On-demand Manufacturing Solution for

Aviation and Aerospace

Find top-notch aerospace components manufacturers for your aviation needs. Our trusted and experienced manufacturers deliver high-quality and reliable components for aircraft and aerospace applications. Explore our comprehensive range of precision-engineered solutions today.

Armed Aircraft Protection

Nuclear-grade boron carbide is used in neutron absorber balls, bricks, detectors, aluminum-based composites, and boron-containing concrete or carbon bricks. Its high neutron absorption and thermal stability make it ideal for reactor control, shielding, and radiation detection. It ensures safety and performance in high-temperature, high-radiation nuclear environments, supporting both power generation and research applications.

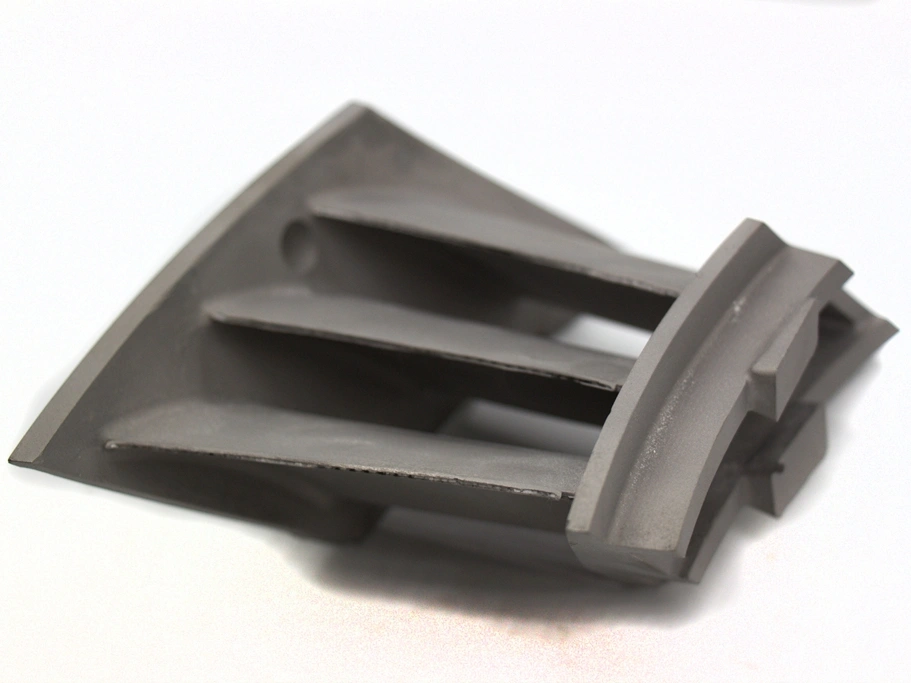

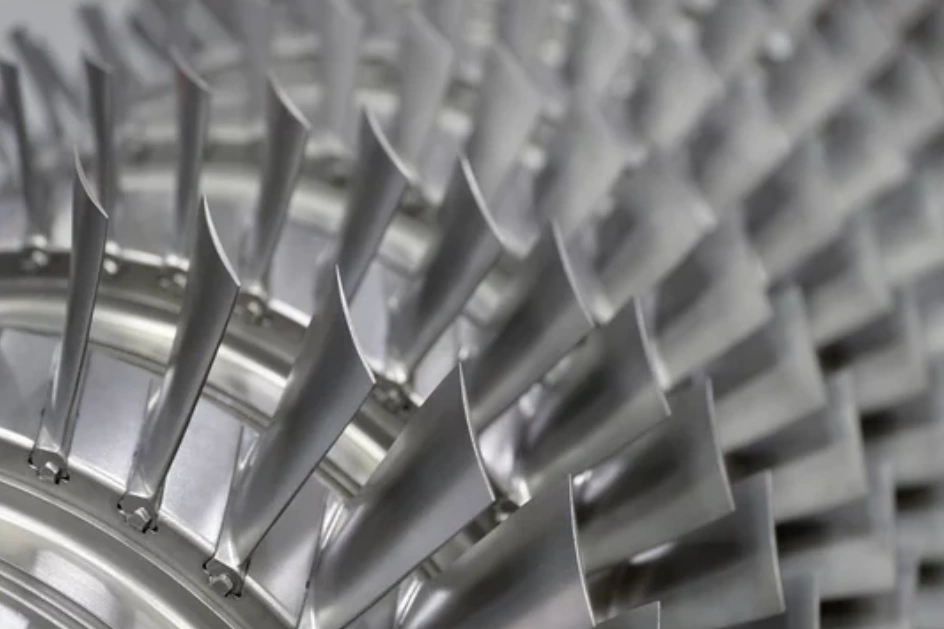

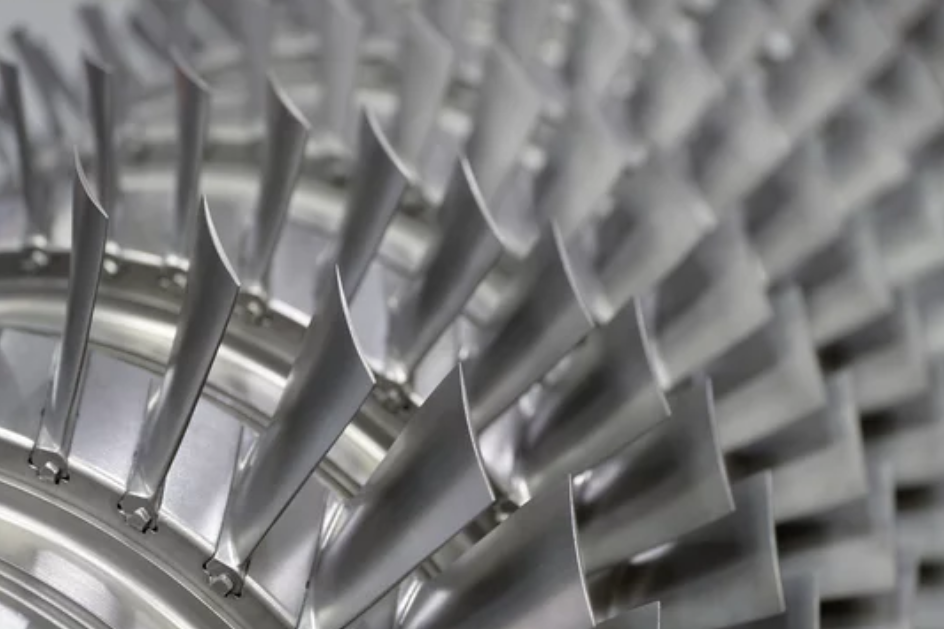

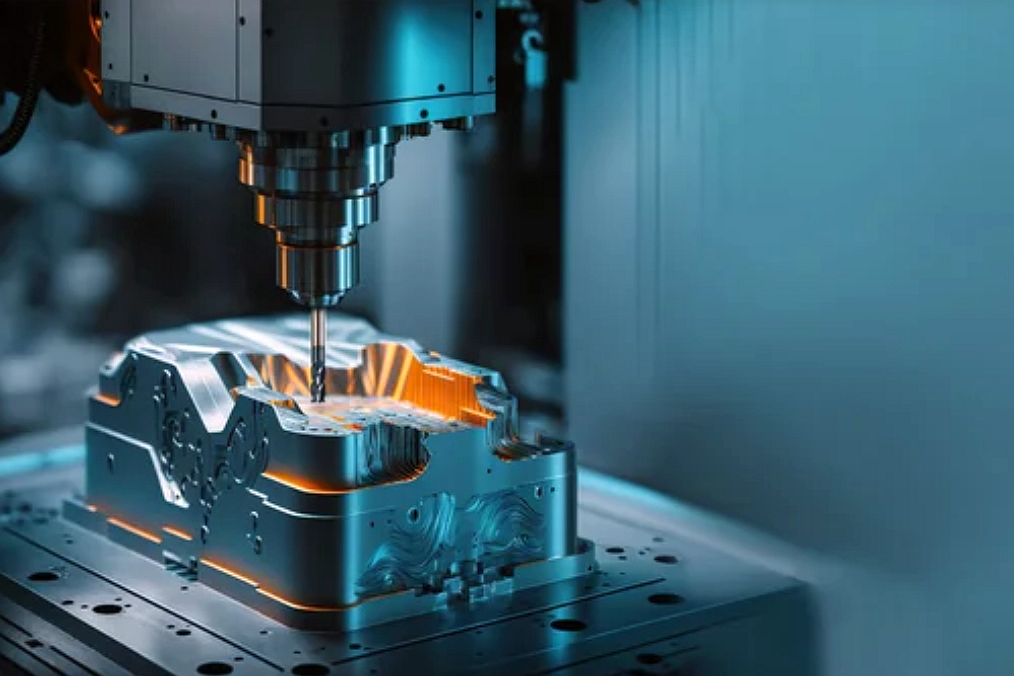

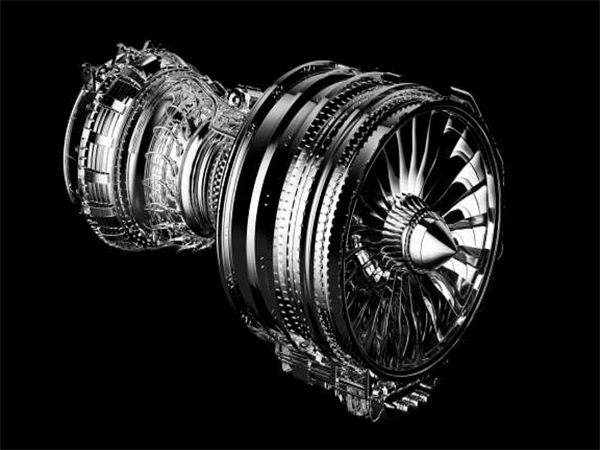

Advanced Aerospace High-Temperature Component Manufacturing

Advanced aerospace components demand superior thermal performance. Our manufacturing solutions include ceramic injection molding (CIM) for insulating and wear-resistant parts, superalloy 3D printing for intricate internal passages, precision CNC machining for turbine blades, and investment casting for complex heat-resistant components. Leverage our expertise to achieve exceptional quality, reliability, and efficiency in aerospace high-temperature applications.

