Surface Treatment | Pictures | Applicable Materials | Key Features |

|---|

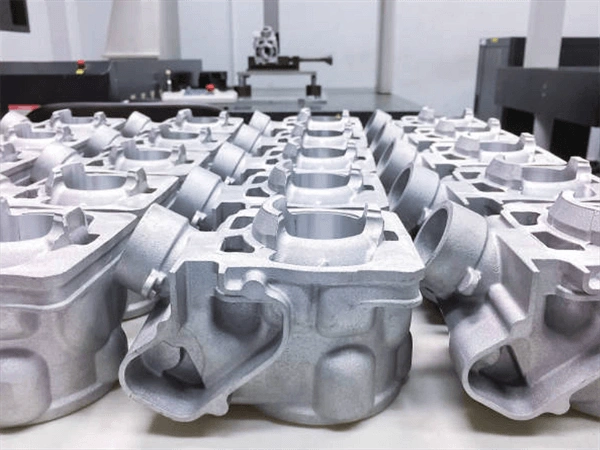

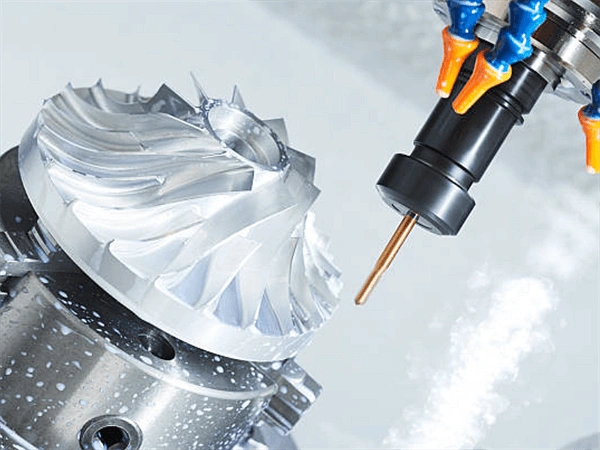

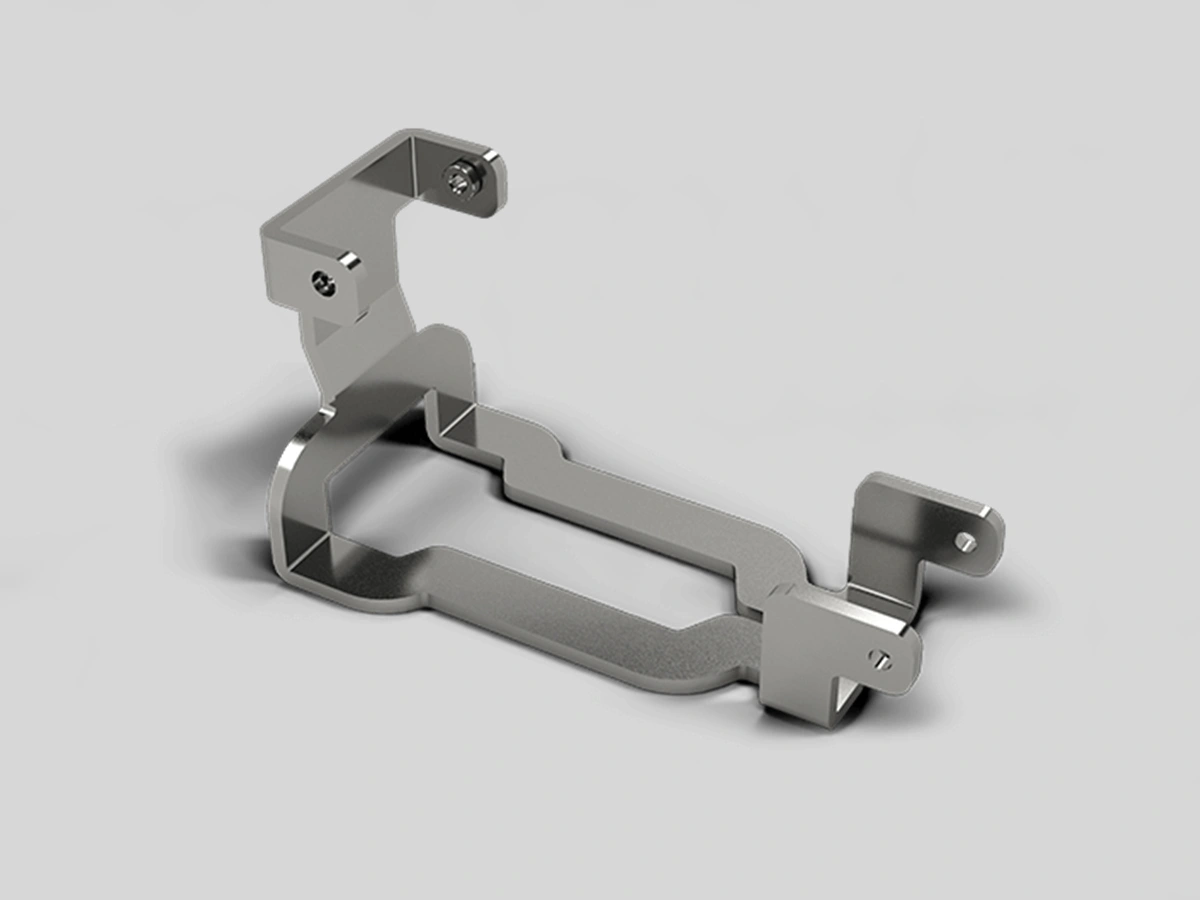

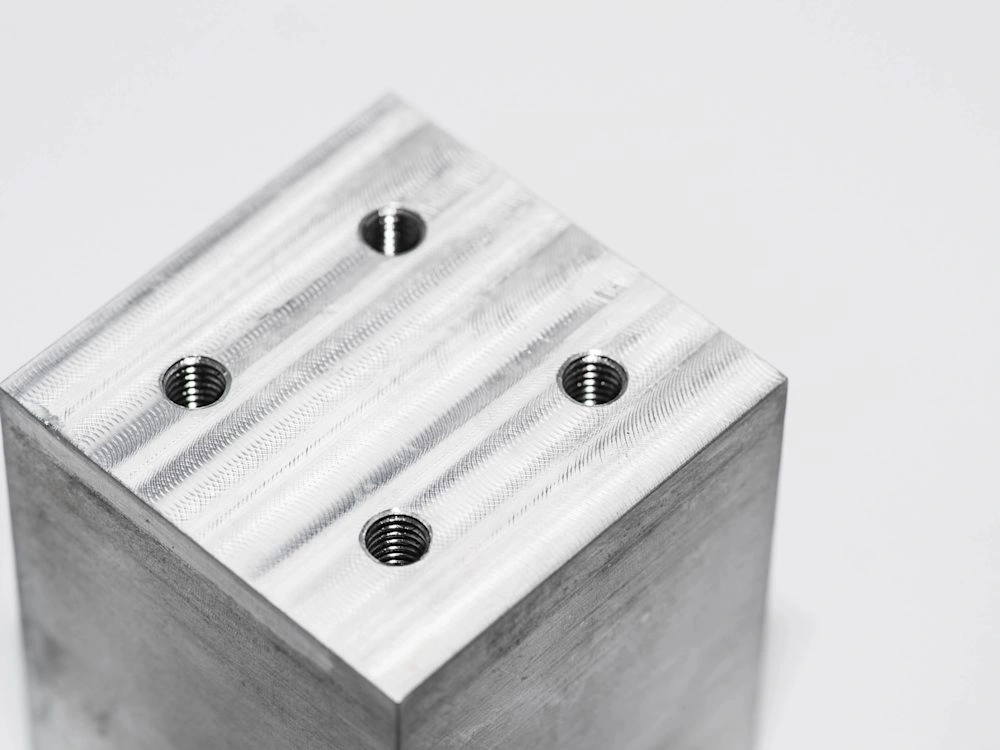

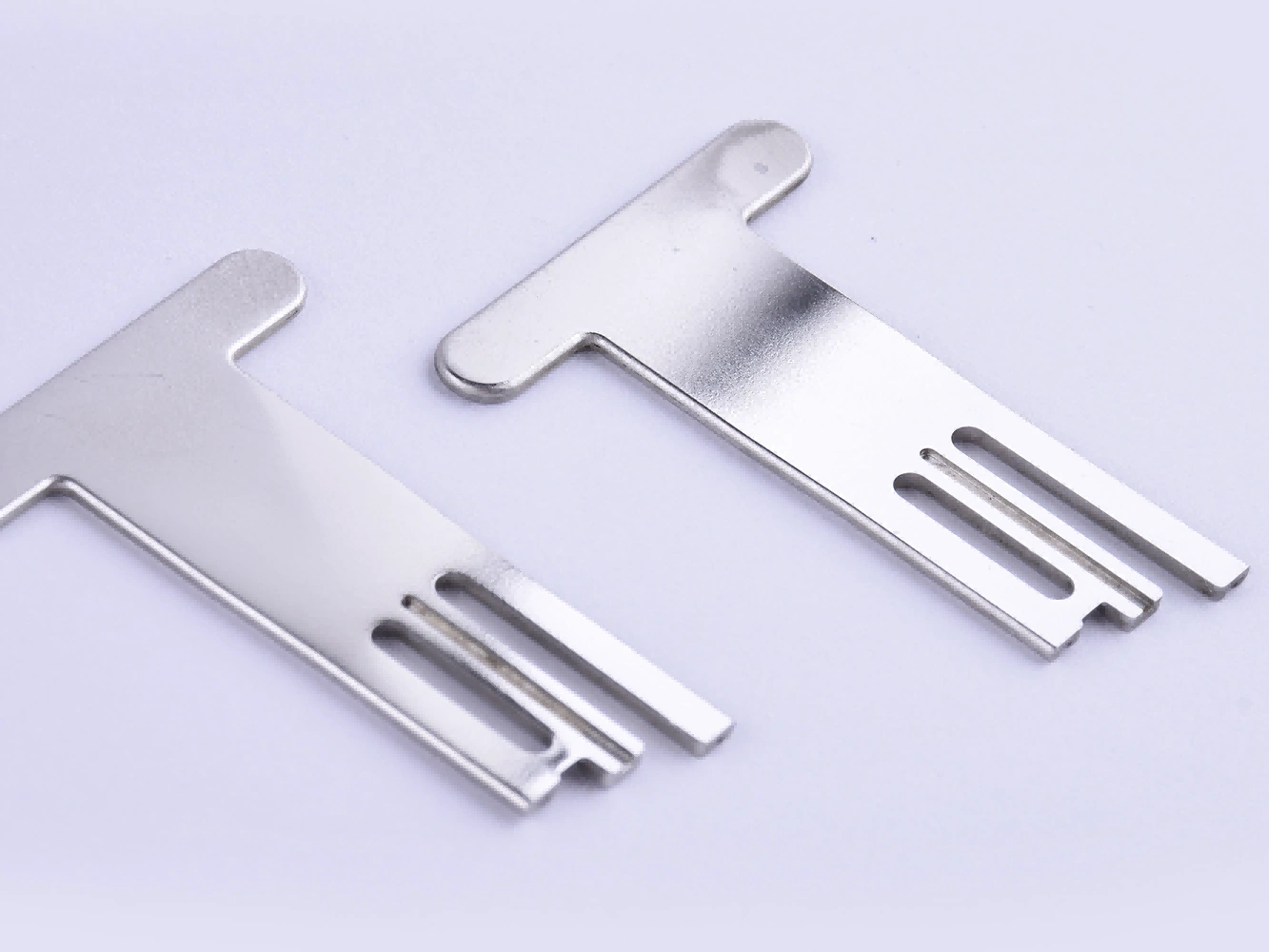

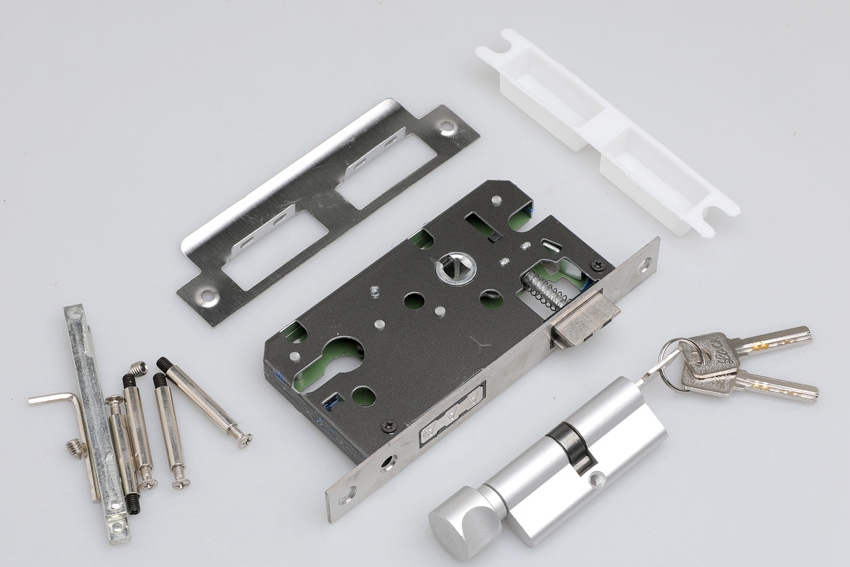

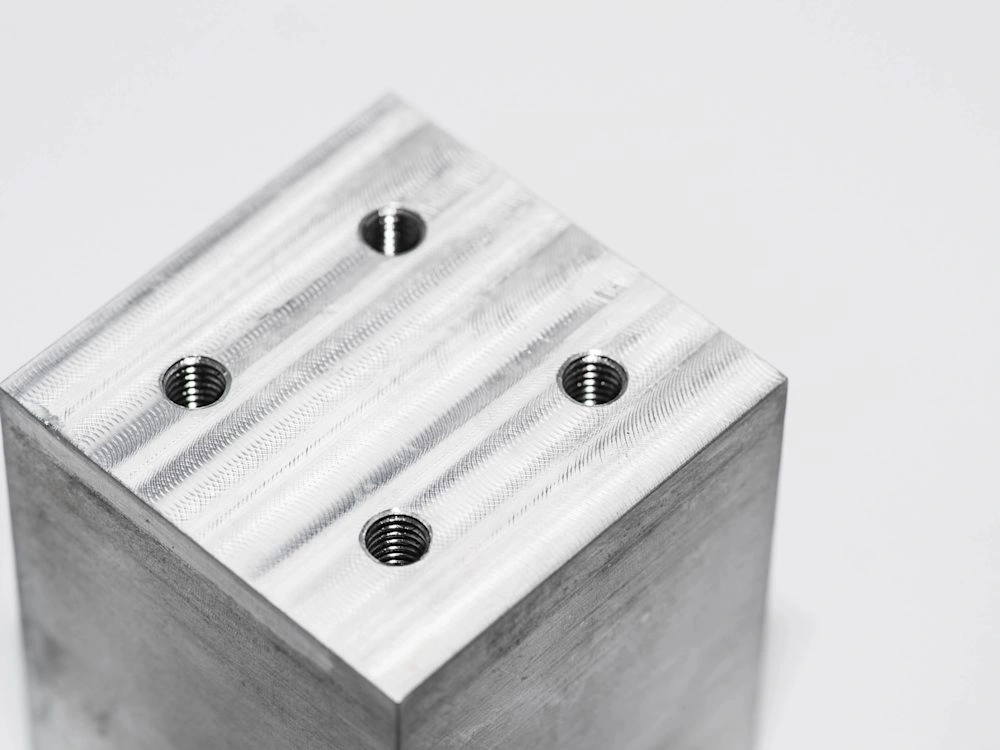

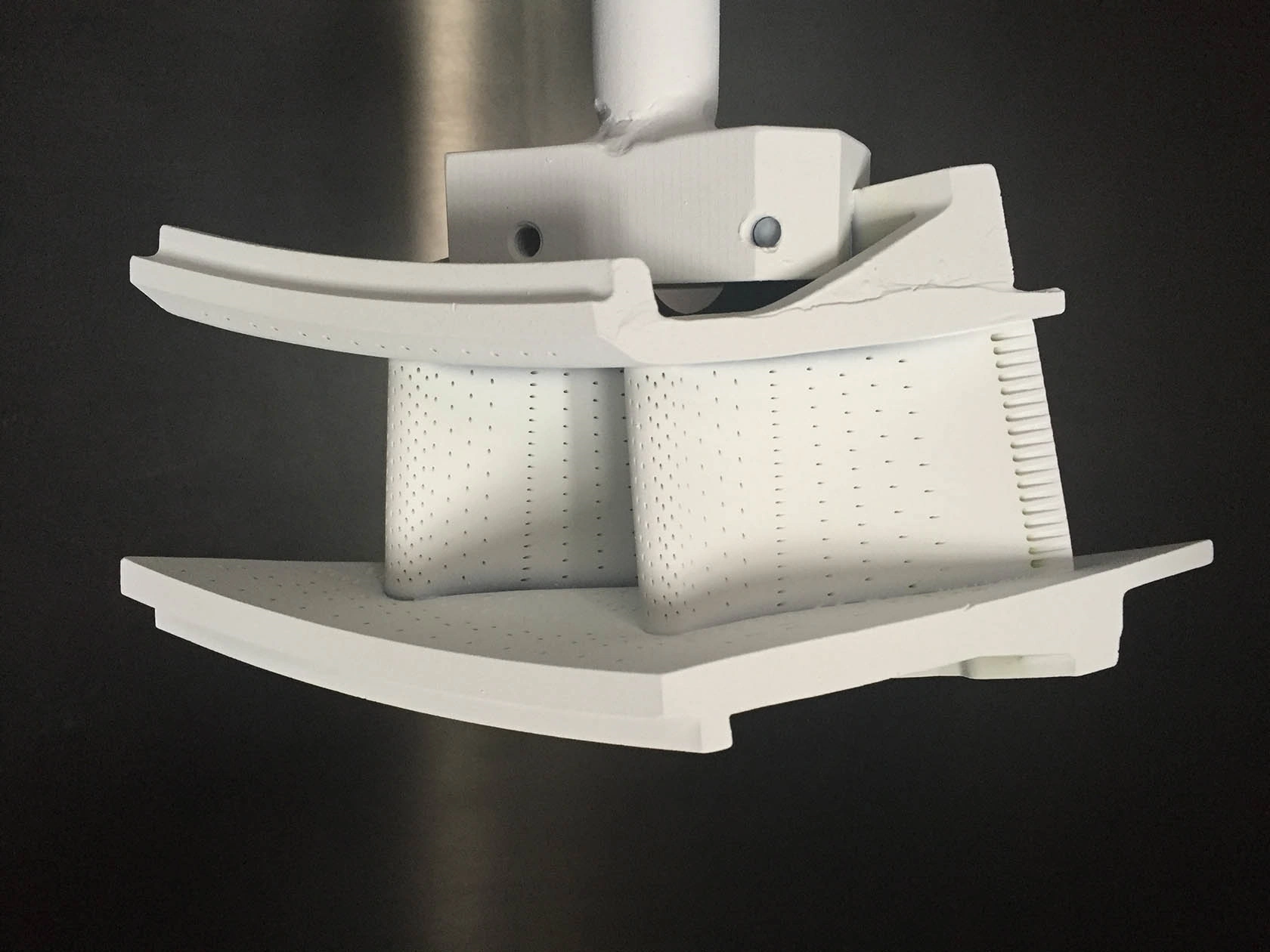

As Machined |  | Metals

Plastics

