Robust Renewable Energy Structural Component Solutions

Robust Structural Component Solutions for Renewable Energy: The Backbone of Green Power

In today’s rapidly growing renewable energy sector, the long-term reliability and environmental resilience of structural components directly determine the lifecycle performance of each project. As the engineering team at Neway, we understand that wind turbines, solar mounting systems, hydropower equipment, and other renewable energy installations must withstand harsh natural conditions. From strong winds and heavy rain to salt spray, extreme temperatures, and continuous vibration, every structural component must deliver outstanding durability and reliability.

Manufacturing Processes for Renewable Energy Structures in Harsh Environments

Welding and Machining of Large Structural Components

In the manufacturing of large-scale renewable energy equipment, we provide comprehensive custom part manufacturing services specifically for key structural components such as wind turbine nacelle bases and tower flanges. Utilizing advanced, heavy-duty welding equipment and strict process control, we ensure that every weld joint meets the highest quality standards. For critical mating surfaces requiring extreme accuracy, we utilize large-format CNC machining services to control flange flatness within 0.1 mm/m, providing a stable and reliable foundation for the entire turbine system.

High-Performance Casting and Forging

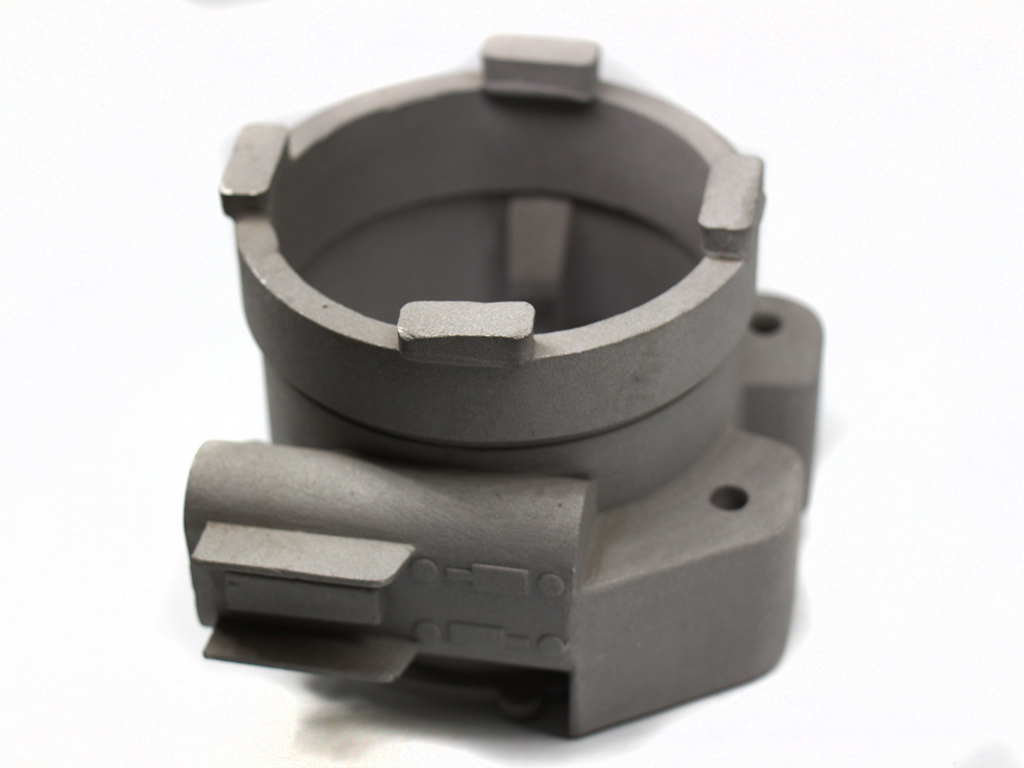

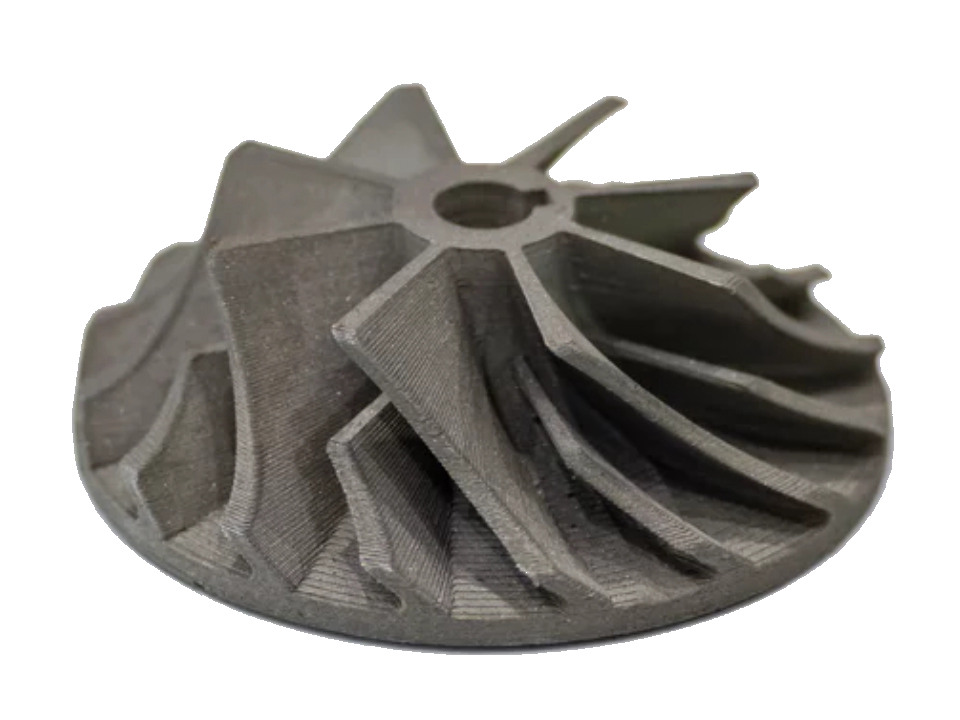

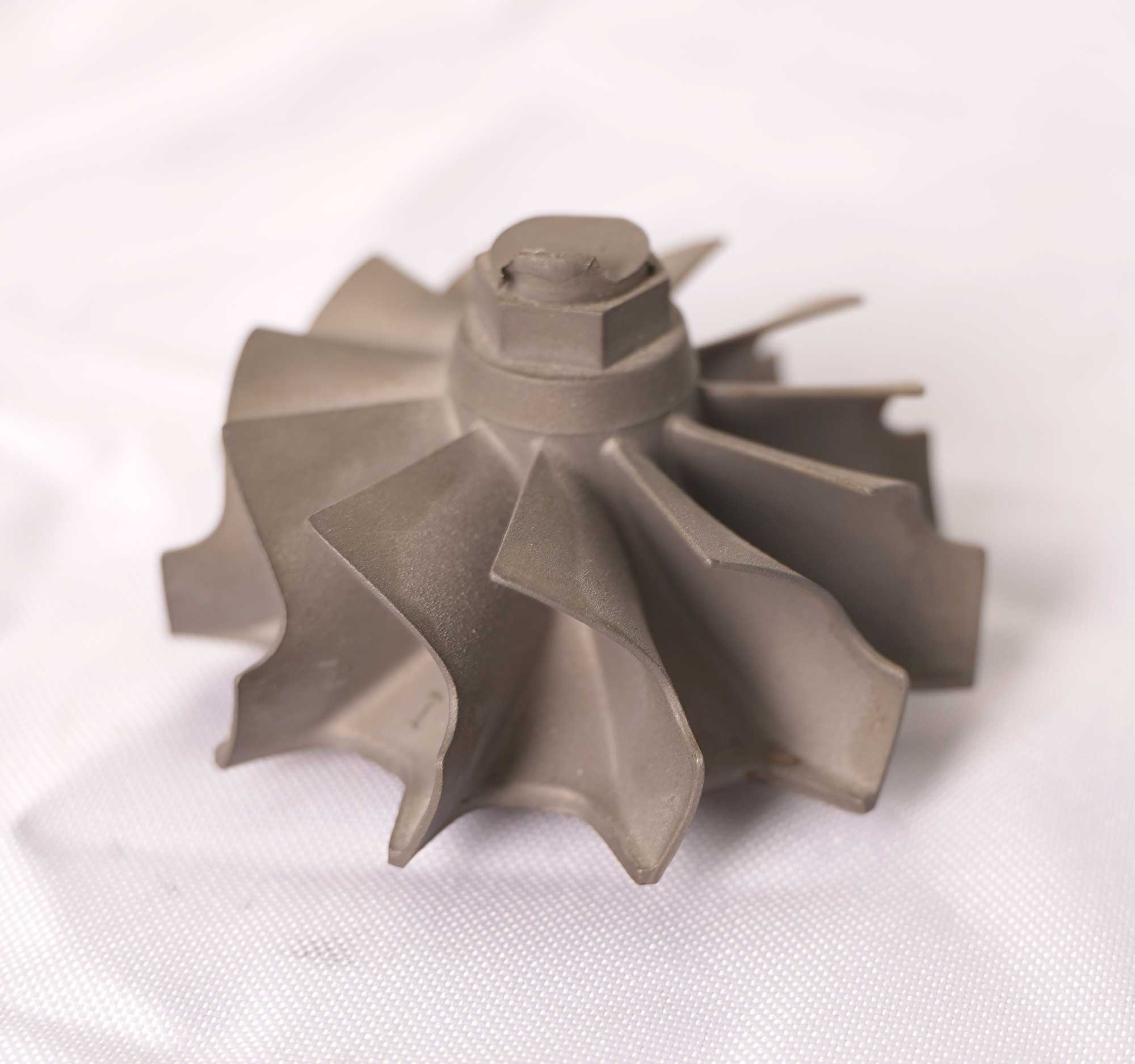

For components subjected to complex loads, we use precision casting services to produce critical parts such as wind turbine hubs and bearing housings. This process enables optimized internal geometries and material distribution, achieving high strength while significantly reducing weight. For even higher performance requirements, we utilize investment casting technology to achieve superior surface quality and dimensional accuracy, ensuring reliable performance over the long term.

Special Sheet Metal Forming and Joining Technologies

In solar mounting systems and tower manufacturing, we fully leverage the advantages of sheet metal fabrication. With advanced laser cutting and automated welding technologies, we produce structural components with high dimensional accuracy and consistent quality. Especially for solar tracking system structures, our precision stamping processes and robust mass production control ensure that tens of thousands of brackets maintain excellent uniformity, providing reliable support for utility-scale solar plants.

