MIM Ti-3Al-2.5V (Grade 9)

Ti-3Al-2.5V (Grade 9) Titanium Injection Moulding

Ti-3Al-2.5V (Grade 9) Injection Moulded Parts

Ti-3Al-2.5V (Grade 9) materials demonstrate distinctive properties when utilized in metal injection molding (MIM) processes. This alloy is renowned for its exceptional combination of high strength and low density, making it particularly advantageous for weight-sensitive applications. Its high tensile and yield strength and excellent corrosion resistance ensure that components produced with Grade 9 titanium maintain their structural integrity in harsh environments.

Furthermore, Grade 9 titanium exhibits superb biocompatibility, making it a preferred choice for medical and dental applications. It can be used to manufacture implants and surgical instruments due to its non-toxic nature and resistance to corrosion in physiological environments. The alloy's ability to withstand extreme temperatures also opens up opportunities in industries like petrochemical processing. In summary, Ti-3Al-2.5V (Grade 9) materials offer a unique blend of strength, lightweight characteristics, corrosion resistance, and biocompatibility, making them versatile and highly valuable in MIM applications across multiple industries.

Typical Properties Of MIM Ti-3Al-2.5V (Grade 9)

Chemical Composition Of MIM Ti-3Al-2.5V (Grade 9)

Element | Titanium (Ti) | Aluminum (Al) | Vanadium (V) |

|---|---|---|---|

Composition (%) | 90.0% | 3.0% | 2.5% |

MIM Ti-3Al-2.5V (Grade 9) Physics and Mechanical Properties

Property | Status | Tensile Strength (MPa) | Yield Strength (MPa) | Impact Strength (J) | Hardness (HRC) | Young's Modulus (GPa) | Poisson's Ratio | Elongation (%) | Density (g/cm³) |

|---|---|---|---|---|---|---|---|---|---|

Typical Values | As Sintered | 620 | 480 | 80 | 15 | 115 | 0.34 | 20 | 4.48 |

Applications and Benefits of Ti-3Al-2.5V (Grade 9) Injection Moulded Parts

Ti-3Al-2.5V (Grade 9) Injection Moulded Aerospace Structures Parts

Ti-3Al-2.5V (Grade 9) injection-molded parts find crucial applications in constructing aircraft components. The alloy's high tensile, yield strength and low density make it an ideal material for manufacturing critical parts such as landing gear components, structural frames, and engine mounts. The lightweight nature of Grade 9 titanium contributes to improved fuel efficiency and overall aircraft performance, while its strength ensures the structural integrity of these components during demanding flight conditions.

Moreover, Ti-3Al-2.5V (Grade 9) is employed in spacecraft and satellite structures. The material's resistance to extreme temperatures and vacuum conditions in space makes it invaluable for constructing satellite frames, propulsion system components, and structural elements in spacecraft. Its corrosion resistance is also vital for prolonged missions in the harsh space environment.

Ti-3Al-2.5V (Grade 9) Injection Moulded Marine Equipment Parts

Ti-3Al-2.5V (Grade 9) injection-molded parts find essential applications in the marine equipment industry, where their unique properties contribute to the durability and performance of various components. One significant use is in the manufacturing of marine propellers and shafts. The alloy's exceptional corrosion resistance is crucial in preventing degradation due to constant exposure to saltwater. Marine vessels, from ships to yachts, rely on these components for efficient propulsion, and Grade 9 titanium ensures their longevity and reliability.

Additionally, Ti-3Al-2.5V (Grade 9) produces underwater instrumentation and sensors. These parts require materials that can withstand the corrosive effects of seawater while maintaining precision and functionality. The alloy's resistance to both corrosion and biofouling makes it a preferred choice for these critical components, ensuring accurate data collection and communication in marine environments.

Ti-3Al-2.5V (Grade 9) Injection Moulded Chemical Processing Device

Ti-3Al-2.5V (Grade 9) injection-molded parts are instrumental in the chemical processing industry. One prominent use is in the manufacturing of chemical reactors and vessels. These components are exposed to aggressive chemicals and high-temperature reactions. The exceptional corrosion resistance and heat tolerance of Grade 9 titanium ensure that these vessels maintain their structural integrity and durability, preventing leaks and ensuring the safety and efficiency of chemical processes.

Moreover, Grade 9 titanium is employed in producing chemical valves and fittings. These critical components require materials that can withstand the corrosive effects of various chemicals, acids, and bases. The alloy's resistance to corrosion ensures that these parts remain durable and reliable over time, contributing to the overall efficiency and safety of chemical processing operations.

