MIM Ti-6Al-7Nb (Grade 26)

Ti-6Al-7Nb (Grade 26) Titanium Injection Molding

Ti-6Al-7Nb (Grade 26) Injection Molded Parts

Ti-6Al-7Nb (Grade 26) materials exhibit distinctive properties when employed in metal injection molding (MIM) processes. Notably, this alloy stands out due to its exceptional biocompatibility, making it a preferred choice for medical and dental applications. It is non-toxic, resists corrosion in physiological environments, and allows bone integration in medical implants. Furthermore, Ti-6Al-7Nb offers excellent fatigue and fracture resistance, ensuring the longevity and reliability of implanted devices.

Additionally, Ti-6Al-7Nb (Grade 26) maintains its structural integrity at elevated temperatures, further expanding its applications. It can be used in aerospace for lightweight structural components requiring heat resistance. This alloy's unique combination of biocompatibility, fatigue resistance, and high-temperature stability positions it as a versatile material in the MIM realm, serving both medical and aerospace industries with precision and reliability.

Typical Properties Of MIM Ti-6Al-7Nb (Grade 26)

Chemical Composition Of MIM Ti-6Al-7Nb (Grade 26)

Element | Titanium (Ti) | Aluminum (Al) | Vanadium (V) | Niobium (Nb) |

|---|---|---|---|---|

Composition (%) | 88.0% | 6.0% | 7.0% | 1.0% |

MIM Ti-6Al-7Nb (Grade 26) Physics and Mechanical Properties

Property | Status | Tensile Strength (MPa) | Yield Strength (MPa) | Impact Strength (J) | Hardness (HRC) | Young's Modulus (GPa) | Poisson's Ratio | Elongation (%) | Density (g/cm³) |

|---|---|---|---|---|---|---|---|---|---|

Typical Values | As Sintered | 650 | 570 | 30 | 25 | 85 | 0.30 | 15 | 4.60 |

Applications and Benefits of Ti-6Al-4V (Grade 5) Injection Molding Parts

Ti-6Al-7Nb (Grade 26) Injection Molded Medical Implants

One of the primary applications of Ti-6Al-7Nb (Grade 26) injection molded parts is in orthopedic implants, especially for load-bearing joints like the hip and knee. These implants require materials that can withstand the mechanical stresses of daily movement while being biocompatible to the human body. Ti-6Al-7Nb's unique composition provides excellent corrosion resistance in physiological environments, ensuring the longevity of implants. Its strength and low Young's Modulus combination also minimize stress shielding, a common issue with implant materials, promoting better long-term patient outcomes.

Furthermore, dental implants are another significant application area. Ti-6Al-7Nb's biocompatibility and corrosion resistance make it an ideal choice for dental implants. These implants fuse with the jawbone, providing a stable foundation for dental prosthetics, such as crowns and bridges. The material's durability and compatibility with the oral environment ensure a comfortable, long-lasting patient solution.

Ti-6Al-7Nb (Grade 26) Injection Molded Dental Implants

Ti-6Al-7Nb (Grade 26) injection molded dental implants address the critical need for materials that can withstand the demanding oral environment while ensuring patient comfort and longevity. Dental implants are widely used to replace missing teeth, and Ti-6Al-7Nb is an excellent choice due to its exceptional biocompatibility and corrosion resistance.

Moreover, Ti-6Al-7Nb's mechanical properties are well-suited for dental applications. It offers a blend of strength and low Young's Modulus, which minimizes stress on the surrounding bone, reducing the risk of stress shielding. This feature ensures that patients receive durable dental implants and experience improved comfort and long-term oral health.

Ti-6Al-7Nb (Grade 26) Injection Molded Surgical Instruments

Ti-6Al-7Nb (Grade 26) injection molded surgical instrument parts, contributing to medical technology advancement and improving surgical procedures' precision and reliability. One of the primary applications is in the production of orthopedic surgical instruments. The alloy's exceptional biocompatibility and resistance to corrosion make it ideal for tools used in joint replacement surgeries. Surgical instruments made from Ti-6Al-7Nb are durable, ensuring they can withstand repeated sterilization processes and maintain their integrity during critical procedures.

Additionally, Ti-6Al-7Nb parts are used in various other surgical instruments, including those used in dental and neurosurgery. These instruments benefit from the material's strength and lightweight properties, allowing surgeons to work with precision and reducing fatigue during lengthy procedures. Furthermore, the biocompatibility of Ti-6Al-7Nb ensures that surgical instruments are safe for use within the human body.

