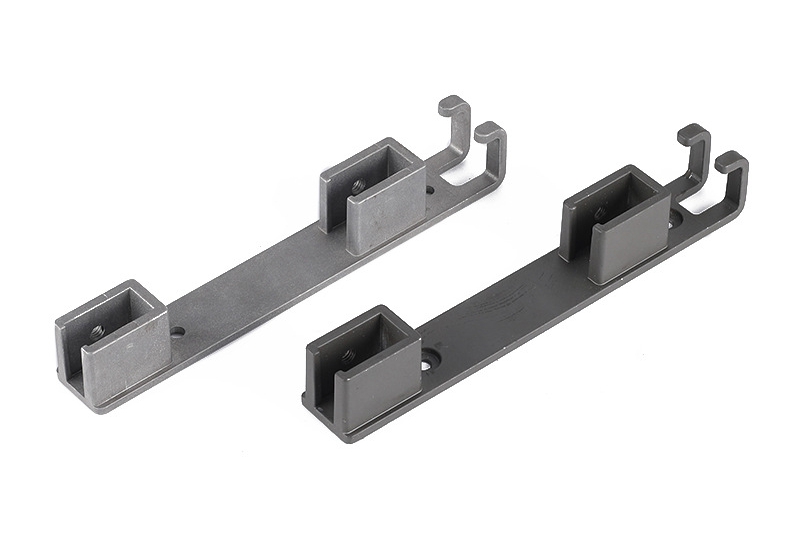

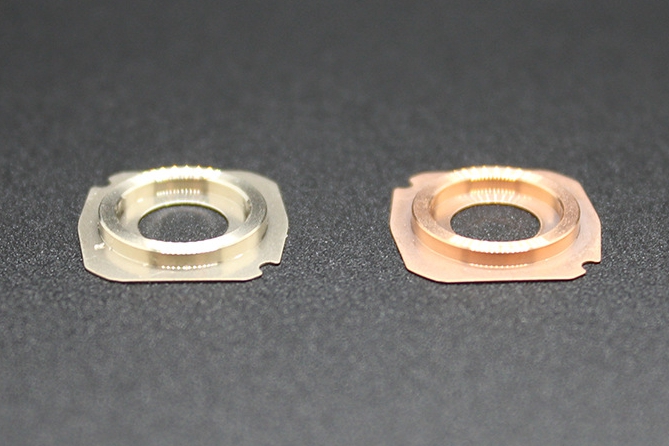

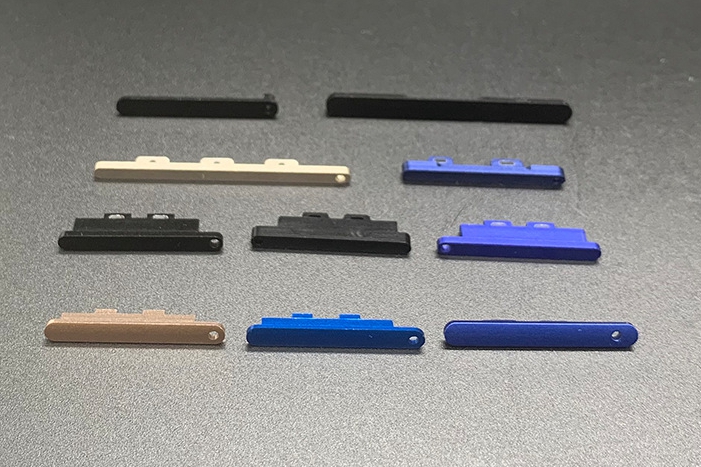

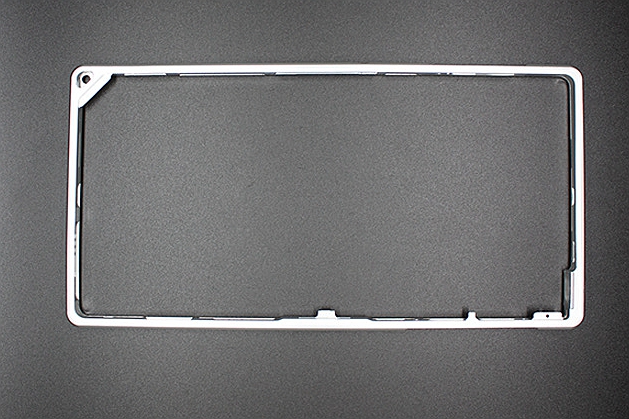

Huawei Mobile Phone Accessories Metal Injection Molding

Huawei Technologies Co., Ltd., commonly called Huawei, is a multinational technology company headquartered in Shenzhen, Guangdong, China. Established in 1987, Huawei has grown to become one of the world's leading providers of telecommunications equipment and consumer electronics.

The company operates in various sectors, including telecommunications networks, smartphones, tablets, laptops, wearables, cloud computing, and artificial intelligence. Huawei's products and services are used by individuals, businesses, and governments in over 170 countries worldwide.

Huawei's needs and requirements in MIM mobile phone accessories

Huawei has diverse needs for MIM accessories for mobile phones. Such as camera bracket, mobile phone button, frame, hinges, SIM card slot, etc. These MIM products are characterized by small size, high precision, and complex design. And Neway's metal injection molding process just meets all needs.

Design Compatibility

Huawei, a leading manufacturer of mobile phones, seeks MIM accessories specifically designed to fit their smartphone models. These MIM products must possess precise dimensions, cutouts, and openings that align seamlessly with Huawei devices, ensuring optimal integration and functionality of Mobile Phone Accessories.