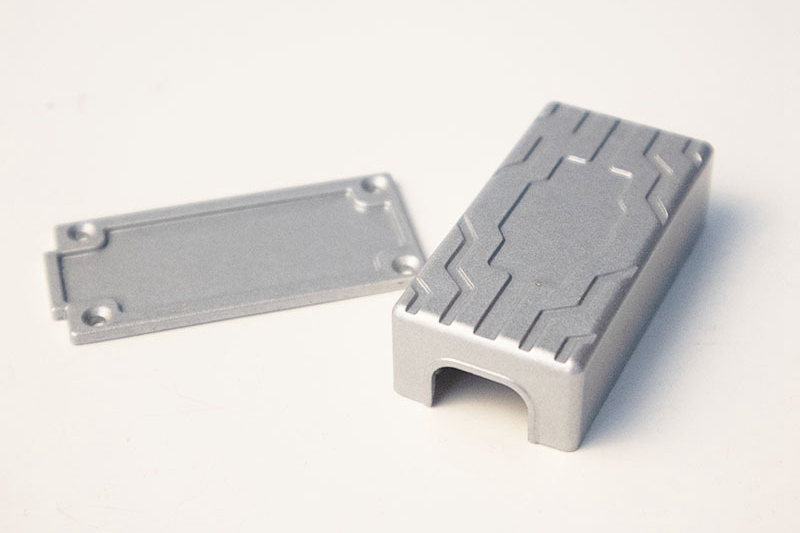

High-Performance Lightweight Aerospace Components Solutions

Achieve critical weight reductions in aerospace with our specialized lightweight component solutions. Our advanced manufacturing techniques include aluminum die casting and gravity casting for complex, lightweight structural parts; 3D printing and CNC machining for optimized geometric precision; and precision sheet metal fabrication for thin-walled structural elements. Enhance your aircraft performance and fuel efficiency while maintaining strength and structural integrity through our expert lightweight manufacturing processes.

