Application Of 5-axis CNC Machining Technology In Aerospace

Brief Overview of Neway's Expertise In CNC Machining

Neway is a leading force in custom parts manufacturing, specializing in metal, ceramic, and plastic components. At the core of our operations is the cutting-edge technology of 5-axis CNC machining, which propels precision and complexity to new heights. Our one-stop service, from rapid prototyping to on-demand production, distinguishes us as a comprehensive solution provider.

Our proficiency in 5-axis CNC milling, routing, and lathe services sets us apart in the dynamic landscape of CNC machining. Using advanced 5-axis machinery empowers us to achieve intricate geometries and tight tolerances with unparalleled efficiency. Neway's commitment to excellence is underscored by our skilled team that translates innovative design concepts into tangible, high-quality parts. Whether it's 5-axis CNC router woodworking or intricate tooling, our services encapsulate a spectrum of applications, demonstrating the versatility and adaptability of our manufacturing capabilities. Clients seeking 5-axis machining services for prototyping or large-scale production can rely on Neway's expertise for precision, reliability, and a seamless end-to-end experience.

Definition and Overview of 5-axis CNC Machining

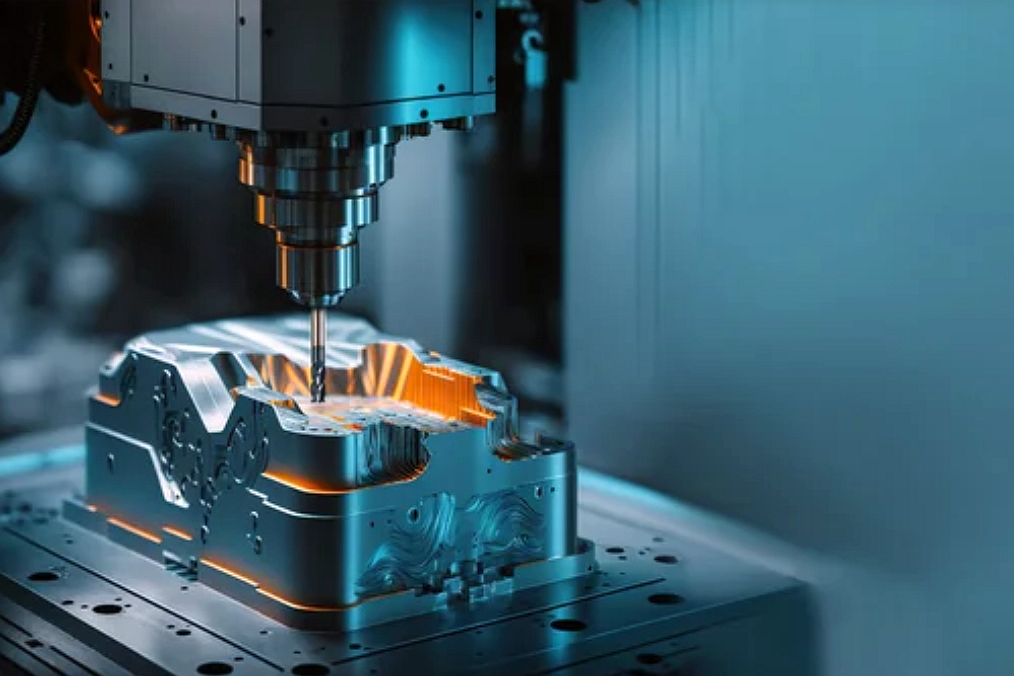

5-axis CNC machining represents the pinnacle of precision engineering, offering a dynamic and versatile method for crafting intricate parts with unparalleled accuracy. Unlike traditional machining methods that operate on three axes, 5-axis CNC machining involves the simultaneous movement of the cutting tool along five axes, X, Y, and Z, and rotation around the X and Y axes. This innovative approach allows for the fabrication of highly complex geometries and intricate designs that would be challenging or impossible to achieve with fewer axes.

In manufacturing, "5-axis CNC machining" encapsulates a sophisticated process wherein a computer-controlled machine precisely carves, shapes, or mills materials such as metal, ceramic, or plastic. As a leader in this domain, Neway excels in harnessing the power of 5-axis CNC machining to deliver custom parts that meet their clients' exacting demands. This technology empowers the production engineer to achieve superior precision and efficiency, ensuring that the final components adhere seamlessly to design specifications.

