Insert Injection Molding Service

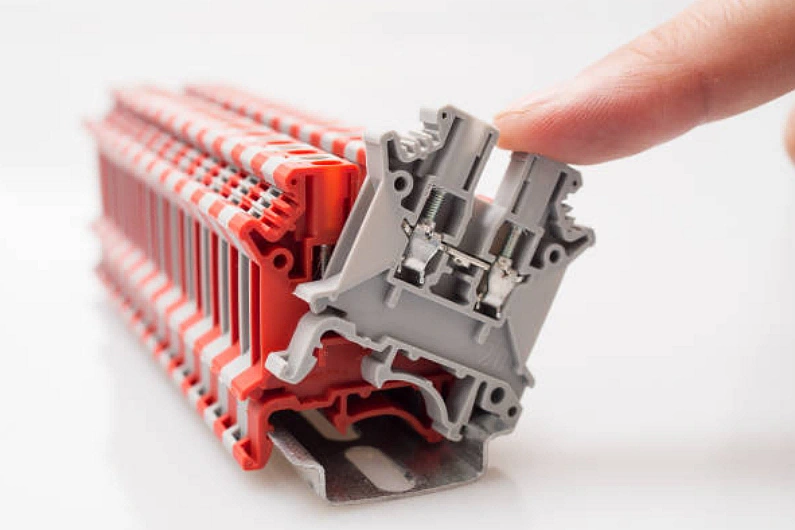

Insert injection molding involves placing pre-made components, like metal parts, into a mold and then injecting plastic around them. It creates strong, integrated assemblies commonly used in industries such as automotive and electronics for enhanced mechanical properties and functionality.

- Insert Materials:

