Streamlining Success How Aluminum Die Casting Accelerates Production and Reduces-costs

Introduction

Aluminum die casting has become a go-to solution for industries seeking efficiency, precision, and cost savings. Manufacturers, particularly those in the automotive and consumer electronics sectors, are utilizing this versatile method to boost productivity, expedite production cycles, and maintain competitive pricing. Aluminum die casting delivers significant value in today's demanding market environment through its rapid manufacturing process, exceptional precision, and lightweight material benefits.

What is Aluminum Die Casting?

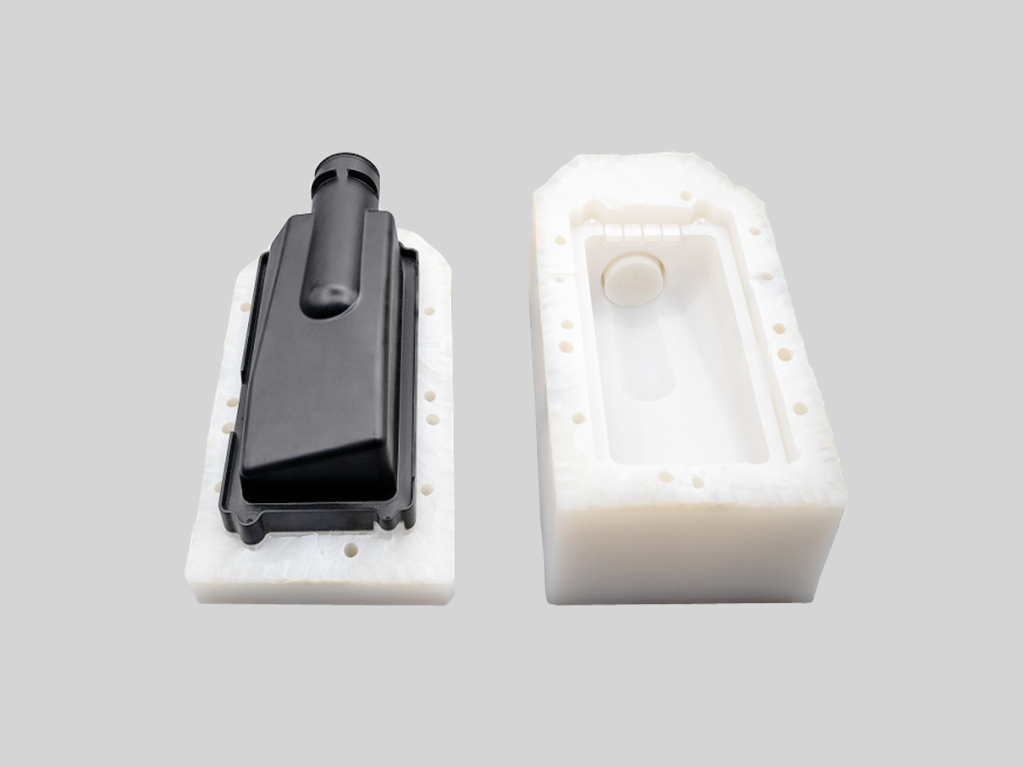

Aluminum die casting is a manufacturing process in which molten aluminum alloys are injected into high-pressure steel molds, commonly referred to as dies. Upon cooling, the aluminum solidifies into complex, precision-engineered shapes. Aluminum’s inherent lightweight properties, excellent corrosion resistance, and high thermal conductivity make it ideal for die-casting.

Compared to other casting techniques, such as sand casting or gravity casting, aluminum die casting produces superior dimensional accuracy and finer surface finishes, reducing or eliminating the need for additional machining processes.

Key Benefits of Aluminum Die Casting

Rapid Production Cycles

The high-pressure injection and rapid solidification inherent in aluminum die casting allow manufacturers to produce complex components at accelerated speeds. Compared to traditional casting methods, aluminum die casting can significantly reduce lead times, enabling quick market response and improved production efficiency.

High Dimensional Accuracy and Precision

Aluminum die casting achieves exceptional accuracy and repeatability due to the use of precisely engineered molds. This reliability is essential in industries such as aerospace and medical devices, where tight tolerances and consistent performance are crucial.

Cost Reduction in Mass Production

Despite the initial investment in mold tooling, aluminum die casting becomes highly cost-effective at scale. Economies of scale substantially lower per-unit costs, particularly in sectors such as e-mobility and telecommunications, where high-volume production is the norm.

Lightweight and Durable Components

Aluminum components produced via die casting offer excellent strength-to-weight ratios, crucial for applications in automotive or aerospace manufacturing. This lightweight durability directly contributes to improved fuel efficiency, enhanced performance, and reduced overall operational costs.