Neway's dedication to 5-axis CNC machining extends beyond mere capability; it embodies a commitment to pushing the boundaries of what is achievable in precision manufacturing. By seamlessly integrating this advanced technique into their one-stop service, Neway ensures that clients benefit from the complexity 5-axis machining affords and a streamlined and efficient production process. This approach underscores Neway's position as an industry leader, providing clients with cutting-edge solutions that set the standard for precision and quality in custom part manufacturing.

Features of 5 Axis CNC Parts in Aerospace

In the aerospace industry, the adoption of 5-axis CNC machining for parts production has revolutionized manufacturing processes, offering distinct features that cater to the demanding requirements of this high-performance sector.

Precision in Complex Geometries:

One of the standout features of 5-axis CNC parts in aerospace is the ability to achieve unparalleled precision in crafting complex geometries. Aerospace components often involve intricate shapes and contours, and the simultaneous movement along five axes allows for precise machining, ensuring that parts meet the stringent tolerances required for optimal performance.

Reduced Setup Time and Increased Efficiency:

5-axis CNC machining minimizes the need for multiple setups compared to traditional machining methods. This reduction in setup time enhances efficiency and decreases the likelihood of errors associated with manual adjustments. This feature is instrumental in maintaining the highest quality standards in the aerospace industry, where precision is paramount.

Enhanced Surface Finish:

Aerospace applications demand precision and impeccable surface finishes to meet aerodynamic and performance specifications. 5-axis CNC machining achieves smooth and flawless surfaces, contributing to aerospace components' overall aerodynamic efficiency and performance. PVD (physical vapor deposition) is the typical surface treatment.

Versatility in Materials:

Aerospace parts often require various materials, including lightweight alloys and composites. Such as titanium alloys, 7075 aluminum. 5-axis CNC machining's versatility extends to working with a broad range of materials, ensuring that the unique material requirements of aerospace applications are met without compromising precision or quality.

Optimized Tool Paths for Efficiency:

5-axis CNC machining allows for optimized tool paths, minimizing air-cutting and improving tool life. This feature is crucial in aerospace manufacturing, where efficiency and cost-effectiveness are as vital as precision. Neway's expertise in 5-axis machining ensures that aerospace components are manufactured with optimal tool paths, maximizing efficiency and quality.

In conclusion, the features of 5-axis CNC parts in aerospace, including precision in complex geometries, reduced setup time, enhanced surface finish, versatility in materials, and optimized tool paths, collectively contribute to elevating the standards of precision, efficiency, and performance in the production of aerospace components. Neway's commitment to utilizing 5-axis CNC machining reinforces its position as a reliable partner for the aerospace industry, delivering cutting-edge solutions that align with the sector's exacting demands.

Benefits of 5-axis CNC Machining

5-axis CNC machining, a pinnacle of precision engineering, offers a multitude of benefits that elevate it as a preferred method in the manufacturing industry:

Complex Geometries:

One of the standout advantages is the ability to produce highly intricate and complex shapes. The simultaneous movement along five axes allows for creating intricate designs, contours, and features that would be challenging or impossible with fewer axes.

Precision and Accuracy:

5-axis CNC machining delivers exceptional precision, ensuring components are manufactured with tight tolerances and high accuracy. This level of precision is crucial in industries where even minor deviations can impact performance and functionality.

Reduced Setups and Tool Changes:

Simultaneously moving along multiple axes reduces the need for multiple setups and tool changes. This efficiency speeds up the manufacturing process and minimizes the risk of errors associated with frequent changes.

Improved Surface Finish:

The multi-axis movement allows smoother toolpaths and superior surface finishes. It is particularly beneficial for industries like aerospace and medicine, where smooth surfaces are essential for functionality and safety.

Increased Productivity:

The efficiency and precision of 5-axis CNC machining contribute to increased productivity. It allows for quicker production times, enabling manufacturers to meet tight deadlines and deliver products to market faster.

Versatility in Material Usage:

5-axis CNC machining can be applied to various materials, including metals, plastics, and ceramics. This versatility is advantageous for manufacturers dealing with diverse materials in various industries.

