On-Demand Production for

Custom Auto Parts

Get the custom auto parts you need, when you need them, through our on-demand production services. Experience fast turnaround times and top-notch quality as we bring your unique automotive visions to life. Discover the convenience and efficiency of on-demand custom auto parts production today.

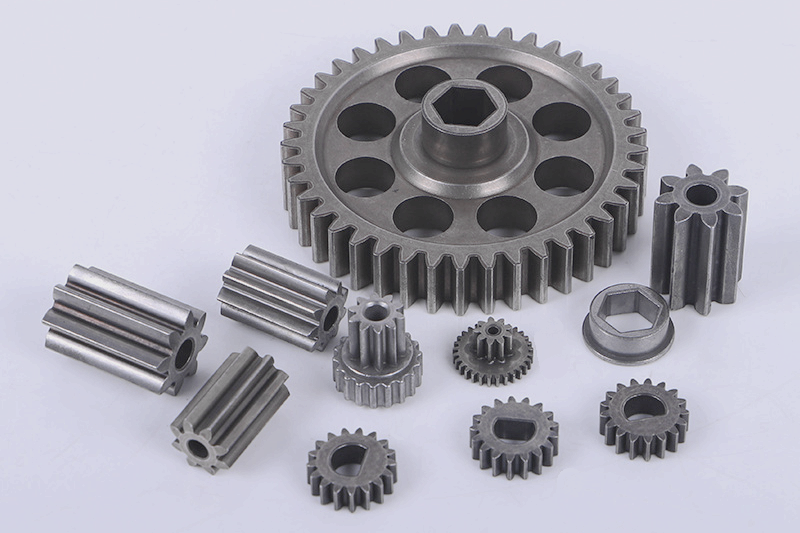

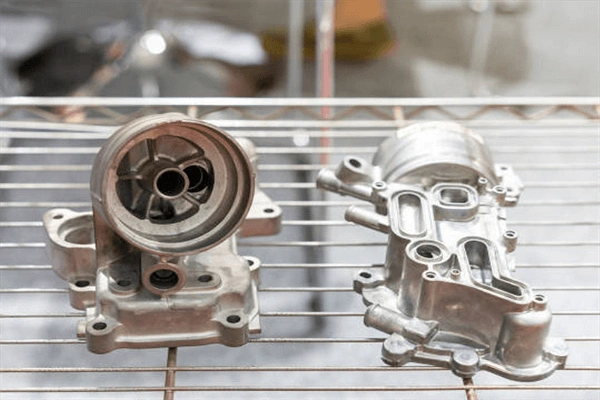

Precision Engine & Transmission Components for Automotive

Automotive engines and transmissions require highly precise, durable components for superior performance and efficiency. Using CNC machining, precision casting, powder metallurgy, and metal injection molding, we manufacture essential automotive parts, including gears, pistons, transmission housings, and valve train components. These precision components provide enhanced mechanical durability, tight tolerances, thermal stability, and reduced weight, essential for modern automotive powertrains and transmissions.

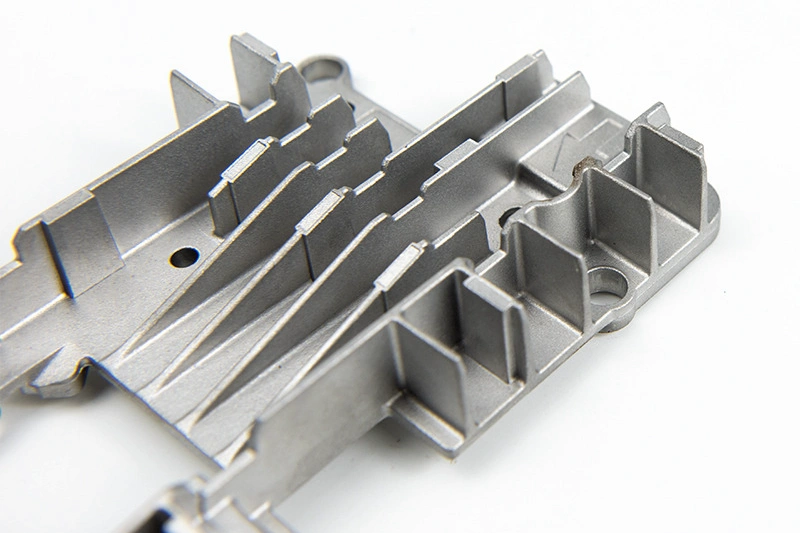

Lightweight Structural Solutions for Automotive Industry

Modern automotive design emphasizes lightweight structures for improved fuel efficiency, performance, and safety. Our aluminum die casting, precision stamping, sheet metal fabrication, and plastic injection molding processes deliver lightweight, strong structural components including chassis parts, suspension systems, body panels, and internal frames. These solutions provide superior strength-to-weight ratios, crashworthiness, corrosion resistance, and compliance with rigorous automotive industry standards.

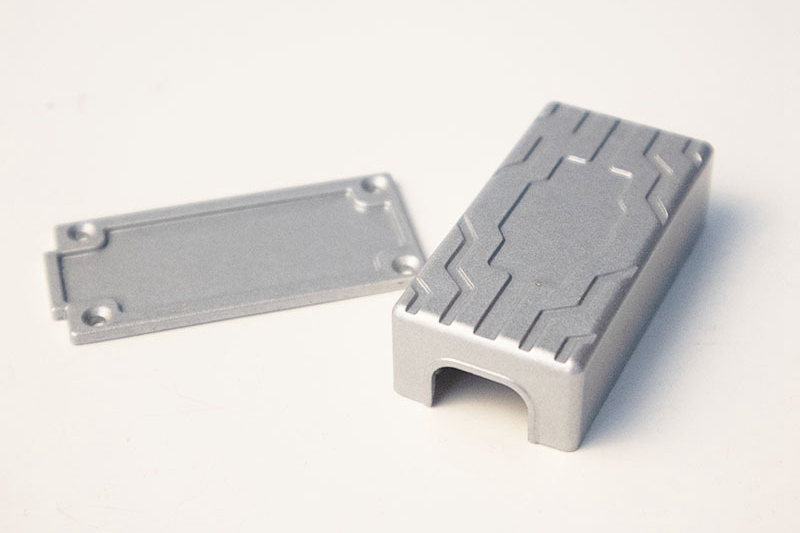

Reliable Electronic Component Manufacturing for Automotive

Automotive electronics demand precision, durability, and reliability under rigorous operating conditions. Leveraging metal injection molding, CNC machining, plastic injection molding, and insert molding, we manufacture precision connectors, sensor housings, electronic control unit (ECU) enclosures, and electrical busbars. These manufacturing solutions ensure reliable electrical connectivity, resistance to environmental stresses, thermal management, and compliance with automotive safety and performance standards.

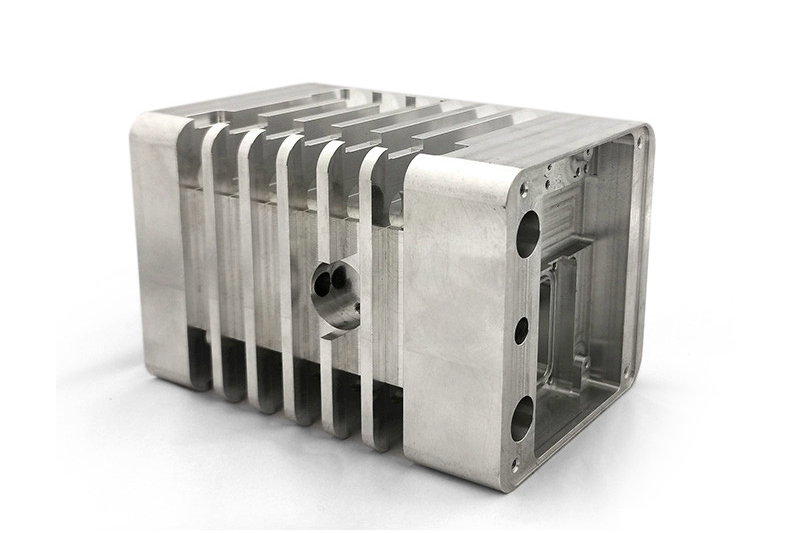

Precision Fuel & Exhaust System Component Manufacturing

Fuel and exhaust system components must withstand extreme conditions, ensuring efficiency, reliability, and compliance with emission standards. Utilizing precision casting, CNC machining, powder metallurgy, and sheet metal fabrication, we produce high-quality fuel injectors, pump components, exhaust manifolds, catalytic converter housings, and emission control parts. These solutions deliver exceptional temperature resistance, corrosion resistance, precise tolerances, and prolonged durability essential for automotive performance.

Rapid Prototyping for Automotive Component Development

Rapid prototyping facilitates swift automotive product development, validation, and performance testing. Using CNC machining, 3D printing, and rapid molding processes, we quickly deliver accurate prototypes of engine components, interior parts, structural assemblies, and electronic enclosures. This enables rapid design iterations, rigorous functionality testing, shortened development timelines, and seamless transition to mass production, enhancing innovation, reliability, and compliance in automotive applications.

Case Study

Let's Start A New Project Today

Explore Related Resources

Solutions

Copyright © 2026 Neway Precision Works Ltd.All Rights Reserved.