Premium Pure SiC Ceramic Membranes for High-Purity Hydrogen Production Systems

Introduction

Introduction

Hydrogen production technologies—such as steam methane reforming, biomass gasification, and water electrolysis—require highly reliable gas separation and purification components. Pure silicon carbide (SiC) ceramic membranes provide thermal stability, chemical resistance, and low fouling, making them ideal for high-purity hydrogen generation. Learn more about our SiC ceramic membrane solutions and ceramic injection molding technologies.

Hydrogen Purification Challenges in High-Temperature Systems

Producing hydrogen at industrial scale often involves gas mixtures with CO, CO₂, CH₄, steam, and various impurities. These conditions—especially at high temperatures (400–700°C)—demand purification systems that can:

Withstand thermal cycling and pressure fluctuations

Remove fine particulates and catalyst poisons

Maintain stable gas flow and purity over long durations

Avoid downtime due to fouling or filter degradation

Conventional polymeric or metal filters fall short in such aggressive environments. Pure SiC membranes offer a superior alternative for both pre- and post-reformer gas polishing.

Key Advantages of Pure SiC Membranes

Neway’s pure SiC ceramic membranes are sintered at 2300°C and constructed with no added sintering aids. Their high structural and chemical integrity makes them uniquely suited for hydrogen production systems:

Thermal Stability: Operating reliably up to 800°C with no structural fatigue

Corrosion Resistance: Inert across pH 0–14 and compatible with reformate gas streams

Hydrophilic Surface: Facilitates water vapor separation and minimizes fouling

Porous Structure: Selectable pore sizes (40nm, 100nm, 2μm) for multi-stage filtration

Property | Typical Value |

|---|---|

Material Purity | SiC >99.5% (no additives) |

Max Operating Temp | 800°C (gas) |

Pore Sizes Available | 40nm / 100nm / 2μm |

Porosity | >45% |

pH Compatibility | 0–14 |

Surface Type | Hydrophilic, oleophobic |

Structure | Monolithic support-integrated membrane |

Integration into Hydrogen Production Systems

Pure SiC membranes can be integrated at several points of a hydrogen production line:

Upstream of PSA or membrane separation

Post-reformer gas polishing stage

Electrolyzer anode/cathode gas filtration

Biomass-derived syngas purification loop

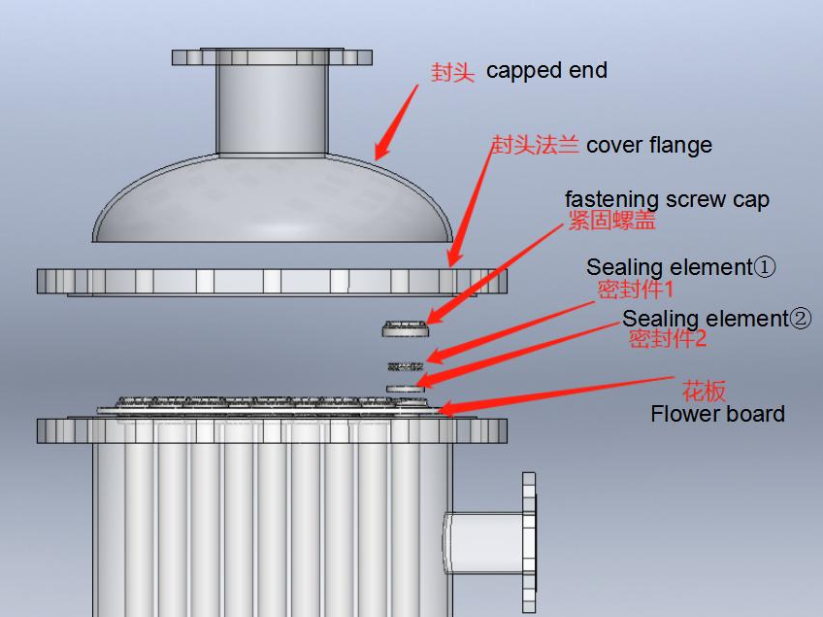

Modules are installed using corrosion-resistant housings, available in 19/37/121-channel designs and 1200mm lengths. They support both continuous flow and backflush-cleanable operations, ensuring extended filter life and minimal downtime.

Case Study: Hydrogen Plant Using Steam Methane Reforming (SMR)

A hydrogen production facility based on SMR technology integrated Neway’s 37-channel SiC membrane modules post-reformer. Outcomes included:

97.8% particulate and aerosol reduction before PSA

Reduced catalyst bed fouling and longer PSA regeneration intervals

Operation stability at 600°C with backflush maintenance every 3 months

Zero membrane failure after 18 months of service

These improvements translated into higher gas purity (>99.99%) and reduced total maintenance cost.

System-Level Benefits

Pure SiC ceramic membranes offer the following systemic advantages in hydrogen production:

Energy Efficiency: Minimal pressure drop, even at high gas flow rates

Operational Longevity: Durable structure withstands steam, acids, and oxidants

Cleanability: CIP-compatible using hot water, chemicals, or steam

Scalability: Modular configuration fits pilot to large-scale H₂ plants

Conclusion

For next-generation hydrogen production systems requiring uncompromising performance in extreme conditions, pure SiC ceramic membranes are the proven solution. Their exceptional durability, filtration precision, and chemical compatibility protect system components while maximizing gas purity and efficiency.

Explore Neway’s SiC membrane solutions or consult our engineers for integration support into your hydrogen production line.