Custom Parts Online Rapid Prototyping Service

Get your innovative ideas off the ground with our rapid prototyping service. We specialize in custom metal and plastic parts manufacturing, providing high-quality prototypes that match your exact specifications.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

Neway Prototyping Service Processing

We offer cost-effective prototyping solutions for your custom metal and plastic parts. Our expertise in manufacturing and prototyping ensures that your project stays within your budget without sacrificing quality.

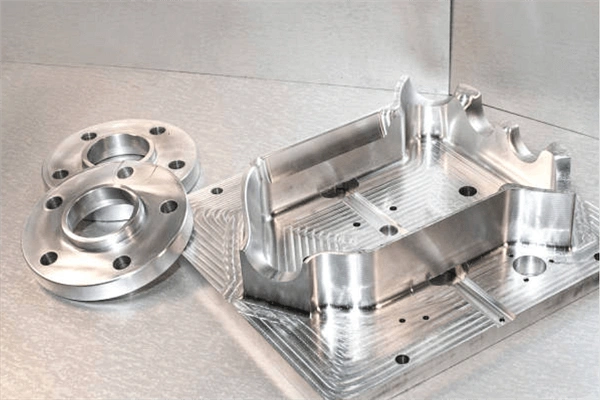

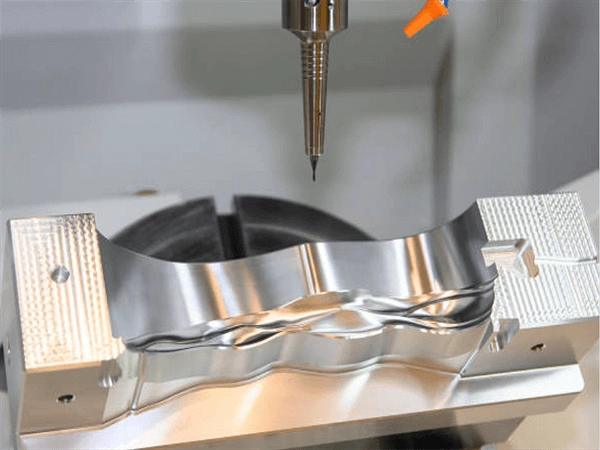

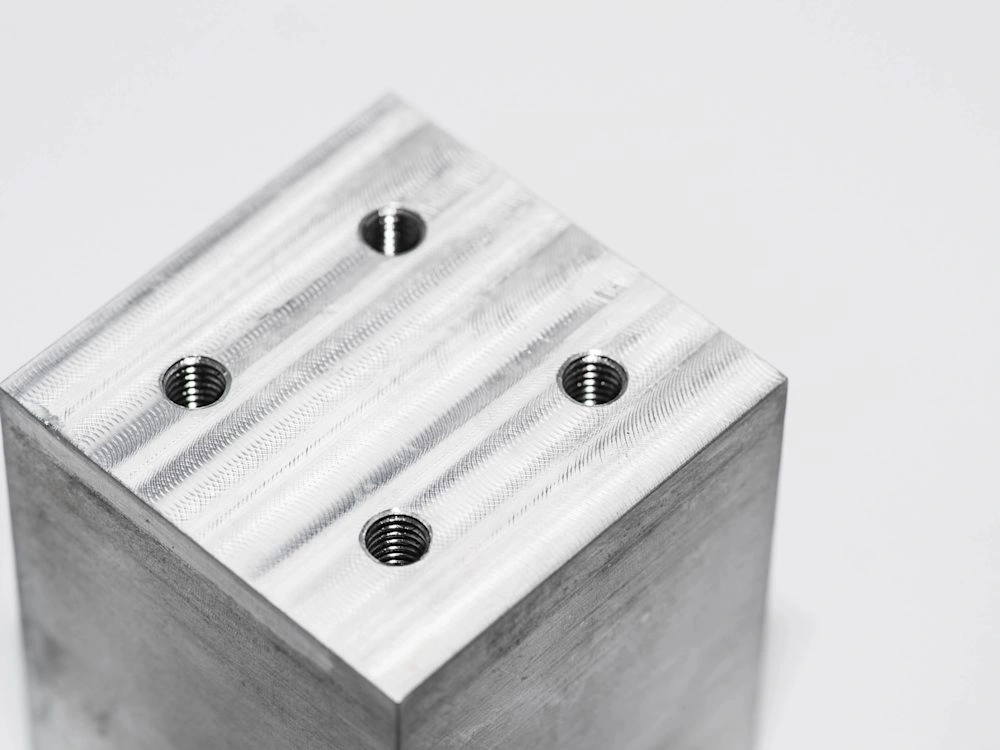

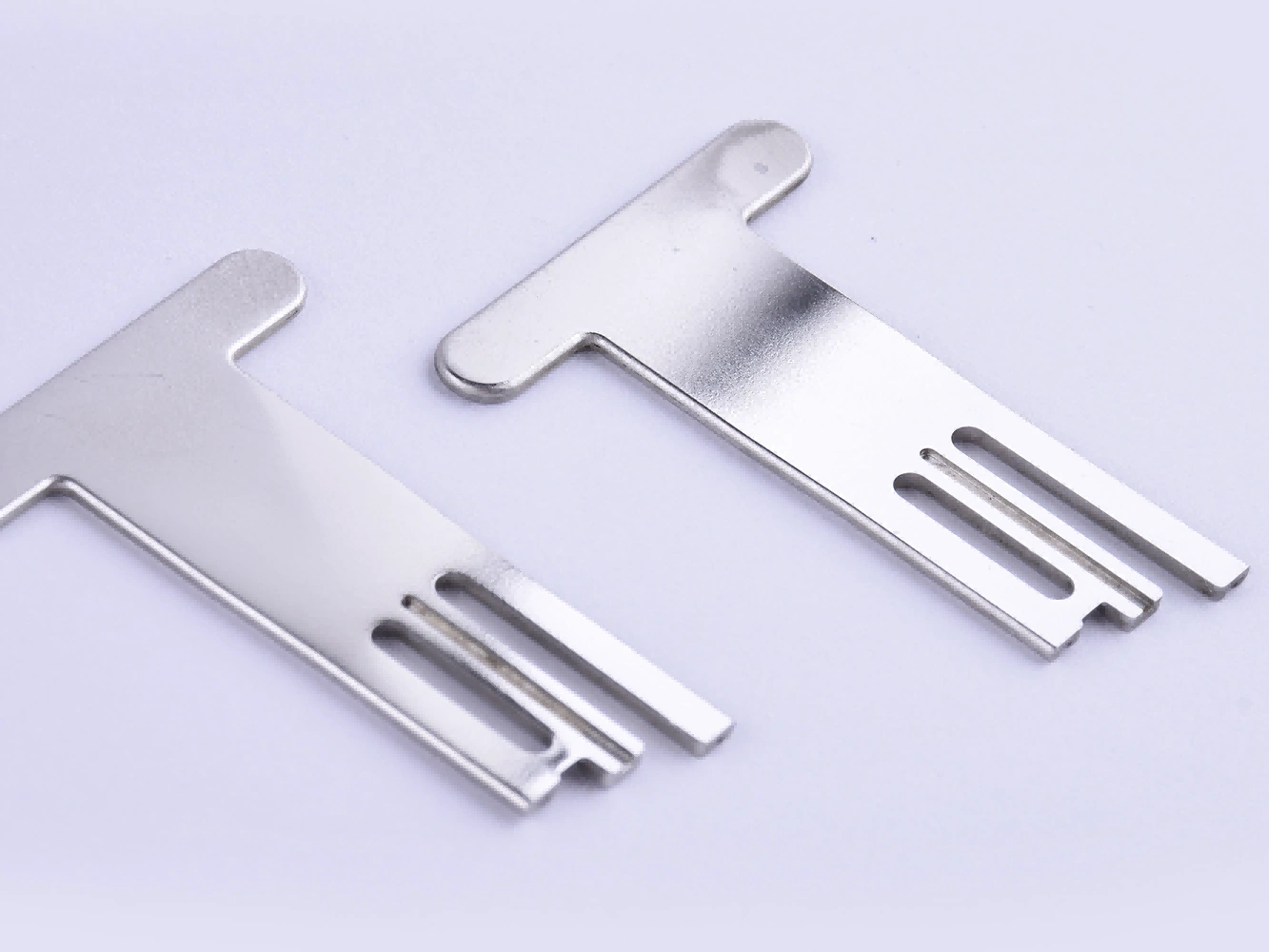

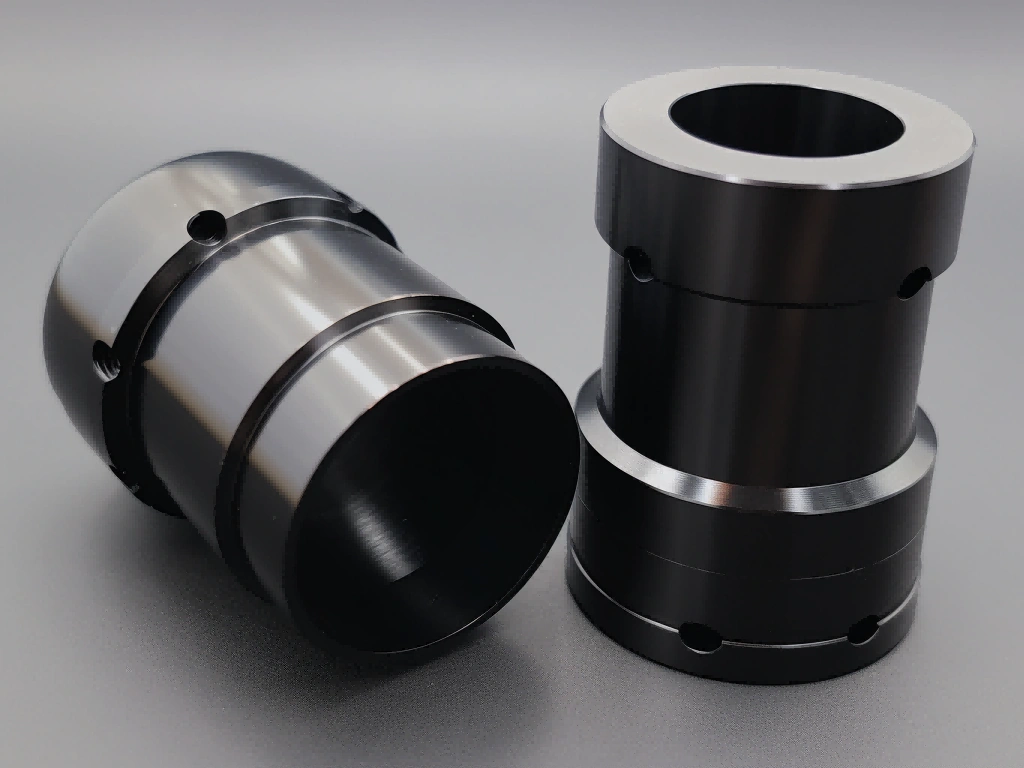

One of the major advantages of CNC machining is its ability to produce complex shapes and features with high precision and accuracy. CNC machines can work with a wide variety of materials, including metals, plastics, and composites, making it a versatile option for prototypin

