On-demand Gravity Casting Manufacturing Service

Explore the differences between gravity casting and other casting methods to determine the best choice for your project.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

What Is Gravity Casting Service

Our Gravity Casting Service leverages the natural force of gravity to produce high-quality metal components with excellent surface finish and structural integrity. Ideal for low-pressure, cost-effective casting of complex geometries with reduced energy consumption.

Applications of Gravity Castings

Our gravity casting process delivers robust components with excellent mechanical properties across diverse industries. Discover high-quality, precision-engineered gravity casted parts used in critical applications.

Gravity Casting Materials

Custom Parts Surface Finishing Available

Our Surface Treatment Service offers specialized finishes for custom parts, enhancing durability, aesthetics, and performance. We provide a range of processes, including Electroplating, Anodizing, Powder Coating, and Thermal Barrier Coatings, tailored to improve corrosion resistance, wear properties, and visual appeal of metal and plastic components across industries.

Learn More

As Machined

Learn More

Painting

Learn More

PVD

Learn More

Sandblasting

Learn More

Electroplating

Learn More

Polishing

Learn More

Anodizing

Learn More

Powder Coating

Learn More

Electropolishing

Learn More

IMD

Learn More

Brushed Finishes

Learn More

Black Oxide

Learn More

Heat Treatment

Learn More

Tumbling

Learn More

Alodine