Ceramics | 1. Precision and Tolerance: Ensures parts meet exact specifications with tight tolerances, crucial for high-accuracy components.

2. Surface Roughness: Achieves specific textures by controlling tool paths, speeds, and feeds during machining.

3. Speed and Cost-Efficiency: Eliminates additional finishing steps, offering a quicker, more cost-effective solution.

4. Material Integrity: Maintains original material properties, avoiding alterations from heat or chemical treatments. |

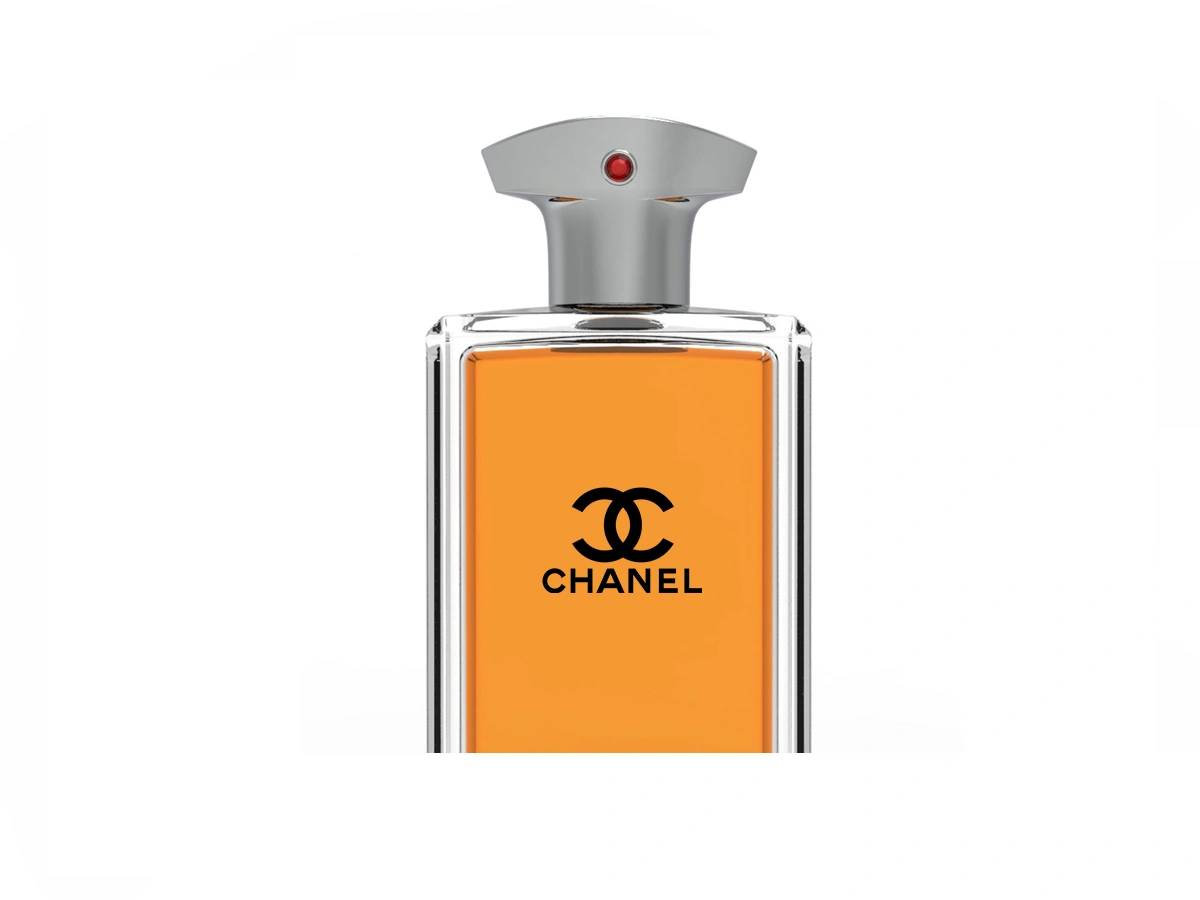

Painting |  | Metals

