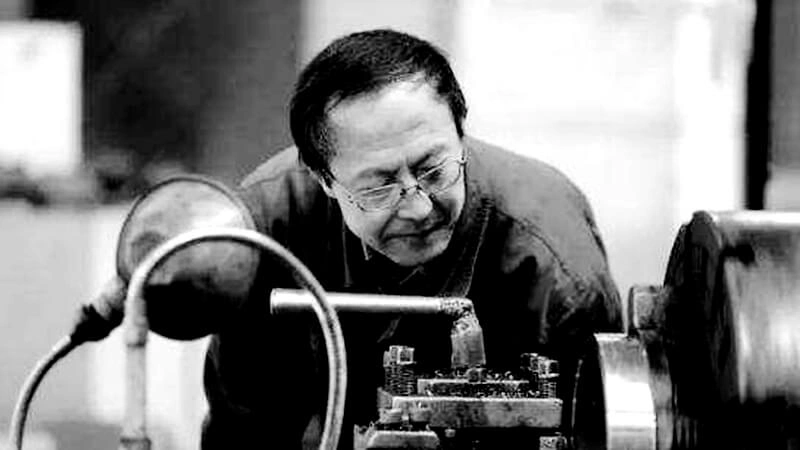

Predecessor of Neway

Initially, the founder couple operated 3 manual lathes and 1 milling machine to serve the local small factory. It mainly provides ordinary lathe parts. Each lathe can produce 800 to 100 parts with a diameter of less than 60 mm per day. and the profit can only support the living. However, in the cumulative production process, the continuous improvement of turning technology can produce more precise parts.

1995

Neway Precision Works Ltd established

With the development of society and industry. Turning parts can no longer meet the local market. So Neway Company was established and the first milling machine was purchased with a loan. And use this milling machine to provide more complex parts for local mechanical equipment manufacturers. Even in the simplest environment, Neway always maintains high requirements for the quality and accuracy of parts, which also makes Neway a high reputation in the local market.

1999

Neway provided a one-stop CNC machining service

Neway started the design and manufacture of simple molds. Neway started the manufacturing of aluminum alloy sand casting mold and laid the foundation for mold design and manufacturing in this process. The products manufactured through the molds produced by Neway have precise tolerances and excellent appearance.

2006

Scale expanding

After seven years of efforts, Neway has developed nearly 500 sets of molds. In the local market, Neway provided 80% of injection molding plants, die-casting plants, and equipment manufacturers with mold design and manufacturing services and won unanimous praise. At the same time, in order to meet the needs of customers, Neway introduced a 3-axis CNC machining center. It also expanded the plant area to provide customers with the best OEM& ODM services.

2007

Start die casting business

Neway horizontally expanded its business scope and added 3 large die-casting machines. Start to die casting OEM service. The production of die-casting is more efficient and material-saving than CNC machining. At the same time, it has higher product stability and consistency. Die casting is also more suitable for mass production services.

2013

Start metal injection molding business

With the rapid development of the Chinese industry, Neway is committed to providing customers with metal parts. And further into the production field of metal injection molding. Designed to produce high-precision and high-complexity small stainless steel and hard alloy OEM production. Solve the low precision problem of precision casting, such as investment casting in producing small stainless steel and complex metal parts.