Surface Treatment and Protection Technologies for Long-Term Service

In the renewable energy field, surface protection has a decisive impact on component lifetime. We apply galvanizing to steel structures, providing long-lasting corrosion protection ideally suited for outdoor applications, with reliable performance over decades. For applications requiring enhanced aesthetics or specific color schemes, we offer powder coating solutions. These coatings provide excellent weather resistance and UV stability, maintaining their color and appearance over extended periods of exposure.

Key Material Choices for Renewable Energy Structural Components

High-Strength Structural Steels and Special Alloys

For material selection, we recommend tailored solutions based on specific application environments. For primary load-bearing structures, we use stainless steel, offering an excellent combination of strength and toughness to withstand dynamic loads during wind turbine operation. For applications requiring higher strength and cost efficiency, we choose carbon steel and, through proper heat treatment and surface protection, ensure reliable performance even in harsh environments.

Lightweight, High-Strength Non-Ferrous Metals

Where weight reduction is critical, we recommend cast aluminum materials. The lightweight properties of aluminum alloys make them ideal for solar tracking systems and upper structures on offshore platforms. For more complex components, we utilize aluminum die casting technology to produce thin-walled, intricate geometries that maximize weight reduction while maintaining the required structural strength.

Typical Applications of Neway Solutions in Renewable Energy

Wind Power Systems

In the energy sector, we provide comprehensive structural solutions for the wind power industry. From nacelle frames and drivetrain supports to internal tower structures and blade root connection interfaces, every component is designed and manufactured with precision and care. We place particular emphasis on fatigue performance, utilizing finite element analysis and physical testing to ensure that each part can withstand continuous operation for 20 years or more.

Photovoltaic and Solar Thermal Systems