Enhanced Surface Finish Quality

Die-cast aluminum components typically exhibit superior surface finishes, which significantly reduce or eliminate the need for secondary finishing steps, such as anodizing or powder coating. This capability further reduces production costs and enhances product aesthetics and durability.

Industries Benefiting from Aluminum Die Casting

Automotive

Automotive manufacturers extensively utilize aluminum die casting to produce engine blocks, transmission housings, and internal components. And alloys such as A380 or ADC12 reduce vehicle weight, improve fuel economy, and enhance vehicle performance.

Aerospace

The aerospace industry demands precision and lightweight components. Aluminum die casting is ideally suited for manufacturing structural parts, brackets, and engine components that must meet rigorous performance and safety standards, significantly contributing to weight reduction and cost efficiencies.

Consumer Electronics

Manufacturers of electronic devices, such as laptops, smartphones, and cameras, leverage aluminum die casting to create durable, high-quality casings and enclosures. The process ensures precision, durability, and excellent aesthetic appeal, enhancing both consumer satisfaction and brand perception.

Telecommunications

Aluminum die casting produces robust components, such as heat sinks, connectors, and housing units, that are essential for reliable telecommunications infrastructure. Aluminum’s excellent thermal management properties ensure optimal device performance and longevity.

E-Mobility

Electric vehicle (EV) components, including battery housings, motor casings, and structural frameworks, greatly benefit from aluminum die casting. This method meets the stringent demands for lightweight yet durable components supporting enhanced vehicle efficiency, safety, and sustainability.

Real-World Case Studies

Automotive Transmission Components

An automotive manufacturer utilized aluminum die casting to produce transmission housings using the A380 alloy. The shift resulted in a 25% reduction in weight and improved production efficiency, cutting manufacturing cycle times by 20%.

Aerospace Structural Brackets

An aerospace company adopted aluminum die casting for structural brackets, achieving significant weight reduction and a 15% improvement in fuel efficiency. Utilizing aluminum alloys with high strength and reduced weight directly translates into operational cost savings.

Consumer Electronics Casings

A leading electronics brand utilized aluminum die casting to manufacture laptop and smartphone casings, thereby significantly enhancing heat dissipation and structural reliability. This transition enhanced product durability, eliminated secondary machining, and reduced overall production costs by approximately 30%.

Best Practices for Optimizing Aluminum Die Casting

Material Selection Guidelines

Selecting the correct aluminum alloy is essential. Alloys such as ADC12 and A356 offer excellent castability and structural properties, ensuring the production of high-quality components and increased production efficiency.

Die Casting Mold Design Considerations

Optimal mold design, including uniform wall thickness, efficient gating systems, and effective venting, significantly improves casting quality and reduces defects such as porosity or shrinkage. Proper design reduces cycle time, enhances productivity, and cuts manufacturing costs.

Process Optimization Strategies

Fine-tuning injection pressures, temperature controls, and mold cooling strategies ensures high-quality castings. Real-time monitoring and automated controls further enhance consistency, reduce downtime, and increase manufacturing throughput.

Addressing Common Challenges in Aluminum Die Casting

Minimizing Porosity

Porosity, caused by trapped gases, is a common challenge in aluminum die casting. Optimizing mold venting, alloy selection, and precise control of injection parameters effectively minimizes porosity, ensuring superior component quality.

Preventing Casting Defects

Common die-casting defects, such as shrinkage and surface imperfections, can be prevented through effective mold design, optimal temperature control, and precise management of process parameters. Regular maintenance and quality inspections further reduce the occurrence of defects.

Managing Die Maintenance Costs

Proper mold maintenance, including routine inspections, preventive maintenance, and timely refurbishments, reduces downtime, improves component quality, and significantly lowers long-term production costs.

Emerging Trends and Innovations

Advancements such as Industry 4.0 technologies, automation, and AI-driven monitoring systems are revolutionizing the aluminum die casting industry. These innovations enhance process accuracy, reduce waste, and increase production speeds. Additionally, sustainable practices, such as adopting recycled aluminum alloys, are becoming increasingly crucial for manufacturers seeking to minimize their environmental impact and meet global sustainability objectives.

Conclusion

Aluminum die casting is a powerful method for accelerating production, ensuring precise component quality, and reducing costs across automotive, aerospace, electronics, and e-mobility industries. Manufacturers who strategically integrate aluminum die casting into their processes benefit from superior product reliability, enhanced efficiency, and sustained cost savings, positioning themselves for competitive success in today's challenging market.