Learn More

Chrome Plating

Learn More

Phosphating

Learn More

Nitriding

Learn More

Galvanizing

Learn More

Lacquer Coating

Learn More

Teflon Coating

Learn More

Thermal Coatings

Learn More

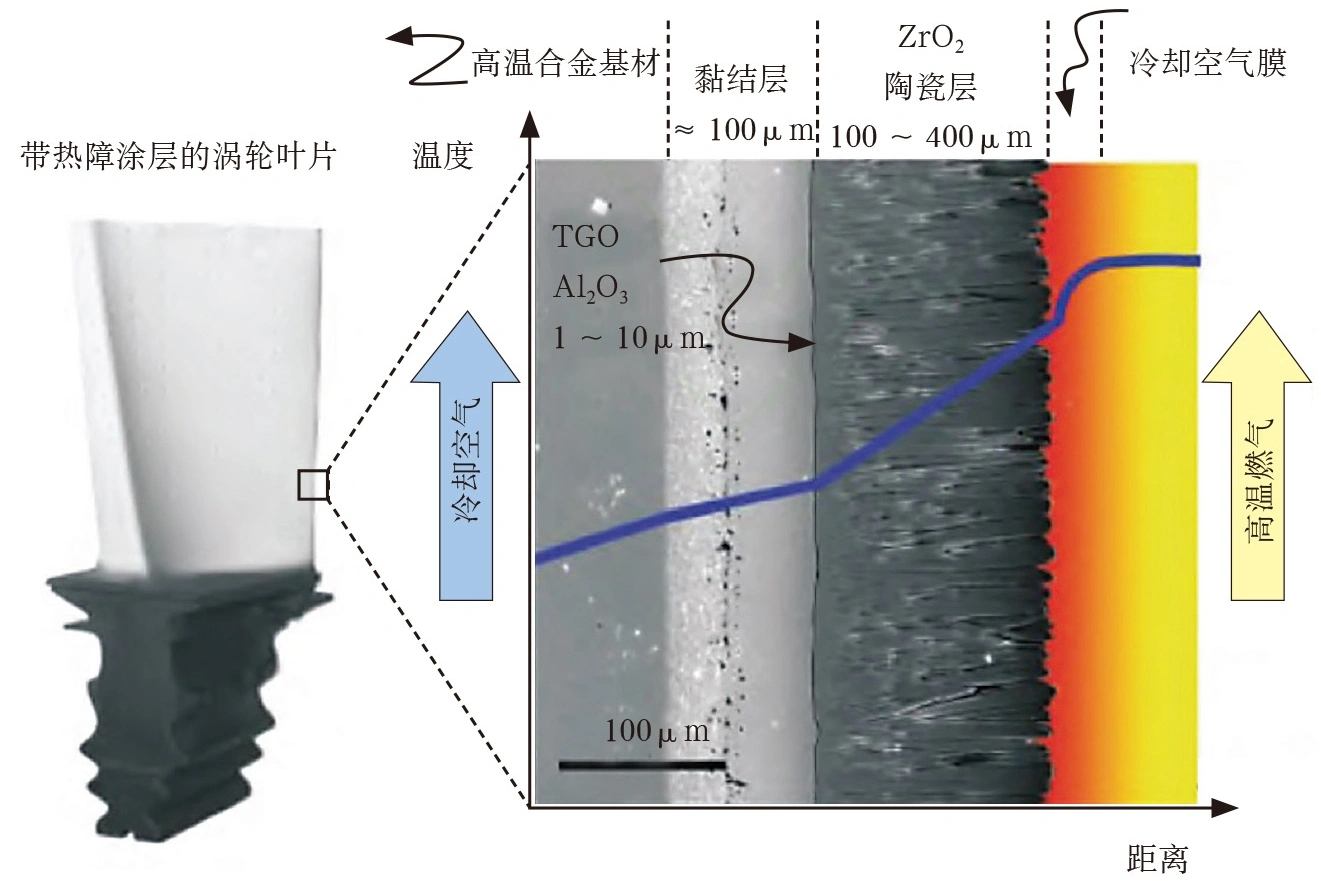

Thermal Barrier Coatings

Learn More

Passivation

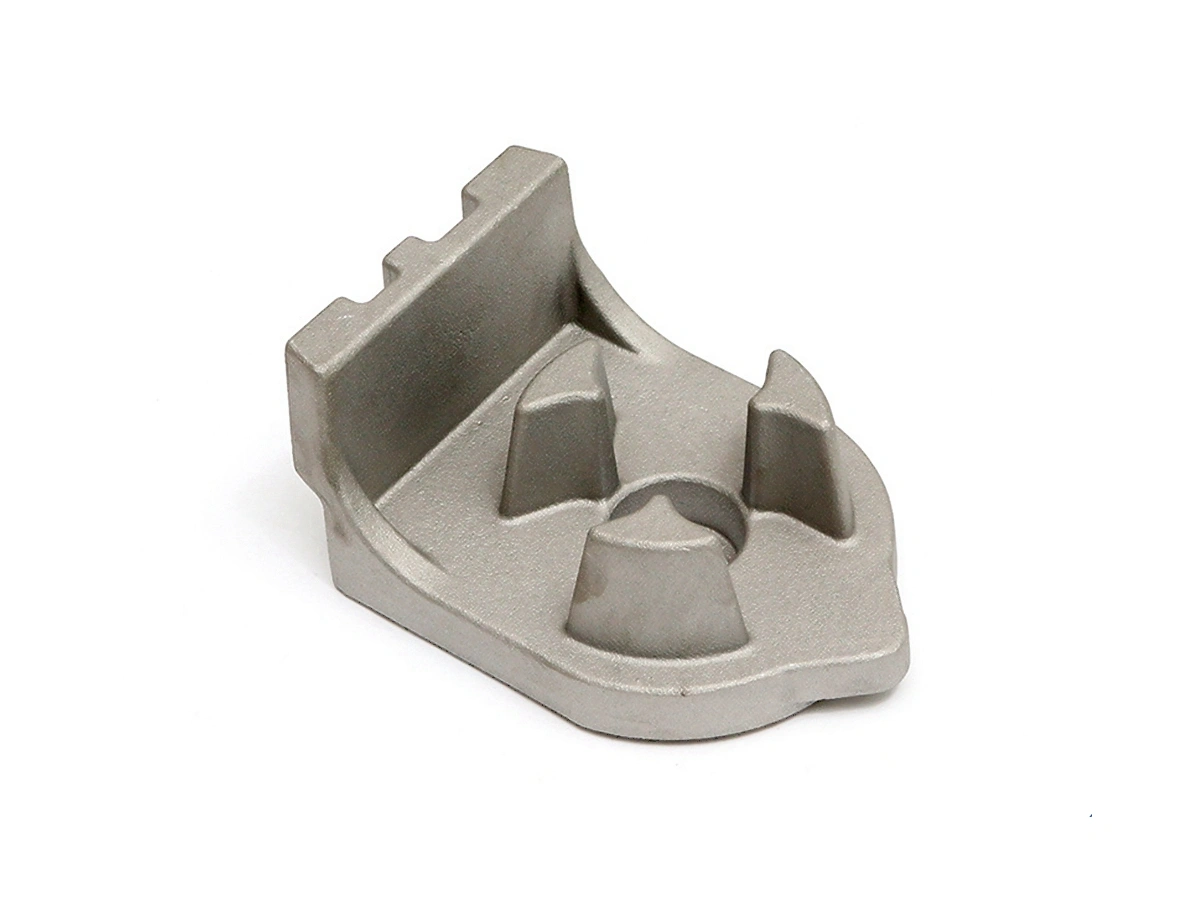

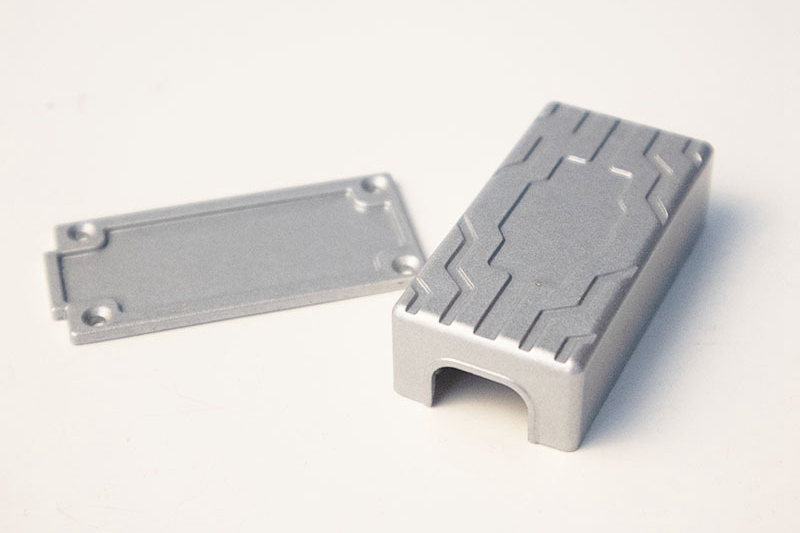

