Dimensional Inspection For Custom Parts With CMM

Introduction

Dimensional inspection is an essential pillar of modern custom parts manufacturing, where achieving micron-level accuracy is often critical to a component’s functional performance and service life. As industries such as aerospace, medical devices, and high-end automotive engineering increasingly demand tighter tolerances and more complex geometries, traditional measurement methods can no longer ensure compliance with advanced quality standards.

Coordinate Measuring Machines (CMMs) have emerged as a gold standard for dimensional inspection, providing unparalleled precision, repeatability, and traceability. Whether verifying first article parts or conducting 100% inspection of finished components, CMMs enable manufacturers to meet rigorous customer and regulatory requirements.

This article explores the role of dimensional inspection for custom parts with CMM, detailing its principles, integration in manufacturing workflows, and the measurable advantages it offers in achieving superior quality assurance across a wide range of precision industries.

What is CMM Dimensional Inspection?

Principles of CMM

Coordinate Measuring Machine (CMM) dimensional inspection is a precision measurement process used to determine the exact geometry of a manufactured part. The CMM operates by moving a probe in three orthogonal axes (X, Y, Z) to collect precise point data from the part’s surfaces. These measurements are then compared to CAD models or engineering drawings to validate dimensional conformity.

CMMs are categorized by their structural design, including bridge-type (the most common), cantilever, gantry, horizontal-arm, and portable articulated arm models. Each type is optimized for specific applications, from small, high-precision components to large aerospace assemblies.

Key Capabilities

Modern CMMs deliver exceptional measurement accuracy—typically in the range of ±1 to ±5 µm for standard systems, and down to sub-micron levels for ultra-precision machines. Their key capabilities include:

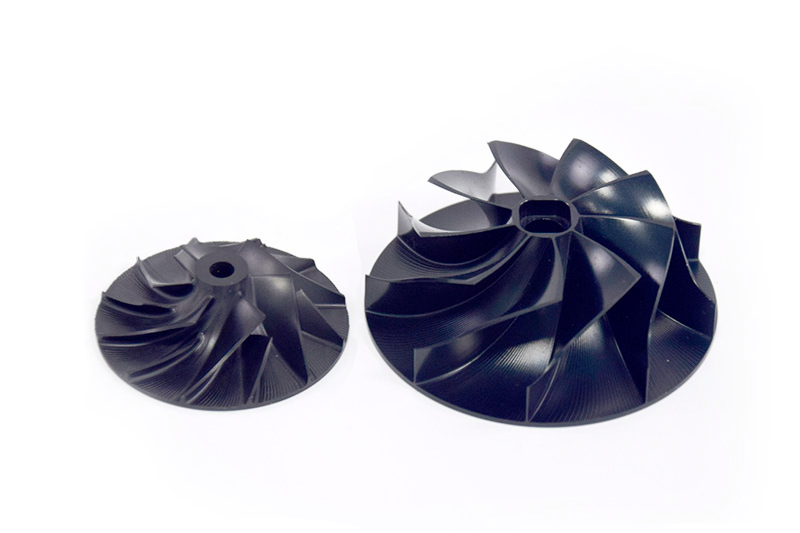

Measurement of complex geometries such as freeform surfaces and tight-tolerance profiles

Full GD&T (Geometric Dimensioning and Tolerancing) analysis

Automated scanning and probing for high-speed, repeatable inspection

This level of precision makes CMMs indispensable for industries where dimensional compliance directly impacts product functionality and safety.

Advantages over Conventional Inspection Methods

Compared to traditional methods such as calipers, micrometers, and fixed gauges, CMM inspection provides several critical advantages:

Higher measurement accuracy and repeatability

Automation-friendly, reducing operator variability

Comprehensive data collection, enabling statistical process control (SPC) and advanced quality analytics

Flexibility — a single CMM system can measure a wide variety of part geometries and sizes

In advanced dimensional inspection for custom parts with CMM, these advantages enable manufacturers to achieve tighter process control, ensure compliance with demanding industry standards, and reduce costly quality escapes.

Why CMM Inspection Matters in Custom Parts Manufacturing

Tight Tolerance Requirements

Precision manufacturing industries are seeing increasingly demanding tolerance specifications. In many applications today:

Aerospace components often require critical dimensions held to within ±5 to ±10 µm to guarantee aerodynamic efficiency and fatigue resistance.