Ti-3Al-2.5V (Grade 9) Injection Moulded UVA Parts

Ti-3Al-2.5V (Grade 9) injection-molded parts have diverse applications in the uncrewed aerial vehicle (UAV) industry, where their unique properties contribute to the performance and reliability of UAVs, commonly known as drones. One significant application is in the manufacturing of drone frames and structural components. The alloy's high strength-to-weight ratio and exceptional corrosion resistance make it an ideal material for constructing lightweight yet durable frames.

Furthermore, Ti-3Al-2.5V (Grade 9) components are utilized in UAV propulsion systems. Parts such as motor mounts and propeller hubs benefit from the alloy's strength and resistance to fatigue. They can withstand the high-speed rotations and stresses of drone propulsion, ensuring UAVs' efficient and reliable operation.

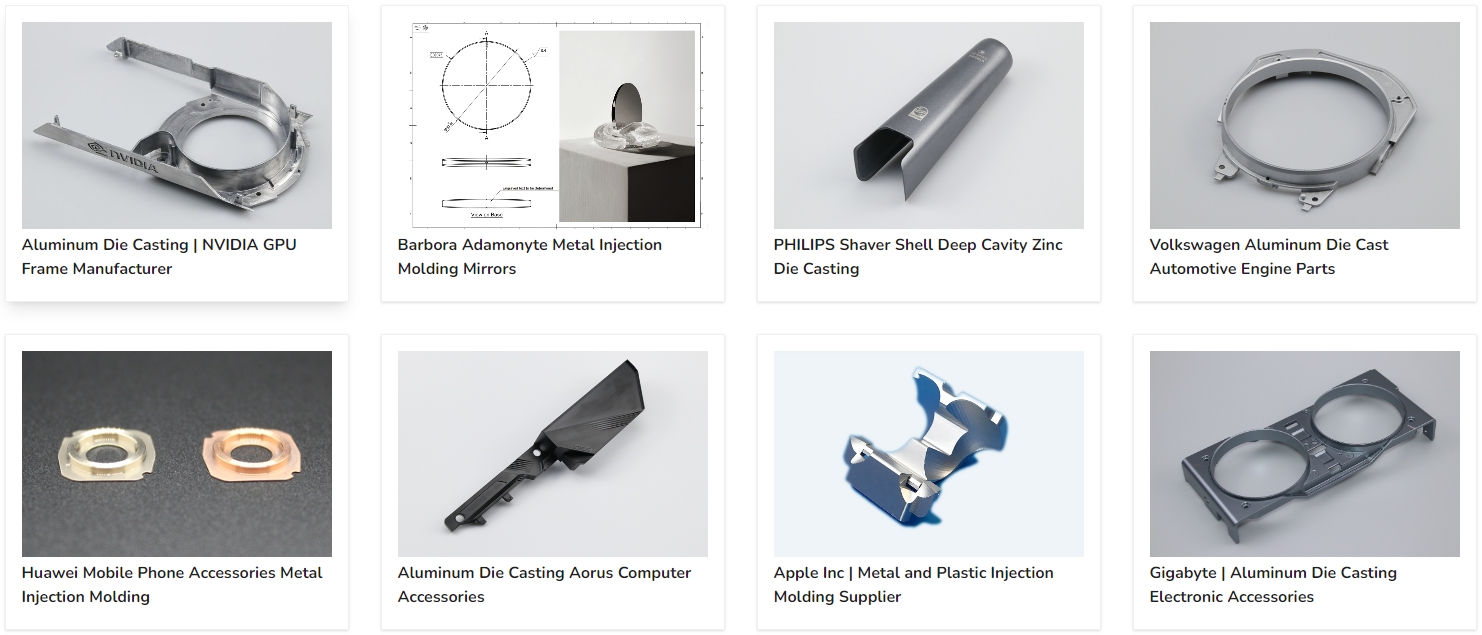

Industry Solution Case Study

Custom parts manufacturing is crucial across diverse industries, and Neway excels in meeting their unique demands. Neway mainly provides customized parts in Aerospace, Medical Devices, Automotive, Telecommunication, Consumer Electronics, Lighting, E-Mobility, Power Tools, Energy, and Locking System Parts Manufacturing. Neway's precision and versatility make it a top choice for custom parts manufacturing across these industries, aligning seamlessly with their specific needs.

MIM FAQs

1. What is metal injection molding used for?

2. What are the factors affecting the tolerance of MIM parts?

3. Which materials are suitable for metal injection molding?

4. What Is The Shrinkage of Metal Injection Molding?

5. 10 Reasons Why MIM Metal Powders Are More Expensive Than Common Bulk Metal Materials?

6. What Are The Applications of Thin-Walled MIM Parts Across Industries?