Online Aluminum Die Casting Manufacturing Service

We offer the custom aluminum casting service from design to finished alu die castings. We are aiming at providing customers with excellent custom aluminum parts in a cost effective way.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

What Is Aluminum Die Casting Service

Our Aluminum Die Casting Service delivers high-quality, cost-effective metal components through a precision process that produces parts with excellent dimensional accuracy and surface finish. Ideal for automotive, aerospace, and industrial applications, our process ensures consistent, high-performance results.

Applications of Aluminum Die Castings

Aluminum die castings offer lightweight, high-strength components widely used in diverse industries. Discover applications in aerospace, automotive, consumer electronics, and more for precision-engineered aluminum parts.

Hot Chamber Die Casting vs. Cold Chamber Die Casting

Hot chamber die casting and cold chamber die casting are two primary methods used in the die casting industry to produce precision metal parts. Each process has distinct characteristics, advantages, and limitations, making them suitable for different materials and applications.

Hot Chamber Die Casting

Hot chamber die casting, also known as gooseneck casting, is a process where the molten metal is contained within the casting machine itself in a heated chamber adjacent to the die cavity. A piston, which is submerged in the molten metal, forces the metal into the die through a gooseneck-shaped passage. This method is highly efficient for metals with low melting points, such as zinc, magnesium, and some low-melting aluminum alloys. The key advantages of hot chamber die casting include faster cycle times due to the proximity of the molten metal to the die, leading to increased production efficiency. However, it is unsuitable for metals with high melting points, as they can damage the casting machine over time.

Cold Chamber Die Casting

In contrast, cold chamber die casting is used for metals with high melting points, such as aluminum and copper alloys. The process involves manually or automatically ladling the molten metal into a cold chamber where a hydraulic or mechanical piston then forces the metal into the die. Since the molten metal is not contained within the machine, this method avoids the potential for damage to the equipment by high-temperature alloys. Cold chamber die casting allows for the production of solid and dense parts with detailed and complex geometries. However, it typically has slower cycle times than hot chamber die casting due to the extra step of ladling the molten metal into the chamber.

Aluminum Die Casting Materials

Neway Aluminum Die Casting Capabilities

Neway specialized in aluminum mold casting and providing custom aluminum die casting services with a wild size range and surface finishings. Get in touch with us and send your drawings for one-stop aluminum casting service

View How Die Casting Works at Neway

Learn the basics of the die casting process including how molten metal is injected into steel molds under intense pressure to create complex metal parts. This video covers the typical materials used like aluminum, zinc, and magnesium alloys as well as key considerations like high initial tooling costs being offset by efficient volume production.

Custom Parts Surface Finishing Available

Our Surface Treatment Service offers specialized finishes for custom parts, enhancing durability, aesthetics, and performance. We provide a range of processes, including Electroplating, Anodizing, Powder Coating, and Thermal Barrier Coatings, tailored to improve corrosion resistance, wear properties, and visual appeal of metal and plastic components across industries.