Optimized Tool Angles:

The ability to tilt and rotate the tool at different angles enhances tool access to the workpiece. This optimized tool approach reduces the need for complex setups and fixtures, improving overall efficiency.

Cost-Effective for Complex Parts:

While 5-axis CNC machining may have higher initial setup costs, it proves cost-effective for producing complex parts. The efficiency, reduced scrap, and minimized rework contribute to long-term cost savings.

Case Study: Aerospace 5axis Machining

Aerostructural Components 5axis Machining

Aerostructural components, such as complex aircraft parts and intricate engine elements, often demand the precision and versatility of 5-axis CNC machining. In the aerospace industry, where intricacy and accuracy are paramount, utilizing 5-axis CNC machining services becomes imperative.

Take, for instance, the production of turbine blades for aircraft engines. These blades often feature intricate airfoil designs and intricate geometries that demand precision in every dimension. The 5-axis CNC machining process allows for simultaneous cutting from multiple angles, ensuring the intricate contours of the blades are accurately reproduced. This capability enhances the engine's overall efficiency and contributes to fuel efficiency and performance.

Moreover, aerostructure components like winglets and fuselage parts often have complex shapes that are challenging to achieve with traditional machining methods. 5-axis CNC milling enables Neway to precisely sculpt these components, reducing material waste and ensuring the final product meets stringent aerospace standards.

By employing 5-axis CNC machining services for such aerostructure components, Neway ensures that the final products exhibit superior quality, dimensional accuracy, and surface finish. It aligns with industry standards and underscores Neway's commitment to delivering high-performance, customized solutions to meet the unique demands of the aerospace sector.

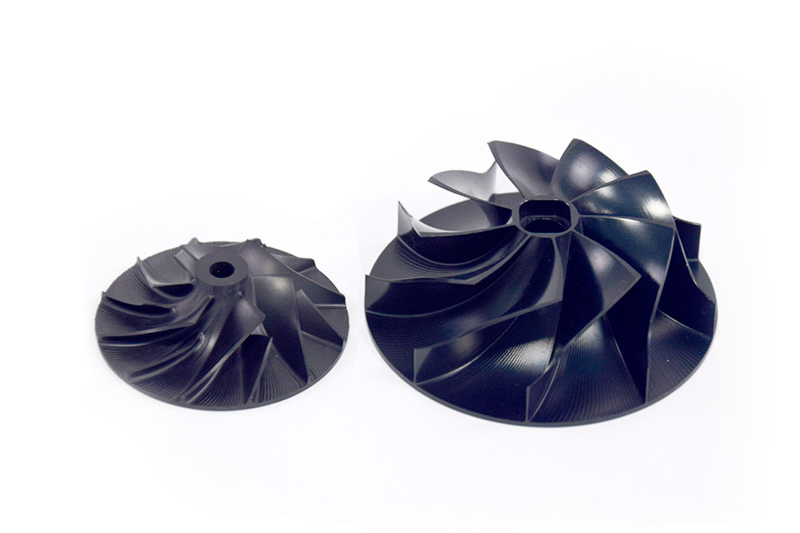

Turbomachinery Parts

Turbomachinery parts, particularly those found in advanced turbines and high-performance engines, often necessitate the precision capabilities of 5-axis CNC machining. An exemplary illustration lies in the production of impellers for gas turbines.

Impellers play a critical role in turbomachinery, driving the efficient flow of air or gas within the system. The intricate geometry of impeller blades demands precision that can be achieved through 5-axis CNC machining. The simultaneous movement of the cutting tool in multiple axes allows for the intricate shaping of the blades, ensuring optimal aerodynamics and performance.

The unique advantage of 5-axis CNC machining becomes evident when crafting the complex curved surfaces of impeller blades. Traditional machining methods may need help to achieve the necessary precision on these intricate contours. However, with 5-axis machining, Neway can precisely control the tool's orientation, facilitating the creation of complex shapes and ensuring the blades meet the stringent tolerances required for turbomachinery applications.