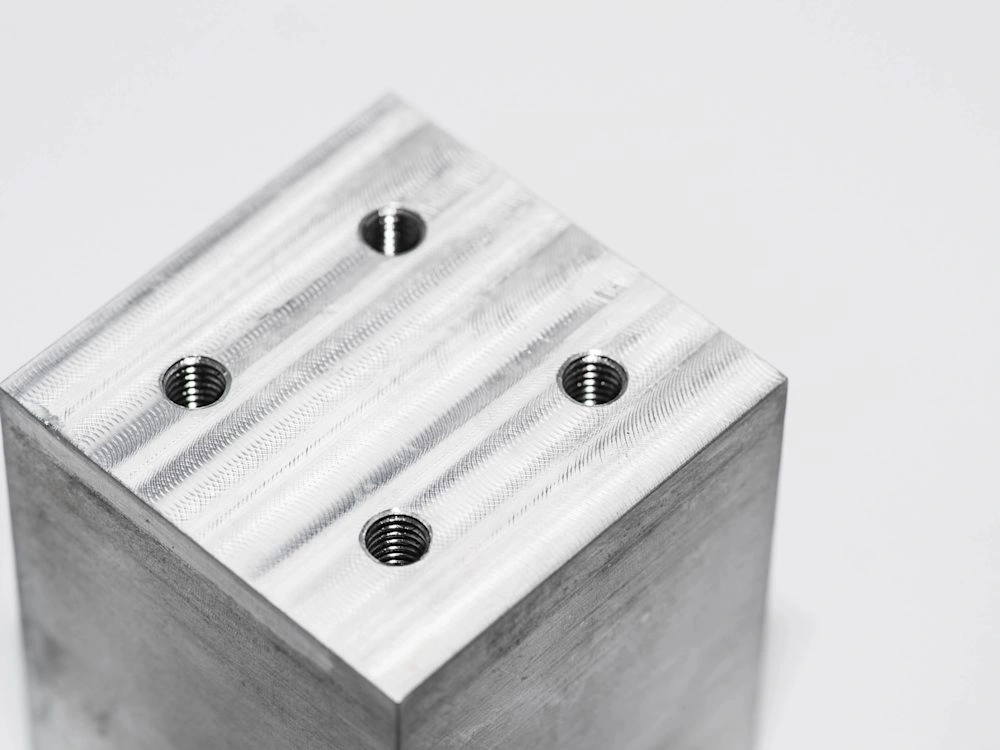

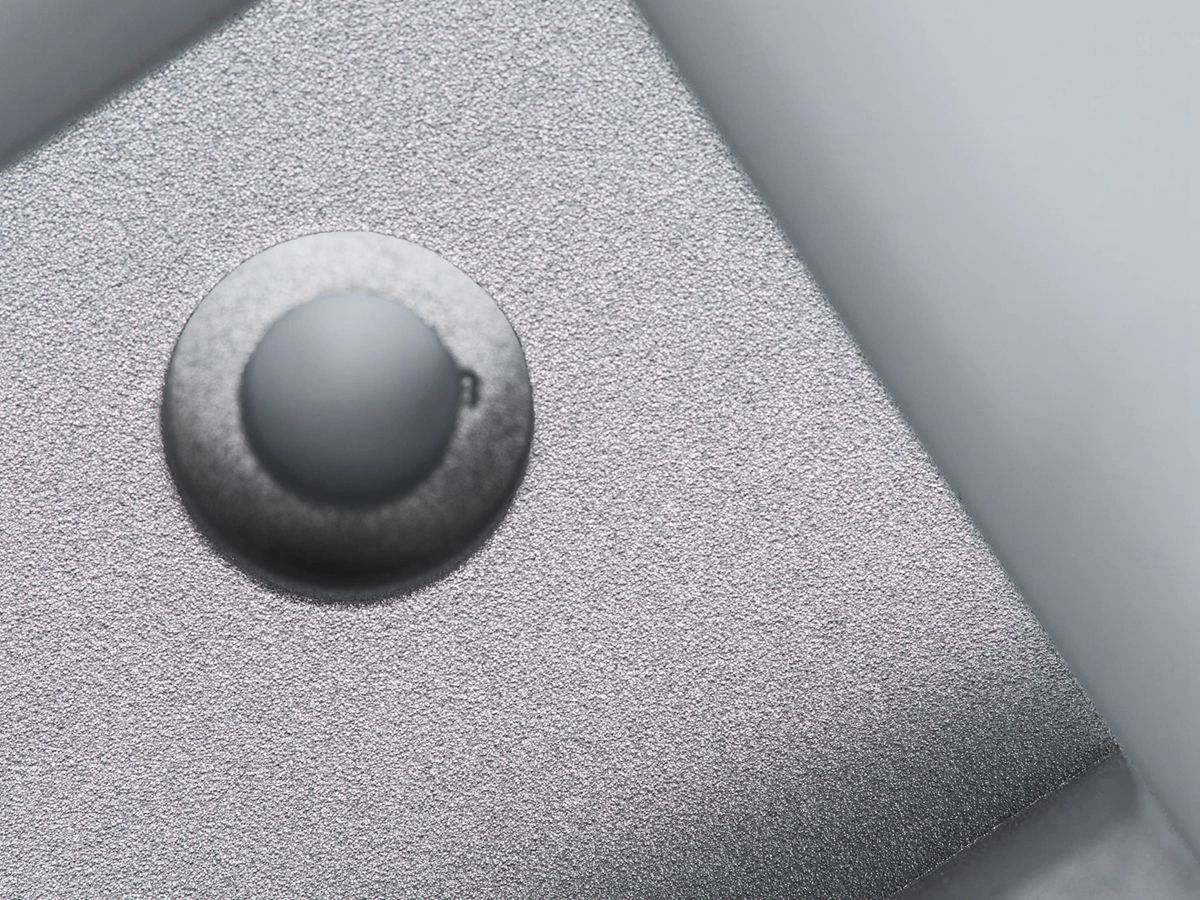

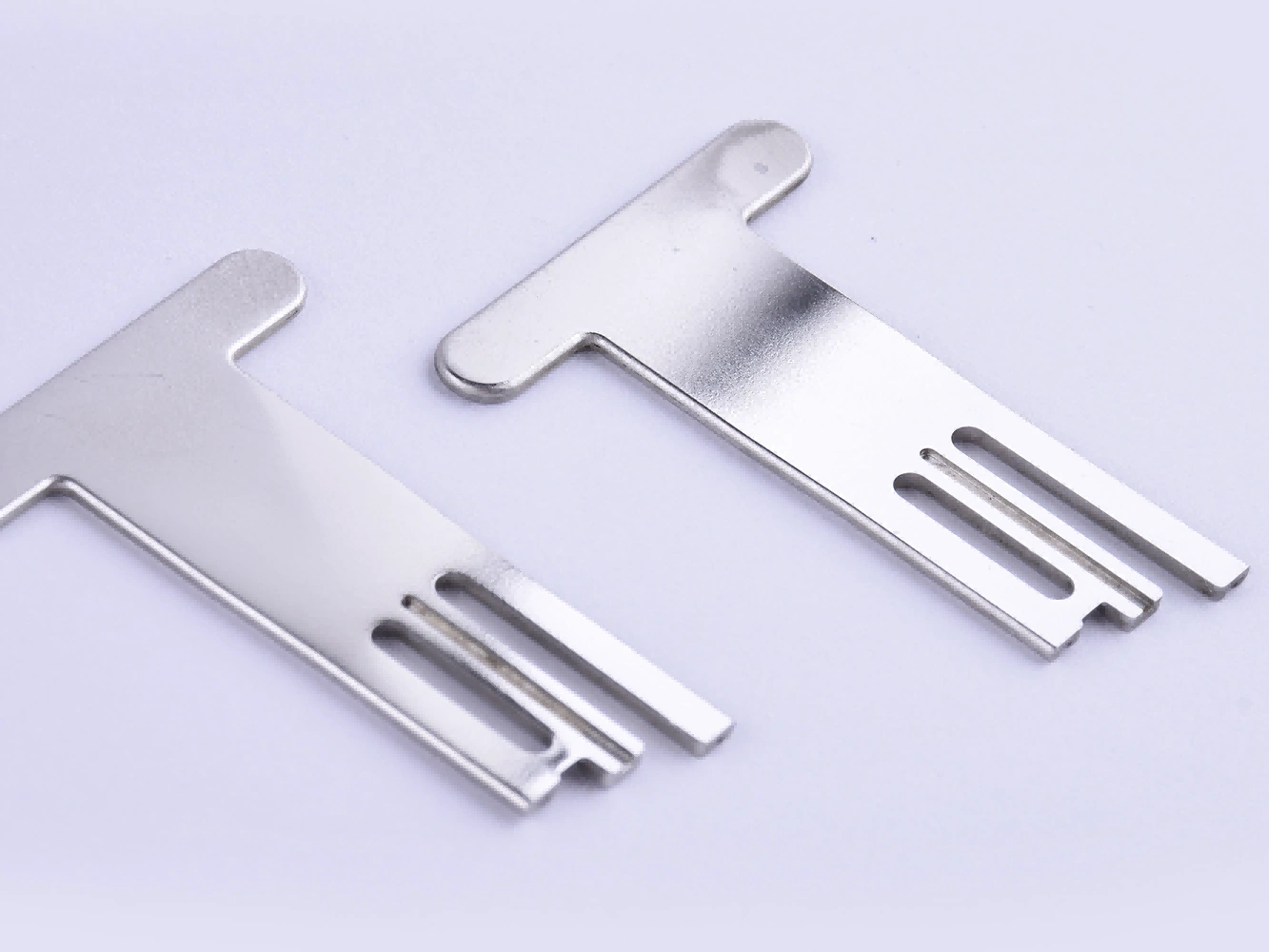

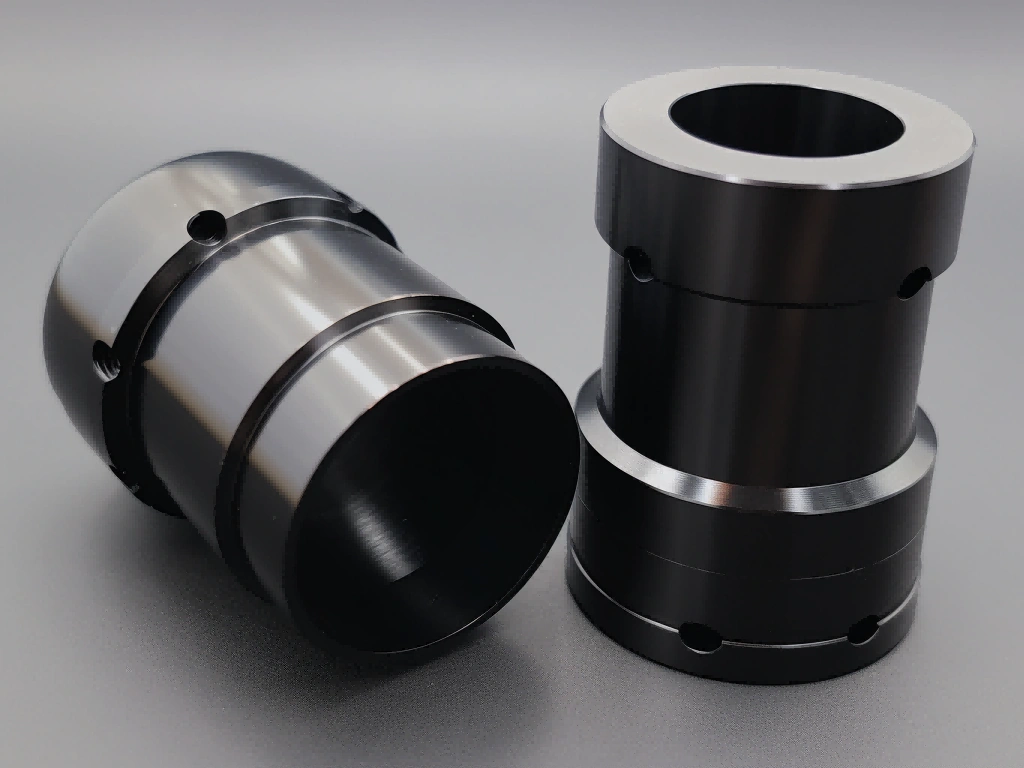

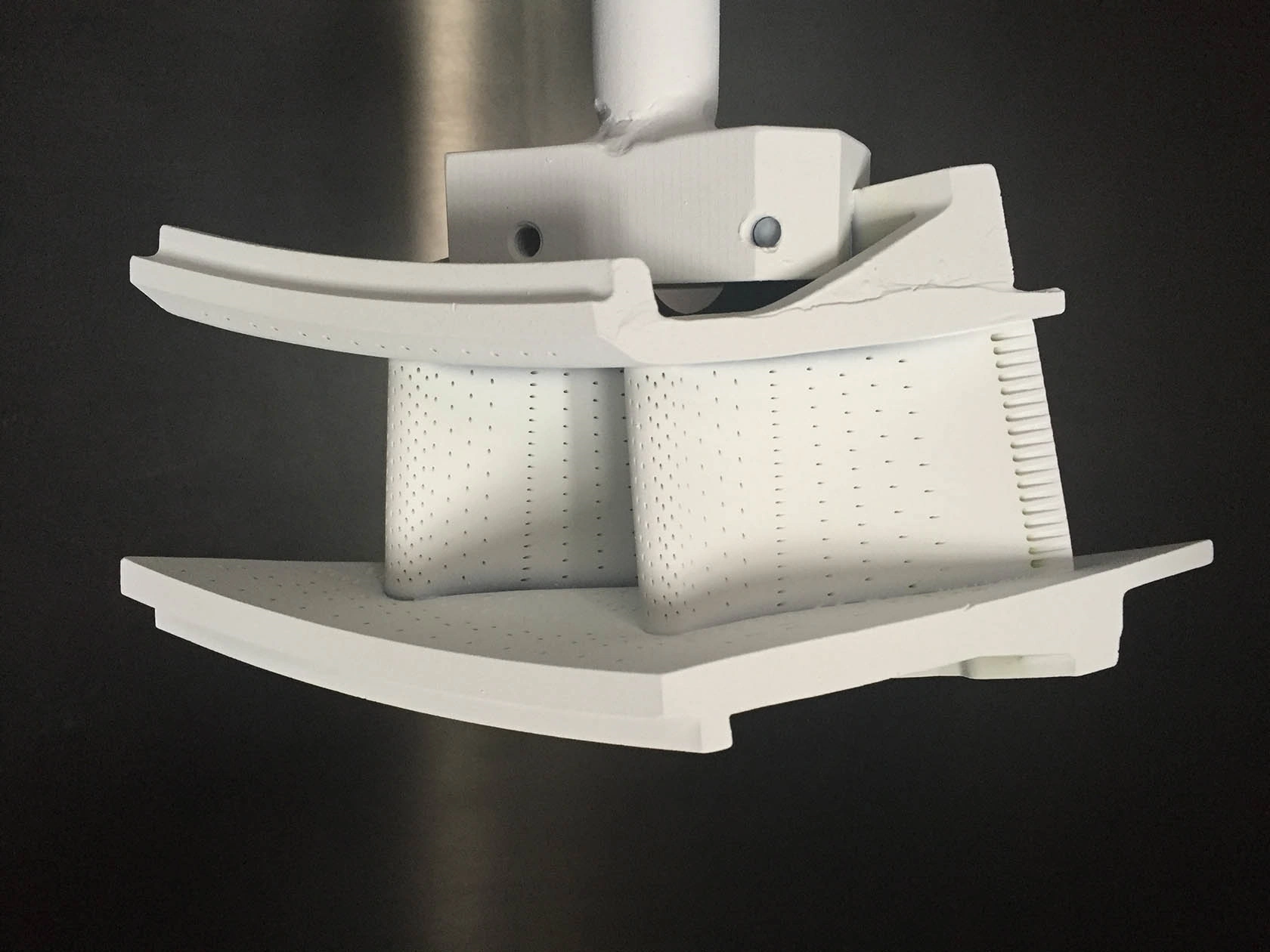

Gravity Cast Parts Gallery

Explore our gravity cast parts gallery showcasing the versatility and wide range of applications for these high-quality components.

Let's Start A New Project Today

Gravity Casting Parts Design Guideline

This guideline offers industry standard values for gravity casting parts to optimize metal flow and solidification while minimizing shrinkage, porosity, and production costs, ensuring high-quality, dimensionally accurate castings.

Frequently Asked Questions

Explore Related Resources

Solutions

Copyright © 2026 Neway Precision Works Ltd.All Rights Reserved.