Medical implants must maintain sub-10 µm dimensional consistency to achieve proper fit and ensure long-term biocompatibility.

Automotive drivetrain and transmission parts demand tolerances of ±10 to ±20 µm to deliver smooth performance and durability.

CMM dimensional inspection provides the accuracy and repeatability required to verify that such specifications are consistently met across full production runs.

Supporting Certifications

Meeting the requirements of international quality standards is a cornerstone of competitive manufacturing:

The AS9100 standard for aerospace mandates full dimensional validation and traceability for flight-critical parts.

ISO 13485 for medical devices requires statistically validated dimensional compliance, particularly for implantable components.

IATF 16949 in automotive demands rigorous dimensional process capability studies and ongoing verification of critical characteristics.

CMM inspection generates precise, traceable measurement data, forming a critical part of the documentation required for compliance with these industry certifications.

Application Examples

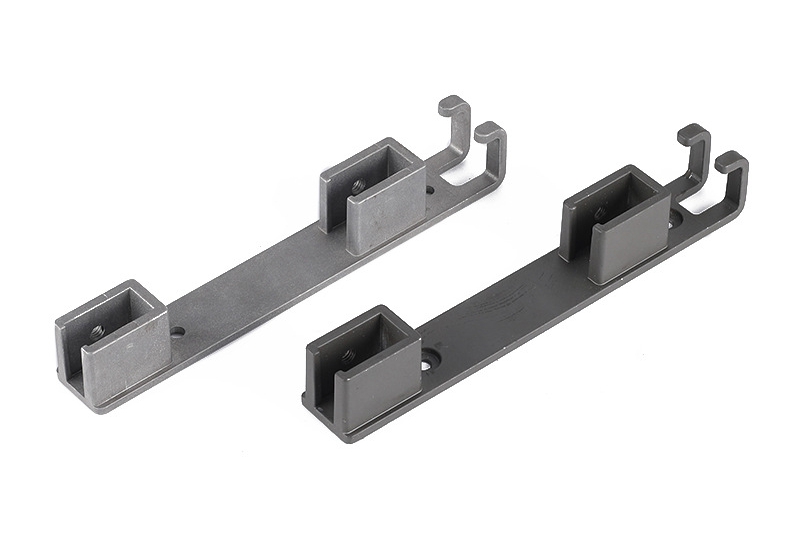

In real-world production environments, CMM inspection is indispensable for ensuring product integrity:

In aerospace, it verifies the dimensional accuracy of thin-wall structural enclosures and aerodynamic surfaces.

In medical device production, CMMs inspect orthopedic implants, surgical tools, and diagnostic assemblies with stringent biocompatibility and geometric requirements.

In automotive manufacturing, CMMs validate lightweight structural components, EV battery housings, and precision drivetrain parts to optimize both performance and energy efficiency.

By enabling manufacturers to ensure and document compliance with such demanding specifications, CMM inspection plays a critical role in maintaining product quality and competitive advantage.

How CMM Inspection is Integrated into Manufacturing Workflows

Raw Material Qualification

The dimensional inspection process begins with raw material qualification. CMM systems verify that incoming blanks—whether cast, forged, or fabricated—meet specified geometrical requirements. For example, in precision casting, CMM inspection confirms dimensional allowances for shrinkage and machining stock, reducing the risk of non-conforming parts at later stages.

By performing this initial validation, manufacturers can identify and eliminate potential issues early in production, improving process efficiency.

In-Process Inspection

CMM inspection plays a vital role in maintaining dimensional control during intermediate production stages. Manufacturers use it for:

First article inspection, confirming that the first production parts meet all design specifications

In-process checks, verifying critical dimensions after key manufacturing steps

In operations such as sheet metal fabrication, CMMs ensure that components like bent enclosures or laser-cut profiles meet flatness, angularity, and profile tolerances before moving to assembly or finishing.

By incorporating CMM inspection into the workflow, manufacturers maintain tight process control and prevent cumulative dimensional deviations.

Final Part Qualification

Final inspection is where CMM systems provide maximum value for verifying complete part geometry. In applications such as CNC machining prototyping, where precision is critical, CMMs are used to validate every dimension of the finished part against the CAD model or engineering drawing.

This ensures that all customer-specified tolerances are met prior to shipment, providing high confidence in product quality.