Learn More

As Machined

Learn More

Painting

Learn More

PVD

Learn More

Sandblasting

Learn More

Electroplating

Learn More

Polishing

Learn More

Anodizing

Learn More

Powder Coating

Learn More

Electropolishing

Learn More

IMD

Learn More

Brushed Finishes

Learn More

Black Oxide

Learn More

Heat Treatment

Learn More

Tumbling

Learn More

Alodine

Learn More

Chrome Plating

Learn More

Phosphating

Learn More

Nitriding

Learn More

Galvanizing

Learn More

Lacquer Coating

Learn More

Teflon Coating

Learn More

Thermal Coatings

Learn More

Thermal Barrier Coatings

Learn More

Passivation

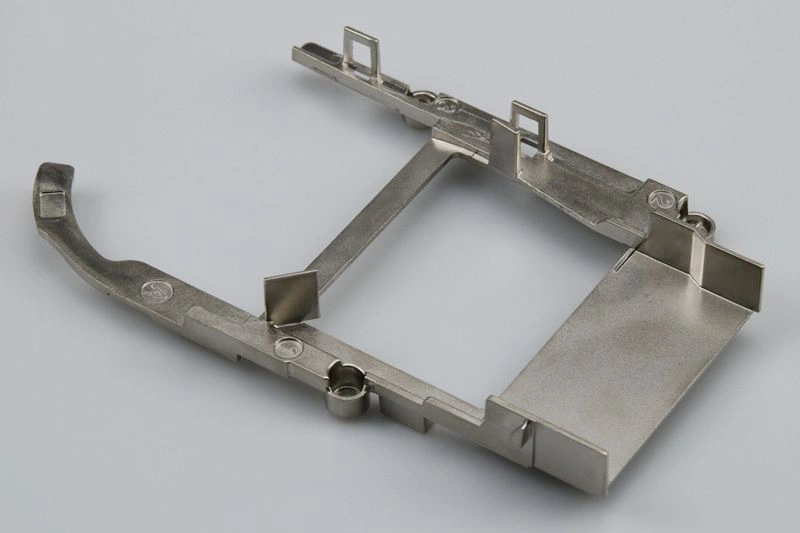

