High-Precision Component Solutions for Consumer Electronics

High-Precision Component Solutions for Consumer Electronics

In today’s highly competitive consumer electronics market, product success often depends on the precision and quality of its internal components. At Neway, the engineering team fully understands the crucial role that high-precision components play in device performance, reliability, and user experience. From smartphones to wearables, from smart home devices to computer accessories, every innovative product relies on precisely manufactured components to bring its design concepts to life.

Advanced Manufacturing Processes to Meet Stringent Consumer Electronics Requirements

Micro-Precision Plastic Injection Molding: The Art of Miniaturization and Complexity

In modern consumer electronics, the trend toward miniaturization requires manufacturing processes that can achieve unprecedented levels of precision. Our plastic injection molding services are optimized for the production of micro components, enabling the manufacture of complex structures with wall thicknesses as low as 0.3 mm. This process is particularly suitable for producing connector interfaces, micro gears, and precision transmission components, ensuring every part meets strict dimensional tolerance requirements. Through precise mold design and process control, we achieve micron-level manufacturing accuracy, ensuring compliance with the most demanding product design specifications.

Metal Injection Molding (MIM): A Mass Production Solution for High-Strength Micro Metal Parts

For micro components that require the performance of metal materials, our Metal Injection Molding (MIM) services provide an ideal solution. This technology combines the geometric complexity of plastic injection molding with the material performance of powder metallurgy, making it particularly suitable for producing small metal parts with intricate geometries. From SIM card trays and camera brackets in smartphones to hinge structures in wearable devices, MIM technology enables the production of high-strength, high-precision components while maintaining cost efficiency for large-scale manufacturing. Our engineering team has extensive experience in optimizing MIM process parameters, ensuring each part achieves optimal material density and mechanical performance.

Ceramic Injection Molding (CIM): Pursuing Excellent Performance and Insulation

For applications requiring high wear resistance, superior insulation performance, or special chemical stability, our Ceramic Injection Molding (CIM) services deliver unique value. Ceramic materials inherently offer high hardness, excellent wear resistance, and outstanding insulation properties, making them ideal for sensor housings, insulators, and specialized wear-resistant components. Our CIM process can produce precision ceramic parts with complex shapes that perform reliably in high-temperature, corrosive, or high-wear environments, providing robust performance support for consumer electronics.

Precision Stamping and CNC Machining: Achieving Extreme Accuracy and Surface Quality

For metal components that demand extremely tight dimensional tolerances and superior surface finish, our sheet metal stamping and precision CNC machining services offer ideal solutions. These processes are particularly well-suited for critical components, such as shielding covers, interface parts, and structural brackets, in electronic devices. Through our comprehensive custom parts manufacturing services, customers receive end-to-end support from design optimization through to final production, ensuring every component meets the highest quality standards.

Surface Finishing and Refinement Technologies That Give Products Their Identity

In consumer electronics, surface finishing is not only about aesthetics but also a key factor in functionality and durability. Our In-Mold Decoration (IMD) technology enables the integration of complex patterns and textures directly during the injection molding process, offering limitless design possibilities for product appearance. For metal components, Physical Vapor Deposition (PVD) technology provides decorative coatings with excellent wear and corrosion resistance while maintaining precise dimensional control. Our electroplating services deliver outstanding protection and visual appeal, ensuring products maintain a like-new appearance even after long-term use.

Core Material Science for Precision Consumer Electronics Components

High-Performance Engineering Plastics: Balancing Strength, Heat Resistance, and Aesthetics

In the consumer electronics sector, material selection has a direct impact on product performance and market competitiveness. Liquid Crystal Polymer (LCP), with its excellent dimensional stability and high-temperature resistance, is a preferred material for high-frequency connectors and micro components. Polyether Ether Ketone (PEEK), renowned for its exceptional mechanical strength and chemical resistance, excels in highly demanding environments. Polycarbonate (PC), with its unique advantages in transparency and impact resistance, is widely used in device housings and transparent elements.

Special Metals and Alloys: Conductivity, Shielding, and Structural Support

Metals play a crucial role in consumer electronics, serving as structural support, electromagnetic shielding, and electrical conductivity. Stainless steel materials, with their superior strength and corrosion resistance, are ideal for both internal structural parts and external visible components. Notably, our MIM 316L solution combines the excellent properties of 316L stainless steel with the flexibility of the MIM process, enabling the production of small metal parts with complex geometries and highly consistent performance.

