Eco-Efficient Alchemy: Material Versatility and Efficiency in Investment Casting

Introduction

Investment casting, commonly referred to as lost-wax casting or high-precision metal forming, has long been recognized for its ability to produce intricate and precise metal components. Investiture casting is emerging as a preferred eco-friendly manufacturing technique in an era emphasizing sustainability. This process enables manufacturers to produce complex and high-quality components while significantly reducing environmental impact through optimized material use and minimized waste. Here, we examine how the material versatility and production efficiency of investment casting foster sustainable manufacturing practices across various industries.

Understanding Investment Casting

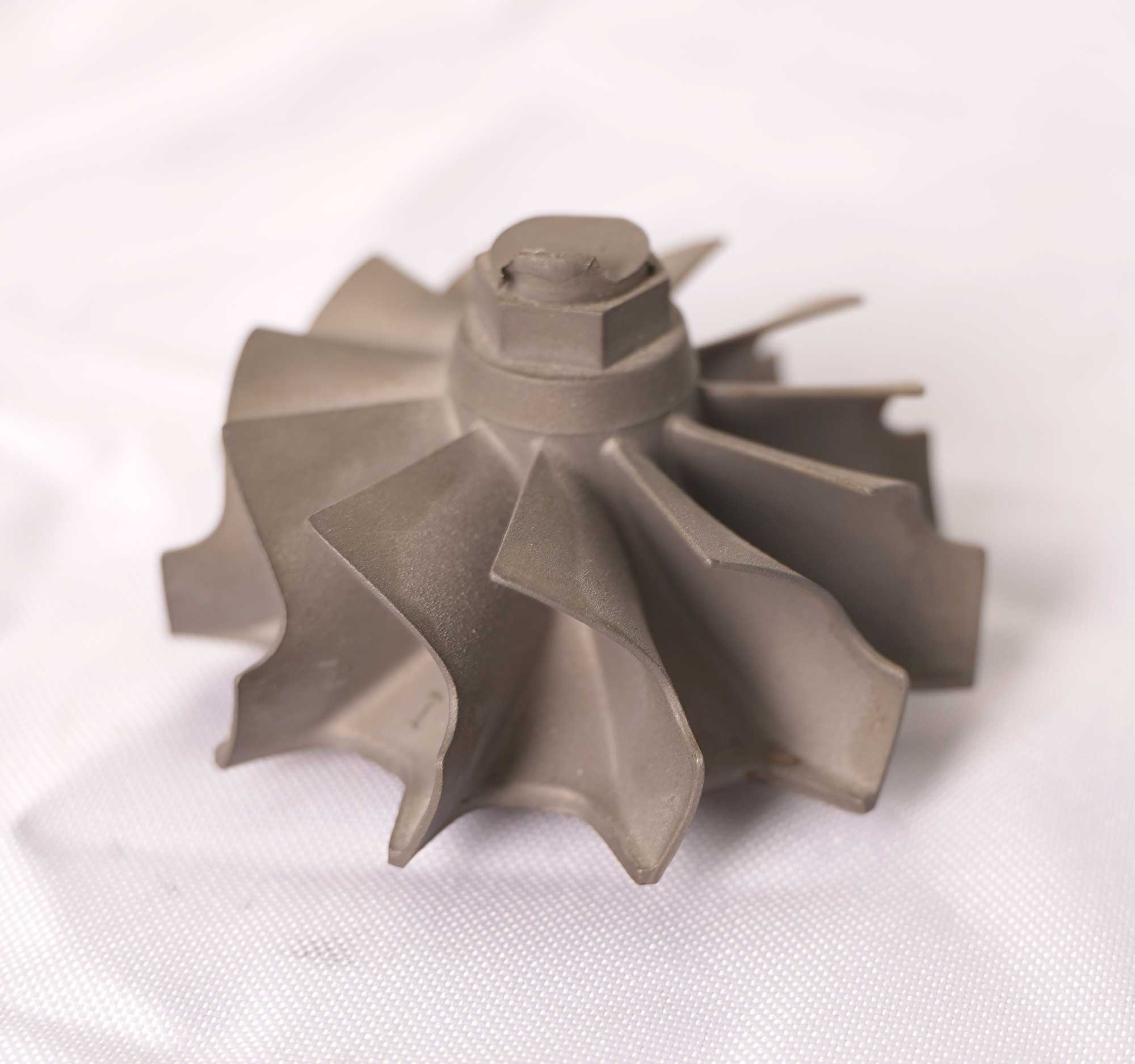

Investment casting involves creating intricate metal components by sculpting a wax model coated in a ceramic shell. After hardening, the wax is removed by heat, leaving a precise mold into which molten metal is poured. When cooled, the ceramic shell is removed, revealing the finished component.

