Boosting Strength with Insert Molding: A Game-Changer for Component Durability

Introduction

In today’s manufacturing landscape, ensuring the production of strong, durable, and reliable products is crucial. Insert molding has emerged as an advanced technique offering substantial advantages in terms of structural integrity, efficiency, and cost-effectiveness. Widely adopted across various industries, including automotive, electronics, and medical devices, insert molding integrates metal or plastic inserts directly into molded components, thereby enhancing performance, reducing assembly complexity, and significantly improving product quality.

Understanding Insert Molding

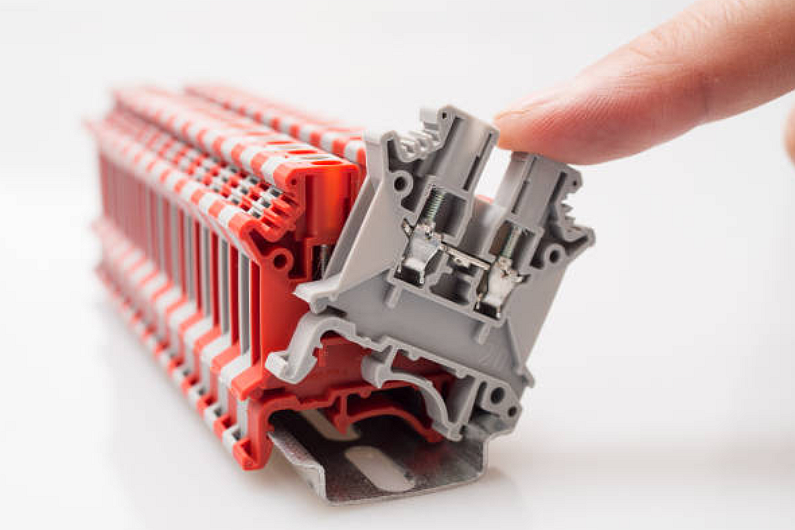

Insert molding is a specialized variation of plastic injection molding, in which pre-manufactured components—typically metal inserts, such as brass, aluminum, or steel—are securely encapsulated within thermoplastic materials, including ABS, nylon, or polypropylene. Unlike conventional molding methods, insert molding unifies separate parts in a single, efficient process, providing superior structural performance and simplifying the manufacturing process.

Comparison with Traditional Molding Processes

Traditional methods produce individual components separately, requiring extensive assembly. Insert molding streamlines production by embedding metal or plastic inserts directly into the molded part, eliminating the need for separate assembly processes, reducing manufacturing time, and enhancing structural integrity.

Key Benefits of Insert Molding

Enhanced Structural Integrity

Insert molding significantly improves product strength by embedding rigid inserts, such as metal fasteners or brackets, into molded plastics. This integration ensures durable, reliable components, especially valuable in demanding environments encountered in automotive or industrial applications.

Increased Resistance to Mechanical Stress

Integrating robust metal or plastic inserts within molded components substantially enhances their resistance to mechanical stresses, which is crucial for high-performance products subject to rigorous use or harsh environmental conditions.

Reduced Assembly Costs and Production Time

By consolidating multiple assembly steps into one streamlined molding process, insert molding reduces labor costs and accelerates production cycles. This method greatly benefits large-scale manufacturing operations, directly boosting efficiency and profitability.

Applications of Insert Molding Across Industries

Automotive Components

The automotive sector frequently utilizes insert molding to produce durable, lightweight parts such as reinforced plastic housings, threaded fasteners, and sensor components. Strong inserts, such as steel or aluminum, embedded within materials like nylon significantly enhance durability, reduce vehicle weight, and improve safety standards.

Electronics and Consumer Devices

In electronics manufacturing, insert molding is crucial for producing reliable connectors, threaded inserts, and structural reinforcements within devices such as smartphones, tablets, and home appliances. These molded components offer superior strength, stability, and extended product lifespan.

Medical Equipment

Medical manufacturers widely employ insert molding to create precise, ergonomic surgical tools, diagnostic equipment, and implantable devices. Using medical-grade materials and embedded metal inserts ensures enhanced performance, safety, and durability, all of which are critical to patient care.

Selecting Materials for Optimal Results

Careful selection of materials is vital for successful insert molding:

Metals (Inserts): Typically brass, aluminum, steel, or stainless steel for durability, strength, and heat resistance.

Plastics (Molding Material): Commonly ABS, nylon, polypropylene (PP), or engineering thermoplastics.

Factors Influencing Material Selection

Thermal Expansion Compatibility: Selecting compatible inserts and plastic materials prevents warping or structural failure.

Adhesion Strength: Selecting materials with compatible bonding properties ensures robust adhesion between the insert and plastic.

Load-Bearing Capacity: Ensuring the selected combination can handle the intended mechanical loads.

Real-World Case Studies

Automotive Industry

An automotive manufacturer implemented insert molding for engine components by embedding steel inserts within plastic housings. This approach improved structural strength by 40% and reduced assembly time by consolidating multiple production steps into a single process.

Electronics Manufacturing

A major electronics producer transitioned to insert molding for connector components in smartphones and laptops. Incorporating brass inserts into ABS housings resulted in a 30% increase in product lifespan, fewer warranty claims, and enhanced customer satisfaction.

Medical Device Industry

A medical device company adopted insert molding for surgical instruments by integrating stainless steel inserts within ergonomic plastic handles. This led to superior instrument precision, reduced surgical fatigue, and improved patient safety outcomes.

Best Practices for Achieving Optimal Strength with Insert Molding

Precision Mold Design

Accurate mold and insert design is crucial for ensuring consistent insert placement, alignment, and secure embedding, which directly impacts component durability and reliability.

Ensuring Robust Adhesion

Selecting compatible materials and employing surface treatments or bonding agents strengthens the adhesion between inserts and molded materials, ensuring long-term product integrity.

Leveraging Automation

Automation through robotics and precision machinery ensures consistency, minimizes errors, reduces production costs, and significantly enhances the overall quality and strength of the product.

Overcoming Common Challenges in Insert Molding

Material Compatibility

Careful evaluation and testing of insert and molding materials, combined with surface treatments, help achieve robust and durable adhesion, effectively overcoming compatibility challenges.

Cost Management and Optimization

While initial tooling and equipment costs may seem substantial, manufacturers quickly recover these expenses through reduced assembly costs and improved efficiency in large-scale production.

Consistency in High-Volume Production

Implementing strict quality control measures, regular equipment maintenance, and automated inspection processes ensures consistently high-quality components, preventing defects and ensuring structural reliability at scale.

Future Trends and Innovations

Advancements in Materials

Emerging innovations, such as hybrid composites, biodegradable polymers, and nanomaterials, will further enhance the strength, sustainability, and versatility of insert-molded products, thereby expanding their applicability across various industries.

Smart Technology Integration

Insert molding is increasingly combined with integrated electronic components and smart technologies, producing multifunctional, intelligent products essential for future IoT applications and advanced consumer devices.

Conclusion

Insert molding represents a powerful solution for manufacturers seeking to enhance product strength, efficiency, and reliability. Widely adopted across diverse industries, including automotive, consumer electronics, and medical equipment, this advanced molding technique significantly enhances structural integrity, streamlines production, and reduces costs. Manufacturers strategically leveraging insert molding will achieve substantial competitive advantages, long-term profitability, and superior market positioning.