How Metal Injection Molding Revolutionizes Mini Motor Accessories

In the ever-evolving landscape of the automotive industry, a revolution is underway – the rise of E-Mobility. This paradigm shift towards electric vehicles (EVs) has captured the world's imagination, offering a sustainable and eco-friendly alternative to traditional gasoline-powered cars. In this article, we delve deep into the heart of this transformation, focusing on a seemingly small yet incredibly significant aspect: Mini Motor Accessories. These unassuming components play a crucial role in enhancing the efficiency and performance of EVs.

But what makes Mini Motor Accessories genuinely remarkable in this electric revolution? The answer lies in the innovative Metal Injection Molding (MIM) technology. Neway, a pioneering expert in metal injection molding, is at the forefront of this groundbreaking development.

Understanding E-Mobility and Mini Motor Accessories

Rapid Growth of E-Mobility

The E-Mobility market is experiencing explosive growth, mirroring the rise of electric vehicles. The demand for EVs is skyrocketing with a growing awareness of environmental concerns and a desire for cleaner energy sources. Consequently, the importance of Mini Motor Accessories is also on the ascent.

E-Mobility Defined

E-Mobility, or electrified mobility, is a seismic shift in the automotive sector, characterized by the electrification of vehicles. EVs represent the pinnacle of this transformation, offering a cleaner and more sustainable mode of transportation. As governments worldwide intensify efforts to combat climate change and reduce carbon emissions, E-Mobility emerges as a pivotal solution.

The Role of Mini Motor Accessories

Mini Motor Accessories may seem inconspicuous in electric vehicles, but their significance cannot be overstated. These accessories encompass various components, including gear mechanisms, connectors, and motor cores. They are the unsung heroes behind the scenes, ensuring electric motors' seamless and efficient operation.

The Advantages of Metal Injection Molding (MIM)

Unlocking the Power of MIM

Metal Injection Molding (MIM) is a manufacturing process that combines the versatility of plastic injection molding with the precision and strength of traditional metalworking. Its relevance in the E-Mobility sector is nothing short of transformative.

Precision and Cost-Effectiveness

MIM stands out for its unparalleled precision, boasting tolerances as tight as ±0.1 mm. Such precision is invaluable in E-Mobility, where efficiency and performance are paramount. Moreover, MIM's cost-effectiveness, achieved through optimized material usage and reduced waste, is a game-changer for producing complex, high-precision parts.

Achieving Precision with MIM

In the E-Mobility industry, precision is critical. MIM can deliver precision values that meet the most exacting standards. Whether crafting intricate gear teeth for optimal power transmission or creating heat-resistant components for electric drivetrains, MIM consistently achieves precision values that ensure peak performance.

Neway's Expertise in Metal Injection Molding

Leadership in the Field

Neway is a participant and a leader in the Metal Injection Molding arena. We are dedicated to pushing the boundaries of what's possible with MIM technology. Our state-of-the-art facilities house cutting-edge MIM machinery and our team of experts is passionate about delivering excellence.

State-of-the-Art MIM Technology

At Neway, we take pride in our commitment to quality and innovation. Our MIM technology is at the forefront of industry advancements, ensuring we consistently deliver top-notch solutions to our clients.

Certifications and Awards

A range of certifications and awards, a testament to our unwavering dedication to excellence, validates our expertise. These accolades not only signify our achievements but also represent the trust our clients place in us.

Case Studies and Applications

Real-World Impact

To truly appreciate the transformative power of MIM, we turn to real-world examples. Mini Motor Accessories produced using MIM exemplify precision and durability. From intricate gear mechanisms that optimize power transmission to heat-resistant components that withstand the rigors of high-speed electric motors, MIM consistently enhances performance.

Neway's Contribution

Neway actively collaborates with clients in the E-Mobility sector, working closely on designs and material selections to create Mini Motor Accessories that exceed expectations. Our MIM technology elevates these accessories, extending their operational life and enhancing performance.

Benefits of the E-Mobility Industry

Driving E-Mobility Forward

MIM isn't merely a manufacturing process; it's a driving force behind the advancement of E-Mobility. Its precision and material versatility contribute to creating lighter, more efficient EVs.

