Cutting Costs and Time in Manufacturing: How Insert Molding Simplifies Production

introduction

In today's competitive market, businesses strive to enhance manufacturing efficiency without sacrificing product quality. One innovative solution is insert molding, which integrates multiple production steps into one streamlined process. This technique significantly reduces manufacturing costs and simplifies assembly procedures, which is particularly beneficial in competitive automotive and consumer electronics sectors.

Understanding the Insert Molding Process

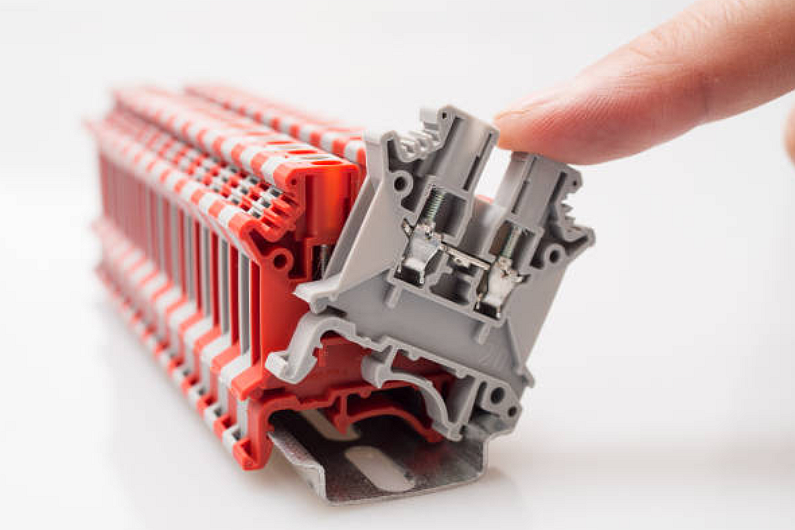

Insert molding involves embedding preformed components—typically metal or plastic inserts—within molten thermoplastics, such as polycarbonate (PC) or polypropylene, during the injection molding process. This approach eliminates the need for secondary assembly steps, such as welding or fastening, thereby significantly reducing production time and labor costs.

Economic Advantages of Insert Molding

Lower Assembly and Labor Costs

Insert molding significantly reduces the number of assembly stages, simplifying production lines and lowering labor costs. Traditional manufacturing processes often involve multiple manual steps, increasing labor and assembly costs. Manufacturers can achieve significant cost savings by integrating components directly, particularly in sectors like automotive manufacturing.

Reduced Material Waste and Improved Efficiency

Precision control over materials in insert molding reduces waste, providing considerable economic benefits. Unlike conventional methods, insert molding ensures minimal scrap generation, enhancing material utilization efficiency. This precise control is particularly valuable when using premium materials such as engineering-grade plastics, resulting in direct economic advantages.

Enhanced Product Durability and Longer Lifespan

Insert molding significantly increases product durability, combining the strengths of different materials into a cohesive whole. Enhanced durability reduces warranty claims, lowers product replacement frequency, and increases customer satisfaction, which is crucial in industries like medical devices, where reliability and precision are paramount.

Industry Applications and Examples

In the automotive industry, insert molding is widely used for components such as sensors and connectors, which greatly simplifies assembly processes and improves reliability. This approach significantly reduces manufacturing costs and enhances component durability, vital in harsh operational environments.

For consumer electronics, insert molding effectively produces robust, precision parts, such as connectors and housings, thereby reducing material waste and lowering total production costs. Electronics manufacturers consistently report a reduction in warranty claims due to the improved durability of insert-molded parts.

Effective Implementation of Insert Molding

To maximize the benefits of insert molding, manufacturers must carefully evaluate material compatibility and optimize mold design. Thorough material testing and strategic selection ensure optimal product performance, cost efficiency, and effective adhesion between substrate and overmold materials.

Manufacturers must also assess initial investment costs, balancing upfront expenses in tooling and equipment against substantial long-term savings from decreased labor, waste reduction, and enhanced production scalability.

Overcoming Common Challenges

Insert molding can present challenges such as material compatibility issues and insert displacement. Mitigating these issues requires thorough compatibility testing, advanced mold design, and optimized injection parameters. Employing experienced molding specialists and utilizing advanced CAD software are effective strategies for overcoming these obstacles.

Future Trends and Innovation

Emerging trends in insert molding highlight a focus on sustainable practices, including the use of bio-based plastics and recycled materials. Additionally, increased automation through robotics and AI-driven process optimization promises further improvements in manufacturing precision, reduced cycle times, and enhanced cost-effectiveness.

Conclusion

Insert molding significantly simplifies manufacturing, delivering substantial cost reductions, improved product quality, and shorter production cycles. Companies seeking to achieve competitive advantages and cost efficiency should consider integrating insert molding into their production strategies and collaborating closely with experienced providers to realize the full potential of this transformative manufacturing solution.