In the solar sector, we supply structural solutions for a wide range of PV systems. From fixed mounting structures for large-scale ground-mounted plants to advanced solar tracking systems, from rooftop mounts for distributed PV to support structures for solar thermal concentrators, we offer optimized solutions for each scenario. Through precise manufacturing processes and rigorous quality control, we ensure that every mounting system maintains stable performance throughout its service life.

Hydropower Facilities

In hydropower applications, we manufacture key structural components for various turbines. From flow passage components and guide devices to valves and gate structures, we have extensive manufacturing experience. For high-head projects in particular, we adopt specialized designs and production processes to ensure that components can withstand extreme water pressure and impact loads.

Choose Neway to Build a Reliable Green Energy Future

At Neway, we always prioritize quality and reliability. Our engineering team has extensive experience in renewable energy projects, providing end-to-end support from design consultation to final delivery. With strict quality management systems and advanced production equipment, we ensure every structural component meets the most demanding technical requirements. From material selection and process definition to production control and final inspection, we apply rigorous standards to guarantee product reliability and consistency.

Conclusion: Robust Structures Supporting a Sustainable Energy Future

Renewable energy is a vital direction for future energy development, and reliable structural components are the foundation for long-term stable operation of renewable installations. With deep expertise in material science, manufacturing processes, and quality control, Neway is committed to delivering highly reliable structural solutions for global renewable energy projects. We believe that through our professional services and high-quality products, we can make a significant contribution to building a sustainable energy future.

FAQ

What corrosion protection and materials are best for offshore wind components?

How to reduce weight and cost of large cast/forged parts while ensuring safety?

How is long-term dimensional stability and corrosion resistance ensured in solar brackets?

How does Neway guarantee dimensional accuracy and weld quality for large structures?

Can Neway deliver full solutions for renewable energy structural parts from design to delivery?