Mini Motor Accessories' Advantage

Mini Motor Accessories benefit immensely from MIM. For instance, engineered with precision, MIM-made motor cores lead to greater motor efficiency, increasing range and decreasing energy consumption. Connectors produced through MIM ensure robust electrical connections, minimizing energy loss and ensuring reliable power transfer.

Efficiency and Sustainability

The efficiency and sustainability of MIM align perfectly with the goals of the E-Mobility sector, driving progress towards cleaner and more sustainable transportation solutions.

More E-Mobility MIM Applications

Reshaping the Industry

Beyond Mini Motor Accessories, MIM is reshaping the entire E-Mobility industry. Battery components, charging connectors, and many other critical parts within EVs benefit from MIM's adaptability.

Exploring MIM Solutions

Explore the diverse spectrum of MIM applications in E-Mobility, and you'll discover how this technology is revolutionizing the sector. Neway invites you to delve into our extensive solutions tailored to meet the evolving needs of the E-Mobility landscape.

Your Partner in MIM

Are you ready to embrace the future of cleaner, more efficient E-Mobility? Contact Neway today and experience the transformative power of Metal Injection Molding. Together, we can create groundbreaking, high-precision Mini Motor Accessories that will shape the future of transportation.

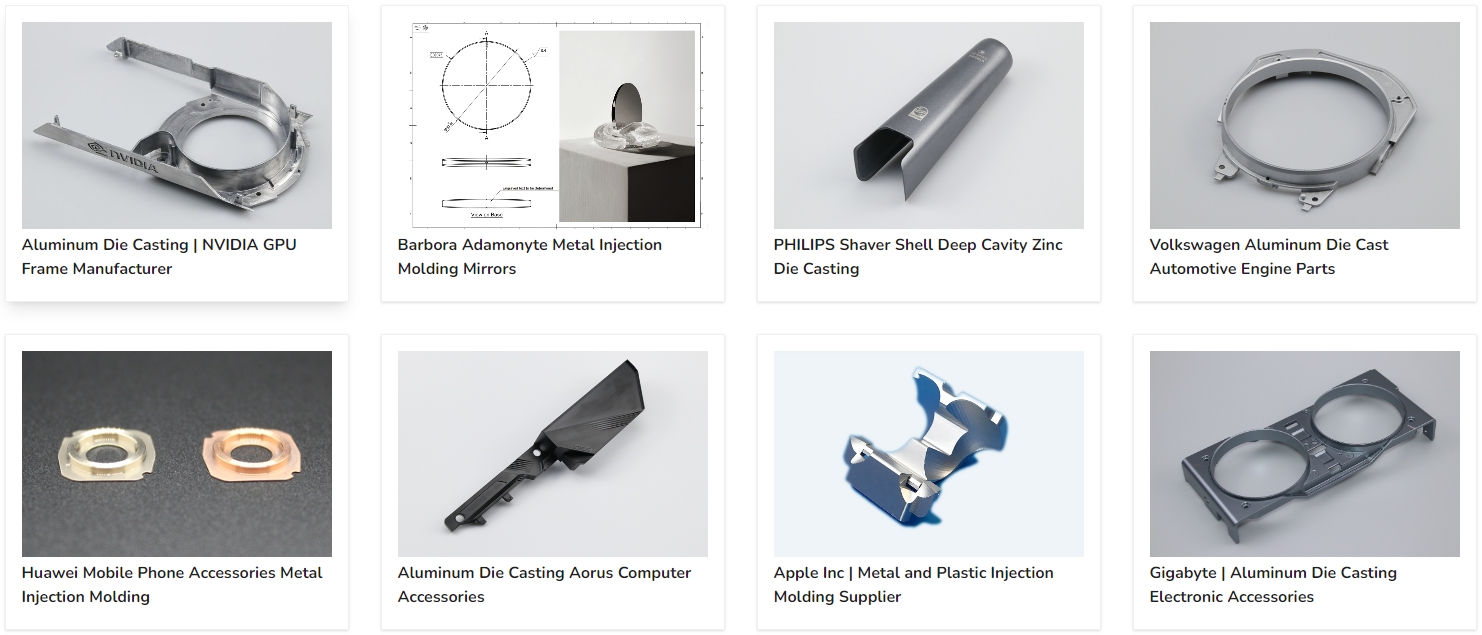

Brand Case Study

Neway has served many world-renowned companies, using its strong manufacturing capabilities and complete quality control system to provide further market competitiveness and quality assurance for major brands.