Accelerated E-Mobility Prototyping & Component Verification

Accelerated E-Mobility Prototyping and Component Verification: The Key to Gaining First-Mover Advantage

In today’s rapidly evolving e-mobility landscape, product development speed has become a decisive factor in business success. As the engineering team at Neway, we fully understand that rapid prototyping and rigorous component verification are core to ensuring product quality and shortening time-to-market. From concept design to mass production readiness, we provide integrated solutions that help our customers gain a competitive edge in an increasingly demanding market.

Rapid Prototyping Strategies for E-Mobility

Multi-Process Collaborative Prototyping Routes

In the e-mobility sector, various components necessitate distinct prototyping approaches. We adopt a multi-process collaborative strategy to select the most suitable technical route for each project. For plastic parts that require quick verification of appearance and assembly, our 3D printing prototyping services can deliver high-precision samples within 24 to 48 hours. For metal components that demand higher mechanical performance and dimensional accuracy, our CNC machining prototyping services can produce functional prototypes with performance close to final production parts. This flexible combination of technologies ensures that customers receive the most suitable samples for validation in the shortest possible time.

Key Subsystem Prototypes: From Battery Packs to Drive Units

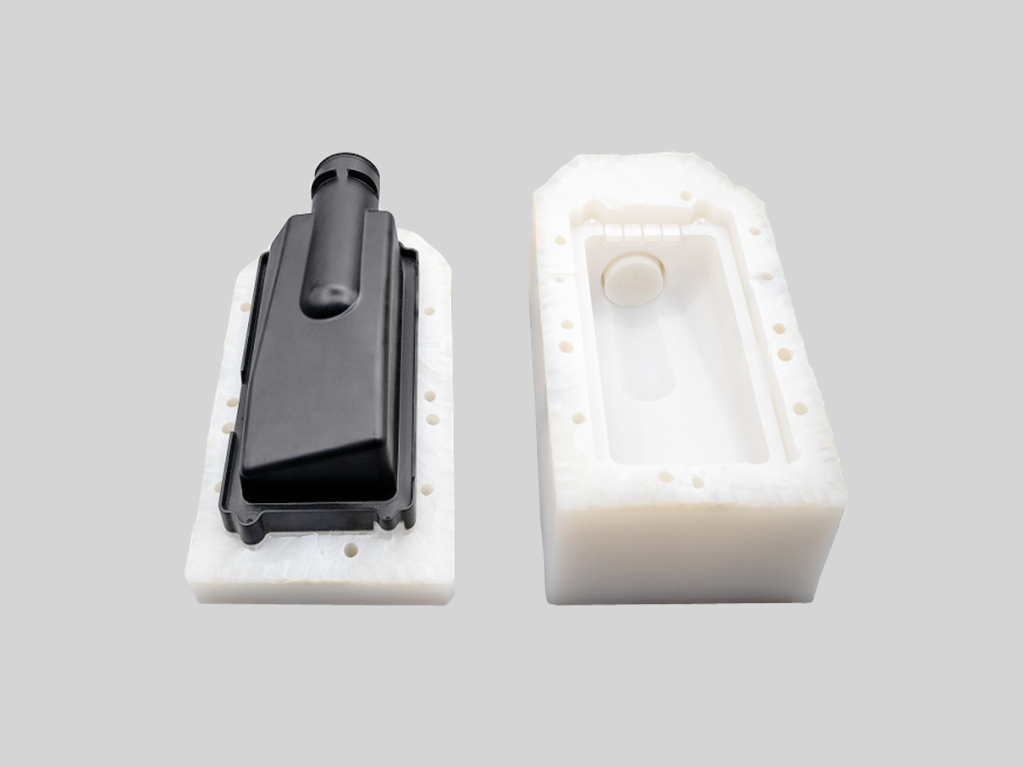

Core subsystems in electric vehicles pose special challenges for prototyping. Through our rapid molding prototyping services, we provide small-batch injection-molded parts for BMS housings, charging interfaces, and related components, supporting early functional testing and user research. At the same time, by utilizing our sheet metal fabrication services, we manufacture battery pack structures, protection brackets, and other metal components to validate system compatibility and reliability from the prototype stage onwards. This comprehensive prototyping capability enables customers to fully optimize system designs before entering mass production.

Design for Manufacturing and Component Optimization

During the prototyping phase, our engineering team conducts manufacturing feasibility analyses in parallel, identifying and resolving potential production issues early. By optimizing part structures, adjusting tolerances, and refining assembly concepts, we ensure each design is highly manufacturable. This forward-looking approach not only increases the success rate of prototyping but also lays a solid foundation for mass production, effectively avoiding cost overruns and schedule delays caused by late-stage design defects.

