How long does it typically take to produce rapid prototypes for functional automotive testing?

Typical Timeframe for Functional Automotive Prototypes

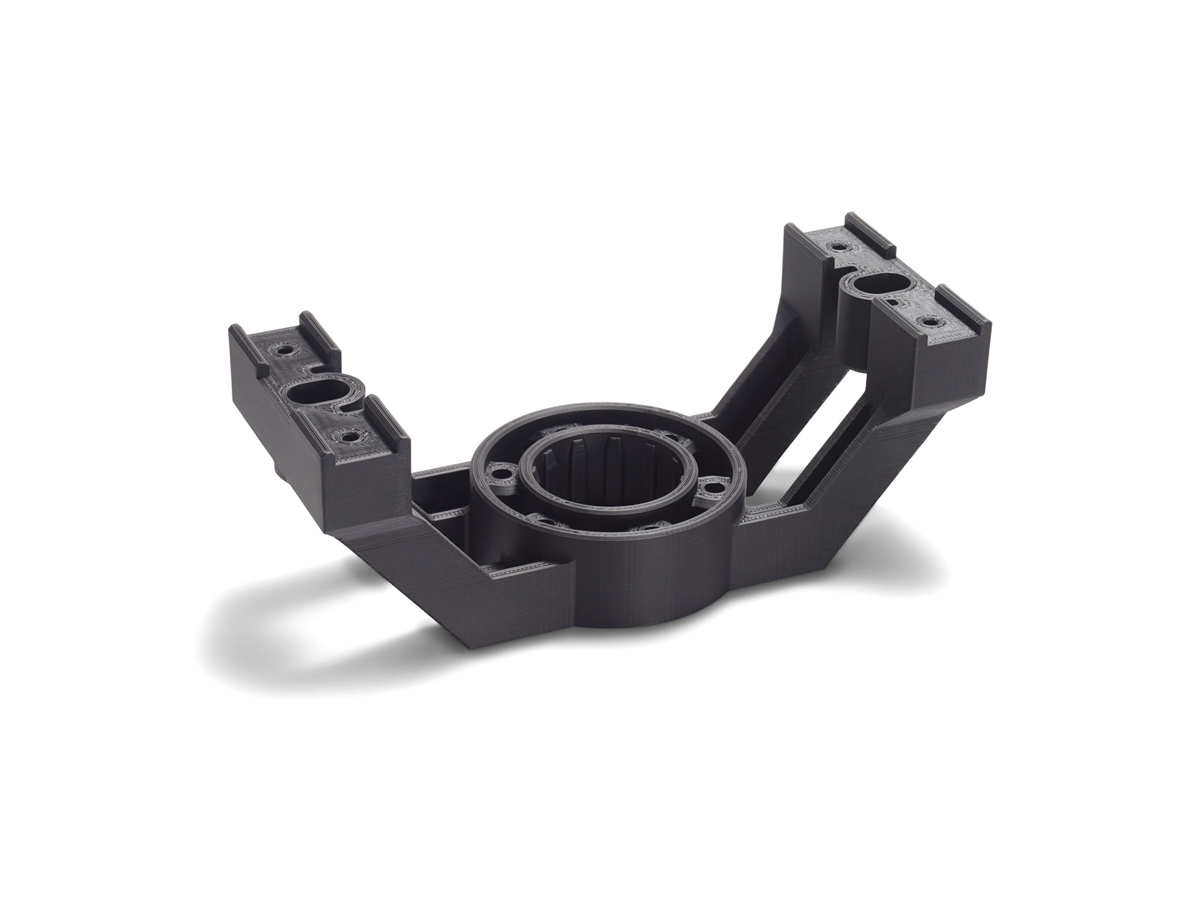

Rapid prototypes for functional automotive testing typically require 3–10 working days, depending on complexity, material choice, and validation requirements. Early design evaluations can be accelerated using flexible prototyping services that determine whether machining, molding, or additive manufacturing provides the shortest path. When close-to-production polymers are needed, prototype tooling through an injection molding service provides representative mechanical behavior. For housings, brackets, and airflow-sensitive parts, 3D printing prototyping ensures fast turnarounds. High-accuracy mating features often rely on CNC machining prototyping, while cast-like prototypes can be supplied through precision casting service to simulate production behavior.

Influence of Manufacturing Processes on Delivery Speed

Manufacturing route selection defines the overall lead time. Additive manufacturing delivers the fastest path for structural evaluations and iterative geometry refinement. For components requiring stiffness and thermal similarity to production, small-batch investment casting or compact aluminum trials using aluminum die casting shorten the cycle without full tooling investment. Mechanism parts, interior clips, or lock modules can be produced using zinc die casting when realistic density and wear characteristics are required. Structural prototype brackets or chassis elements processed via sand casting maintain reasonable strength while keeping the schedule tight. These processes combine speed with the mechanical fidelity needed for vehicle-level durability checks.

Material Selection and Readiness for Functional Testing

Mechanical, thermal, and environmental demands influence which materials move quickest through prototyping. Interior and electronic housings can be produced efficiently using ABS, while transparent or impact-resistant components benefit from polycarbonate (PC). Additively manufactured metals, such as 6000 series aluminum or AlSi10Mg, offer fast throughput with meaningful structural properties. When functional loads require steel-like characteristics, carbon steel provides the durability necessary to support suspension, bracket, and underbody tests. Early collaboration ensures each material aligns with target stiffness, fatigue, and assembly requirements.

Surface Preparation for Testing-Ready Prototypes

Prototypes must be assembly-ready to support functional automotive evaluations. Dimensional surfaces often remain in an as-machined finish to simplify alignment verification, whereas exterior or corrosion-sensitive components may undergo a rapid painting process to emulate production coatings. These treatments generally add 1–2 days, ensuring the prototype’s performance represents the final system integration. Because Neway supports demanding sectors including automotive, e-mobility, and power tools-style actuation modules in vehicles, our workflows balance schedule with the realism required for fitment, NVH, and durability testing.

Collaboration for Faster Prototype Cycles

Clear requirements, boundary conditions, and testing criteria significantly compress prototype timelines. When CAD data, tolerances, and performance expectations are defined early, complete prototype loops—including machining, molding, casting, finishing, and assembly—can be completed in about a week. More complex assemblies, multi-material builds, or components requiring multiple finishing steps will experience a slight delay, but Neway’s integrated approach ensures that automotive teams receive functional, test-ready parts with minimal downtime.