Custom Parts Online Plastic Injection Molding Service

Reliable custom plastic injection molding companies for your OEM plastic molding parts. Start your project today to get exceptional custom-injected plastic parts at a competitive price. We provide injection molding, over molding, and inserting services for thermoset and thermoplastic plastics.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

Advantages of Plastic Injection Molding Service

Plastic Injection Molding Service offers high production efficiency, intricate part creation with exceptional detail, enhanced part strength through fillers, and significant cost savings due to minimal waste and automated processes. It excels in delivering quality, durable components rapidly and economically.

Plastic Injection Molded Parts Applications

Our plastic injection molding process produces high-quality, durable components used across diverse industries. Discover the extensive applications for precision-engineered plastic parts.

Plastic Injection Molding Materials

Plastic Molding In-Mole Decoration(IMD)

Plastic molding In-Mole Decoration(IMD), usually translated as injection molding surface treatment technology, or injection molding surface decoration technology, IMD is currently an internationally popular surface decoration technology, mainly used in surface decoration and functional panels of home appliances, commonly used in mobile phone windows Lens and shell, washing machine control panel, refrigerator control panel, air conditioner control panel, automobile instrument panel, rice cooker control panel, panels, signs and other appearance parts in various fields.

In-Mold Labeling (IML)

The biggest difference between these two processes is whether there is a transparent protective film on the surface of the product. In-mold insert injection molding has very remarkable characteristics. The surface is a layer of hardened transparent film, the middle is a printing pattern layer, and the back is a plastic layer. Because the ink is sandwiched in the middle, the product can prevent the surface from being scratched. Flowers and abrasion resistance, and can keep the color bright for a long time and not easy to fade. IML is also known as IMF.

In-Mold Transfer (IMR)

In-mold transfer printing. This process is to print the pattern on the film and use the film feeding machine to attach the film to the mold cavity for injection molding. After injection, the patterned ink layer is separated from the film, and the ink layer remains. The plastic parts with decorative patterns on the surface are obtained on the plastic parts. There is no transparent protective film on the surface of the final product, and the film is only a carrier in the production process. However, the advantage of IMR lies in the high degree of automation in production and the low cost of mass production.

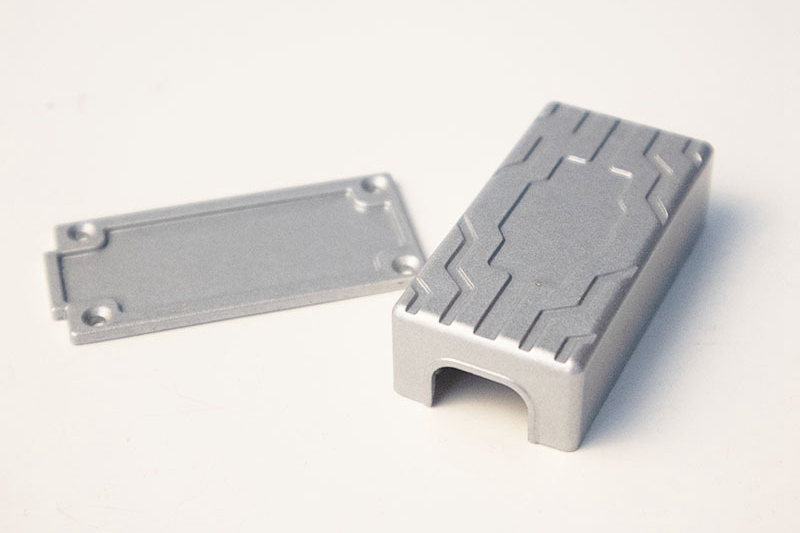

Custom Parts Surface Finishing Available

Our Surface Treatment Service offers specialized finishes for custom parts, enhancing durability, aesthetics, and performance. We provide a range of processes, including Electroplating, Anodizing, Powder Coating, and Thermal Barrier Coatings, tailored to improve corrosion resistance, wear properties, and visual appeal of metal and plastic components across industries.

