Custom On-Demand Manufacturing for

Energy Industry

We provide precision on-demand manufacturing solutions tailored to the unique demands of the energy sector, including oil & gas, renewables, and nuclear applications. From CNC-machined turbine housings to custom-cast high-temperature components, our rapid production capabilities ensure tight tolerances, material traceability, and industry-standard compliance. Whether for prototyping or low-volume production, we support critical energy systems with fast turnaround and certified quality.

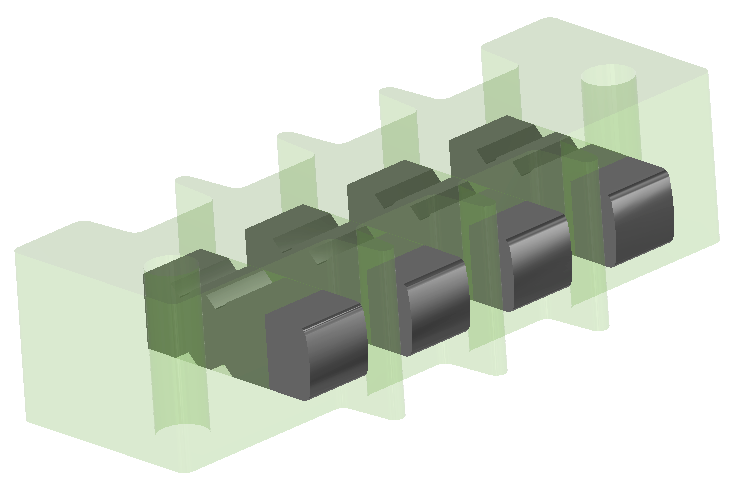

Application of Boron Carbide B4C in Nuclear

Nuclear-grade boron carbide is used in neutron absorber balls, bricks, detectors, aluminum-based composites, and boron-containing concrete or carbon bricks. Its high neutron absorption and thermal stability make it ideal for reactor control, shielding, and radiation detection. It ensures safety and performance in high-temperature, high-radiation nuclear environments, supporting both power generation and research applications.

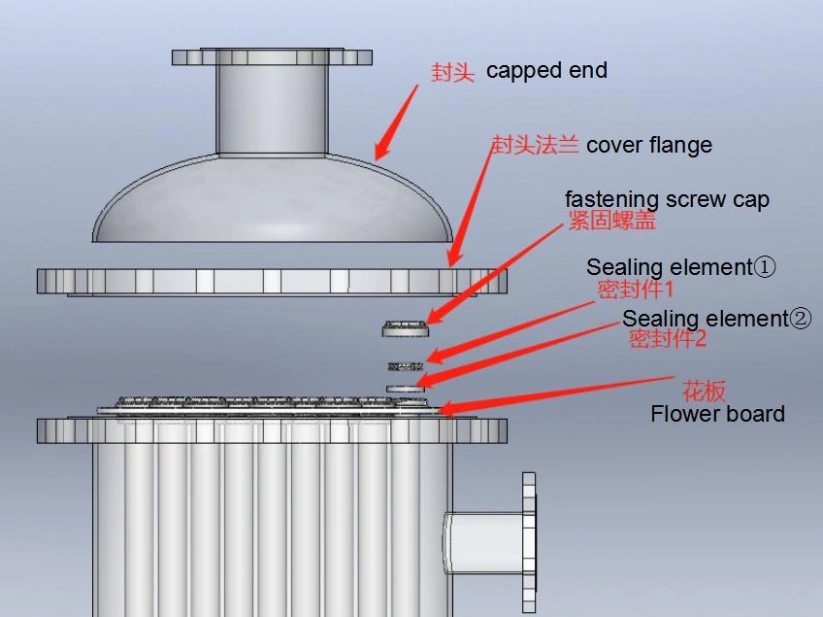

Pure SIC Ceramic Filter Membrane

SIC ceramic membrane - pure SIC membrane: The water treatment membrane produced using silicon carbide material features ultra-high hardness, high temperature resistance, resistance to acid and alkali corrosion, high flux, and high hydrophilicity. Its flux can reach up to 100 times that of traditional organic membrane materials and 3-5 times that of conventional ceramic membranes.