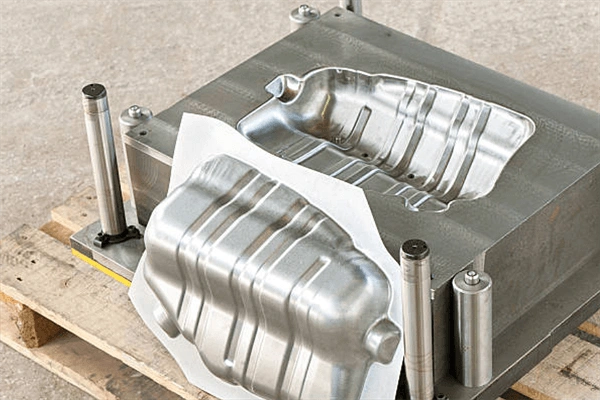

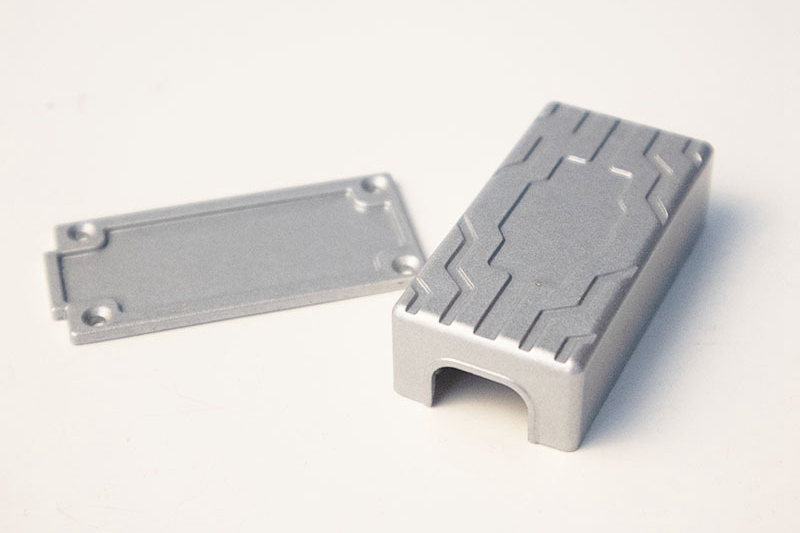

The main advantage of rapid molding is its ability to produce large quantities of parts quickly and cost-effectively. This makes it an ideal choice for prototyping parts that will be mass-produced later. Rapid molding also allows for the creation of complex geometries and features that would be difficult or impossible to achieve with other manufacturing methods.