Ti-6Al-7Nb (Grade 26) Injection Molded UAV Parts

Ti-6Al-7Nb (Grade 26) injection molded parts find valuable applications in unmanned aerial vehicles (UAVs), also known as drones. These applications leverage the alloy's unique combination of properties to enhance the performance and reliability of UAVs. One primary use is in drone frames and structural components. The lightweight yet robust nature of Ti-6Al-7Nb makes it an ideal material for manufacturing frames, ensuring durability while minimizing overall weight.

Furthermore, Ti-6Al-7Nb components are employed in UAV propulsion systems. These parts, such as motor mounts and propeller hubs, benefit from the alloy's strength and resistance to fatigue. They withstand the high-speed rotations and stresses of drone propulsion, ensuring UAVs' efficient and reliable operation.

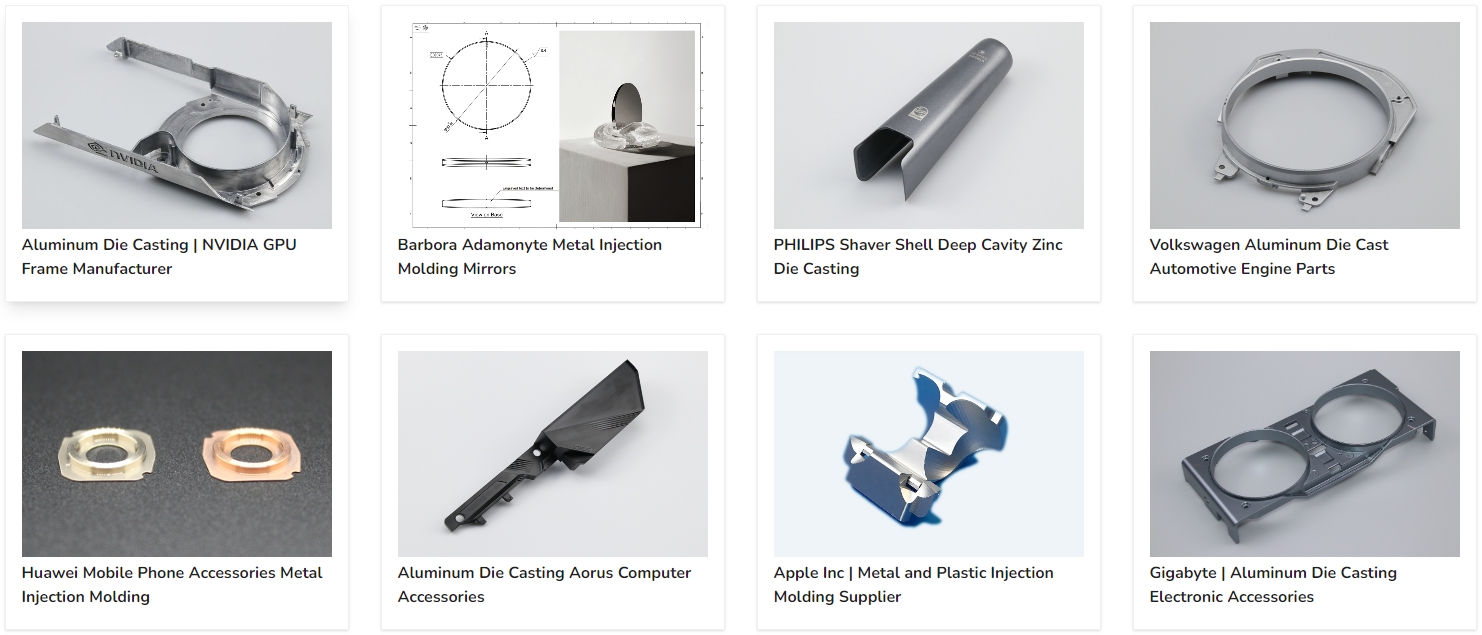

Industry Solution Case Study

Custom parts manufacturing is crucial across diverse industries, and Neway excels in meeting their unique demands. Neway mainly provides customized parts in Aerospace, Medical Devices, Automotive, Telecommunication, Consumer Electronics, Lighting, E-Mobility, Power Tools, Energy, and Locking System Parts Manufacturing. Neway's precision and versatility make it a top choice for custom parts manufacturing across these industries, aligning seamlessly with their specific needs.

MIM FAQs

1. What is metal injection molding used for?

2. What are the factors affecting the tolerance of MIM parts?

3. Which materials are suitable for metal injection molding?

4. What Is The Shrinkage of Metal Injection Molding?

5. 10 Reasons Why MIM Metal Powders Are More Expensive Than Common Bulk Metal Materials?

6. What Are The Applications of Thin-Walled MIM Parts Across Industries?