Neway Quality Assurance

Quality assurance is critical for ensuring that products or services meet the desired level of quality, and for achieving customer satisfaction, brand reputation, compliance, cost savings, and continuous improvement.

PCDA System

The PDCA system plays a vital role in custom parts manufacturing by enabling continuous process improvement. It helps define requirements (Plan), execute machining steps (Do), inspect deviations (Check), and adjust designs or processes (Act). This cycle enhances quality control, reduces costs, and ensures consistent delivery, supporting standardized yet flexible production of non-standard components.

Coordinate Measuring Machine (CMM)

CMM ensures dimensional precision in custom parts by verifying geometric accuracy, detecting deviations, and validating complex surfaces against 3D CAD models. It supports high-precision quality control for tight-tolerance non-standard components.

Optical Comparators for Profile Inspection in Custom Parts

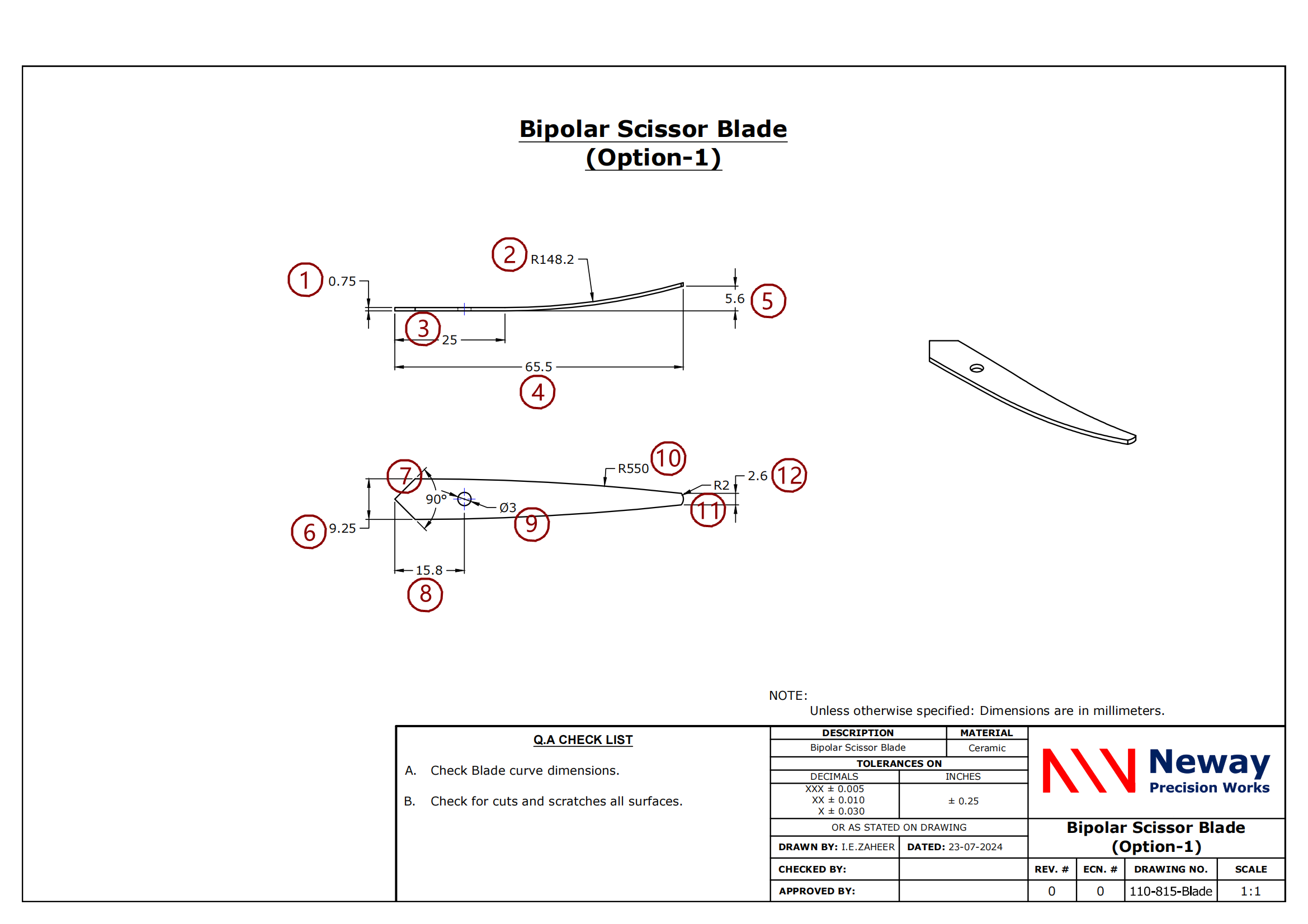

Optical comparators enable non-contact profile inspection and dimensional verification of custom parts, especially small or delicate components. They enhance visual QC, template matching, and first article validation with high magnification accuracy.