Learn More

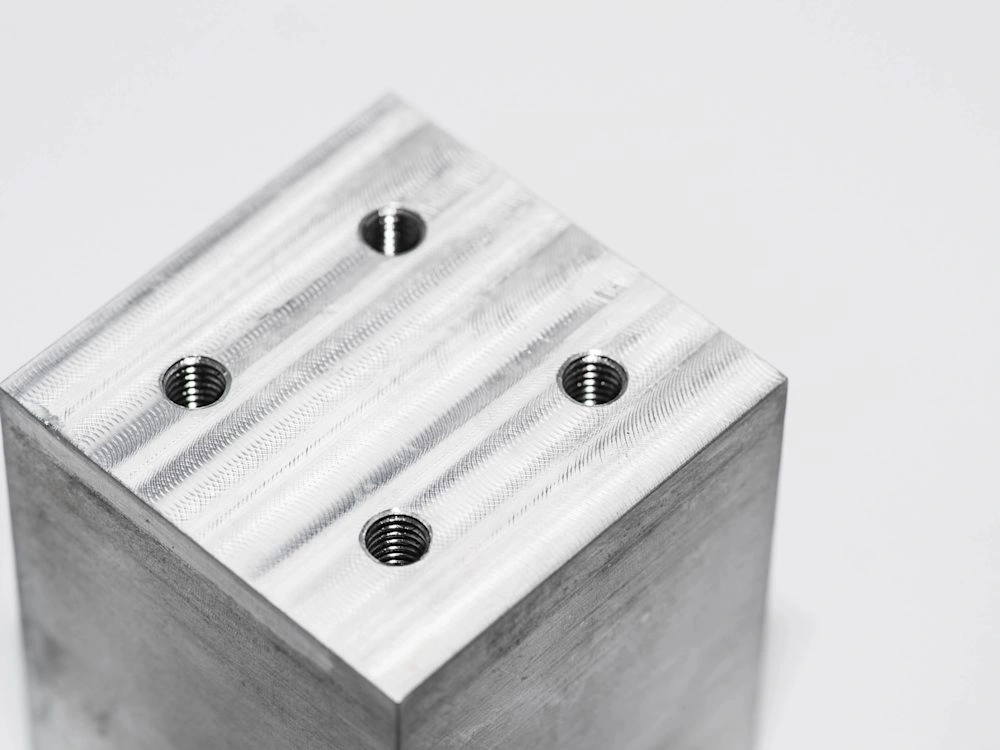

As Machined

Learn More

Painting

Learn More

PVD

Learn More

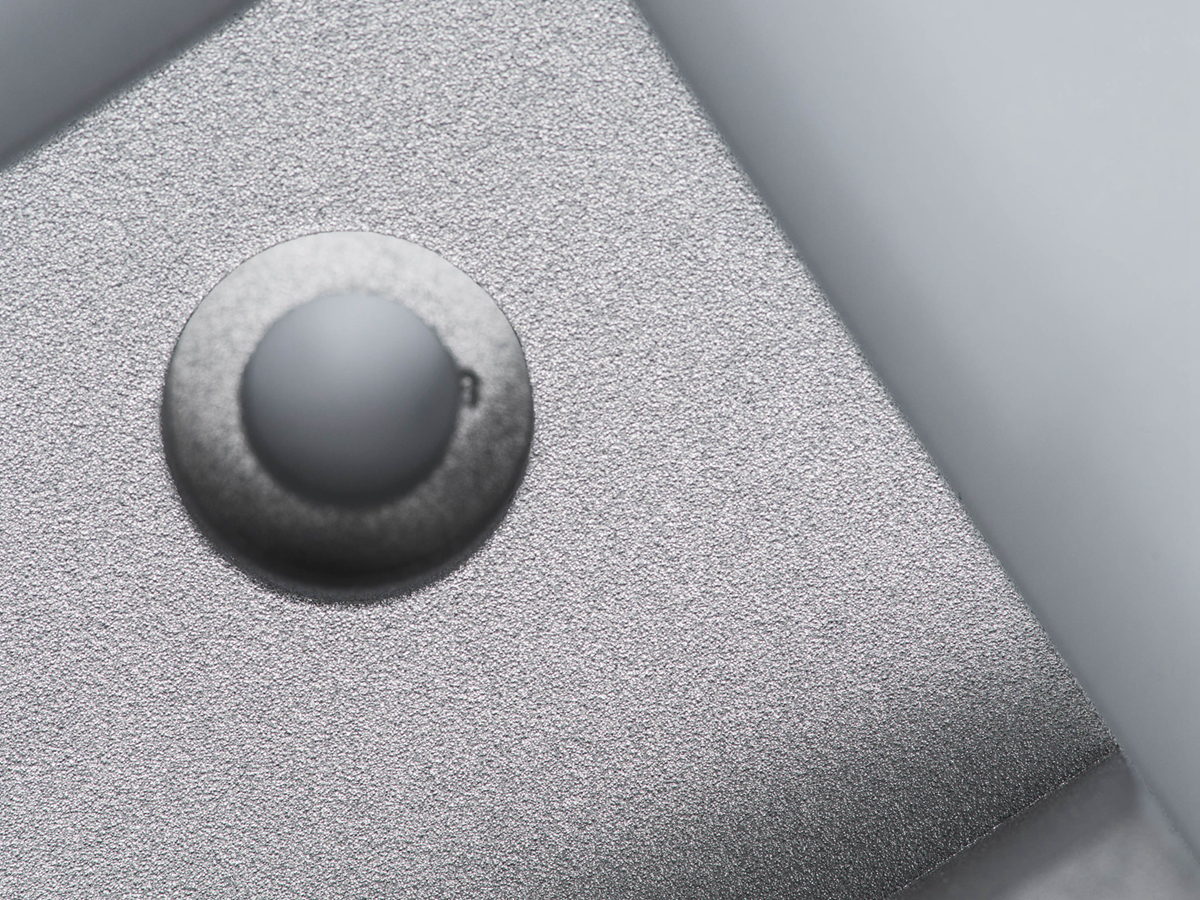

Sandblasting

Learn More

Electroplating

Learn More

Polishing

Learn More

Anodizing

