Aluminum Die Casting Aorus Computer Accessories

Project Background and Client Overview

Aorus, a high-performance sub-brand of the global technology leader Gigabyte, specializes in advanced gaming hardware and premium graphics card accessories. Recognizing the need for superior stability and aesthetics in their graphics supports, Aorus partnered with Neway Precision for our expertise in aluminum die casting, precision CNC machining, and high-quality surface painting processes.

Product Introduction

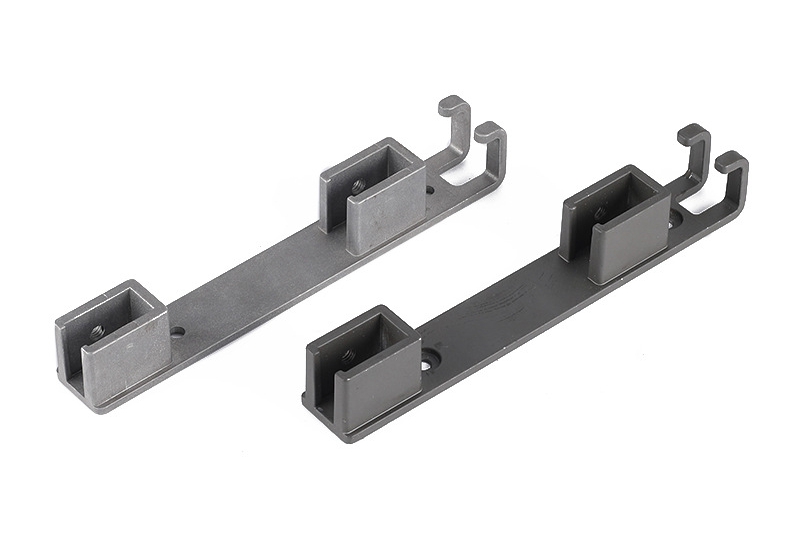

The Aorus Graphics Support is a specialized accessory designed to securely hold and aesthetically complement high-end graphics cards. Crafted from robust aluminum alloy, this component provides essential structural support, preventing GPU sagging and enhancing overall system stability. CNC machining ensures precision fitting, while professional-grade painting achieves a premium finish aligned with Aorus’s high aesthetic standards.

Client Introduction

Aorus, powered by Gigabyte, is globally recognized for cutting-edge gaming products, graphics cards, and system accessories designed for enthusiasts and professionals. Committed to exceptional quality and innovative design, Aorus continues to set industry benchmarks in gaming hardware performance and aesthetics.

Project Requirements and Technical Challenges

Key technical requirements set by Aorus included:

Strong yet lightweight aluminum die-cast supports with precise geometry and dimensional accuracy (±0.02 mm tolerances).

CNC machined surfaces to ensure accurate and secure installation with various GPU models.

Premium-grade painting providing consistent visual appeal, durability, and corrosion resistance.

Technical challenges involved achieving defect-free casting surfaces suitable for precision CNC finishing and painting, maintaining consistent dimensional accuracy, and ensuring paint adhesion and durability.

Manufacturing Process and Solutions

Process Step | Description |

|---|---|

Aluminum Die Casting | Selected A380 aluminum alloy for its excellent mechanical strength, casting precision, and lightweight characteristics, ensuring robust structural integrity. |

CNC Precision Machining | Performed precision CNC machining on critical mounting and alignment features, achieving dimensional accuracy within ±0.02 mm tolerances for perfect fitting and installation. |

Professional Painting | Applied high-quality painting processes, providing aesthetically pleasing surfaces, consistent texture, and superior corrosion and wear resistance. |

Throughout production, rigorous quality control was enforced, ensuring consistency in casting quality, machining accuracy, and painting uniformity, fully meeting Aorus’s strict specifications.

Project Outcome and Client Feedback

All Aorus Graphics Supports were delivered on schedule, supported by comprehensive quality inspection and dimensional verification reports demonstrating compliance with high manufacturing standards.

Aorus praised Neway Precision’s ability to produce precisely cast, accurately machined, and beautifully finished components, particularly highlighting the exceptional visual quality and structural robustness of the final product. The graphics supports significantly enhanced user satisfaction, complementing Aorus’s premium GPU lineup.

Photographic documentation demonstrated product quality, showcasing precise machining and flawless painted finishes in installed setups.

Conclusion and Strategic Impact

The successful collaboration with Aorus highlights Neway Precision’s capabilities in aluminum die casting, high-precision CNC machining, and advanced painting processes. Delivering components that meet stringent gaming industry standards underscores our commitment to quality, precision, and aesthetic excellence, reinforcing our reputation as a reliable manufacturing partner for leading global tech brands.

Call-to-Action

Explore Neway Precision’s specialized manufacturing solutions:

FAQs about Aorus Graphics Support Project

What makes aluminum alloy ideal for gaming accessory manufacturing?

How does CNC machining ensure compatibility across different GPU models?

What painting techniques does Neway Precision employ to achieve premium finishes?

How does Neway Precision control dimensional accuracy in aluminum die casting?

What typical lead times are involved in producing custom graphics supports?