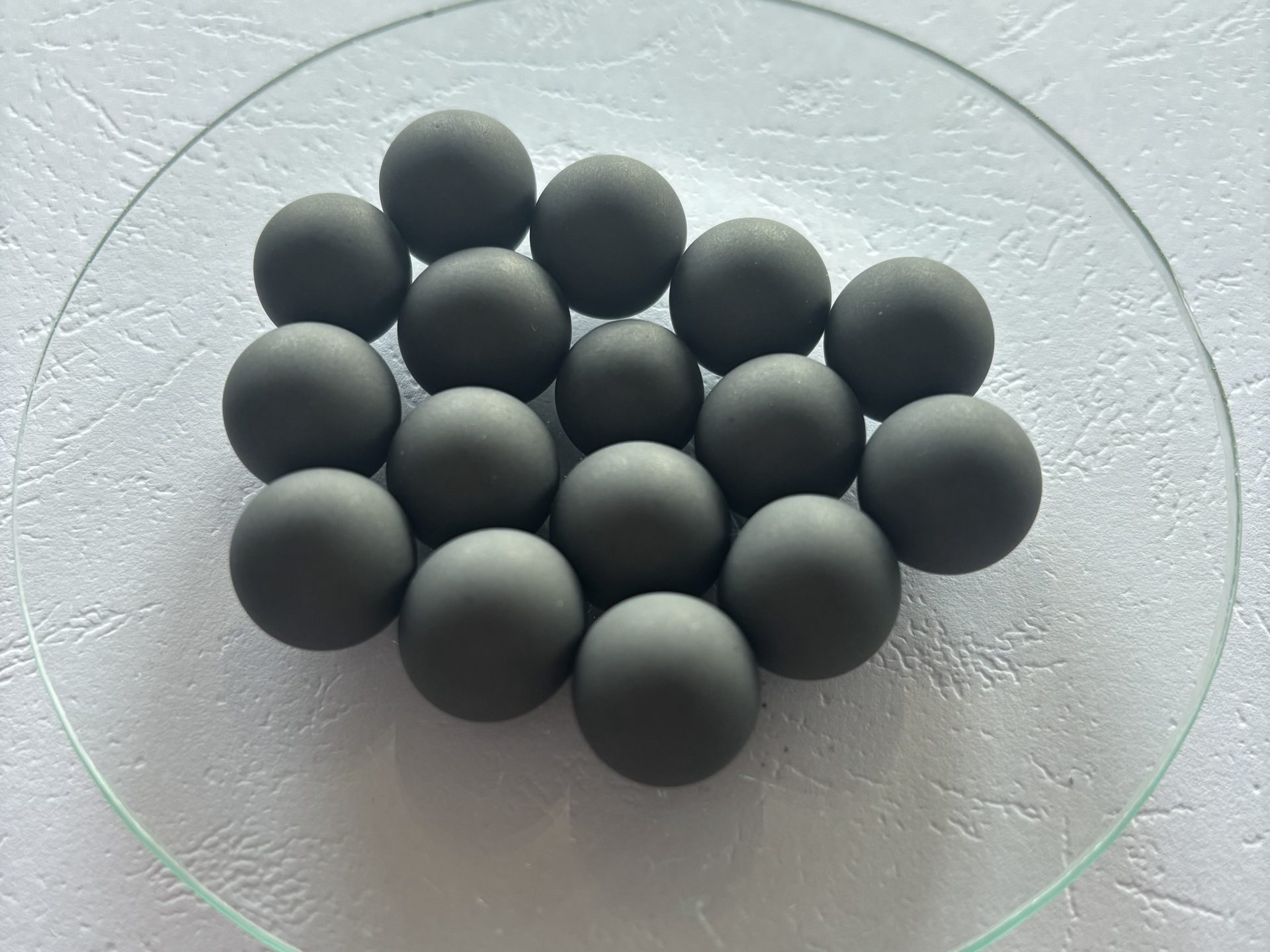

Nuclear B4C Neutron Shielding Blocks for Reactor Safety and Radiation Control

Introduction to B4C Shielding in Nuclear Systems

Boron carbide (B4C) is a neutron-absorbing ceramic material used extensively in nuclear applications. With a high neutron capture cross-section due to its enriched boron-10 content, B4C plays a vital role in radiation control and structural shielding. In nuclear power plants and research reactors, B4C shielding blocks ensure safety, reduce exposure, and enable precise neutron flux management.

Engineering Advantages of B4C Shielding Blocks

B4C’s neutron absorption coefficient is approximately 600 barns for thermal neutrons when enriched in ¹⁰B. Compared to traditional shielding materials, B4C offers:

High effectiveness per unit thickness

Low density (~2.52 g/cm³) enabling lightweight designs

Chemical and thermal stability under reactor conditions

Compatibility with stainless steel and composite shielding systems

These properties make it ideal for shielding assemblies in spent fuel storage, reactor walls, and transport casks.

Material Specifications and Composition

Our plant provides nuclear-grade B4C shielding blocks that comply with ASTM C751 and ASTM C750 standards. We offer customized formulations with:

Boron-10 enrichment from 85% to 95%

Total B4C content above 98%

Trace impurity control for reduced activation

Depending on customer specifications, we can also integrate aluminum, stainless steel, or polymeric binders into shielding assemblies.

Manufacturing Process and Form Factor Options

Our facility supports both powder compression molding and ceramic injection molding for forming B4C blocks. Post-molding, blocks are sintered under controlled conditions to achieve >98% theoretical density.

We deliver various geometries including:

Solid shielding plates and tiles

Modular interlocking block assemblies

Control rod absorbers

Insert modules for spent fuel casks

Each product is tailored to reactor specifications, ensuring dimensional accuracy, thermal resilience, and isotopic consistency.

Integration into Reactor Shielding Systems

B4C shielding is used in critical systems such as:

Core peripheral shielding in pressurized water reactors (PWRs)

Channel walls in research reactors

Radial shielding layers in dry cask storage systems

Hot cells and fuel reprocessing lines

In many applications, B4C is integrated with structural cast stainless steel or supported within sheet metal fabricated frames for ease of installation.

Surface Treatment and Assembly

For enhanced performance, B4C blocks can undergo surface finishing processes such as passivation, coating, or thermal barrier treatment. These reduce outgassing, improve chemical compatibility, and extend operational lifetime in high-radiation environments.

Certification and Documentation

All B4C shielding blocks are supplied with full material traceability and compliance documentation, including:

Isotopic composition reports (¹⁰B content)

Density and porosity measurement

Neutron attenuation simulation validation

Conformance to ASTM and ANSI/ANS 6.4.2 standards

Engineering Support for Shielding System Design

We provide engineering support from initial material selection through final assembly. Our ceramic team collaborates with reactor safety engineers to customize B4C shielding solutions, ensuring they meet critical specifications for neutron attenuation, thermal stress, and structural integration.

FAQs

What are the typical neutron attenuation rates of B4C blocks?

How is dimensional stability maintained under reactor thermal cycles?

Can B4C shielding blocks be integrated with stainless steel or aluminum frames?

What are the maximum dimensions available for hot-pressed B4C blocks?

Are enriched ¹⁰B B4C materials export-controlled or license-dependent?