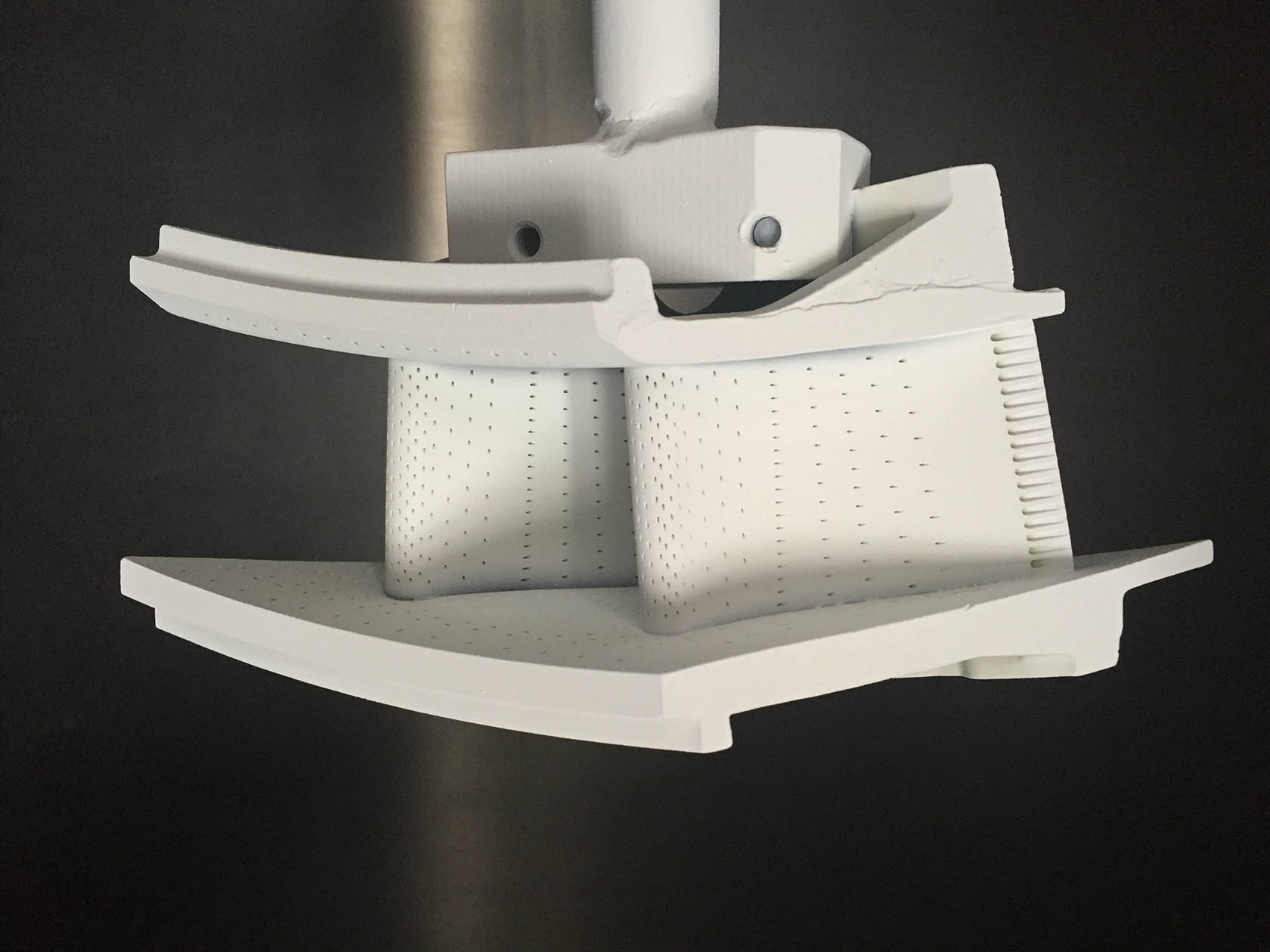

Advanced Turbine and Generator Component Manufacturing

Turbines and generators require precision-engineered components for maximum efficiency, reliability, and operational longevity. Utilizing advanced manufacturing techniques such as precision casting, CNC machining, powder metallurgy, and EDM, we produce turbine blades, stators, rotor shafts, and intricate cooling channels. Our precision components meet rigorous industry standards, enhance thermal efficiency, reduce downtime, and support reliable performance in power plants, hydroelectric systems, and wind energy facilities.

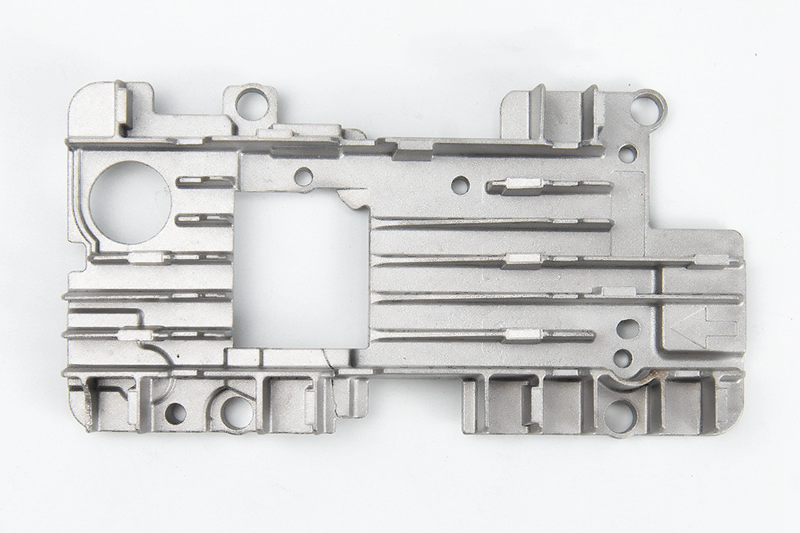

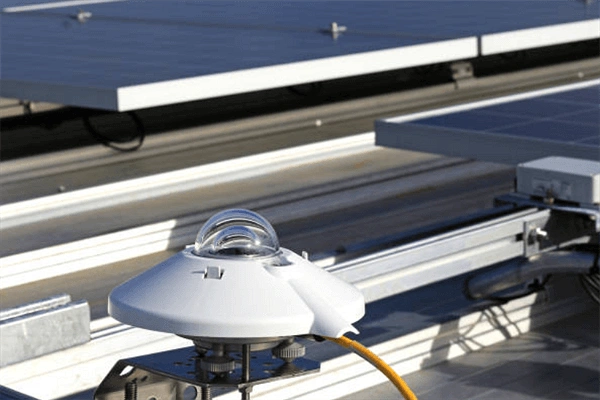

Robust Renewable Energy Structural Component Solutions

Renewable energy systems require robust and corrosion-resistant structural components designed to withstand harsh environmental conditions. Employing aluminum die casting, metal stamping, laser cutting, and sheet metal fabrication, we manufacture durable turbine nacelles, solar mounting structures, and hydropower supports. These components deliver exceptional structural integrity, corrosion resistance, ease of installation, and maintenance-free performance for wind, solar, and hydropower infrastructure.

Case Study

Let's Start A New Project Today

Explore Related Resources

Solutions

Copyright © 2026 Neway Precision Works Ltd.All Rights Reserved.