MIM-CoCrW

MIM-CoCrW MIM Parts Manufacturer

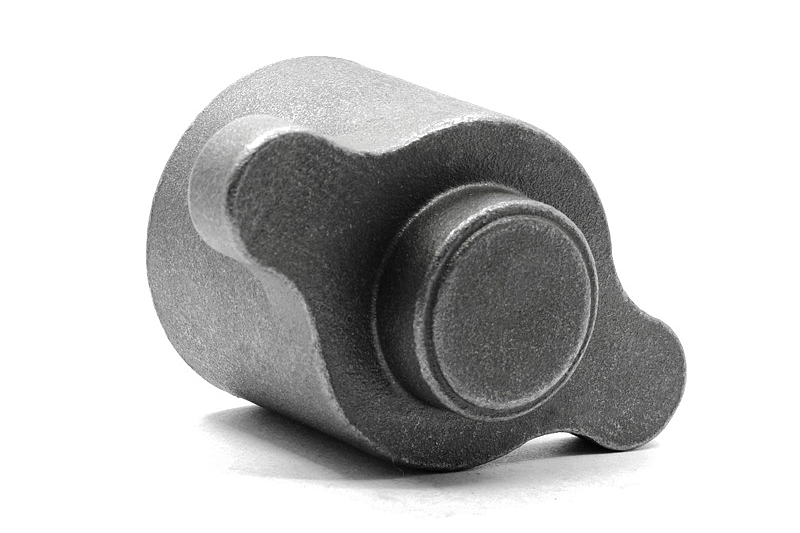

CoCrW MIM Parts in Oil & Gas Equipment

CoCrW MIM parts are components made using the Metal Injection Molding (MIM) process from a cobalt-based alloy known as CoCrW. These parts offer exceptional corrosion resistance, high strength, and precision, making them ideal for various oil and gas equipment applications.

Typical applications of CoCrW MIM parts in oil and gas equipment:

Valve Components

Downhole Tools

Pump Components

Connectors and Fittings

Instrumentation

Typical Properties of MIM-CoCrW Cobalt Alloy

MIM-CoCrW Chemical Composition

Cobalt (Co) | Chromium (Cr) | Tungsten (W) | Nickel (Ni) | Iron (Fe) | Molybdenum (Mo) | Carbon (C) | Silicon (Si) | Phosphorus (P) | Sulfur (S) |

|---|---|---|---|---|---|---|---|---|---|

52.0% | 28.0% | 13.0% | 3.0% | 2.5% | 0.5% | 0.02% | 0.02% | 0.01% | 0.01% |

MIM-CoCrW Physics and Mechanical Properties

Status | Tensile Strength (MPa) | Yield Strength (MPa) | Impact Strength (J) | Hardness (HRC) | Young's Modulus (GPa) | Poisson's Ratio | Elongation (%) | Density (g/cm³) |

|---|---|---|---|---|---|---|---|---|

As Sintered | 750 | 650 | 12 | 40 | 190 | 0.3 | 6 | 8.4 |

MIM-CoCrW Injection Molded Applications

MIM-CoCrW injection-molded Valve Components.

MIM-CoCrW injection-molded valve components offer many benefits that make them indispensable in critical valve applications. Firstly, these components exhibit exceptional resistance to wear, corrosion, and high temperatures. In valve systems where abrasive fluids, aggressive chemicals, or elevated temperatures are expected, CoCrW components maintain their integrity, ensuring long-term reliability and reduced maintenance costs.

Secondly, CoCrW valve components are known for their precision and complex geometries achievable through injection molding. This precision ensures a tight and consistent fit within the valve assembly, minimizing the risk of leaks and optimizing flow control. Moreover, CoCrW's mechanical strength allows for creation of robust and durable valve components that can withstand the demanding conditions often encountered in industrial processes.

MIM-CoCrW Injection molding Instrumentation Fittings

MIM-CoCrW injection-molded instrumentation fittings offer a range of highly advantageous benefits in demanding industrial and scientific applications. First and foremost, these fittings are prized for their exceptional resistance to corrosion and wear. In industries where exposure to aggressive chemicals, high pressures, and extreme temperatures is every day, CoCrW fittings excel. Their ability to withstand harsh environments ensures the long-term reliability of instrumentation systems, reducing maintenance costs and downtime.

Secondly, the precision achievable through the injection molding process allows for intricate and complex geometries in CoCrW instrumentation fittings. This precision ensures a secure and leak-free connection within instrumentation setups, minimizing the risk of inaccuracies or contamination.

MIM-CoCrW MIM sintering Connectors and Fittings

MIM-CoCrW connectors and fittings are known for their exceptional corrosion resistance, making them ideal for applications in harsh environments. Whether used in chemical processing, oil and gas exploration, or aerospace, CoCrW connectors and fittings withstand exposure to corrosive substances. Their corrosion resistance prevents degradation, leaks, and system failures, improving industrial processes' safety and efficiency.

MIM-CoCrW connectors and fittings provide outstanding mechanical strength and durability. The MIM process allows for precise manufacturing of complex geometries, ensuring a secure and leak-free connection in critical systems. Additionally, the high tensile strength and wear resistance make CoCrW components capable of withstanding the rigors of high-pressure and high-stress applications.

MIM-CoCrW Metal Injected Pump Components

MIM-CoCrW metal-injected pump components excel in corrosion resistance, making them invaluable in environments with aggressive fluids or chemicals. CoCrW pump components withstand corrosion and maintain their structural integrity over extended periods, whether in chemical processing, oil and gas extraction, or water treatment. This exceptional corrosion resistance significantly reduces maintenance requirements and downtime, contributing to cost-effectiveness and uninterrupted operations.

MIM-CoCrW pump components possess superior wear resistance. In pumps where abrasive substances are present, such as slurry or wastewater pumps, CoCrW's durability ensures extended service life and minimized wear and tear. The precision achievable through metal injection molding ensures tight tolerances and intricate geometries, promoting efficient fluid transfer and reduced energy consumption. CoCrW's mechanical strength also allows these components to withstand the high pressures and mechanical stresses associated with pumping applications.

Industries We Cover In Metal Injection Molding

As an experienced metal injection molding manufacturer, Neway is involved in many industries and trusted by big brand companies.

The industries we cover include: