Rapid Prototyping for Automotive Component Development

Rapid Prototyping in Automotive Component Development: The Core Engine Driving Innovation

In the increasingly competitive automotive industry, the speed of innovation directly determines market competitiveness. Rapid prototyping has become a key tool for automakers and suppliers to shorten development cycles, reduce costs, and optimize designs. From concept validation to functional testing, precisely manufactured prototypes enable engineers to verify designs, evaluate manufacturability, and make necessary adjustments before committing to mass production. As the engineering team at Neway, we thoroughly understand the strict requirements of the automotive industry in terms of accuracy, materials, and efficiency, and provide solutions through multiple advanced prototyping technologies.

Essential Rapid Prototyping Processes in Automotive Component Development

CNC Machining Prototypes: The Preferred Choice for High-Precision Metal and Plastic Parts

In automotive prototyping, CNC machining plays a vital role due to its exceptional accuracy and wide material compatibility. This subtractive manufacturing process is particularly well-suited for producing functional test parts that require high strength and heat resistance. Whether it is engine brackets, transmission components, or brake system parts, CNC machining can deliver mechanical properties and dimensional accuracy that closely match those of the final product. Our CNC machining prototyping services, supported by multi-axis machines, can process a wide range of engineering materials from aluminum alloys to high-strength steels, providing reliable test samples for automotive engineers.

3D Printing Prototypes: Unmatched Complexity and Speed

Additive manufacturing has revolutionized the process of automotive prototype development. For components with complex internal channels, lightweight structures, or integrated functionalities, 3D printing offers unparalleled design freedom. Automotive engineers can leverage our 3D printing prototyping services to quickly produce complex geometries such as intake manifolds, custom fixtures, cooling systems, and even cylinder heads. With material options ranging from SLA photopolymer resins to metal 3D-printed aluminum alloys, different needs are met, from visual models to fully functional testing parts.

Rapid Tooling: The Bridge Between Prototyping and Low-Volume Production

When projects require low-volume prototypes for market testing or pre-production validation, rapid tooling provides an ideal solution. This technology combines the material performance of traditional injection molding with fast turnaround, making it especially suitable for interior, exterior, and various functional plastic components. Our rapid molding prototyping services enable customers to obtain low-volume injection-molded parts at a relatively low cost for assembly validation, durability testing, or early-stage marketing activities.

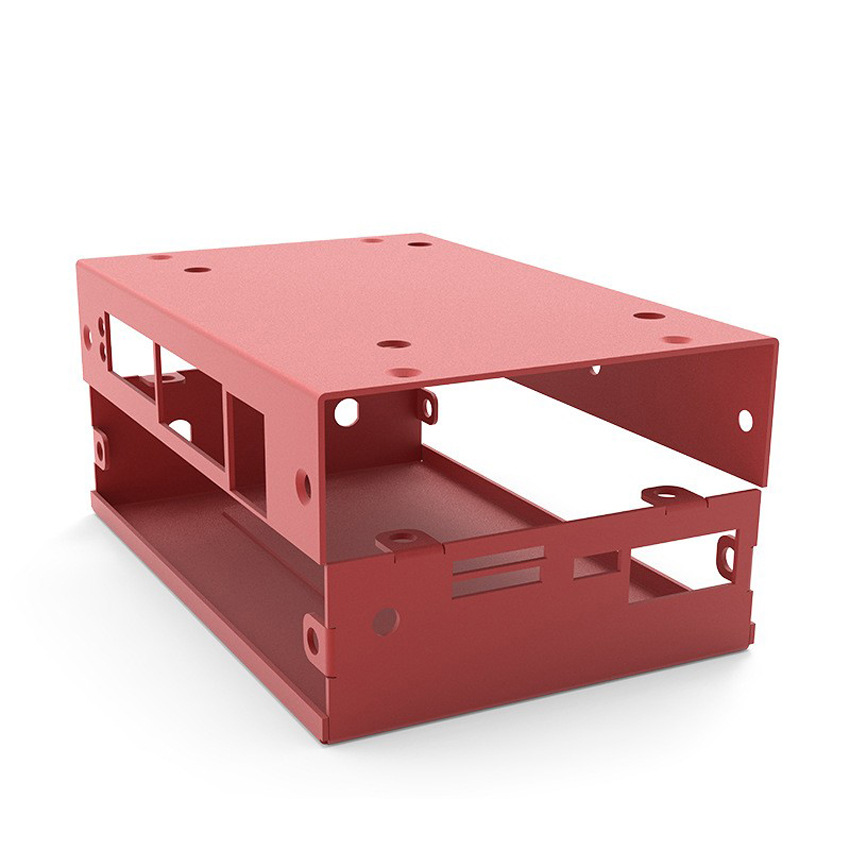

Sheet Metal Prototyping: From Brackets to Enclosures

A large number of metal brackets, housings, and structural components in vehicles are manufactured using sheet metal processes. Our sheet metal fabrication services, combined with advanced laser cutting technology, enable the quick and accurate production of sheet metal prototypes of varying complexity. From battery trays and sensor brackets to control unit housings, we ensure every prototype aligns with the design intent and provides a reliable reference for subsequent mass production.

From Blank to Finished Part: Finishing and Post-Processing of Prototypes

Precisely manufactured prototypes often require appropriate post-processing to achieve the desired appearance and functional performance. Surface finishing not only enhances aesthetics but also improves corrosion resistance, wear resistance, or other specific properties. For exposed automotive components, our powder coating services offer a wide range of colors and textures while increasing surface durability. Anodizing provides excellent protection and a premium finish for aluminum parts. For components requiring mirror-like or ultra-smooth surfaces, professional polishing processes can eliminate surface defects and meet stringent optical or fluid dynamics requirements.

Choosing the Right Materials for Your Automotive Prototypes

Metal Materials: The Foundation of Strength and Heat Resistance

Automotive prototypes impose strict demands on material performance, especially in critical applications such as powertrain and chassis systems. Aluminum die casting materials, with their excellent strength-to-weight ratio and thermal conductivity, are widely used for engine components, transmission housings, and brake calipers. Zinc alloys, renowned for their outstanding fluidity and dimensional stability, are ideal for producing small parts with complex geometries. For applications demanding extremely high strength and corrosion resistance, such as exhaust systems or turbocharger components, stainless steel materials offer a robust solution.

Plastics and Polymers: Enablers of Lightweighting and Complex Designs

With the acceleration of vehicle lightweighting, high-performance engineering plastics play an increasingly important role in prototype development. Nylon (PA), with its excellent mechanical strength and wear resistance, is widely used for gears, bearings, and structural components. For high-temperature environments in engine bays or EV battery management systems, PEEK provides continuous-use temperatures up to 250°C while maintaining exceptional mechanical properties and flame resistance.

Advanced Specialty Materials: For Extreme Environments

Ongoing advancements in automotive technology, especially in electrification and intelligence, demand higher-performing materials. Through our Ceramic Injection Molding (CIM) services, we offer ceramic materials with excellent thermal stability, electrical insulation, and wear resistance—ideal for applications such as sensor insulators, fuel cell components, and power electronics.

Application Cases of Rapid Prototyping in Different Automotive Systems

Powertrain and Engine Systems

In powertrain development, rapid prototyping accelerates the entire journey from concept to validation. Whether for internal combustion engines or electric drive systems, precisely manufactured prototypes play a critical role. Our automotive solutions team has supported customers in producing intake manifold prototypes to optimize airflow distribution through functional testing, as well as in developing sensor bracket prototypes that withstand high temperatures and vibration in the engine compartment.

Interior and Cabin Ergonomics

Automotive interior components must meet aesthetic expectations while directly influencing user experience and safety. With rapid prototyping, designers can quickly iterate parts such as air vents, control panels, and display housings to optimize touch, usability, and assembly fit. Multi-material prototypes can simulate the final product's surface textures and color schemes, providing intuitive references for informed decision-making.

Lighting Systems

Modern automotive lighting systems integrate technology, safety, and styling, presenting unique challenges for the development of prototypes. Our lighting solutions team uses transparent materials and precision optical surface manufacturing to provide high-quality prototypes for headlamp housings, inner lenses, and light guides. These prototypes validate optical performance while ensuring optimal integration with vehicle body design.

E-Mobility and Sensors

The shift toward vehicle electrification and automation drives demand for a new generation of components. Our e-mobility solutions focus on prototypes for battery management system housings, power electronics, connectors, and sensor brackets. These parts often require stringent sealing, thermal management, and EMI shielding performance. By leveraging rapid prototyping, we help customers thoroughly validate the feasibility of their designs before investing in mass production.

Five Key Factors in Selecting a Professional Prototyping Partner

When choosing a rapid prototyping supplier, automotive companies should carefully evaluate several key aspects. Industry experience determines how well the supplier understands automotive-specific requirements. Technical capabilities are reflected in the advancement of equipment and the diversity of processes. Material expertise affects whether they can recommend the most suitable materials for specific applications. Quality control systems ensure the consistency and reliability of prototypes. Responsiveness directly impacts overall project timelines. As a long-term partner to the automotive industry, Neway has built a solid foundation in all these areas, committed to providing end-to-end support from design consultation to final delivery.

Conclusion: Accelerate Your Next-Generation Automotive Project from Concept to Reality

Rapid prototyping has become an indispensable driver of automotive innovation. By selecting the right manufacturing processes, materials, and professional partners, automotive companies can significantly shorten development cycles, reduce project risks, and ultimately bring higher-quality products to market. With extensive industry experience and comprehensive technical capabilities, the Neway team stands ready to support your next automotive project and help turn innovative concepts into practical solutions.

FAQ

How long does it typically take to produce rapid prototypes for functional automotive testing?

Which metal materials are recommended for high-heat-resistant components?

What are the main differences between 3D printing and CNC machining for automotive prototypes?

Can you support the stringent quality standards and material certifications?

How to choose a cost-effective manufacturing process for my sheet metal bracket prototype?