Material Selection

Huawei emphasizes material preferences for MIM parts in their mobile phone accessories. Common materials like stainless steel, titanium, and various alloys are carefully chosen to strike a balance between durability, lightweight construction, and aesthetic appeal. Meeting Huawei's quality standards is paramount in selecting the right materials for MIM manufacturing.

Manufacturing Precision

Huawei places a premium on manufacturing precision for its MIM accessories. Leveraging the capabilities of MIM technology, intricate designs, and complex geometries can be achieved. Huawei may have specific design requirements necessitating precise molding, minimal parting lines, and impeccable surface finishes to ensure exceptional Mobile Phone Accessories.

Quality and Durability

Reflecting Huawei's commitment to delivering high-quality smartphones, they expect the same level of quality and durability in their MIM accessories. These meticulously crafted accessories must endure regular use, offer reliable device protection, and maintain optimal functionality and appearance over time.

Aesthetics and Brand Identity

Huawei prioritizes design aesthetics and seeks MIM accessories that align seamlessly with its brand identity. The Mobile Phone Accessories should possess an attractive appearance, and sleek finish, and harmonize with the overall design language of Huawei smartphones, enhancing the user experience.

Production Capacity and Efficiency

As a global company, Huawei requires MIM manufacturers capable of meeting their production volume demands for Mobile Phone Accessories. The chosen MIM company must exhibit efficient manufacturing processes, maintain reliable supply chains, and possess the capability to meet strict production deadlines, ensuring timely delivery of high-quality products.

By considering these key factors, Huawei strives to offer its customers a range of superior Mobile Phone Accessories through metal injection molding (MIM) processes.

Why MIM Process Suit for Smart Phone Parts Production

Metal injection molding (MIM) has emerged as a preferred manufacturing method for producing small smartphone parts, offering a range of advantages that cater to the specific needs of mobile phone accessories.

Complex Geometries

MIM enables the production of small smartphone parts with intricate and complex geometries that are challenging to achieve using conventional manufacturing techniques. This flexibility allows for creating custom designs that fit seamlessly within the limited space available in mobile devices.

High Precision

MIM ensures exceptional dimensional accuracy and repeatability, making it ideal for small parts that require precise dimensions and tight tolerances. The high precision achieved through MIM guarantees optimal functionality and compatibility of mobile phone accessories with the overall device.

Consistent Quality

MIM offers consistent material properties and production repeatability, resulting in uniform part quality across large production volumes. The manufacturing process ensures that small smartphone parts exhibit consistent dimensions, mechanical properties, and surface finishes, guaranteeing reliable performance and enhancing the user experience.

Material Versatility

MIM provides various material options, including various alloys, stainless steel, and titanium. Manufacturers can select materials that offer the desired combination of strength, durability, and lightweight characteristics, aligning with the stringent requirements of small smartphone parts.

Cost Efficiency

MIM is a cost-effective manufacturing method for small smartphone parts due to its ability to produce complex shapes in high volumes with minimal post-processing requirements. The streamlined production process reduces the need for additional machining or assembly operations, leading to cost savings in terms of time and labor.

Scalability

MIM is highly scalable, making it suitable for the mass production of small smartphone parts to meet market demand. The process enables high production rates, ensures consistent quality control, and optimizes material usage, allowing manufacturers to efficiently fulfill the requirements of mobile phone accessories.

By leveraging the benefits of MIM, manufacturers can produce small smartphone parts that boast intricate designs, precise dimensions, consistent quality, and optimal performance. This, in turn, contributes to the overall functionality, aesthetics, and user satisfaction of mobile phone accessories.

Neway Metal Injection Molding Capabilities

Neway Metal Injection Molding (MIM) offers a wide range of capabilities for the production of precision components using the MIM process. Some of the key capabilities of Neway Metal Injection Molding include:

Design and Engineering Support

Neway MIM provides design and engineering support to help optimize component designs for the MIM process. Their team of experts collaborates with clients to ensure that the design is suitable for MIM manufacturing, resulting in improved efficiency and product quality.

Material Selection and Customization

Neway MIM offers a variety of material options for MIM production. They work with different materials such as stainless steel, titanium, and various alloys, allowing for a comprehensive range of applications and specific customer requirements.

In addition to the MIM metal materials that can be purchased and used in production on the market, Neway can customize MIM powder according to customer needs. Alloy powders with different properties can be achieved through different metal composition ratios.

Complex Geometries

Neway MIM specializes in producing components with complex geometries. The MIM process allows for intricate designs, thin walls, and intricate features that are not easily achievable with traditional manufacturing methods.

High Precision

Neway MIM ensures high precision in component production. They utilize advanced technology and equipment to achieve tight tolerances and accurate dimensions, meeting customers' most stringent requirements.

Surface Finishing

Neway MIM offers various surface finishing options to enhance the appearance and functionality of MIM components. These options include polishing, plating, coating, and other customized surface treatments based on client specifications.

Quality Control

Neway MIM has stringent quality control measures throughout the production process. They employ advanced inspection techniques and quality assurance protocols to ensure that the produced components meet the highest standards of quality and reliability.

Scalability and Production Efficiency

Neway MIM has the capability to handle both small and large production volumes. They employ efficient manufacturing processes and production planning to meet customer demands while maintaining cost-effectiveness and timely delivery.

Assembly and Integration

Neway MIM can provide additional services such as simple component assembly and integration. This ensures that customers receive fully functional and ready-to-use components, reducing the need for additional manufacturing steps.

Overall, Neway Metal Injection Molding offers a comprehensive range of capabilities, including design support, material selection, complex geometries, high precision, surface finishing, quality control, scalability, and assembly. These capabilities enable them to deliver high-quality MIM components that meet the diverse needs of their customers. If you are looking for a reliable powder metallurgy supplier, please contact us now.