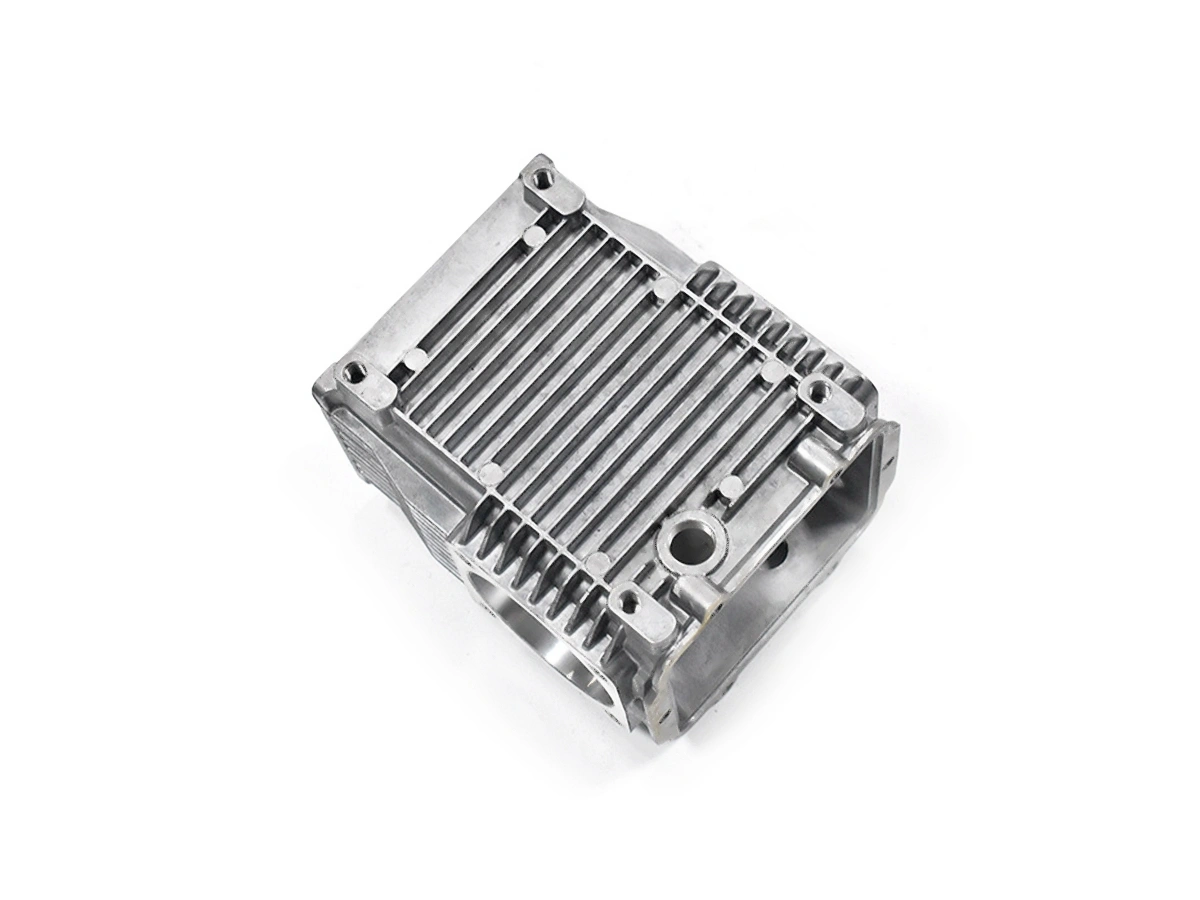

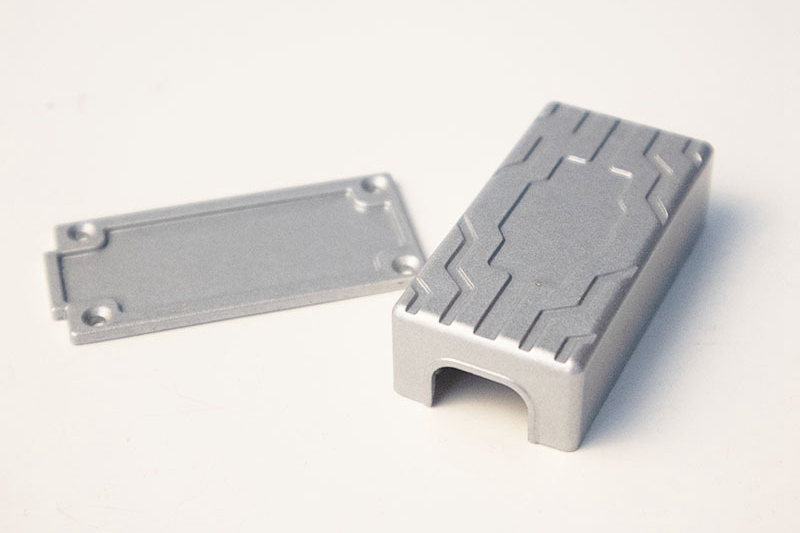

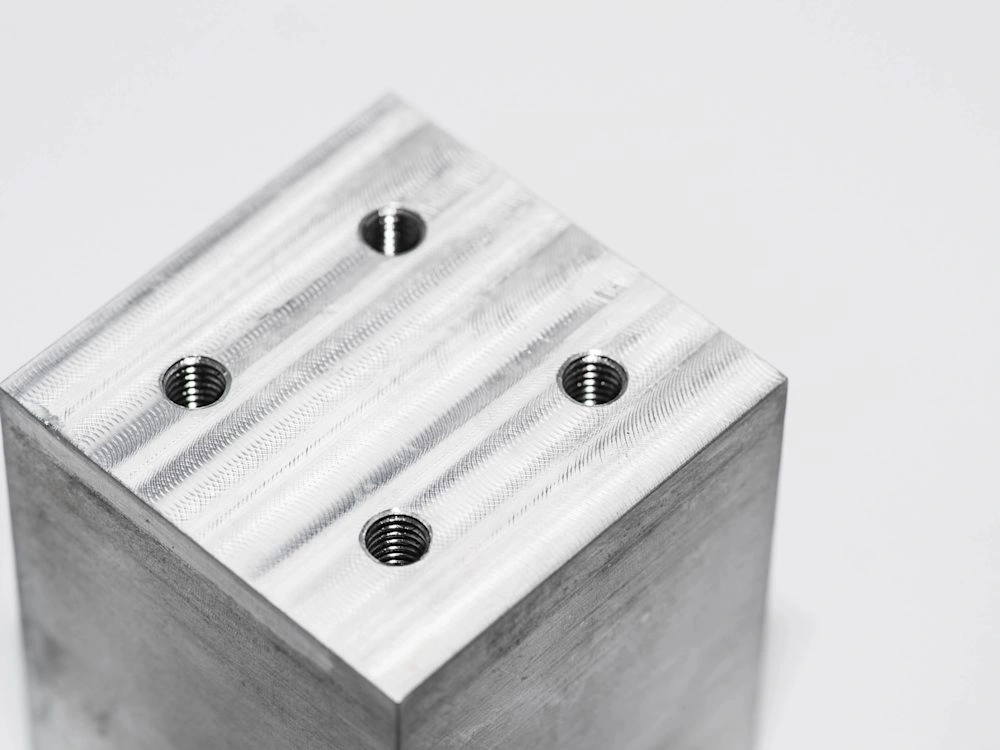

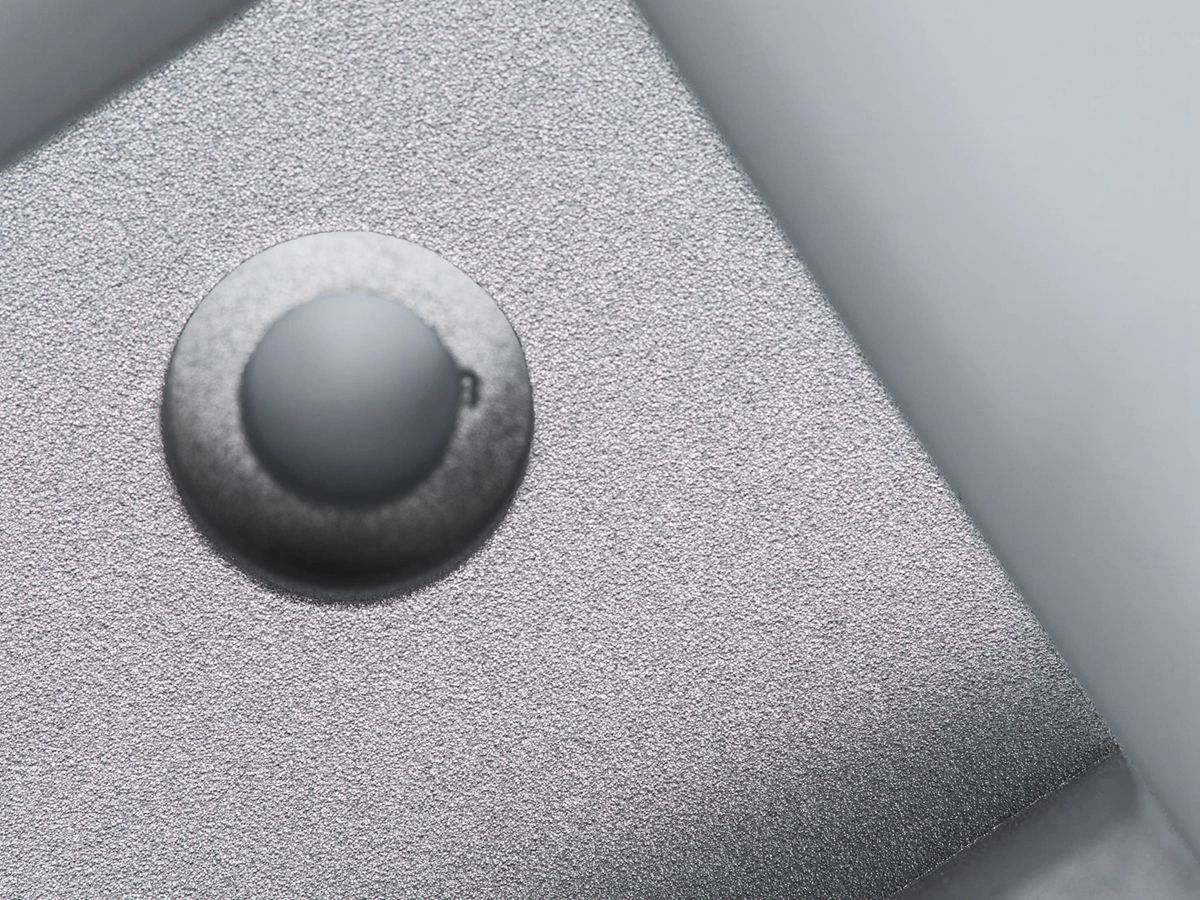

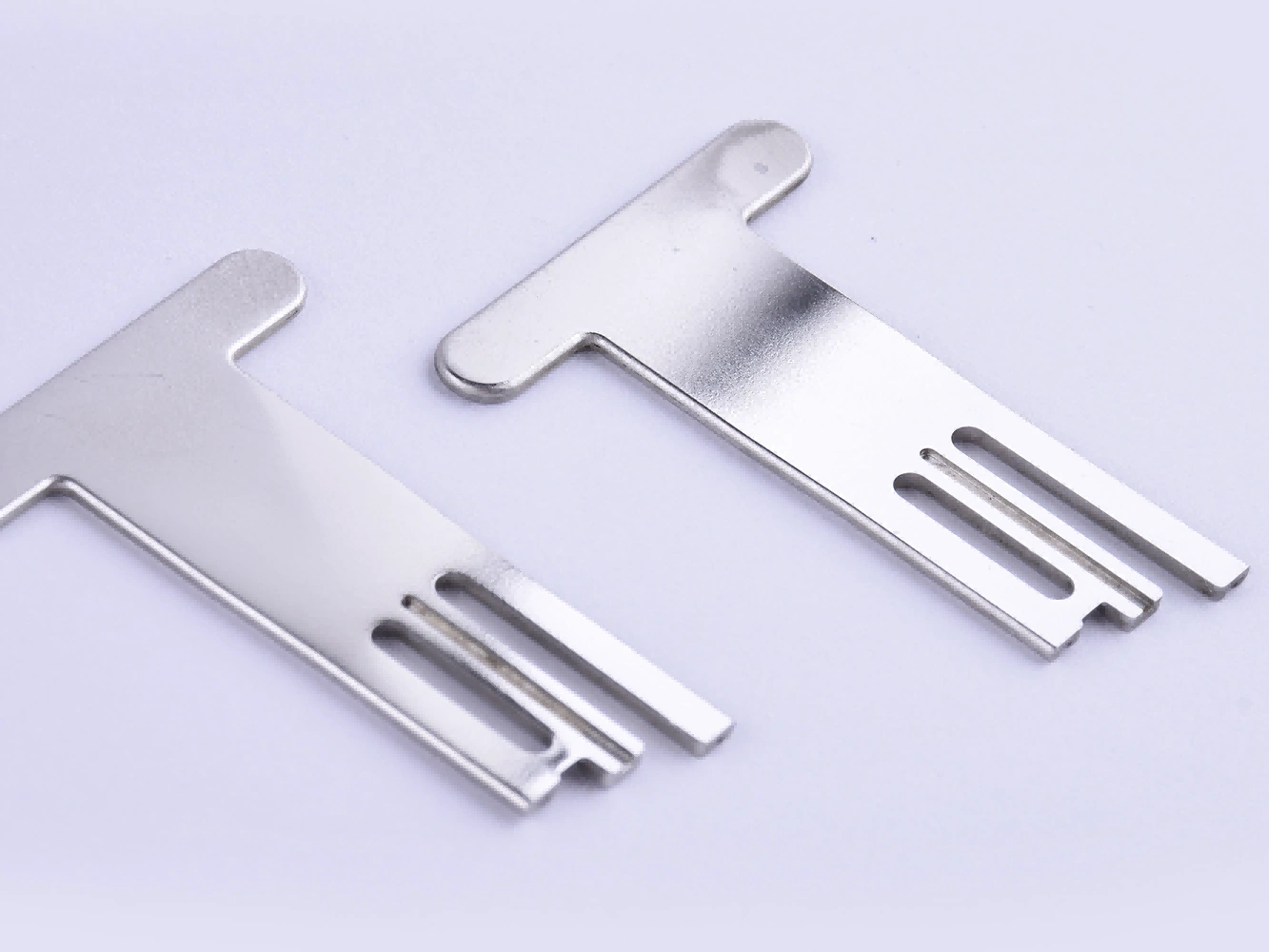

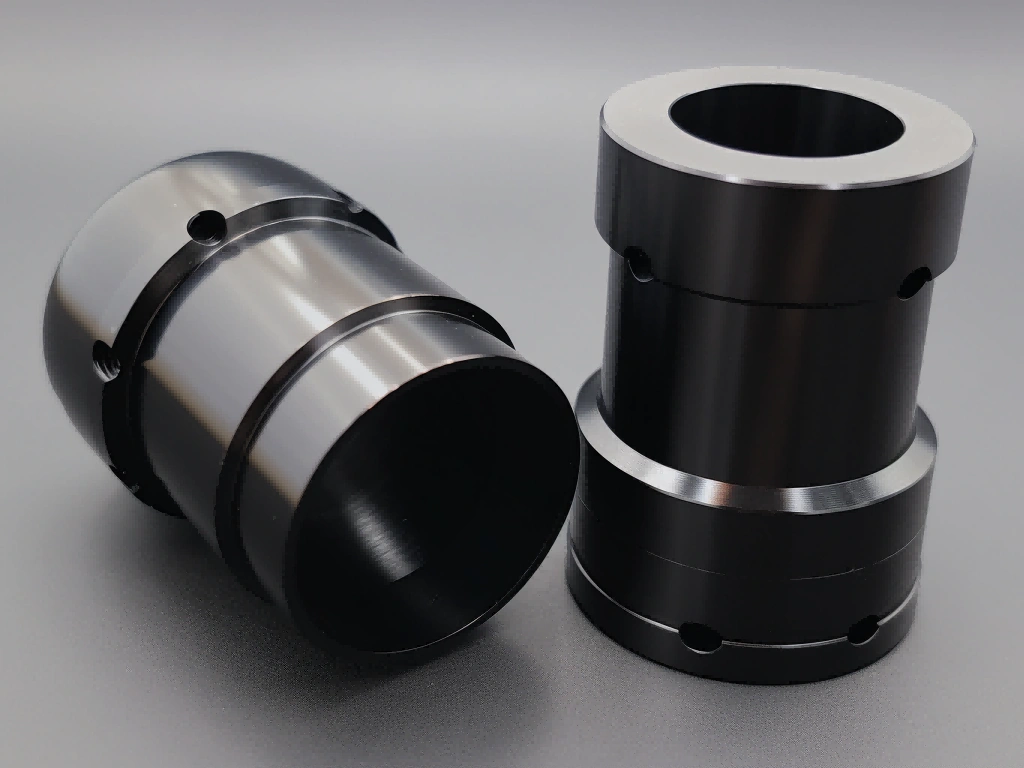

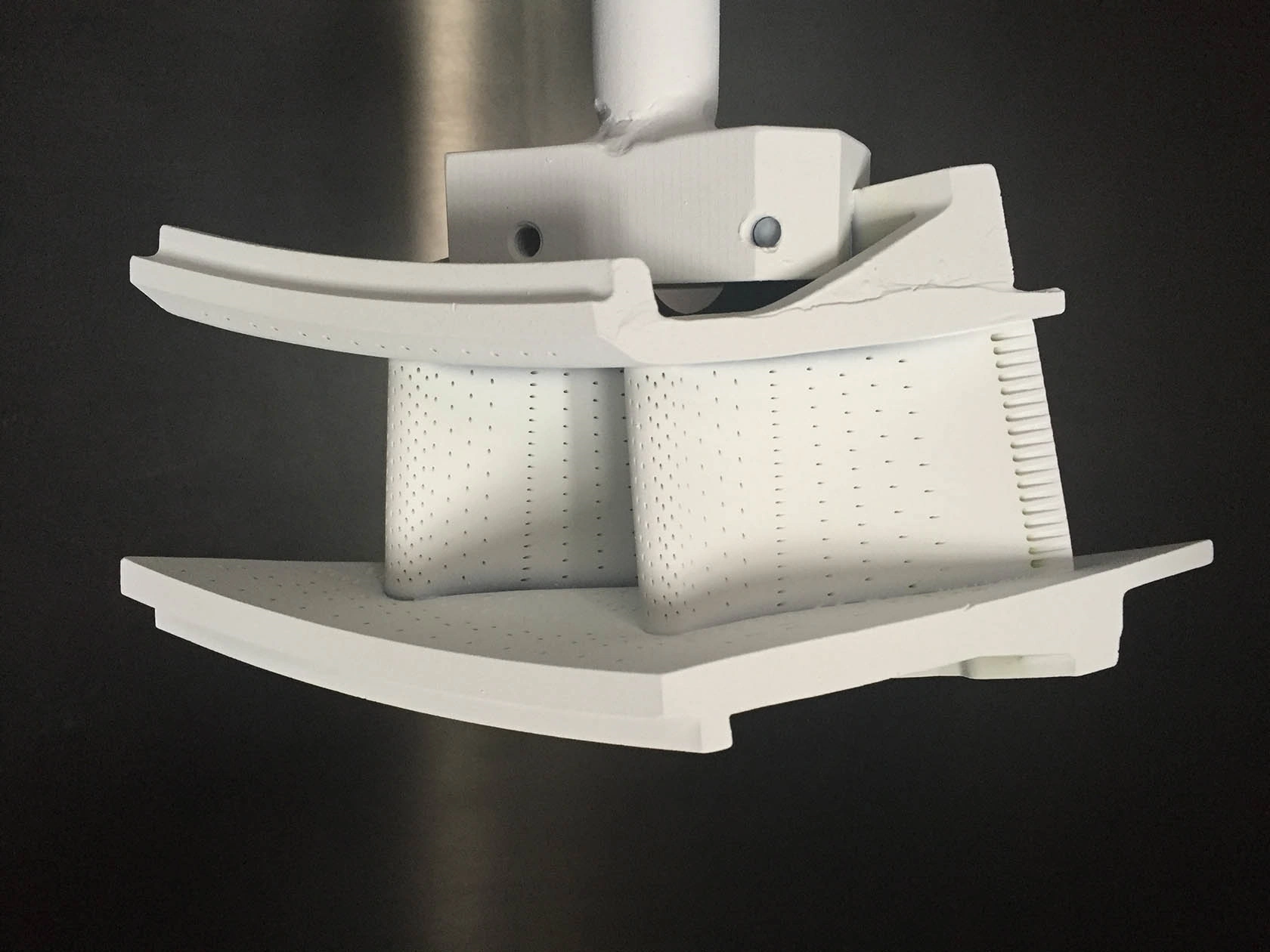

Aluminum Casting Parts Gallery

Aluminum Casting Parts Gallery showcases a stunning collection of meticulously crafted aluminum castings. Explore our gallery to witness the intricate details and exquisite designs of our diverse range of aluminum casting parts. From automotive components to aerospace applications, our temperature-controlled casting process ensures precision and durability. Discover the artistry and engineering prowess behind our aluminum castings as you browse through our visually captivating gallery.

Let's Start A New Project Today

Aluminum Die Castings Design Tips

Learn these Aluminum Die Castings Design Tips to enhance your manufacturing efficiency, reduce defects, and improve overall product consistency. By following industry-standard values, you can optimize cooling, minimize stress concentrations, and streamline tooling processes, resulting in durable, high-quality cast components.

Frequently Asked Questions

Explore Related Resources

Solutions

Copyright © 2026 Neway Precision Works Ltd.All Rights Reserved.