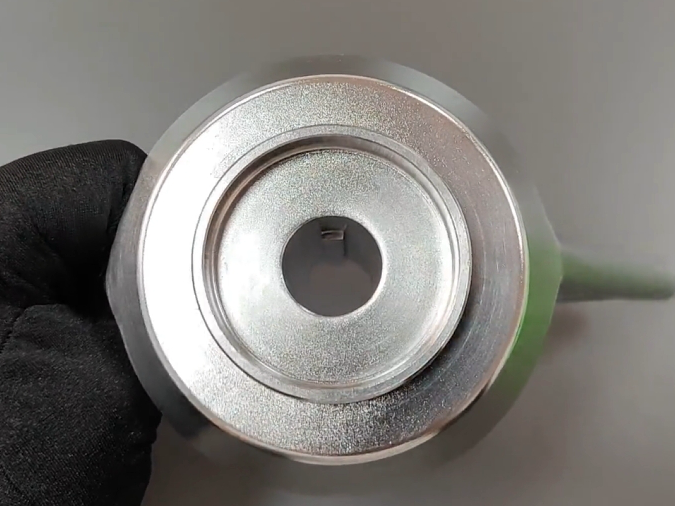

3D Scanning Measuring Instrument for Custom Parts Quality

3D scanning instruments capture full-surface geometry of complex custom parts with high resolution. They support non-contact inspection, reverse engineering, and digital validation against CAD for precision-driven manufacturing workflows.

450KV Line Array Industrial CT for Internal Defect Inspection

450KV industrial CT enables non-destructive internal inspection of dense custom parts. It detects porosity, inclusions, and structural defects with micron-level accuracy, ensuring integrity in aerospace, medical, and precision engineering components.

Dynamic and Static Fatigue Tester for Structural Validation

Fatigue testers simulate long-term static and dynamic loading on custom parts to evaluate structural endurance, deformation resistance, and failure thresholds. They ensure mechanical performance reliability in safety-critical applications.

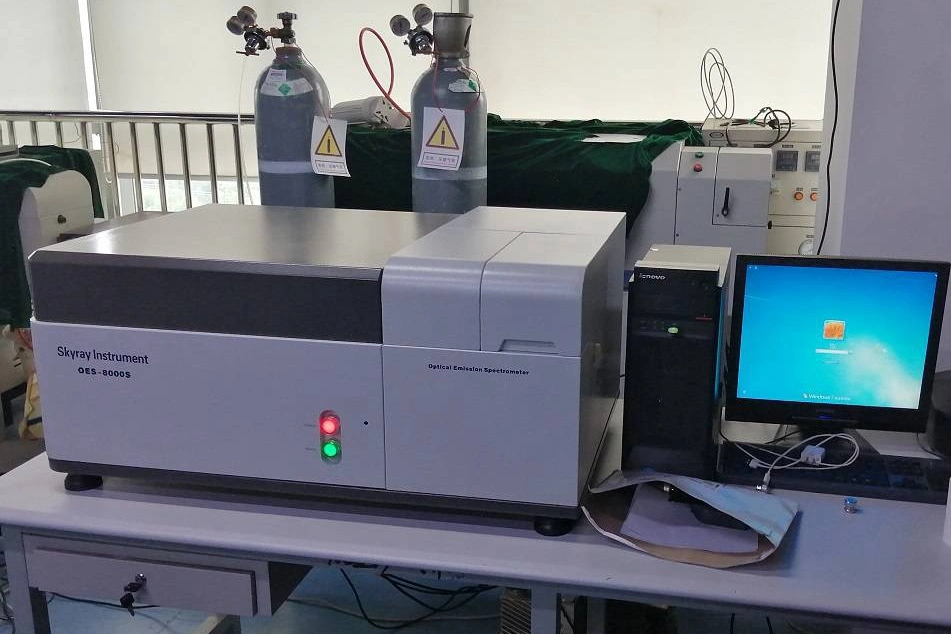

Direct Reading Spectrometer for On-Site Alloy Composition Control

Direct reading spectrometers provide rapid, on-site elemental analysis of metallic custom parts and raw materials. They verify alloy grade, ensure chemical conformity, and support batch consistency in precision manufacturing.

Glow Discharge Mass Spectrometer (GDMS)

GDMS enables ultra-trace elemental analysis in custom parts manufacturing, ensuring raw material purity and detecting sub-ppm impurities. It supports critical applications requiring high reliability by verifying alloy consistency, enhancing material qualification, and preventing failure risks.

Explore Related Resources

Solutions

Copyright © 2026 Neway Precision Works Ltd.All Rights Reserved.