Additionally, 5-axis CNC machining enhances the overall efficiency of the manufacturing process. By reducing the need for multiple setups and tool changes, Neway can streamline production, minimize errors, and deliver turbomachinery parts with consistent quality. It aligns with industry demands for high-precision components and highlights Neway's commitment to utilizing advanced machining technologies for superior results in turbomachinery applications.

Aircraft Interiors and Exteriors Parts

When delving into aircraft manufacturing, the significance of 5-axis CNC machining in crafting interiors and exteriors becomes evident. Take the aircraft wing components, a critical facet of aerospace engineering.

The intricate contours and complex shapes of aircraft wings demand precision in production, and 5-axis CNC machining is instrumental in achieving this. The method allows for simultaneous movement of the cutting tool along five different axes, enabling the fabrication of intricate wing profiles with utmost accuracy.

In the case of wing exteriors, the streamlined and aerodynamic designs play a pivotal role in enhancing fuel efficiency and overall performance. 5-axis CNC milling ensures that these external components are manufactured with meticulous attention to detail, resulting in smoother surfaces and precisely engineered airfoil shapes. It contributes to the aircraft's aerodynamic efficiency but also aids in reducing drag, ultimately optimizing fuel consumption.

Moreover, for aircraft interiors, where space utilization and weight considerations are paramount, 5-axis CNC machining proves invaluable. The technique facilitates the creation of lightweight yet structurally robust components, such as seating structures and overhead compartments. By intricately carving out components from materials like aluminum or composite materials, 5-axis CNC machining enables the production of parts that meet both safety and ergonomic requirements.

Applying 5-axis CNC machining in crafting aircraft wing components exemplifies its indispensable role in achieving the intricate designs essential for optimal aerodynamics, fuel efficiency, and interior functionality. This method aligns with Neway's commitment to providing cutting-edge manufacturing solutions that blend precision with innovation in the aerospace sector.

Challenges and Solutions

Aerospace 5-axis CNC machining, while offering unparalleled precision and versatility, comes with its challenges. Understanding and addressing these challenges is crucial for ensuring the seamless production of high-quality components. Here, we delve into the primary challenges and innovative solutions associated with aerospace 5-axis CNC machining:

Complex Programming Requirements:

Challenge: Programming for 5-axis machining demands a higher level of complexity due to the multitude of axes and the need for synchronized movements.

Solution: Implementing advanced CAM (Computer-Aided Manufacturing) software streamlines programming. With its expertise, Neway utilizes state-of-the-art CAM solutions that simplify the programming process, ensuring efficiency and accuracy.

Tool Access and Interference:

Challenge: Achieving optimal tool access to all surfaces without interference can be challenging, especially in intricate aerospace components.

Solution: Utilizing specialized tooling and toolpath optimization strategies helps mitigate interference issues. Neway's commitment to precision involves employing cutting-edge tooling technologies, ensuring access to even the most challenging geometries.

Material Variability:

Challenge: Aerospace components are often crafted from diverse materials, each with unique machining characteristics.

Solution: Neway's 5-axis CNC machining services are adaptable to various aerospace materials, including aluminum, titanium, and composites. The expertise lies in selecting appropriate cutting parameters and tooling based on the specific material properties, ensuring optimal results.

Quality Assurance:

Challenge: Maintaining high-quality standards is paramount in aerospace manufacturing, requiring rigorous quality control measures.

Solution: Neway implements a comprehensive quality assurance process that includes in-process inspections and post-machining checks. This commitment to quality aligns with aerospace industry standards, ensuring that every component meets stringent criteria.

Cost Considerations:

Challenge: 5-axis CNC machining is often perceived as a cost-intensive process, impacting overall project budgets.

Solution: Neway employs a holistic approach, optimizing machining strategies to reduce cycle times and enhance efficiency. It ensures that while maintaining quality, the overall cost-effectiveness of the 5-axis CNC machining services is maximized.

By addressing these challenges head-on with innovative solutions, Neway distinguishes itself as a leader in aerospace 5-axis CNC machining. The commitment to overcoming complexities and delivering precision aligns seamlessly with the aviation industry's demands for cutting-edge, reliable components.

Brand Case Study

Neway has served many world-renowned companies, using its strong manufacturing capabilities and complete quality control system to provide further market competitiveness and quality assurance for major brands.