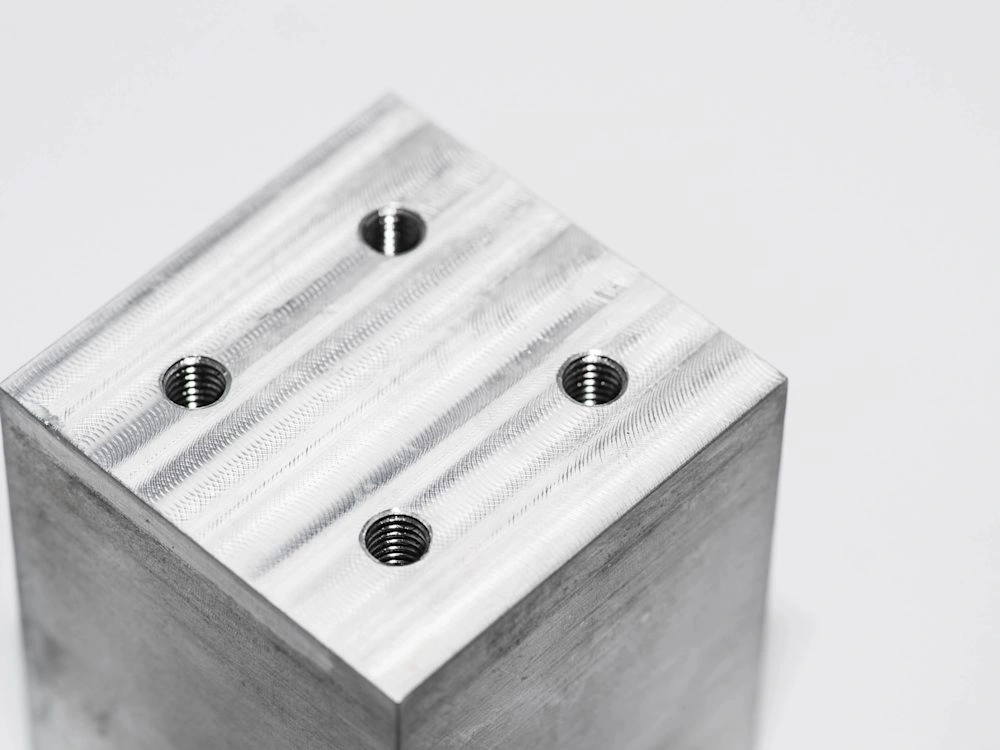

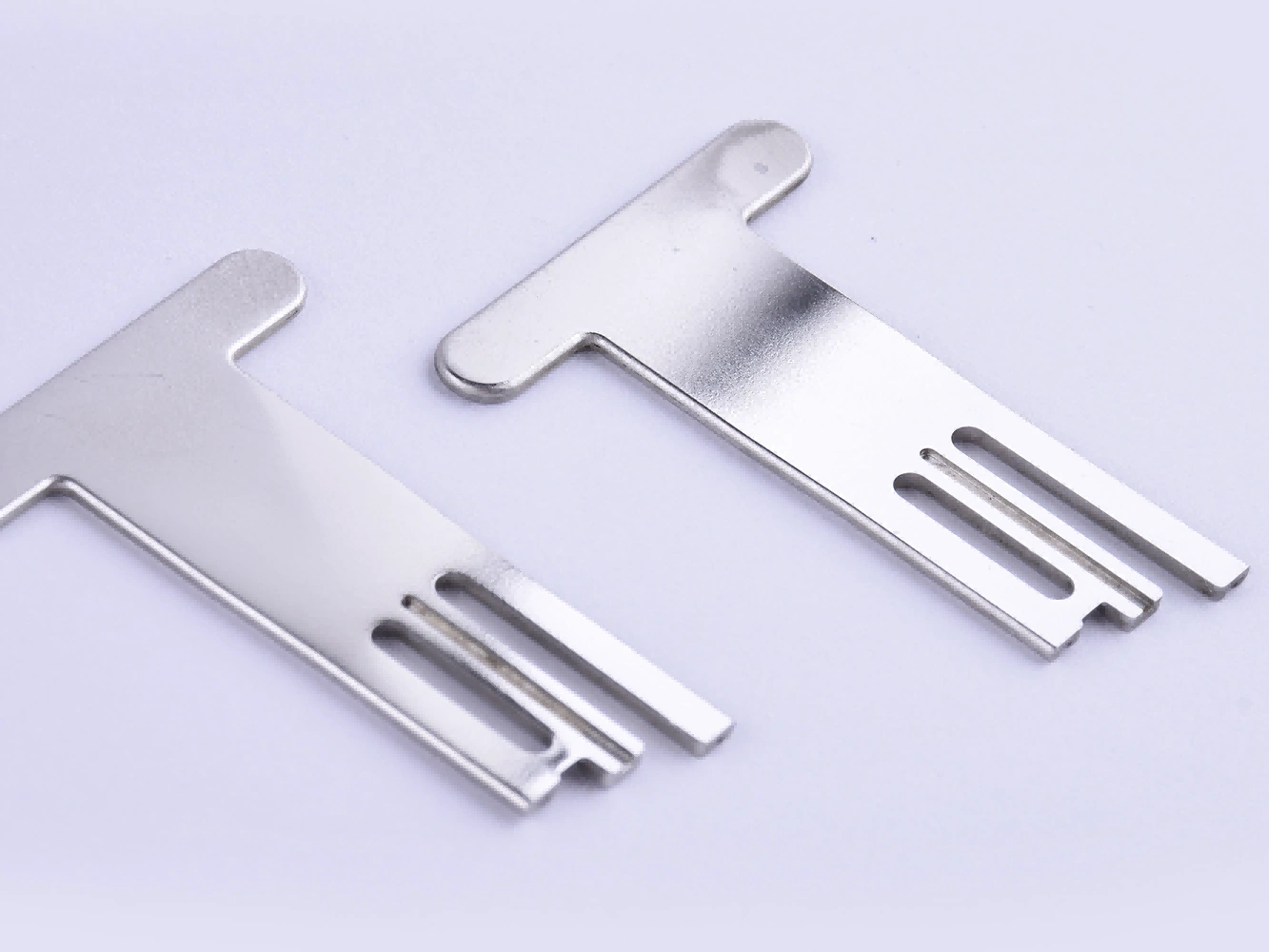

- Metals: Stainless steel, brass, aluminum, and nickel-plated carbon steel are famous for their strength and durability. Plastics: High-performance plastics like PEEK or nylon can be used for inserts when chemical resistance or insulation is required.