Learn More

Powder Coating

Learn More

Electropolishing

Learn More

IMD

Learn More

Brushed Finishes

Learn More

Black Oxide

Learn More

Heat Treatment

Learn More

Tumbling

Learn More

Alodine

Learn More

Chrome Plating

Learn More

Phosphating

Learn More

Nitriding

Learn More

Galvanizing

Learn More

Lacquer Coating

Learn More

Teflon Coating

Learn More

Thermal Coatings

Learn More

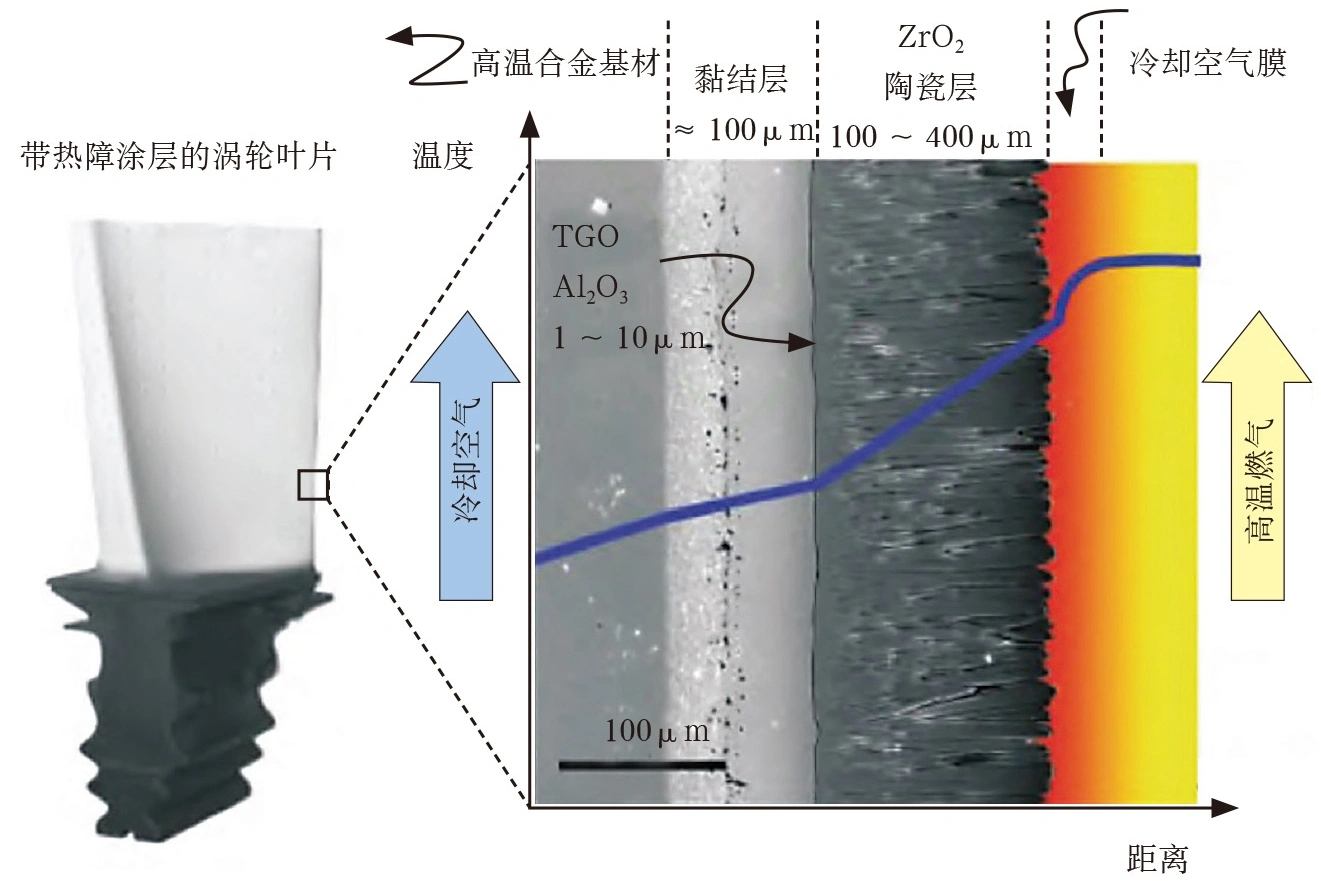

Thermal Barrier Coatings

Learn More

Passivation