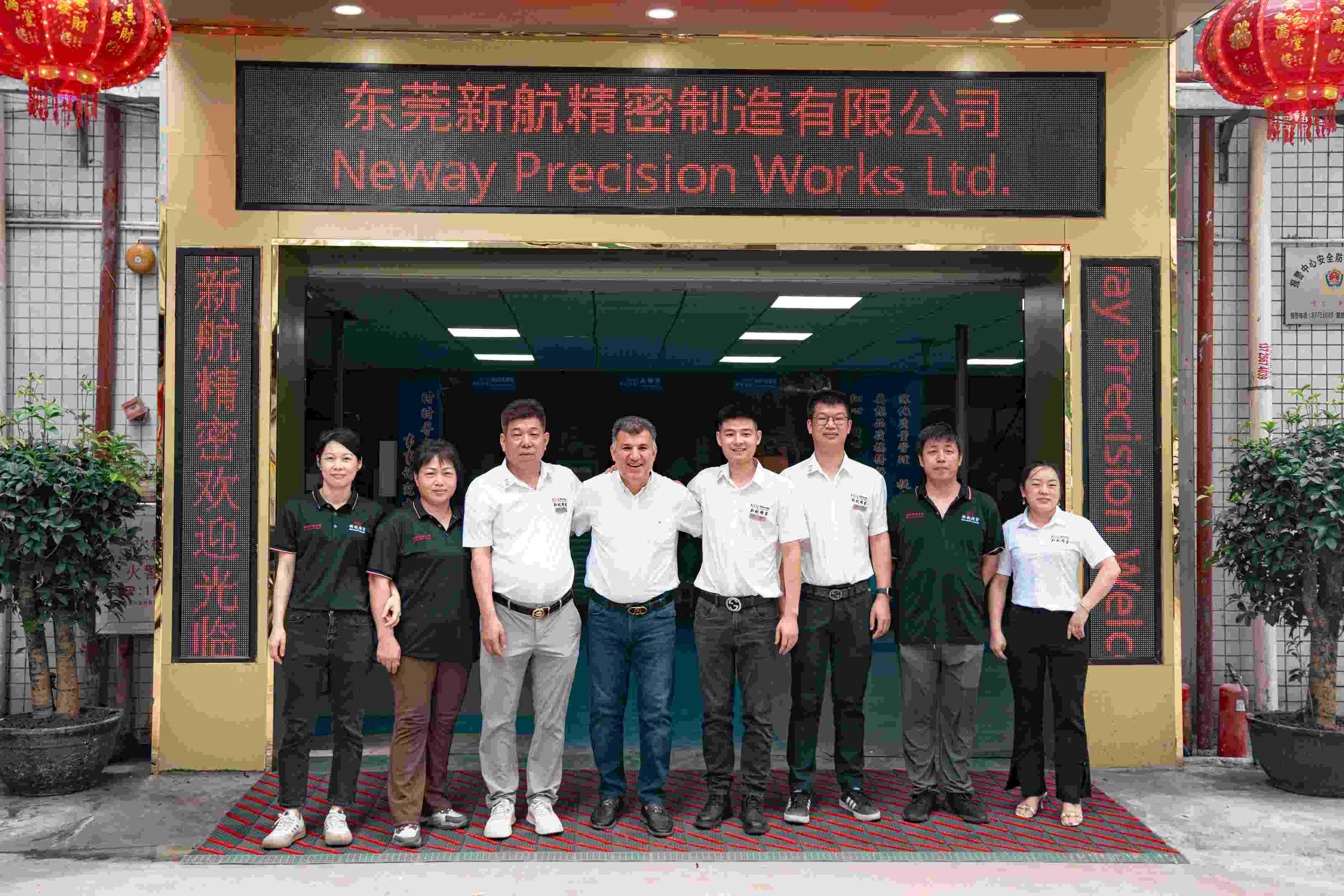

2018

The original founder retires. Introduction of new power

NewayPrecision and CEDCO Gmbh jointly established a high-temperature alloy parts manufacturing production line. Including single crystal casting, equiaxed crystal castingand post-processing production lines for high-temperature alloy parts. Mainly provide high-quality, high-temperature alloy parts for aerospace, petroleum, drilling, natural gas, and other industries.

2019

Planning for automated unmanned workshops

In order to further reduce the customer's production costs. Neway is planning an automated workshop, using machines to replace labor to reduce production costs...This is a huge challenge for Neway, an automated workshop has extremely high initial costs. But Neway will keep reforming to adapt to the market.

2021

Heavy Cutting CNC Machining Workshop

We have established a CNC heavy-duty cutting and machining center department, and all the equipment are V855 or above. The CNC machining center has three rigid guides or two linear guides and one rigid guide. Including more than 30 3-axis, 4-axis, and 5-axis equipment. We focus on cutting hard metals such as high-temperature alloys and titanium.

2023

Neway's 30th birthday. Auto production line finished

Neway keeps increasing the automation of production lines. And submitted another customer's satisfactory answer. At present, the cost of operating workers in the Chinese market is about 1000 USD per month. The automation equipment to replace a worker is about 10000 USD. After installing automation equipment for 1 year, the equipment can start to provide its residual value. Provide customers with more competitive prices in the market competition.

2024

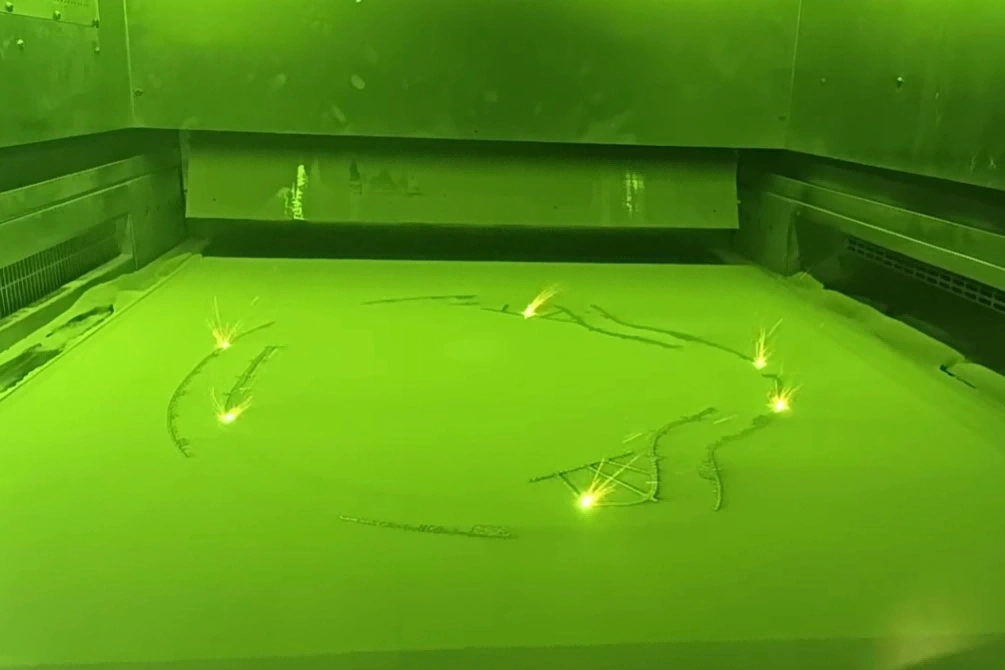

Superalloy Parts Manufacturing Technology

Neway introduces more advanced high temperature alloy casting technology and CNC machining technology. Provides single crystal casting technology with better high temperature performance. Provides superalloy 3D Printing prototyping service. Established a complete super alloy parts manufacturing division. More than 60 people work for this division. Provides one-stop service such as proofing, casting, post-processing, surface treatment, etc. for super alloy parts.

Solutions

Copyright © 2026 Neway Precision Works Ltd.All Rights Reserved.