- Injection Molding Materials:

- Thermoplastics: Commonly used plastics include ABS (Acrylonitrile Butadiene Styrene), polypropylene (PP), polyethylene (PE), polycarbonate (PC), and nylon. These materials are chosen for their moldability, strength, and durability.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

Advantages of Insert Molding Service

Insert Molding Service integrates inserts into plastic parts during molding, enhancing structural integrity, reducing assembly costs, and improving reliability. This process allows for complex designs and material combinations, offering streamlined production and design flexibility, ideal for manufacturing robust and multifunctional components efficiently.

Custom Insert Molding Parts Applications

Our custom insert molding process seamlessly integrates inserts into molded components for enhanced strength and functionality. Explore a diverse range of applications across multiple industries.

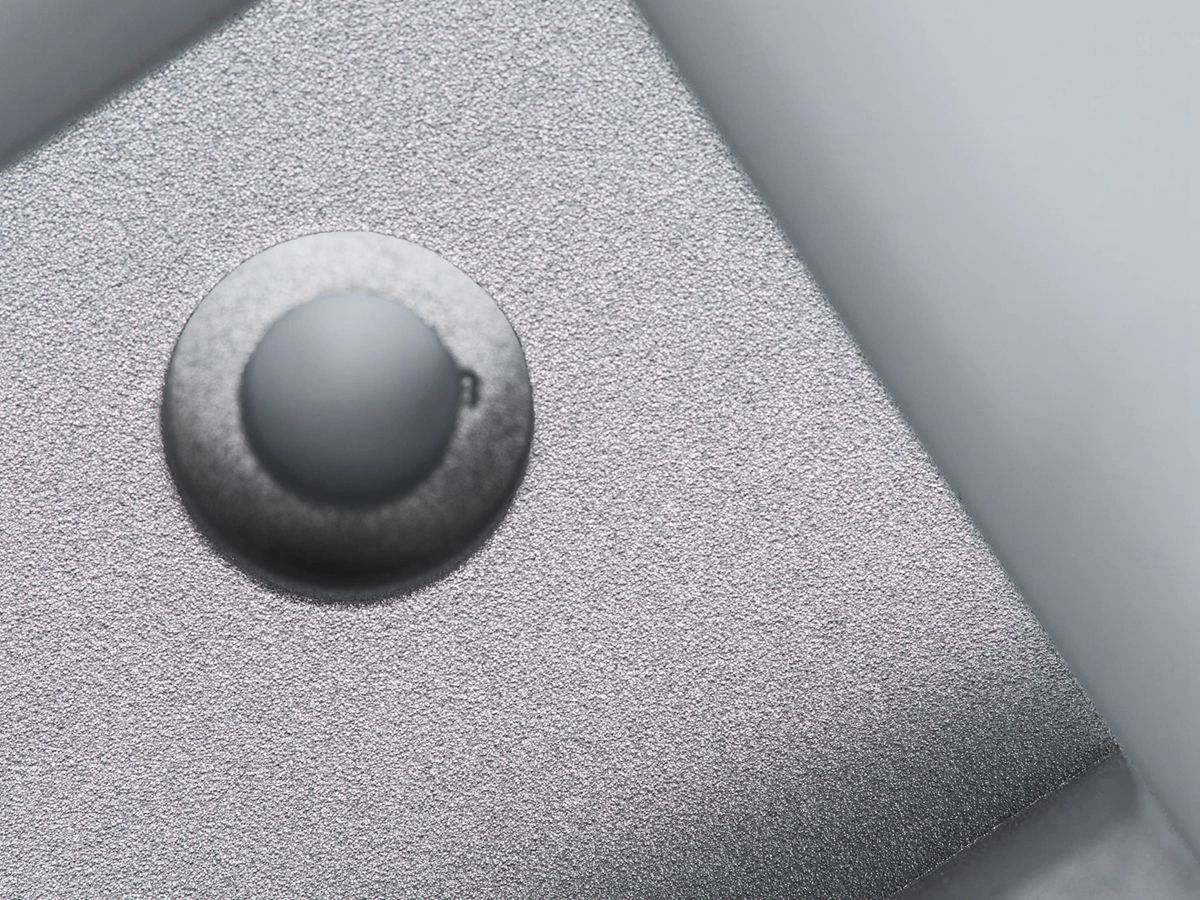

Custom Parts Surface Finishing Available

Our Surface Treatment Service offers specialized finishes for custom parts, enhancing durability, aesthetics, and performance. We provide a range of processes, including Electroplating, Anodizing, Powder Coating, and Thermal Barrier Coatings, tailored to improve corrosion resistance, wear properties, and visual appeal of metal and plastic components across industries.