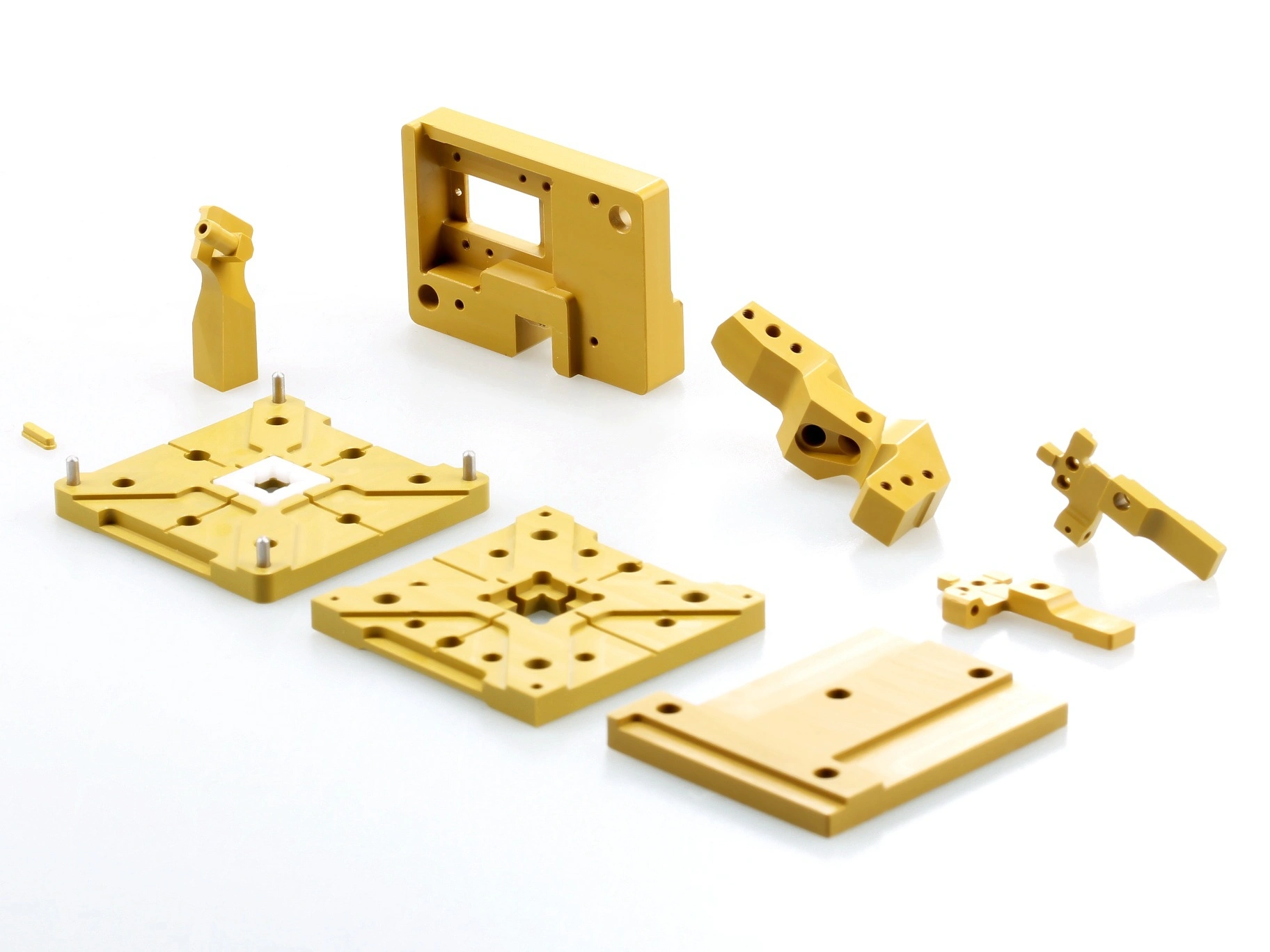

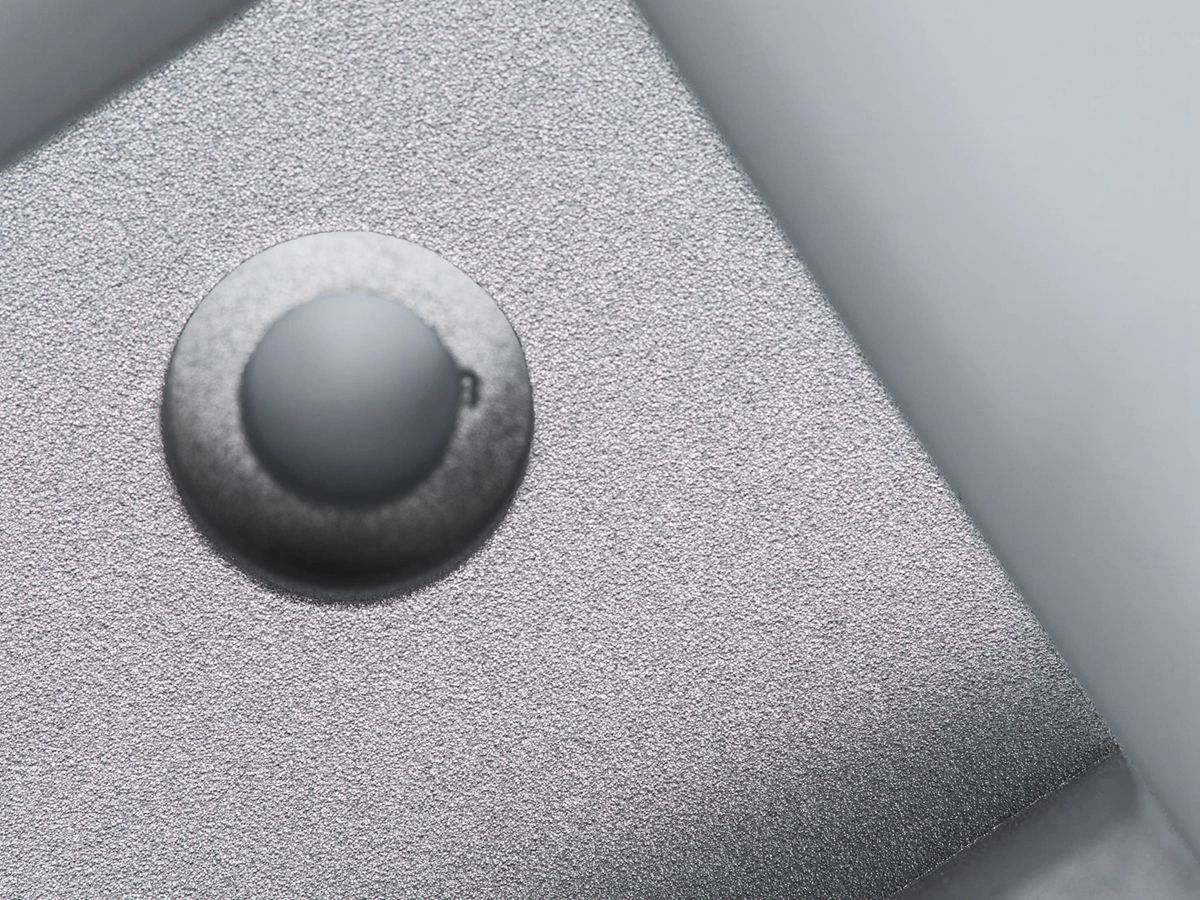

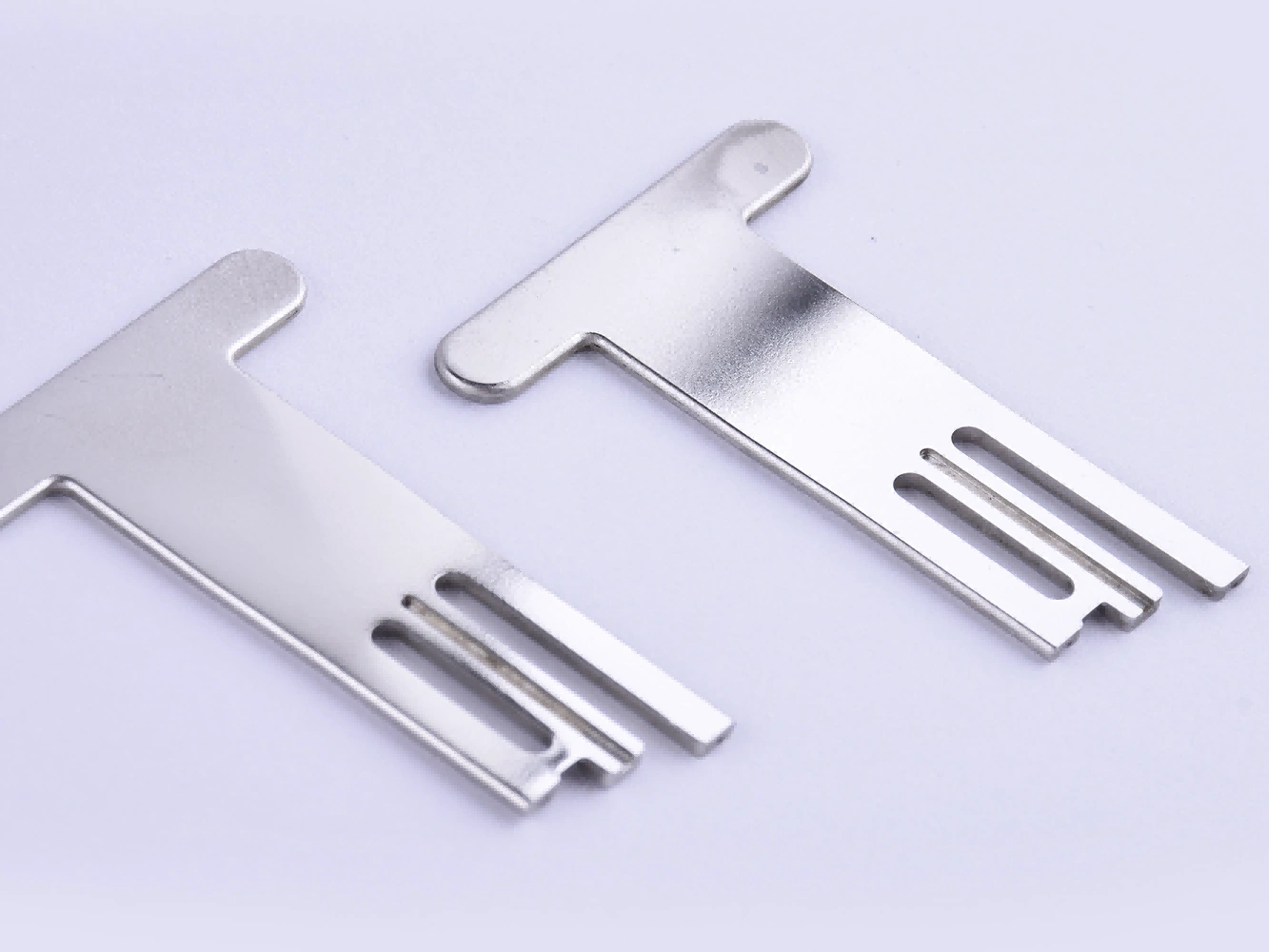

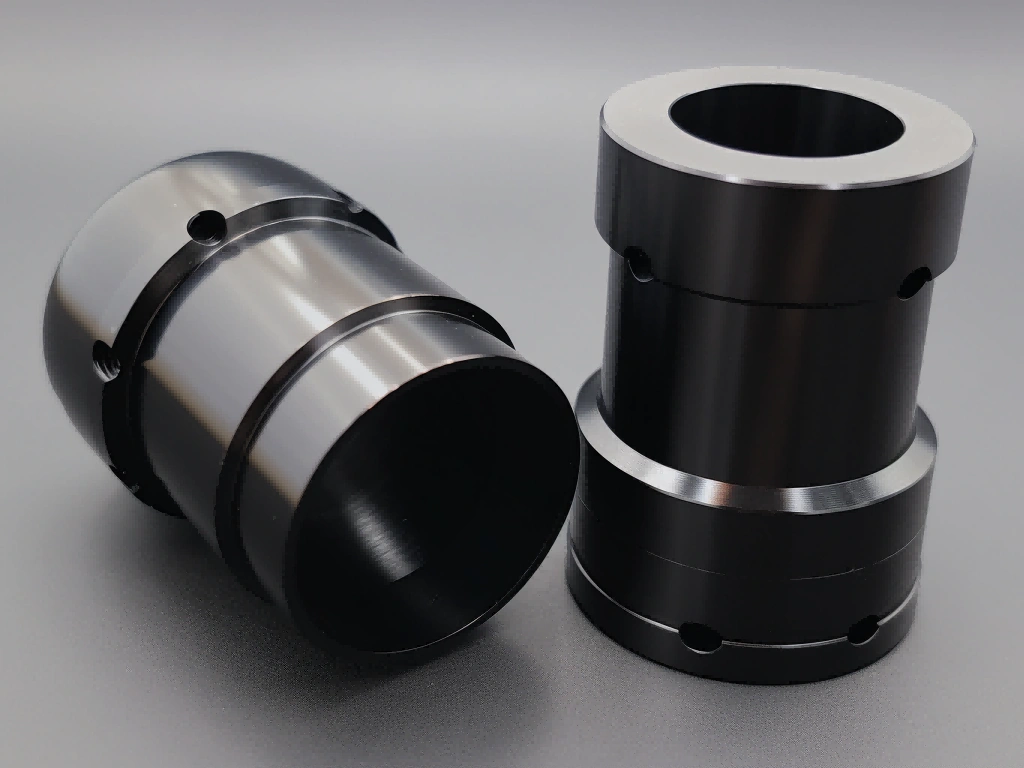

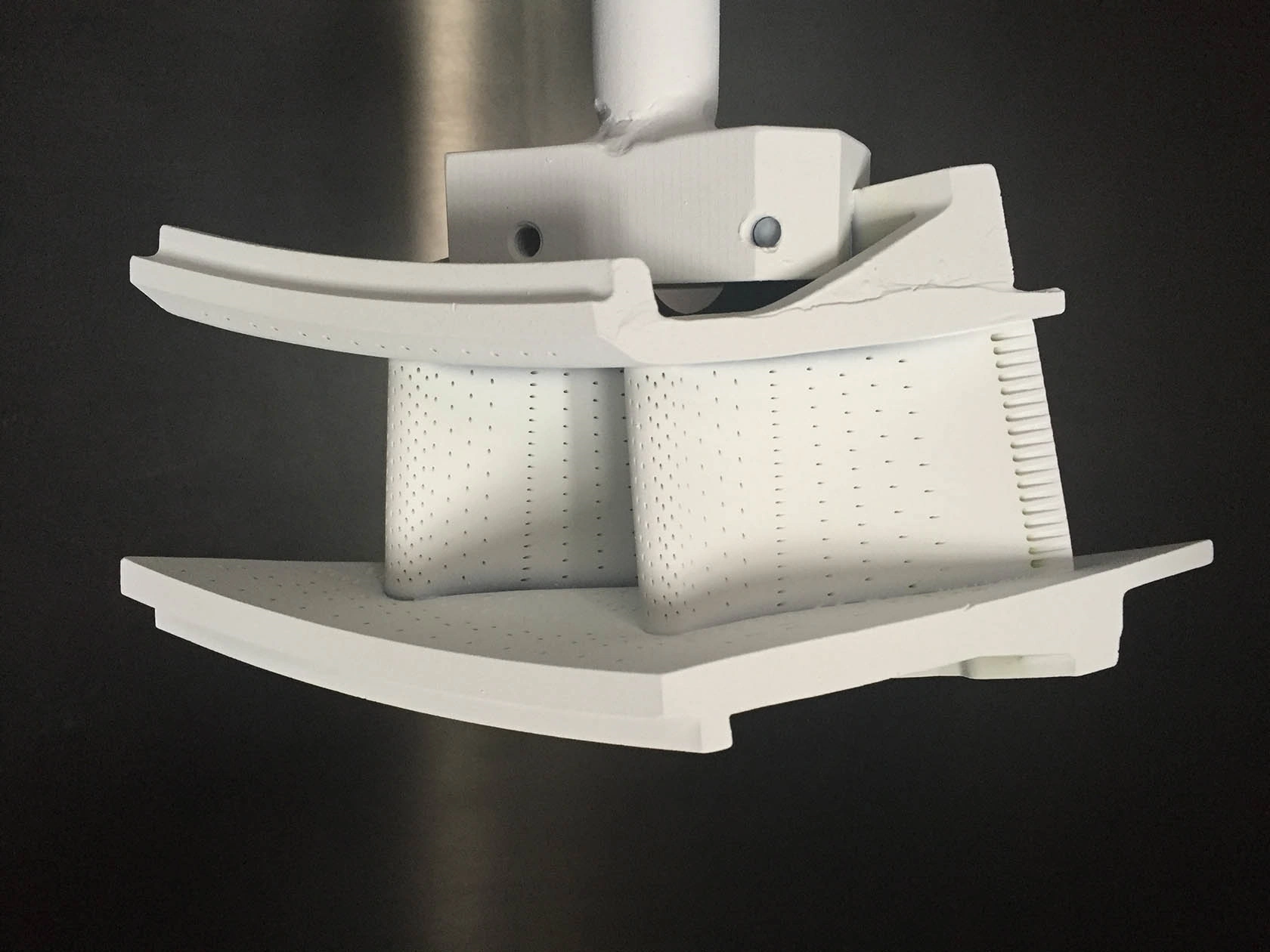

Plastic Molding Parts Gallery

At plastic molding parts gallery, we understand that every project is unique. That's why we work closely with our customers to ensure that their custom parts are designed to meet their exact specifications. With our attention to detail and commitment to quality, you can trust that your custom parts will exceed your expectations.

Let's Start A New Project Today

Custom Plastic Injection Molding Parts Design Suggestion

Understand the design limits for custom plastic injection molding parts. These guidelines help optimize dimensions, tolerances, wall thickness, and production volumes to achieve cost-effective, high-quality injection molded components.

Frequently Asked Questions

Explore Related Resources

Solutions

Copyright © 2026 Neway Precision Works Ltd.All Rights Reserved.