Battery Component Solutions for Advanced Electric Mobility

Precision Battery Components: The Core Pillar of the Electric Mobility Revolution

In today’s rapidly advancing electric mobility landscape, the battery system, as the power core of the entire vehicle, directly determines safety, driving range, and service life. As the engineering team at Neway, we fully understand the critical role of battery component manufacturing in the e-mobility sector. From battery pack structures to thermal management systems, from high-voltage connections to cell support components, every precisely manufactured part is essential to ensuring the reliable operation of the battery system.

Key Component Manufacturing for Electric Mobility Battery Systems

Battery Pack and Enclosure: The First Line of Defense for Safety and Lightweighting

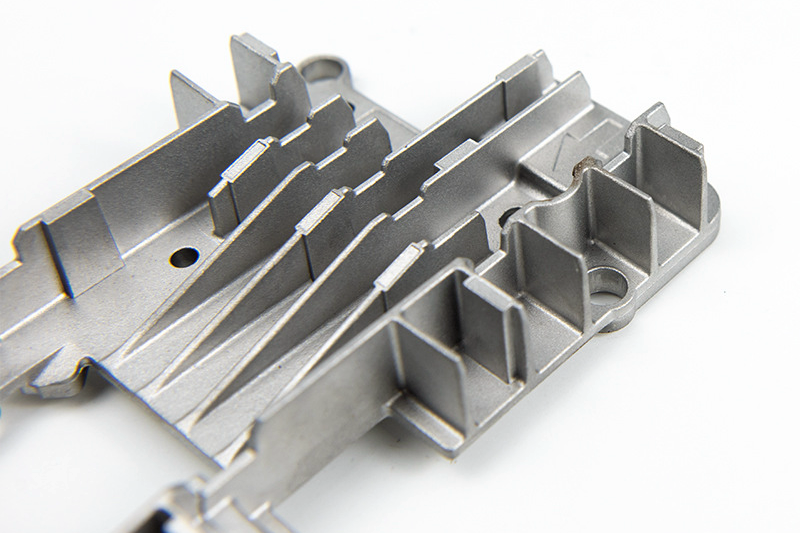

The battery pack enclosure serves as the first protective barrier for battery cells and must strike a delicate balance between lightweight construction and structural strength. Our aluminum die casting technology enables the production of integrated lower battery housings with complex rib structures, achieving optimal weight control while ensuring rigidity. For battery pack frames that require greater design flexibility, we utilize sheet metal fabrication, employing precise laser cutting and bending to create highly sealed battery enclosures. These enclosures not only meet IP67 and above protection ratings but are also validated through rigorous vibration and impact testing.

Busbars and High-Voltage Connectors: Efficient Energy Transmission Channels

Within the battery system, efficient energy transmission relies on precision connection components. We use advanced sheet metal stamping technology to produce high-conductivity copper and aluminum busbars, ensuring stable and efficient current flow. Through precise tooling design and process control, we manufacture complex-shaped connectors with tight tolerances, effectively reducing contact resistance and minimizing energy loss. These critical conductive components establish reliable electrical connections between battery modules and provide a stable power supply for the entire drive system.

Thermal Management Components: Key to Battery Performance and Longevity

Battery thermal management has a direct impact on both performance and the battery's life cycle. Our plastic injection molding services are dedicated to producing cooling plates and thermal management components for battery systems. By using high-performance engineering plastics and precision molding technologies, we manufacture cooling components with complex internal channels that ensure uniform coolant distribution and effective temperature control during operation. These parts offer excellent sealing performance and can withstand exposure to chemicals from coolants and long-term thermal cycling.

BMS Structural Components and Cell Brackets

The protective housings and precision structures for the Battery Management System (BMS) are vital to system reliability. Through our metal injection molding services, we produce BMS shielding housings and connector components with excellent electromagnetic shielding and structural strength. At the same time, precision cell brackets and insulating spacers ensure each cell remains securely positioned within the battery pack, preventing damage or short-circuit risks caused by vibration or displacement.

Surface Treatments to Enhance Battery Component Performance and Durability

Surface treatment processes play a crucial role in the manufacturing of battery components. For aluminum battery housings, we apply anodizing to form a dense oxide layer that significantly improves corrosion and wear resistance. Busbars and high-voltage connectors are treated with specialized electroplating processes to enhance conductivity and oxidation resistance, ensuring long-term reliability of electrical connections. For exposed battery pack structural components, powder coating provides a uniform and durable protective layer that resists environmental corrosion and aging.

Key Material Selection for Battery Components

Lightweight and High-Strength Metal Materials

In terms of metals, cast aluminum materials, with their excellent strength-to-weight ratio, are the preferred choice for battery housings. Through optimized alloy compositions and heat treatment processes, we achieve housing materials that meet diverse strength and durability requirements. For conductive components, we select high-purity copper alloys to ensure outstanding electrical conductivity and mechanical strength. Specialized forming processes also guarantee dimensional stability.

High-Performance Engineering Plastics and Insulation Materials

For applications requiring insulation and chemical resistance, we recommend PEEK, whose exceptional high-temperature performance and mechanical strength make it ideal for battery connectors and high-stress structural parts. For general insulating brackets and protective components, nylon (PA) offers an excellent balance of performance and cost-effectiveness, performing particularly well where higher flame-retardant ratings are required.

Applications of Neway’s Battery Component Solutions in E-Mobility

Electric Passenger Cars and Buses

In the electric mobility sector, we supply key components for battery systems to multiple renowned automotive manufacturers. From passenger cars to large buses, we develop customized battery component solutions based on varying usage scenarios and packaging constraints. These components must not only meet stringent safety standards but also operate reliably under complex road conditions and diverse climate environments.

Electric Two-Wheelers and Micro Vehicles

For more compact electric two-wheelers and micro vehicles, we have developed dedicated battery component solutions. Through highly integrated designs and precision manufacturing, we maximize energy density and safety within limited space. These components reduce overall vehicle weight while maintaining structural integrity, thereby improving driving range and overall efficiency.

Energy Storage Systems and Supporting Infrastructure

In stationary energy storage systems and charging infrastructure, our battery component solutions also play a vital role. Working closely with energy storage system manufacturers, we provide reliable battery rack structures and thermal management components for large-scale storage cabinets, ensuring system stability and safety over long-term charge and discharge cycles.

Advantages of Choosing Neway as Your Battery Component Manufacturing Partner

As experts in battery component manufacturing, Neway is committed to providing comprehensive services from design support to mass production. We operate under a robust quality management system, implementing strict quality control at every stage—from raw material inspection to final product shipment. Our engineering team brings extensive industry experience and can deliver optimized manufacturing solutions tailored to customer requirements. Through continuous technological innovation and process improvement, we ensure every battery component meets the highest standards of safety and performance.

Conclusion: Partner with Neway to Build a Reliable Power Core for Next-Generation E-Mobility

In this era of rapidly growing electric mobility, robust battery component solutions are the key to technological breakthroughs and market success. With deep technical expertise and extensive manufacturing experience, Neway has established itself as a trusted partner for numerous leading companies. We look forward to collaborating with more industry partners to drive innovation in electric mobility technologies and contribute to a sustainable future of transportation.

FAQ

How to lightweight battery enclosures while keeping strength and safety?

Which surface treatments improve busbar conductivity and oxidation resistance?

What are the pros and cons of plastic vs metal thermal management parts?

How does Neway ensure quality consistency and traceability in mass production?

What is the typical development cycle for battery components from prototype to production?