This casting method accommodates a broad range of materials, including robust stainless steel alloys, durable aluminum alloys, titanium alloys, bronze, brass, and diverse carbon steel materials. This material flexibility positions investment casting as a versatile choice for high-standard manufacturing requirements.

Environmental Advantages of Investment Casting

Efficient Material Use and Waste Reduction

Investment casting excels at producing near-net-shape components, significantly reducing excess material usage compared to conventional methods such as sand casting or traditional machining. This precise shaping ensures minimal waste, directly lowering environmental impact.

High Recyclability

The metals commonly used in investment casting, such as recyclable nickel-based alloys and aluminum, inherently support sustainable manufacturing. Excess metals and mold materials can be reused efficiently, thereby further reducing their ecological footprint.

Energy-Efficient Manufacturing

Investment casting typically demands less energy per component compared to other manufacturing techniques. The controlled melting processes and efficient handling of materials lead to lower energy consumption, enabling businesses to reduce emissions and achieve their sustainability goals.

Reduced Carbon Footprint

Investiture casting significantly reduces carbon emissions through meticulous material conservation, the use of recyclable alloys, and optimized production processes, aligning effectively with corporate environmental initiatives.

Economic and Operational Advantages

Reduced Costs Through Material Efficiency

The inherent precision of investment casting cuts down material wastage, thereby decreasing production expenses. Minimizing post-processing machining requirements and eliminating unnecessary waste reduces overall manufacturing costs, enhancing profitability.

Shorter Production Cycles

Investment casting's streamlined process accelerates production timelines, increasing overall output efficiency. This quick turnaround reduces labor costs and overhead, boosting operational effectiveness and market responsiveness.

Enhanced Product Quality and Performance

The detailed precision achievable through investment casting ensures consistently high-quality, reliable components. Such accuracy enhances product performance, durability, and longevity, creating significant value for manufacturers and consumers.

Market Competitiveness

Utilizing investment casting enables companies to differentiate themselves by delivering sustainably produced, high-quality components. Embracing such practices enhances market reputation, brand trust, and consumer loyalty.

Real-World Industry Applications

Renewable Energy Sector

Investment casting supports renewable energy technologies by producing essential precision components such as turbine blades and generator components. The process ensures long-term reliability and operational excellence, which are crucial for renewable energy systems.

Automotive Industry

In automotive applications, investment casting produces precision-engineered, lightweight components, including engine parts, transmission systems, and exhaust components. These high-performance parts help meet stringent fuel efficiency and emission standards.

Aerospace and Aviation

Precision and reliability are critical in aerospace manufacturing. Investment casting produces critical components, such as turbine blades and structural supports, which are essential for ensuring flight safety and operational reliability. The process aligns seamlessly with the aerospace industry’s rigorous sustainability targets and stringent manufacturing requirements.

Medical and Healthcare

Investment casting excels in the production of medical devices, where precision and biocompatibility are paramount. Components such as surgical instruments, medical implants, and diagnostic tools greatly benefit from the exacting standards that can be achieved with this process.

Addressing Common Surface Finish Challenges

Despite numerous advantages, investment casting can encounter challenges, including surface imperfections, minor defects, and shrinkage irregularities.