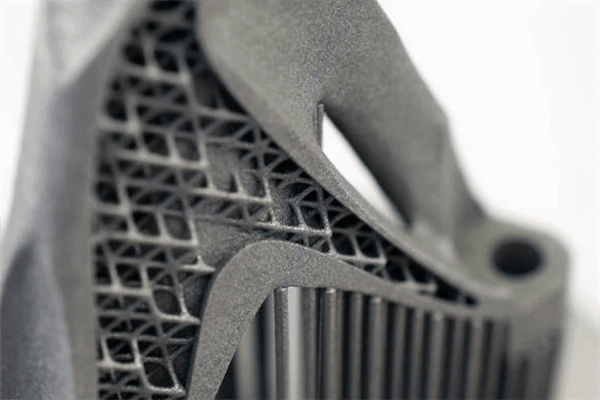

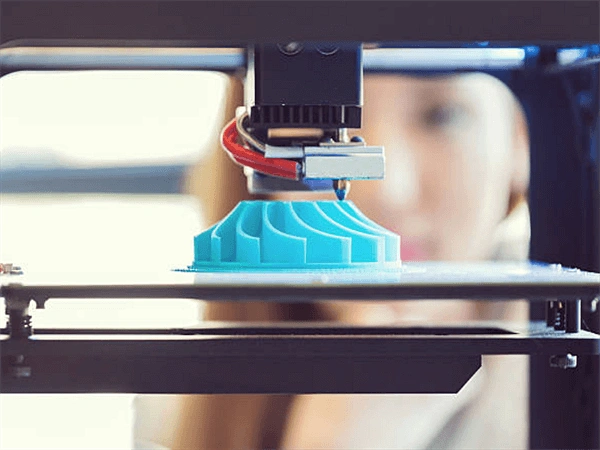

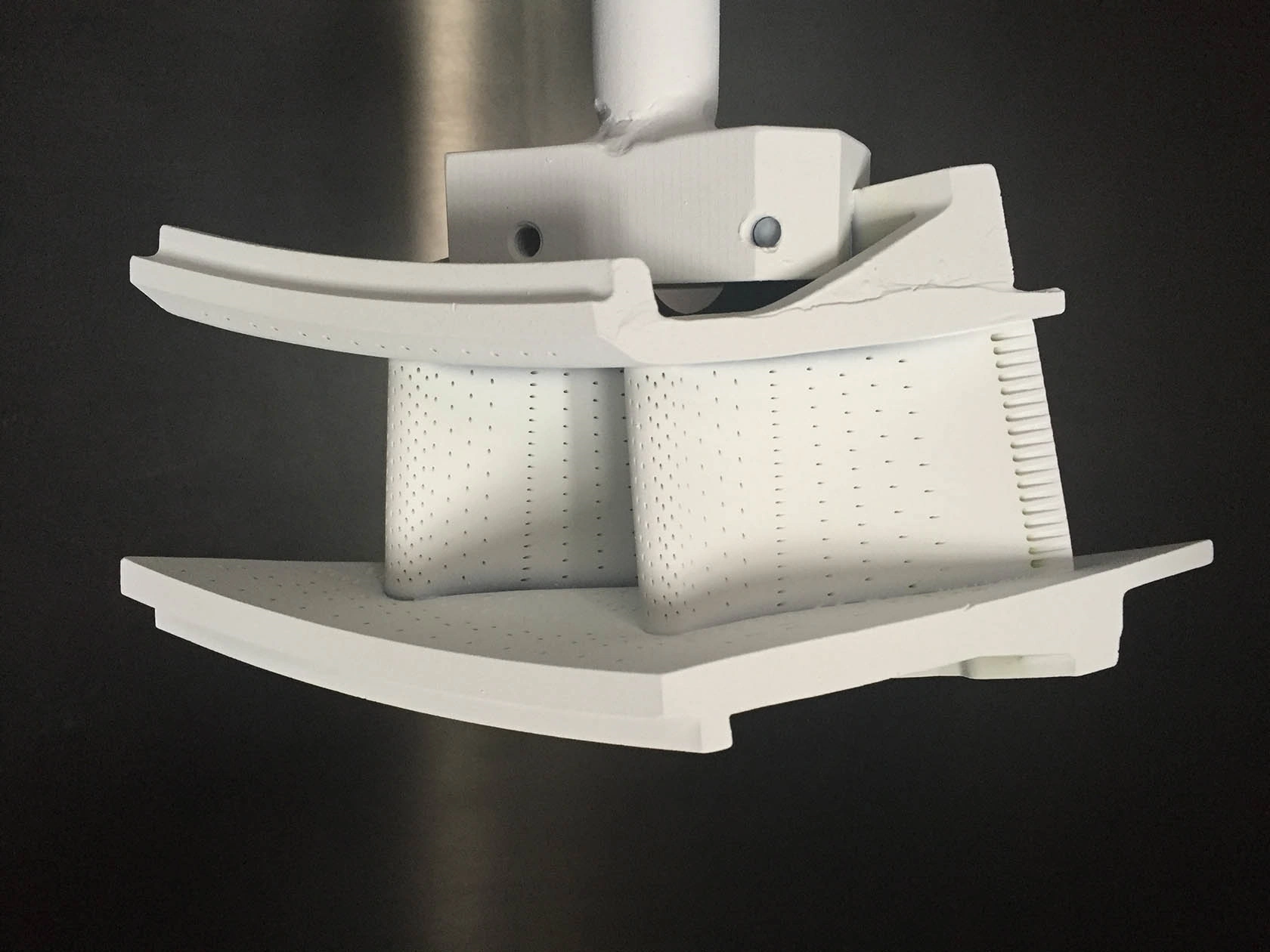

3D printing is a highly versatile prototyping method that can create complex shapes and geometries with ease. It also allows for the creation of parts with internal features and cavities that would be difficult or impossible to achieve with other methods. Additionally, 3D printing can produce parts quickly and with minimal material waste, making it a cost-effective option for prototyping.

Prototyping Methods Comparison