Plastics | 1. Aesthetic Enhancement: Elevates visual appeal with vibrant, long-lasting colors.

2. Protective Barrier: Shields components from environmental degradation and corrosion.

3. Versatility: Compatible with multiple substrates including metals and plastics.

4. Customization: Offers varied finishes and textures tailored to specific applications. |

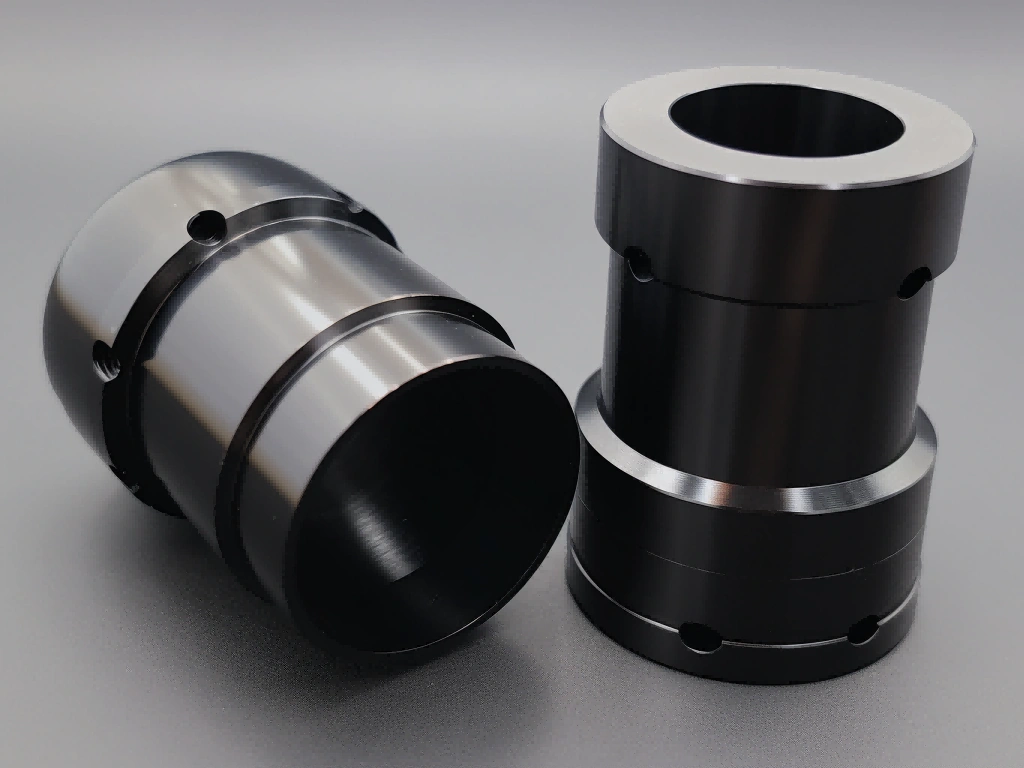

PVD |  | Metals

Plastics

Ceramics | 1. High Durability: Produces hard, wear-resistant coatings for extended part life.