Best Practices for Overcoming Challenges

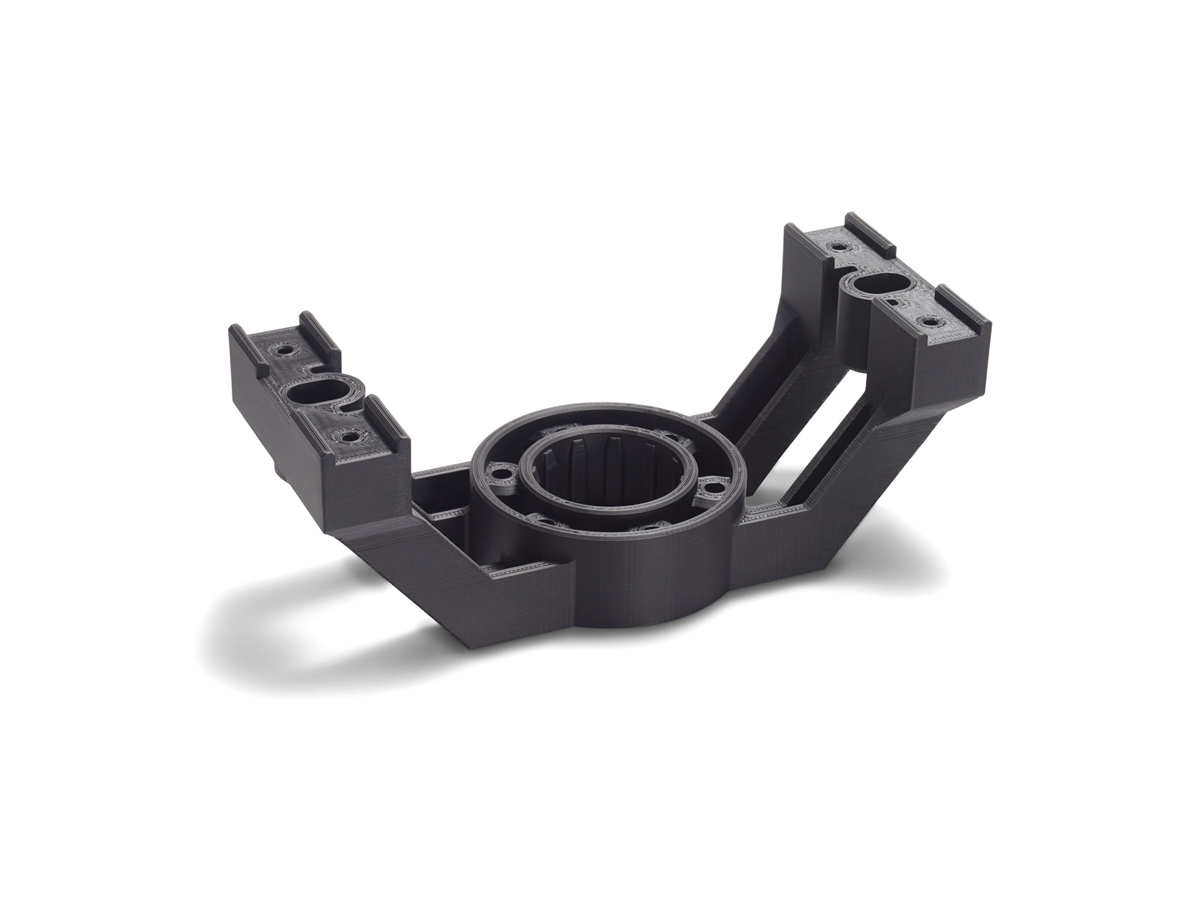

Leveraging advanced precision CNC tooling and sophisticated casting simulation software helps identify and prevent these issues early in production. Rigorous inspection routines and ongoing collaboration with specialized casting providers also ensure consistently high-quality finished products.

Future Trends in Eco-Efficient Investment Casting

Advances in Sustainable Materials

Research continues into environmentally superior alloys and recyclable materials that promise enhanced performance and sustainability in investment casting. Emerging materials, such as high-temperature alloys and specialized ceramics, are likely to further enhance eco-efficiency.

Renewable Energy Integration

Investment casting operations are increasingly incorporating renewable energy sources to minimize their environmental impact. The adoption of clean energy solutions directly lowers carbon emissions, further strengthening the sustainability of the investment casting process.

Automation and Technological Innovations

Investment casting rapidly embraces automation and digitalization technologies, improving precision, consistency, and overall process efficiency. These innovations significantly reduce waste and resource consumption, aligning investment casting with global sustainability goals.

Conclusion

Investment casting’s combination of material versatility, environmental sustainability, economic efficiency, and high precision positions it as a critical manufacturing process for today’s sustainability-focused market. Industries committed to minimizing their ecological footprint and enhancing product quality and reliability will increasingly rely on investment casting. Businesses adopting these practices realize economic benefits and strengthen their corporate responsibility and environmental stewardship commitments.