Learn More

As Machined

Learn More

Painting

Learn More

PVD

Learn More

Sandblasting

Learn More

Electroplating

Learn More

Polishing

Learn More

Anodizing

Learn More

Powder Coating

Learn More

Electropolishing

Learn More

IMD

Learn More

Brushed Finishes

Learn More

Black Oxide

Learn More

Heat Treatment

Learn More

Tumbling

Learn More

Alodine

Learn More

Chrome Plating

Learn More

Phosphating

Learn More

Nitriding

Learn More

Galvanizing

Learn More

Lacquer Coating

Learn More

Teflon Coating

Learn More

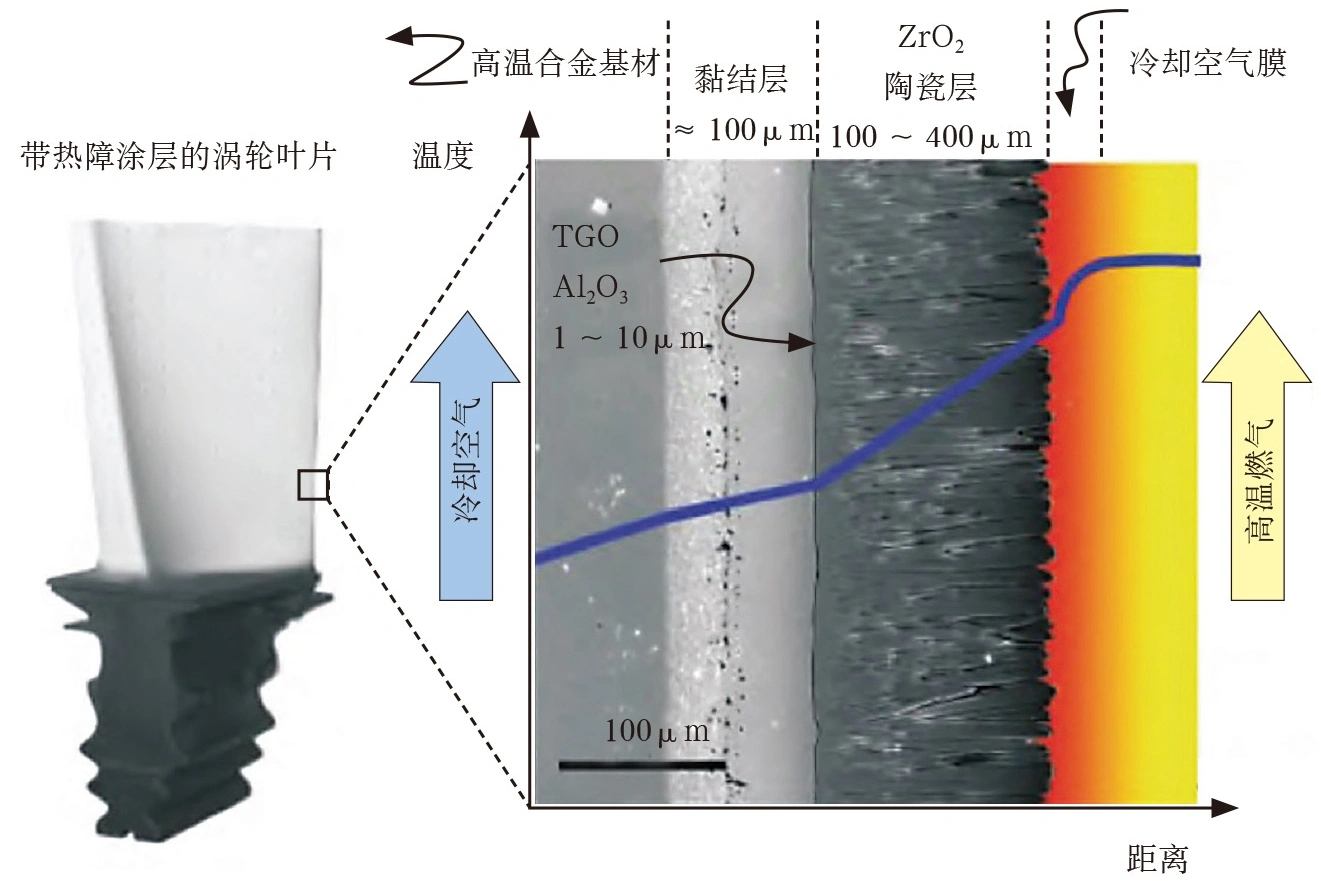

Thermal Coatings

Learn More

Thermal Barrier Coatings

Learn More

Passivation

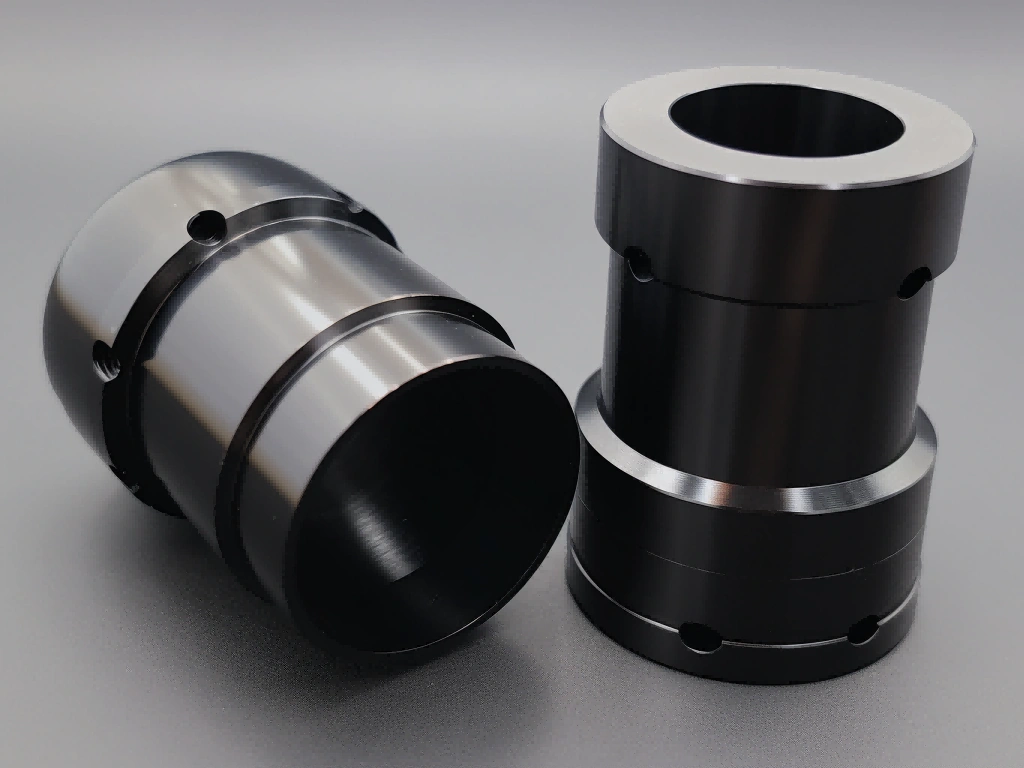

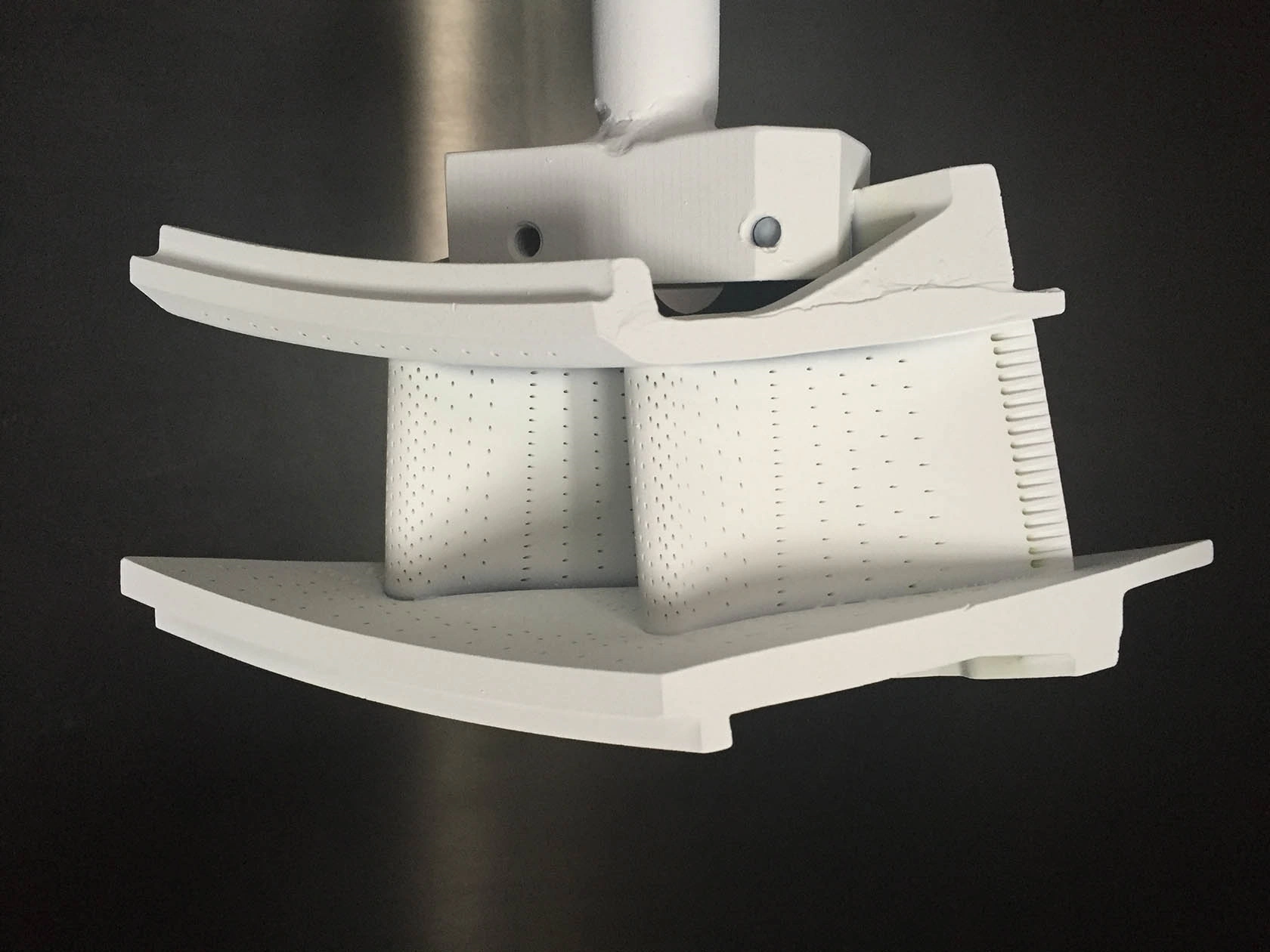

Custom Parts Gallery

Discover a wide range of custom insert molding parts through our visually appealing gallery.

Let's Start A New Project Today

Custom Insert Molding Parts Design Suggestion

Understand the design limits for custom insert molding parts. These guidelines help optimize dimensions, wall thickness, insert integration, tolerances, and production volumes to achieve cost-effective, high-quality parts with secure plastic-to-insert bonding.

Frequently Asked Questions

Explore Related Blogs

Solutions

Copyright © 2026 Neway Precision Works Ltd.All Rights Reserved.