2. Decorative Options: Offers a range of metallic finishes for enhanced aesthetics.

3. Environmentally Friendly: Uses minimal chemicals and generates less waste.

4. Precise Application: Ensures uniform and consistent coating thickness for optimal performance. |

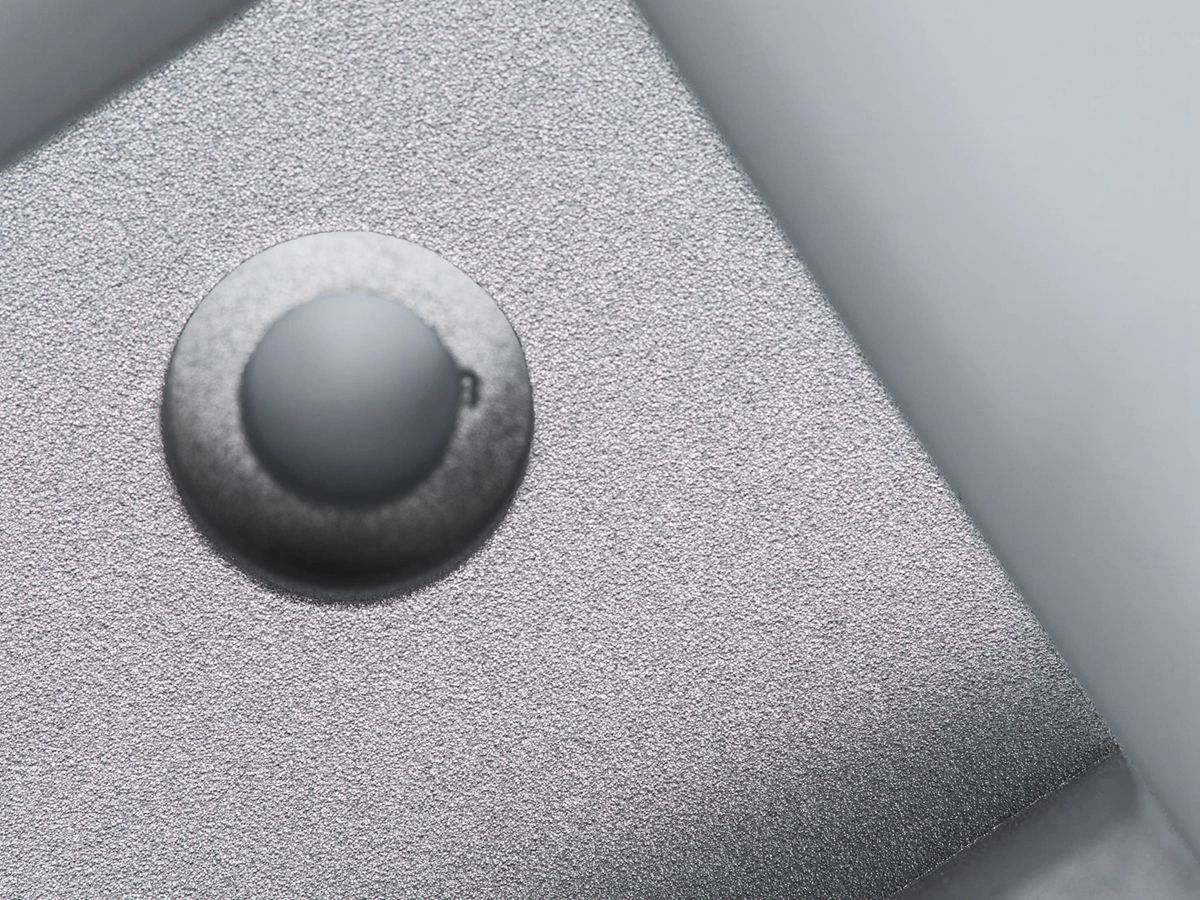

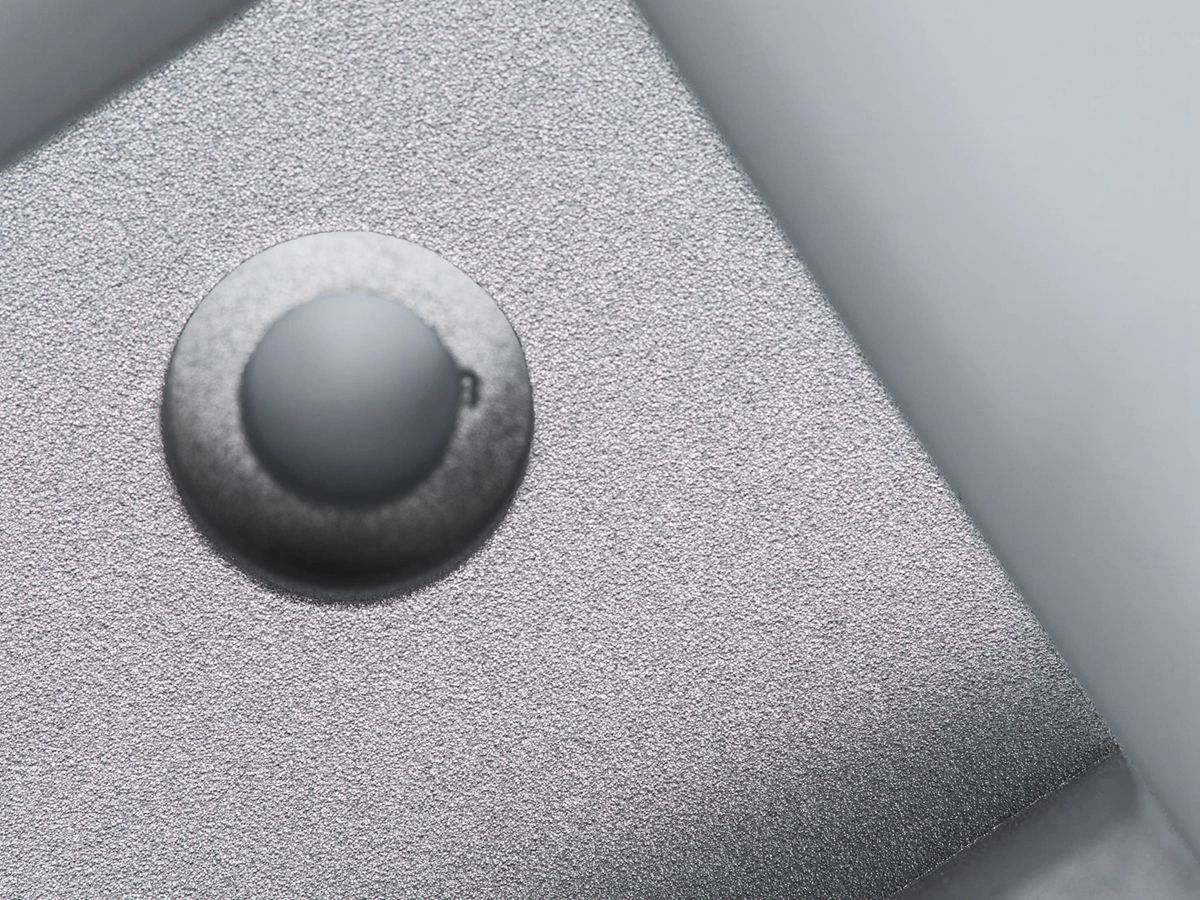

Sandblasting |  | Metals

Plastics | 1. Surface Preparation: Effectively cleans and roughens surfaces for improved coating adhesion.

2. Versatility: Suitable for metals, plastics, and composites.

3. Uniform Texture: Provides consistent surface roughness for subsequent treatments.

4. Efficiency: Rapidly removes contaminants, streamlining the finishing process. |

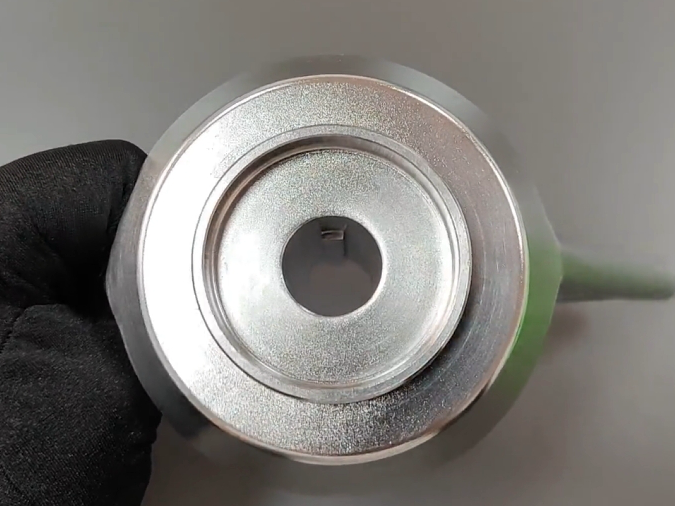

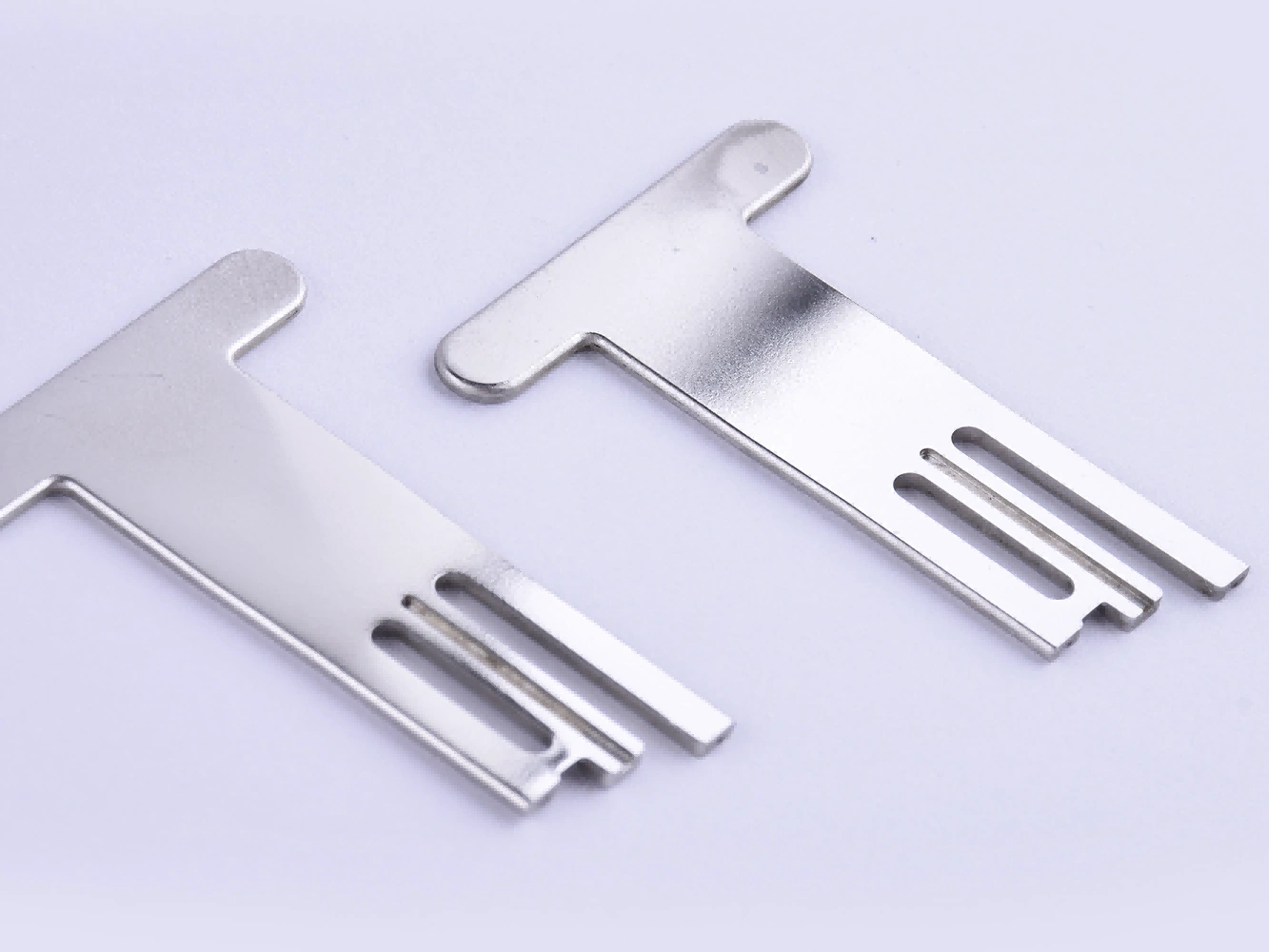

Electroplating |  | Metals

Plastics | 1. Enhanced Durability: Improves resistance to wear, corrosion, and abrasion.

2. Improved Aesthetics: Delivers a lustrous, uniform finish.

3. Customizable Thickness: Allows precise control over coating thickness.

4. Functional Performance: Enhances surface hardness and electrical conductivity. |

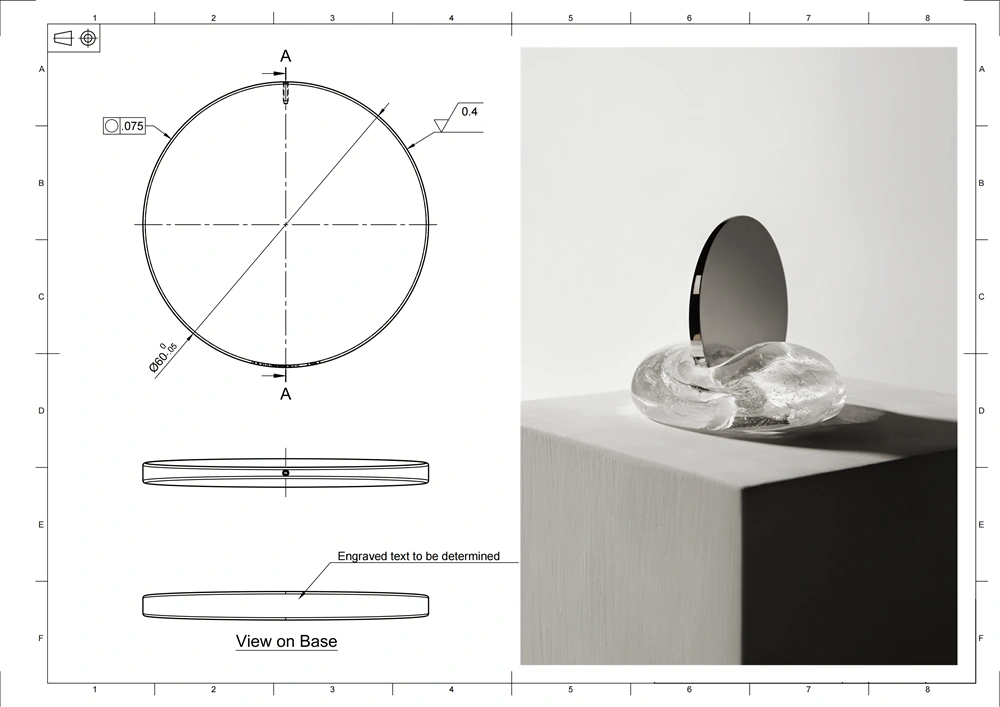

Polishing |  | Metals

Plastics

Ceramics | 1. Superior Smoothness: Achieves a mirror-like, high-gloss finish.

2. Defect Elimination: Removes surface imperfections, scratches, and tool marks.

3. Enhanced Reflectivity: Boosts visual appeal with increased brightness.

4. Improved Cleanliness: Simplifies cleaning and maintenance of components. |

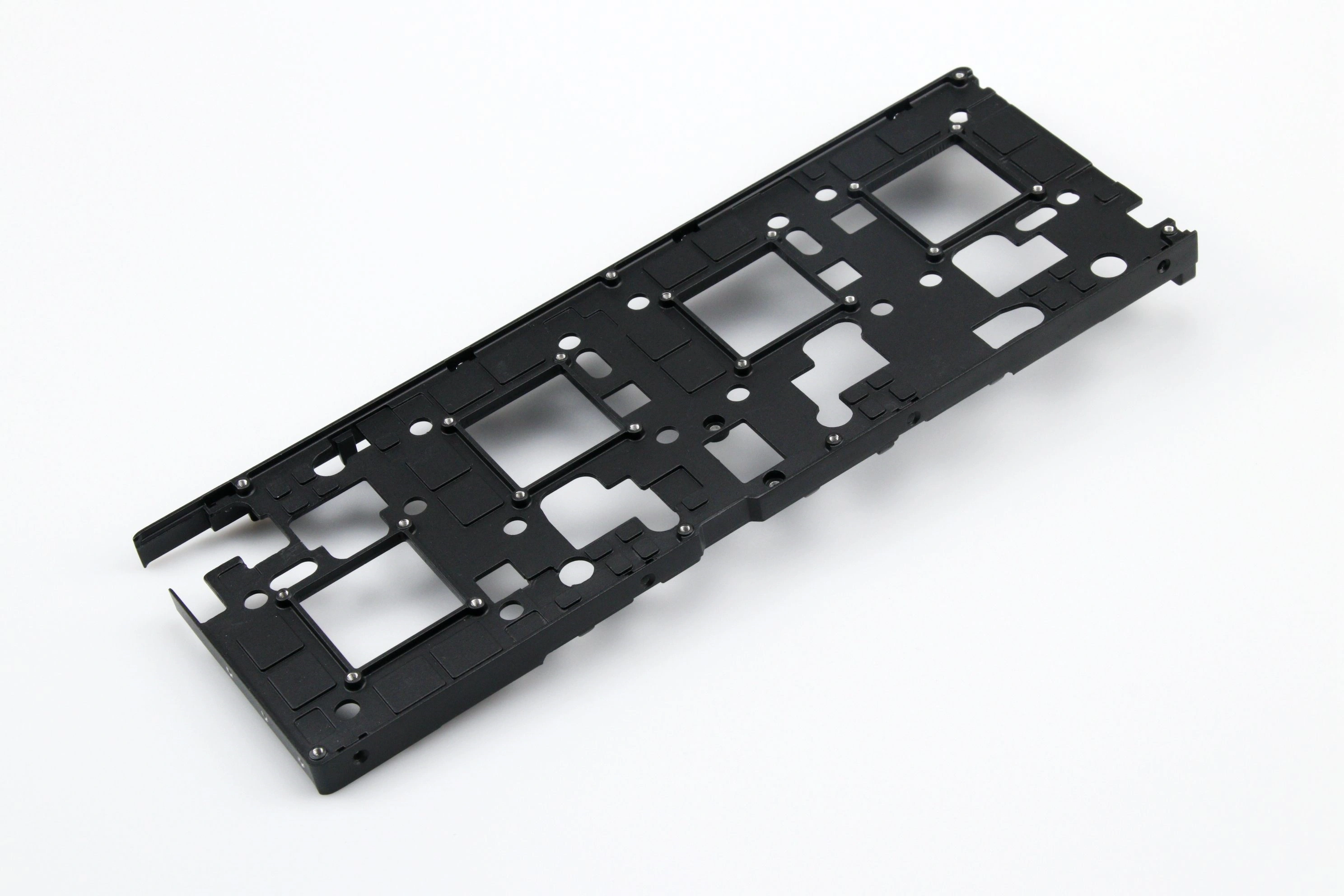

Anodizing |  | Aluminum | 1. Corrosion Resistance: Forms a protective oxide layer on aluminum surfaces.

2. Increased Hardness: Enhances surface durability and wear resistance.

3. Color Customization: Enables vibrant, long-lasting color options.

4. Electrical Insulation: Improves the insulating properties of anodized parts. |

Powder Coating |  | Metals | 1. Durable Finish: Provides a tough, resistant coating for metal parts.

2. Uniform Application: Ensures even coverage without drips or runs.

3. Eco-Friendly: Utilizes low-VOC, environmentally friendly processes.

4. Versatile Appearance: Available in a wide range of colors and textures. |

Electropolishing |  | Metals | 1. Ultra-Smooth Finish: Creates a clean, bright, and smooth surface.

2. Enhanced Corrosion Resistance: Minimizes surface imperfections that may lead to rust.

3. Improved Cleanability: Simplifies cleaning by reducing adhesion of contaminants.

4. Consistent Quality: Provides a uniform finish on complex geometries. |

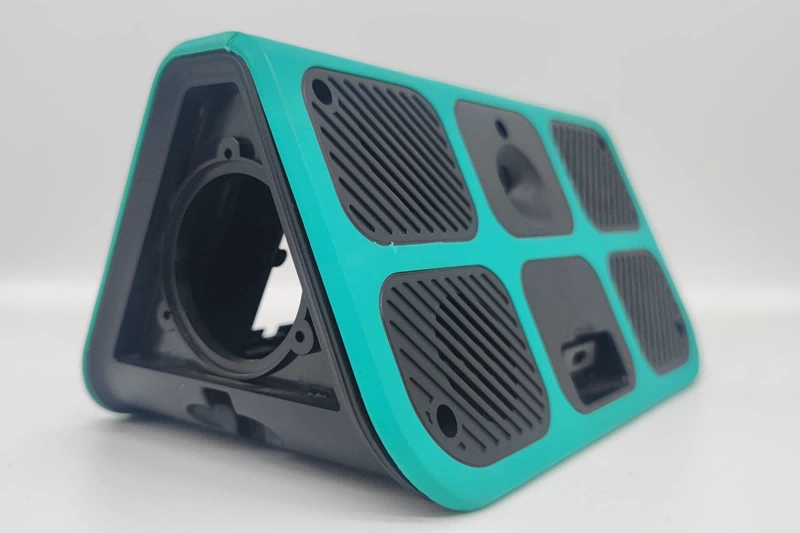

IMD |  | Plastics | 1. Integrated Process: Merges decoration with molding for seamless production.

2. High Detail: Achieves intricate designs and textures on plastic surfaces.

3. Enhanced Durability: Ensures the decoration is an integral part of the component.

4. Cost Savings: Reduces post-molding finishing steps and labor. |

Brushed Finishes |  | Metals

Plastics | 1. Unique Texture: Delivers a soft, satin-like finish with a subtle directional grain.

2. Imperfection Concealment: Masks minor surface flaws while adding visual depth.

3. Enhanced Aesthetics: Provides a modern, refined appearance.

4. Versatility: Suitable for both decorative and functional applications. |

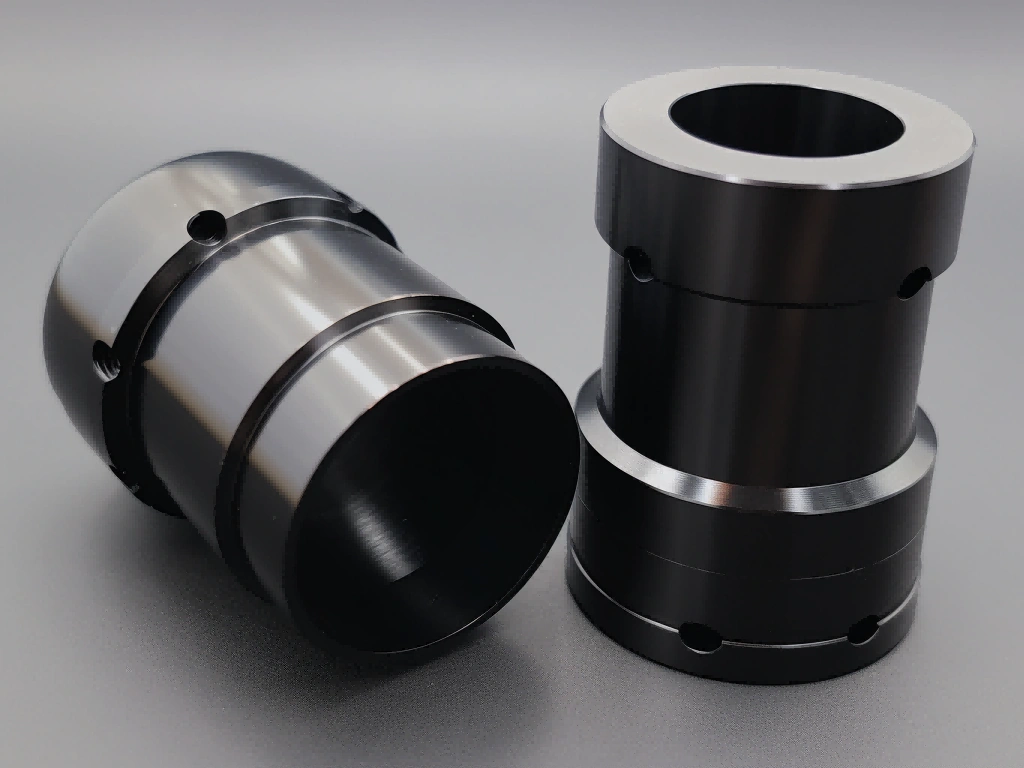

Black Oxide |  | Metals | 1. Corrosion Protection: Provides a protective matte finish that resists rust.