Precision Structural Component Manufacturing for Aerospace

Deliver aerospace-grade precision and reliability with our precision structural component manufacturing capabilities. Metal Injection Molding (MIM) produces intricate connectors and miniature valves; Powder Pressing Molding creates robust structural and turbine disk components; Plastic Injection Molding and Insert/Overmolding deliver durable, insulated housings and connectors. Leverage these processes to optimize aerospace assemblies requiring exceptional accuracy, strength, and reliability under rigorous operational conditions.

Rapid Prototyping and Aerospace Component Verification

Accelerate aerospace component development and validation with our rapid prototyping services. CNC machining and 3D printing enable rapid iteration of aerodynamic structures and internal components for fit and functional verification. Rapid molding provides short-run manufacturing for real-world testing. This approach reduces development timelines and ensures components meet aerospace standards, enabling seamless transition from prototype stages to full-scale production.

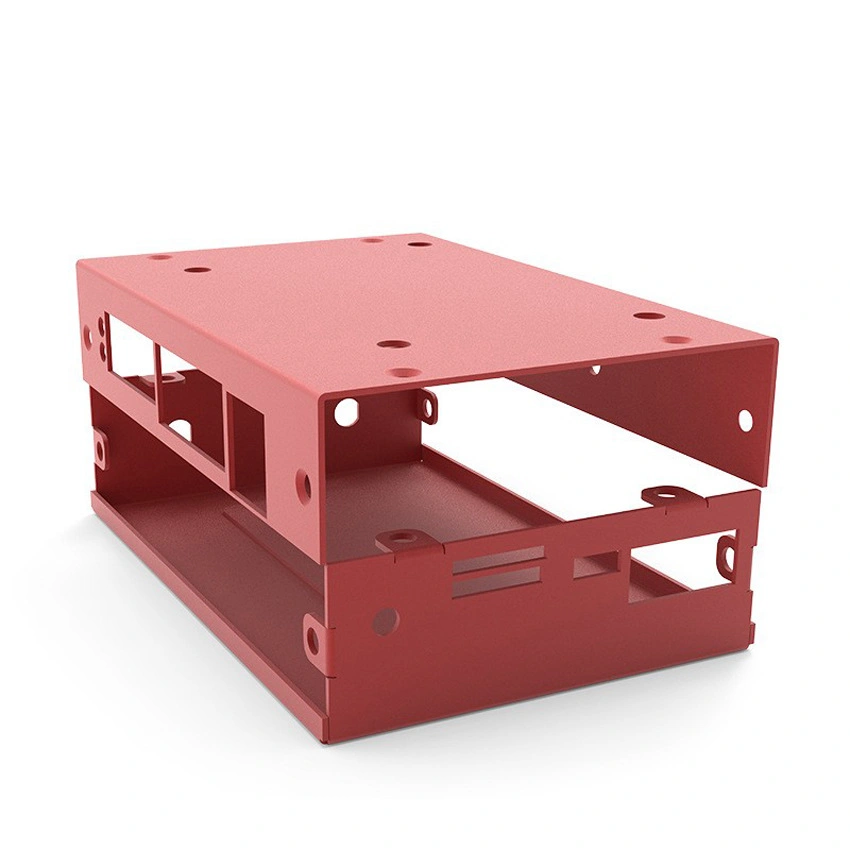

Precision Aerospace Sheet Metal & Enclosure Fabrication

Our advanced aerospace sheet metal and enclosure fabrication processes enable precision, lightweight, and durable structures. Laser and plasma cutting ensure precision profiles; metal bending creates aerodynamic surfaces; stamping provides reinforced structures for aircraft skins and internal brackets. Utilizing aerospace-grade aluminum and titanium alloys, we ensure components meet stringent aerospace standards for weight optimization, durability, corrosion resistance, and aerodynamic performance.

Aluminum Die Casting Aerospace Components Manufacturing

Experience excellence in aluminum die casting aerospace components manufacturing. Our industry-leading experts specialize in producing high-quality, lightweight components for the aerospace sector. With advanced techniques and stringent quality control, we deliver precise and durable solutions for your aircraft. Discover the perfect combination of strength and efficiency with our aluminum die casting aerospace components manufacturing capabilities.

Case Study

Let's Start A New Project Today

Explore Related Resources

Solutions

Copyright © 2026 Neway Precision Works Ltd.All Rights Reserved.