Rigorous Component Verification and Testing Systems

Structural and Durability Testing

We have established a comprehensive testing laboratory to conduct full structural and durability validations on prototype components. By simulating real-world operating conditions—including vibration, mechanical shock, and fatigue tests—we accurately assess component reliability throughout the vehicle's full lifecycle. For safety-critical components such as battery pack structures and motor mounts, we implement testing procedures that are even stricter than industry standards to ensure stable performance under extreme conditions.

Environmental Resistance and Sealing Tests

Electric vehicles operate in complex and changing environments, which place higher demands on environmental adaptability. Our environmental testing includes thermal cycling, damp heat aging, and salt spray corrosion tests to thoroughly validate material stability and service life. For components requiring protection—such as battery packs and drive motors—we conduct sealing tests in accordance with IP67 and above, ensuring reliable operation even under harsh environmental conditions.

Electrical and Signal Integrity Verification

In electrical system verification, we focus on the reliability of contacts, insulation performance, and electromagnetic compatibility of high-voltage connectors. Using specialized test equipment, we simulate electrical loads during vehicle operation to validate the long-term stability of connectors. Additionally, we perform comprehensive signal integrity testing on sensor harnesses to ensure accurate and reliable data transmission.

Key Material Selection for Prototyping and Validation

Alignment Between Prototype Materials and Production Materials

During prototyping, we place special emphasis on material choices that reflect final production conditions. For metal components, we prioritize aluminum alloys that are consistent with our mass production plans to ensure that their mechanical and thermal properties are representative. For plastic components, we recommend engineering plastics such as polycarbonate (PC), which not only offer excellent processability but also provide mechanical strength and environmental resistance similar to production-grade materials.

Prototyping with High-Performance Materials

With the advancement of e-mobility technologies, demand for high-performance materials continues to grow. At the prototype stage, we can already support special engineering plastics such as PEEK, whose outstanding high-temperature resistance makes it ideal for motor insulation components, charging interfaces, and similar applications. For components requiring higher strength and corrosion resistance, we use stainless steel to manufacture functional prototypes, ensuring that test results are accurate and representative.

How Neway Solutions Accelerate E-Mobility Projects

Shortening Design Iteration Cycles

Through our rapid prototyping services, customers can shorten traditional design iteration cycles from weeks to just days. This efficiency boost allows engineering teams to complete more rounds of design optimization in less time, significantly accelerating product development. In one project, we assisted a customer in completing three rounds of battery pack structural design iterations within two weeks, ultimately achieving a 15% weight reduction while increasing structural stiffness by 20%.

Reducing Development and Market Risks

In the e-mobility sector, product reliability is directly tied to brand reputation and user safety. Through rigorous verification testing, we help customers identify and resolve potential issues in the early stages of development. For example, in our collaboration on Volkswagen aluminum die-cast engine components, our comprehensive testing helped the customer avoid the risk of large-scale recalls that could have been triggered by material defects.

Success Story: Rapid Passage from Concept to Validation

A recent flagship project involved developing a battery pack thermal management system for a well-known EV manufacturer. From receiving the concept design to completing all validation tests, the entire process took only four weeks. In the first week, we delivered functional samples for initial testing via rapid prototyping; in the following three weeks, we completed multiple design optimizations and full validation. This allowed the customer to meet project milestones two months ahead of schedule, securing a crucial time advantage for product launch.

Choose Neway to Fast-Forward Your E-Mobility Innovation

At Neway, we understand the critical importance of time in e-mobility programs. Our strengths lie not only in state-of-the-art equipment and robust process systems, but also in our deep industry experience and systematic engineering capabilities. From material selection and process optimization to prototyping and validation testing, our professional team works closely with customers to ensure optimal performance at every stage. With strict quality control and disciplined project management, we ensure each project is delivered on schedule and meets the highest quality standards.

Conclusion: Driving the Future of E-Mobility with Speed and Reliability

In today’s fast-moving e-mobility environment, rapid prototyping and rigorous component verification have become essential to maintaining competitiveness. With comprehensive technical capabilities and extensive project experience, Neway is dedicated to helping customers accelerate innovation and ensure product reliability. We believe that through our professional support, customers can more quickly transform innovative ideas into successful products and jointly advance the development of e-mobility technologies.

FAQ

What is the shortest lead time to a fully tested drivetrain prototype?

How to simulate real EV operating conditions during prototype validation?

What validation needs apply to high-voltage safety components?

How do Neway’s standards align with ISO and regulatory requirements?

If a test fails, can Neway support quick redesign and re-prototyping?