Explore the benefits of different prototyping methods: CNC Machining offers precision and durability, 3D Printing excels in complexity and speed, while Rapid Molding is cost-effective for medium volumes, combining good surface finish and dimensional accuracy for diverse materials.

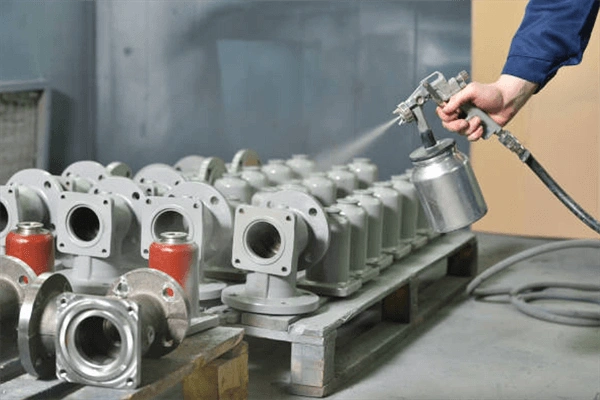

Custom Parts Surface Finishing Available

Our Surface Treatment Service offers specialized finishes for custom parts, enhancing durability, aesthetics, and performance. We provide a range of processes, including Electroplating, Anodizing, Powder Coating, and Thermal Barrier Coatings, tailored to improve corrosion resistance, wear properties, and visual appeal of metal and plastic components across industries.

