Robust SiC Ceramic Filters for Efficient Syngas Cleanup in Gasification Plants

Introduction

Introduction

Syngas, produced through biomass and waste gasification, offers a cleaner alternative to fossil fuels. However, its purification is complex due to the presence of fly ash, tar aerosols, and reactive gases. Pure silicon carbide (SiC) ceramic membranes from Neway enable efficient, high-temperature cleanup of syngas, protecting downstream equipment while ensuring energy conversion efficiency. Learn more about SiC filtration technologies and ceramic injection molding solutions we provide.

Syngas Cleanup Requirements in Gasification Processes

Gasification converts solid feedstocks into syngas (H₂, CO, CH₄) by partial oxidation, producing byproducts like soot, particulates, and condensable hydrocarbons. Efficient filtration is essential to:

Prevent catalyst fouling in FT synthesis or methanation

Avoid clogging in gas turbines or internal combustion engines

Reduce corrosion in heat exchangers and scrubbers

Traditional filters struggle with temperature limits and fouling. Pure SiC ceramic filters solve these issues by enabling hot gas filtration directly at the gasifier outlet, reducing system complexity and energy loss.

Why SiC Ceramic Filters Are Ideal for Syngas

Neway’s sintered SiC membranes offer the following advantages for gasification plants:

Extreme Thermal Stability: Reliable performance up to 800°C under continuous gas flow.

High Filtration Efficiency: Micron and submicron particulates captured with 40nm–2μm pore sizes.

Anti-Fouling Hydrophilic Surface: Contact angle ~0.3° promotes low-tar adhesion and easy regeneration.

Corrosion Resistance: Stable in acid gases and high-pH syngas environments.

Performance Metric | Typical Value |

|---|---|

Material Purity | SiC >99.5%, no sintering additives |

Operating Temperature | 1°C–800°C (gas) |

Pore Size Range | 40nm, 100nm, 2μm |

Porosity | >45% |

Chemical Resistance | pH 0–14, ozone, hydroxyl radical |

Structural Design | Integrated membrane/support body |

Cleanability | Compatible with backflush, steam, CIP |

Case Study: Syngas Filtration in a Biomass Power Plant

A 10 MW biomass gasification unit required continuous syngas cleaning before catalytic conversion. Neway’s multi-core SiC membrane modules were installed in a crossflow setup, delivering:

98.6% particulate removal efficiency

Stable pressure drop under 0.25 bar after 6 months

Continuous operation at 600°C with minimal maintenance

Catalyst life extension by over 40% due to reduced fouling

These results enabled the plant to meet syngas purity requirements without adding downstream wet scrubbing units.

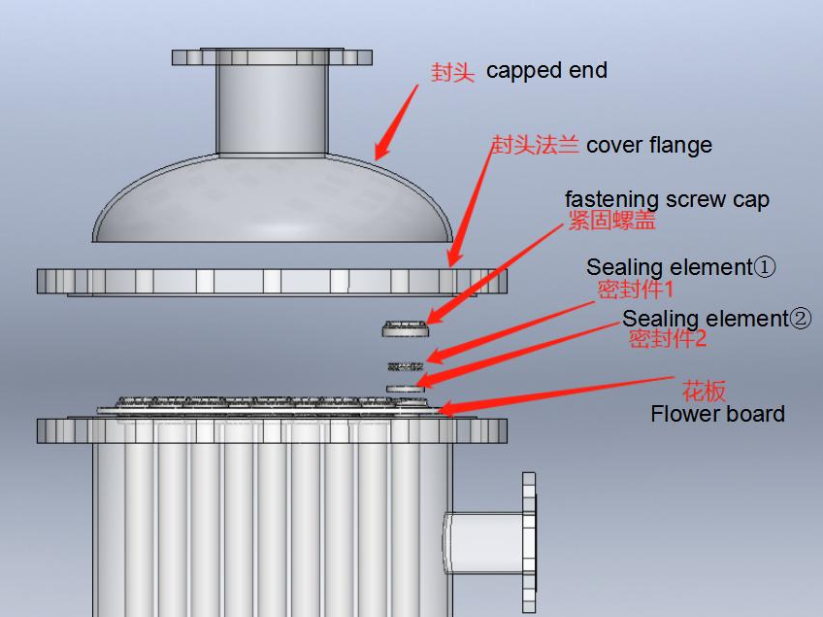

System Integration and Module Configuration

Our SiC ceramic filters are assembled into modular housings—available in 19/37/121 channel designs—with pressure shells made from stainless steel or corrosion-resistant composites. Standard module length is 1200mm with custom configurations available for high-flow systems.

Crossflow filtration minimizes fouling by shearing suspended solids from the membrane surface. The system supports automated cleaning via gas or liquid backflush, maintaining high recovery efficiency (>95%) even under high solids load (>50 NTU equivalent).

Advantages Over Conventional Filtration Systems

Withstands ash, tar, and corrosive gases at high temperatures

Eliminates need for cooling and wet scrubbers

Reduces operational downtime and maintenance costs

Delivers higher energy efficiency in syngas conversion

Conclusion

For syngas cleanup in gasification plants, pure SiC ceramic filters represent a robust and cost-effective upgrade to conventional separation technologies. With proven thermal endurance, anti-fouling design, and long service life, they safeguard downstream processes and boost plant efficiency.

To explore how Neway can customize SiC membrane modules for your syngas application, visit our SiC ceramic membrane service page.