Advanced Ceramic Materials: Enabling Specialized Functions

For specific applications, ceramic materials offer distinctive performance advantages. Zirconia (ZrO2), with its high toughness, wear resistance, and biocompatibility, has become an ideal choice for premium consumer electronic products. From smartwatch cases to smartphone camera decorative rings, zirconia ceramics deliver outstanding tactile quality and long-term durability.

Applications of Neway’s High-Precision Solutions in Consumer Electronics

Smartphones and Mobile Devices

In the smartphone sector, our high-precision manufacturing capabilities are fully demonstrated. By supplying key components to leading global brands, we have gained extensive experience in the manufacturing of consumer electronics. For example, our metal injection molding services for Huawei mobile phone accessories ensure the precision and consistency of each component, meeting the stringent requirements of high-volume production.

Wearable Devices and Internet of Things (IoT)

With the rapid development of wearable devices and IoT, there is a growing need for miniaturized components with high reliability. We have developed dedicated process and material solutions for these fields to ensure that components maintain excellent performance and reliability even at extremely small sizes.

Audio Devices and Smart Home

In audio devices and smart home applications, we provide manufacturing services for critical components to multiple international brands. As an approved supplier of metal and plastic injection molding for Apple, we deeply understand the uncompromising quality and precision standards of consumer electronics and integrate this philosophy into every stage of our manufacturing process.

Computers and Accessories

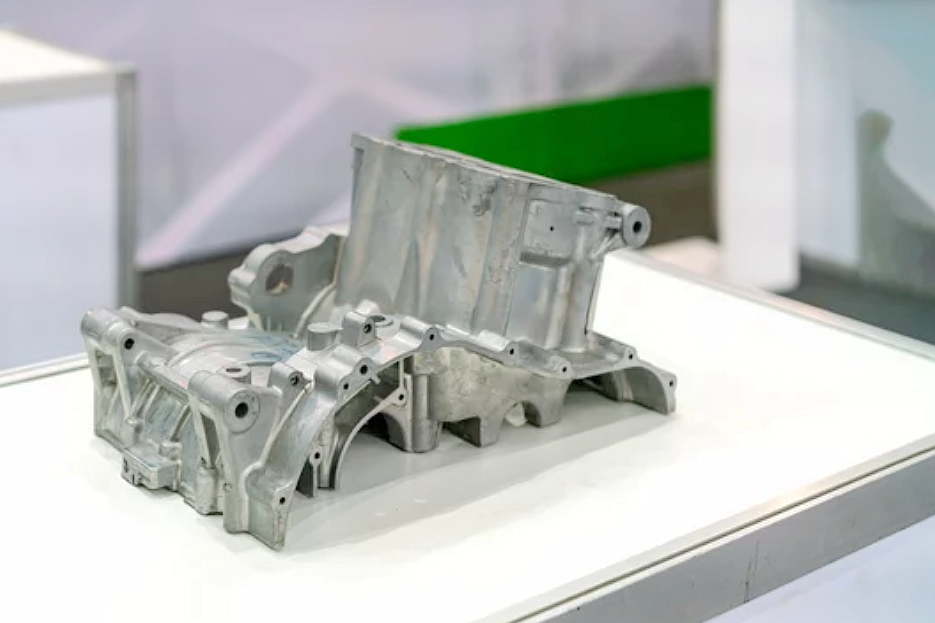

In the computer and accessories sector, our capabilities are equally well recognized. By providing aluminum die casting services for Aorus computer accessories, we demonstrate our expertise in producing complex structural components, delivering reliable hardware support for high-performance computing devices.

Five Reasons to Choose Neway as Your High-Precision Manufacturing Partner

Choosing Neway means choosing a partner with deep technical expertise and extensive industry experience. We not only provide advanced manufacturing processes and material solutions but, more importantly, fully understand the extreme demands of consumer electronics for quality, precision, and reliability. From initial design consultation to final mass production, our engineering team is involved throughout the process to ensure every stage meets the highest standards. Our robust quality assurance system and well-structured supply chain management ensure customers receive a stable and reliable product supply.

Conclusion: Partner with Neway to Turn Your Consumer Electronics Innovations into Reality

In the rapidly evolving consumer electronics industry, having a reliable and high-precision manufacturing partner is crucial. Leveraging years of industry experience and technical expertise, Neway has become the preferred partner for many globally renowned brands. Whether your product is in the concept phase or approaching mass production, our engineering team is ready to provide professional technical support and manufacturing services, working with you to transform innovative ideas into successful products.