Learn More

As Machined

Learn More

Painting

Learn More

PVD

Learn More

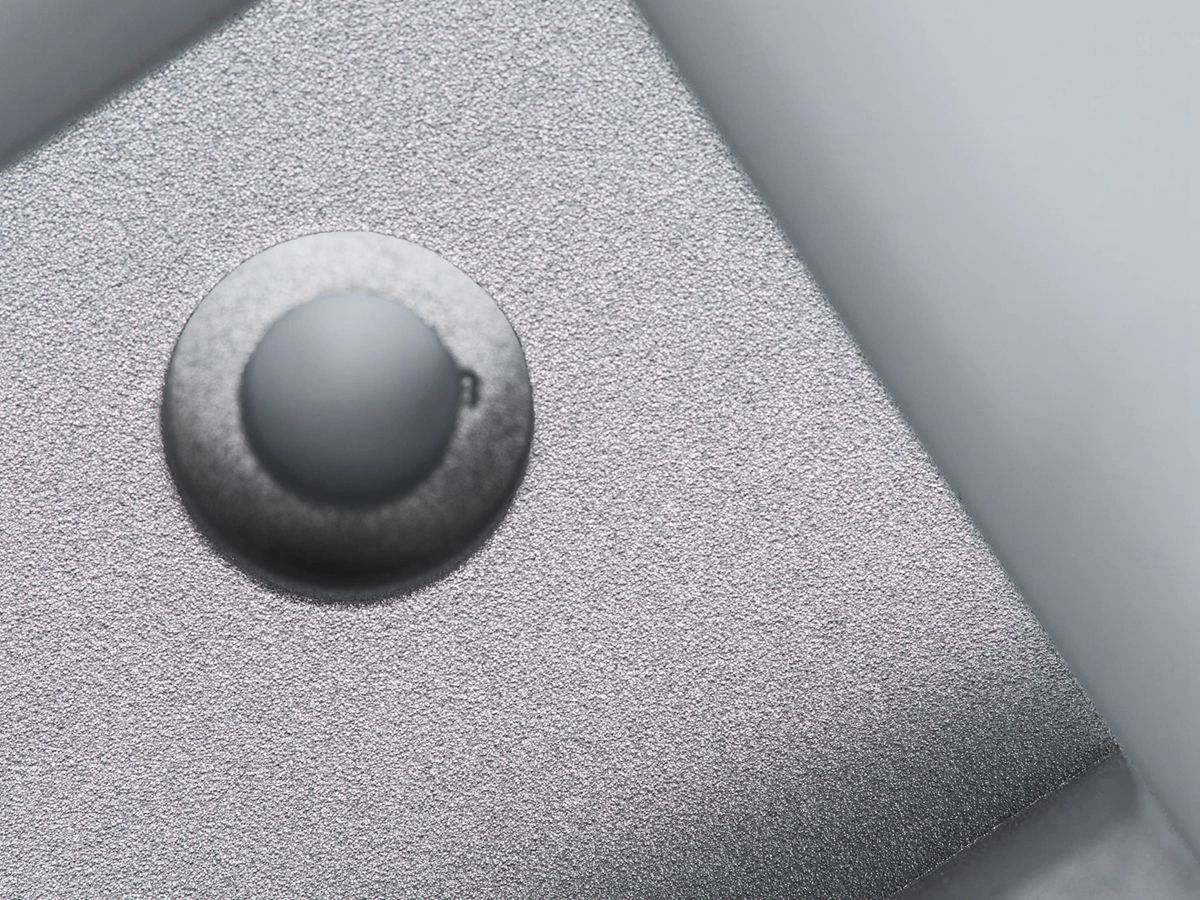

Sandblasting

Learn More

Electroplating

Learn More

Polishing

Learn More

Anodizing

Learn More

Powder Coating

Learn More

Electropolishing

Learn More

IMD

Learn More

Brushed Finishes

Learn More

Black Oxide

Learn More

Heat Treatment

Learn More

Tumbling

Learn More

Alodine

Learn More

Chrome Plating

Learn More

Phosphating

Learn More

Nitriding

Learn More

Galvanizing

Learn More

Lacquer Coating

Learn More

Teflon Coating

Learn More

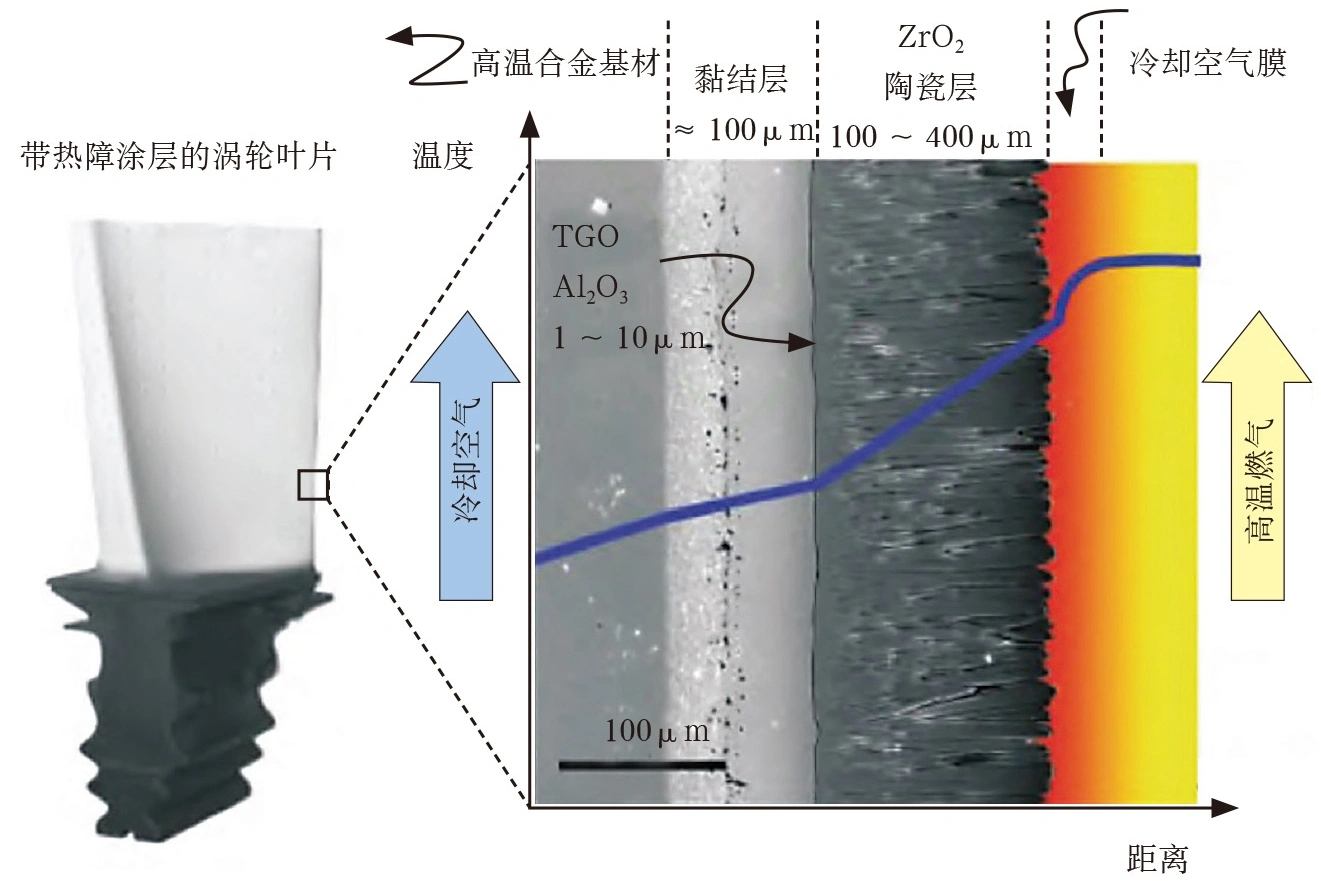

Thermal Coatings

Learn More

Thermal Barrier Coatings

Learn More

Passivation

Custom Parts Gallery

At our custom parts gallery, we understand that every project is unique. That's why we work closely with our customers to ensure that their custom parts are designed to meet their exact specifications. With our attention to detail and commitment to quality, you can trust that your custom parts will exceed your expectations.

Let's Start A New Project Today

How to Choose the Prototyping Processing

Prototyping is a crucial process in product development that enables businesses to test, validate, and optimize their designs before moving into full-scale production. The benefits of prototyping include cost reduction, faster time to market, design optimization, and testing for potential issues or flaws. By identifying and addressing design flaws early on, businesses can save on costly mistakes and ensure that the final product is optimized for performance and cost-effectiveness. Additionally, prototyping allows for the testing of different materials, configurations, and features to ensure the final product meets requirements and specifications. Ultimately, prototyping is an essential step towards successful product launches and long-term success for businesses.

Material Requirements

Consider the type of material you need for your prototype. Some prototyping processes, such as CNC machining, offer a wide range of materials, while others, like 3D printing, have more limited material options.

Frequently Asked Questions

Explore Related Resources

Solutions

Copyright © 2026 Neway Precision Works Ltd.All Rights Reserved.