2. Sleek Appearance: Offers a uniform, dark finish that enhances product aesthetics.

3. Low Maintenance: Requires minimal upkeep once applied.

4. Cost-Effective: Delivers durable protection without expensive materials. |

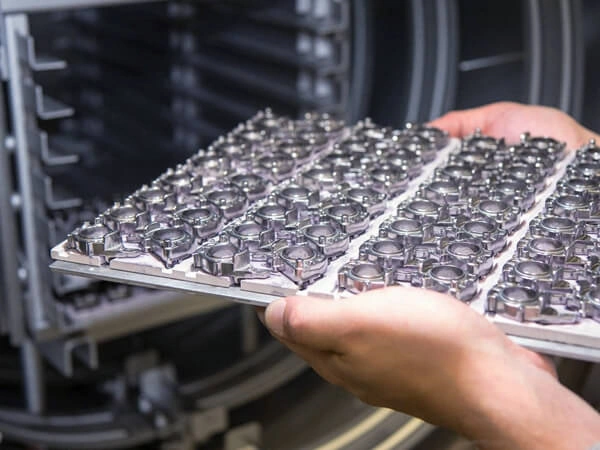

Heat Treatment |  | Metals | 1. Material Strength: Enhances hardness and tensile strength of components.

2. Stress Relief: Reduces internal stresses for improved dimensional stability.

3. Wear Resistance: Increases durability and resistance to deformation.

4. Process Control: Customizable heating and cooling cycles for optimal performance. |

Tumbling |  | Metals

Plastics

Ceramics | 1. Surface Smoothing: Effectively deburrs and polishes parts for a refined finish.

2. Consistency: Provides uniform deburring across complex geometries.

3. Efficiency: Automates post-processing for increased productivity.

4. Versatility: Suitable for a range of materials and component sizes. |

Alodine |  | Metals | 1. Corrosion Inhibition: Forms a protective film on metal surfaces.

2. Improved Adhesion: Prepares surfaces for subsequent coatings or paints.

3. Chemical Resistance: Enhances resistance to environmental chemicals.

4. Lightweight Protection: Provides effective corrosion protection without adding significant weight. |

Chrome Plating |  | Metals | 1. High Luster: Provides a bright, reflective finish for an upscale appearance.

2. Wear Resistance: Enhances surface hardness and prolongs component life.

3. Corrosion Protection: Shields metal surfaces from environmental degradation.

4. Consistent Coating: Achieves uniform thickness for optimal performance. |

Phosphating |  | Metals | 1. Pre-Treatment: Prepares metal surfaces for enhanced coating adhesion.

2. Corrosion Resistance: Forms a protective layer to inhibit rust formation.

3. Improved Adhesion: Ensures subsequent finishes bond effectively.

4. Cost Efficiency: Offers an economical solution for surface preparation. |

Nitriding |  | Metals | 1. Enhanced Hardness: Increases surface hardness for improved wear resistance.

2. Low Distortion: Performed at lower temperatures to maintain part integrity.

3. Extended Lifespan: Reduces friction and prolongs component durability.

4. Uniform Treatment: Provides consistent surface improvement across components. |

Galvanizing |  | Metals | 1. Superior Corrosion Protection: Coats parts with zinc to prevent rust.

2. Longevity: Extends the lifespan of metal components in harsh environments.

3. Minimal Maintenance: Requires little upkeep once applied.

4. Broad Applicability: Ideal for outdoor and industrial applications. |

Lacquer Coating |  | Metals

Plastics | 1. Glossy Finish: Provides a smooth, high-gloss appearance.

2. Protective Barrier: Shields surfaces from moisture, chemicals, and abrasion.

3. Versatile: Suitable for various substrates including metals and plastics.

4. Quick Drying: Enables faster production turnaround. |

Teflon Coating |  | Plastics

Metals | 1. Non-Stick Surface: Offers excellent release properties for improved performance.

2. Chemical Resistance: Protects against corrosive substances.

3. Low Friction: Reduces wear and tear on moving parts.

4. Durable Coating: Maintains its properties under high stress and temperature. |

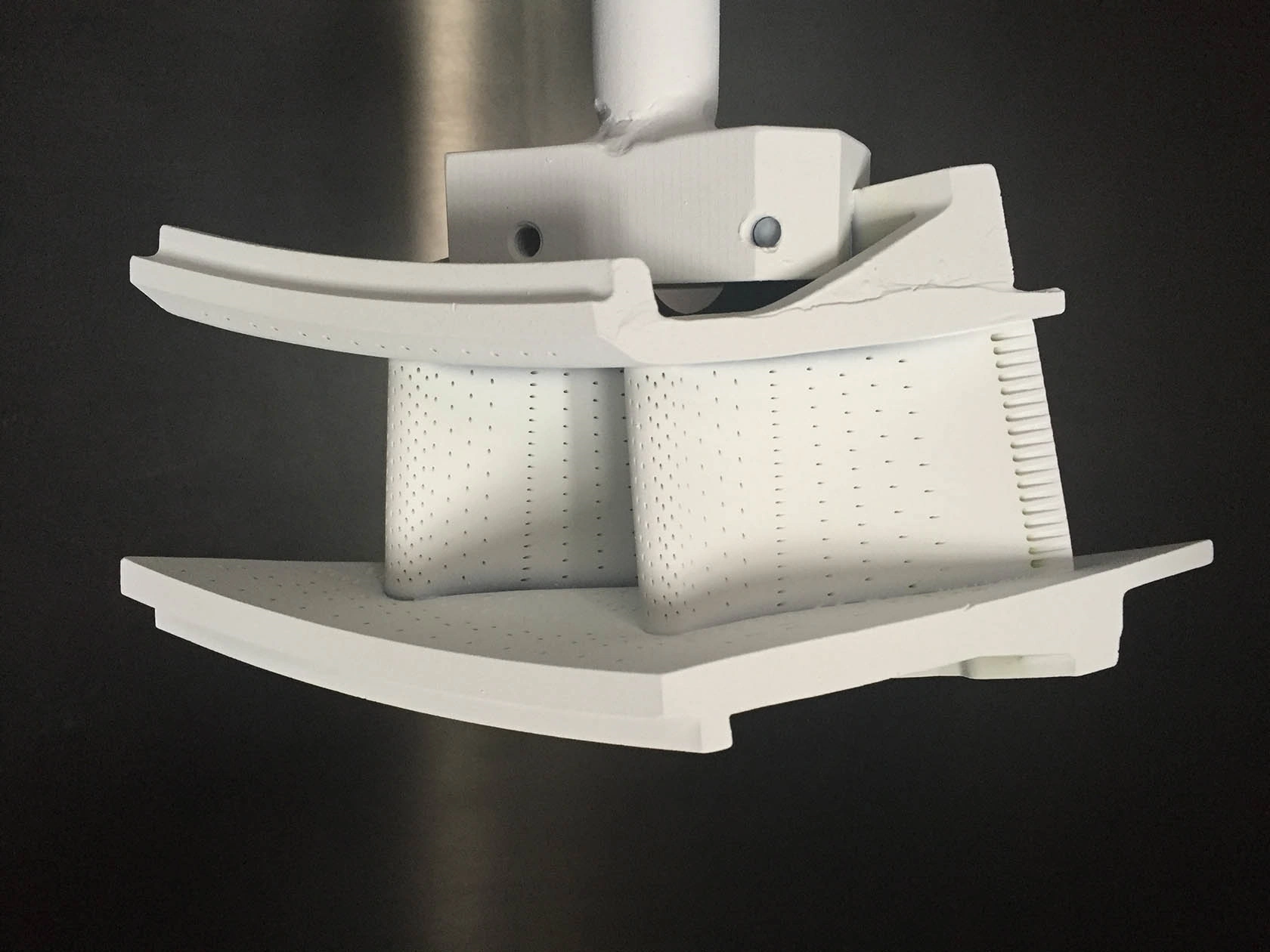

Thermal Coatings |  | Metals | 1. High-Temperature Resistance: Protects parts in extreme heat environments.