Traceability and Documentation

Modern CMM systems generate detailed inspection reports that become part of the permanent product record. When combined with methodologies such as PDCA control, these reports support continuous quality improvement and traceability throughout the product lifecycle.

Dimensional data collected from CMM inspection is also used for statistical process control (SPC), helping manufacturers monitor process stability and drive long-term quality improvements.

Case Study: CMM Inspection in Precision Aerospace Parts

Project Scope

An aerospace manufacturing project involved producing thin-walled aluminum enclosures for advanced avionics systems. The project requirements specified:

Dimensional tolerances within ±5 microns for interface features

Geometric tolerances for flatness, parallelism, and profile

Complex internal and external surfaces to house sensitive electronics

The combination of thin-wall geometry and complex surfaces required a highly controlled fabrication process. The production sequence combined precision aerospace sheet metal processes, supported by advanced precision aerospace sheet metal fabrication and finishing methods.

CMM Application

CMM inspection was implemented at several key stages of the workflow. Initial first article inspections were performed to verify tooling and fixture accuracy. In-process inspection checkpoints monitored critical dimensions after major forming and machining steps to detect any deformation. The final inspection used automated CMM routines to perform full geometric verification of every enclosure produced.

The capability of the CMM to accurately measure thin sections and complex freeform surfaces provided essential feedback to the production team, enabling rapid process adjustments.

Outcomes

Integrating CMM inspection resulted in measurable improvements:

Dimensional yield increased from 93 percent to 99 percent

Non-conformance and rework rates were reduced by over 40 percent

Inspection throughput was improved through automation, enabling faster delivery times

Statistical process control data collected through CMM inspection supported ongoing optimization of the high-precision CNC machining process, resulting in further quality gains

This case study highlights how CMM inspection is an essential tool for achieving and maintaining the stringent dimensional requirements of aerospace components.

Advantages of CMM in Custom Parts Inspection

Enhanced Accuracy

CMM systems deliver superior measurement accuracy for verifying the geometry of complex components. Modern equipment offers volumetric accuracy between ±1 micron and ±5 microns, which is essential for industries that produce precision custom parts.

Through dense point cloud data, CMM inspection enables precise validation of freeform surfaces, intricate features, and hidden geometries that traditional tools cannot accurately measure.

Time and Cost Savings

CMM inspection reduces inspection cycle time compared to manual methods. Automated routines quickly verify numerous dimensions, improving throughput and productivity on the shop floor.

Early detection of dimensional deviations during in-process checks also prevents downstream non-conformance, helping manufacturers reduce scrap and rework costs. For high-value industries such as aerospace, medical, and automotive, this efficiency translates to substantial operational savings.

Data-Driven Quality Control

Beyond inspection, CMM systems provide rich datasets that support advanced quality management. Integrated with manufacturing execution systems, CMM data enables process monitoring and statistical process control.

Applying methodologies such as PDCA control, manufacturers can use inspection data to drive continuous improvement initiatives. This supports not only higher quality but also improved process stability and capability.

As demonstrated through practical CMM inspection, combining dimensional accuracy with data-driven control helps manufacturers maintain a competitive edge in precision manufacturing.

Future Trends in CMM Inspection for Custom Parts

Automation and In-Line Inspection

As demand for high-mix, low-volume production increases, manufacturers are integrating CMM technology directly into production lines. In-line and near-line CMM systems enable real-time inspection feedback, allowing immediate correction of process deviations.

For modern custom parts manufacturing service, where precision and lead time are critical, automated CMM solutions reduce inspection bottlenecks and support higher throughput without compromising quality.

Digital Twin Integration

The adoption of digital twin methodologies is reshaping how manufacturers approach quality control. CMM inspection data is now used to update and validate digital twins of physical components, enabling predictive quality management.

This approach supports closed-loop manufacturing, where dimensional data informs upstream process adjustments, ensuring parts conform to design intent across the entire product lifecycle.

Data-Driven Process Optimization

Advanced data analytics and AI-driven insights are transforming how manufacturers leverage CMM data. By combining real-time inspection results with quality systems and continuous improvement practices such as PDCA control, manufacturers can proactively identify trends, optimize process parameters, and enhance product quality.

As detailed in the evolution of CMM inspection, these capabilities are enabling manufacturers to shift from reactive to predictive quality management, improving competitiveness in precision manufacturing markets.