2. Thermal Insulation: Reduces heat transfer for improved energy efficiency.

3. Prolonged Component Life: Minimizes thermal degradation over time.

4. Versatile Application: Ideal for superalloy and high-performance components. |

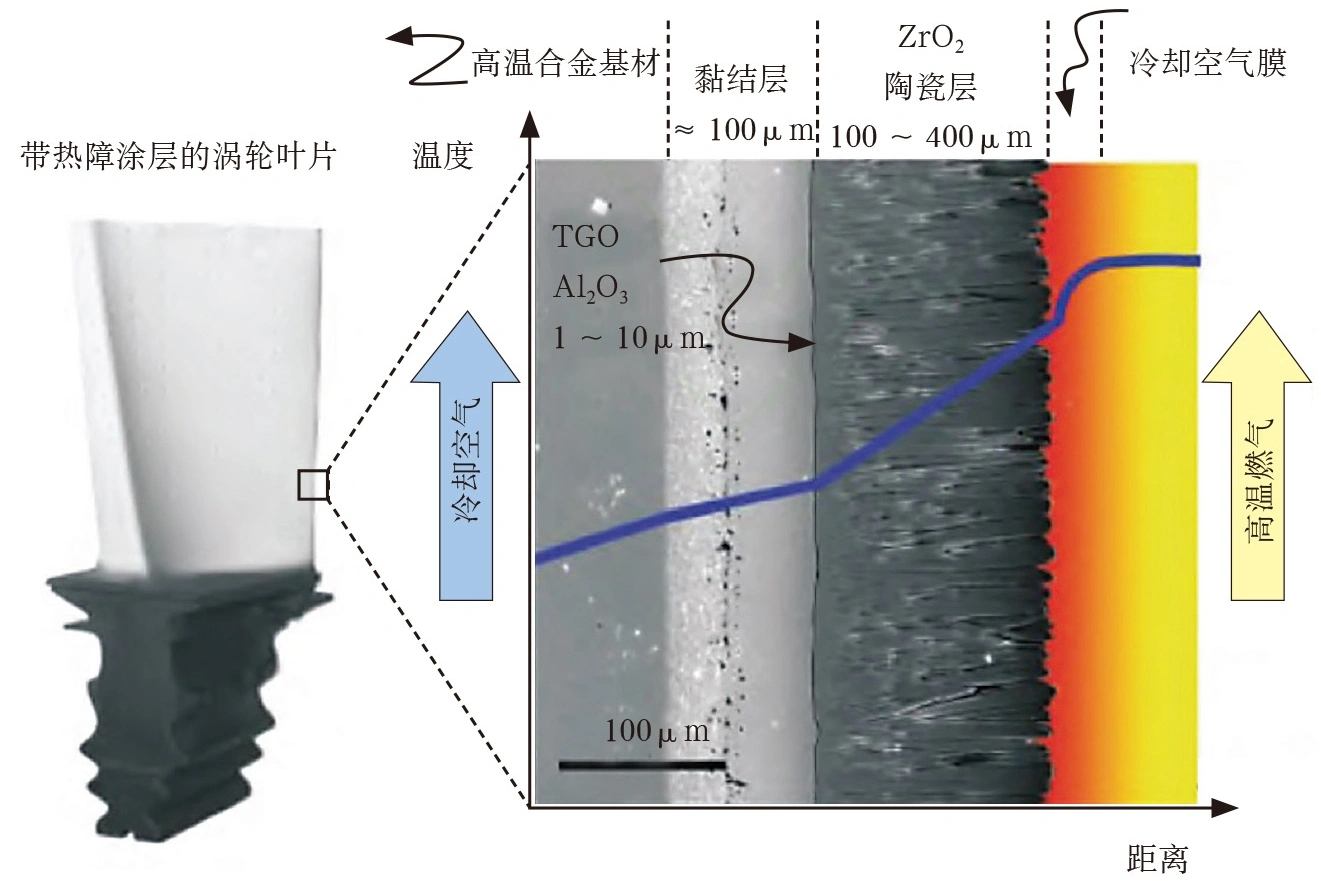

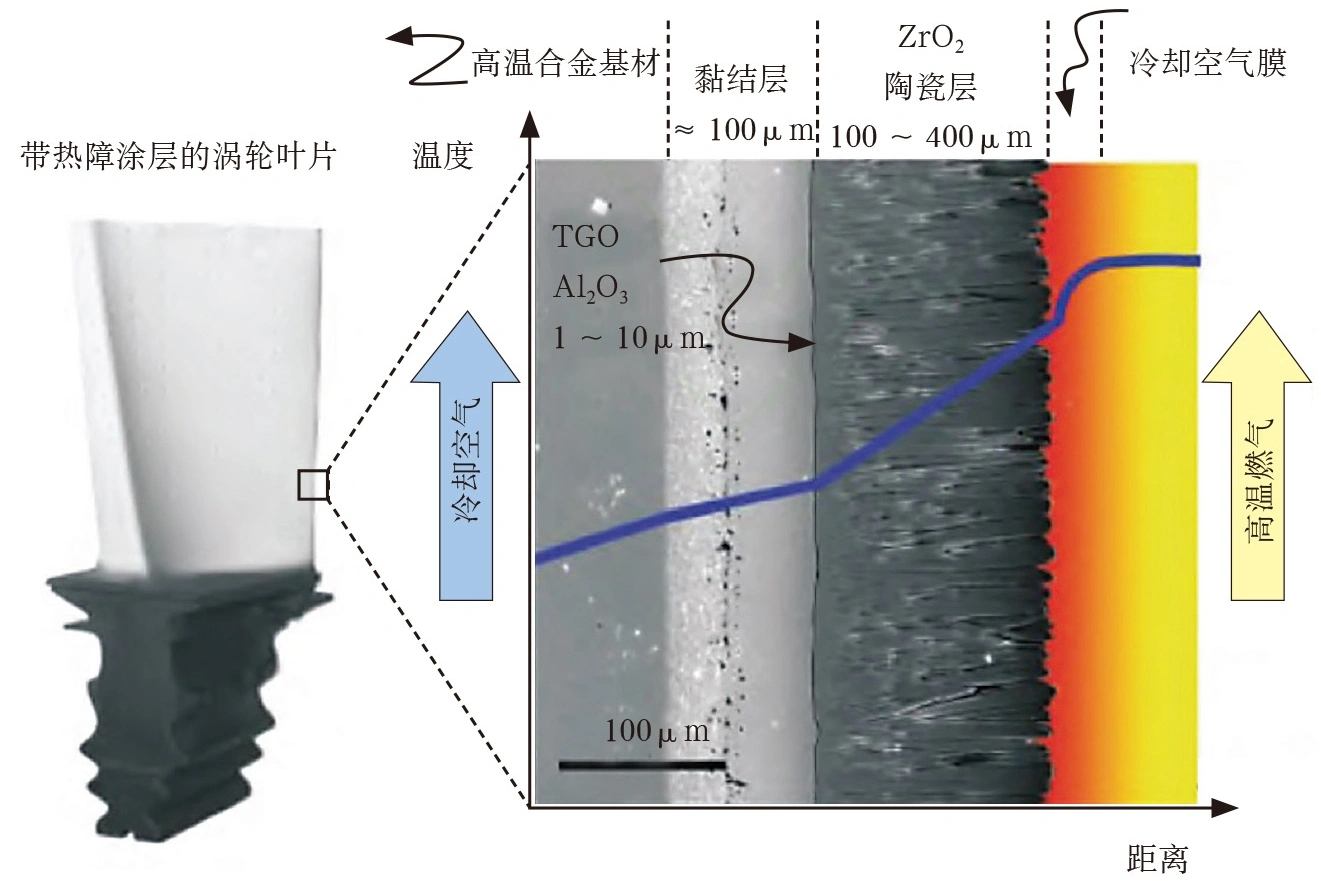

Thermal Barrier Coatings |  | Metals | 1. Heat Protection: Shields components from extreme thermal stresses.

2. Enhanced Durability: Reduces wear in high-temperature applications.

3. Energy Efficiency: Improves thermal insulation and performance.

4. Advanced Materials: Utilizes cutting-edge technology for superior protection. |

Passivation |  | Metals | 1. Corrosion Resistance: Enhances metal surfaces by forming a protective oxide layer.

2. Surface Stability: Improves long-term durability and uniformity.

3. Clean Appearance: Results in a smooth finish free of contaminants.

4. Low Maintenance: Reduces the need for frequent re-coating. |