MIM W-Ni-Fe

Tungsten Alloy MIM W-Ni-Fe Injection Molding

MIM W-Ni-Fe Injection Molding Electronics Industry Components

MIM W-Ni-Fe (Tungsten-Nickel-Iron) components in electronics offer high density and magnetic properties. Typical applications include:

Electrical Contacts: Ensuring reliable conductivity in various electronic devices.

Radiation Shielding: Protecting sensitive electronic equipment from radiation.

Connector Pins: Precision connectors for signal transmission.

Sensor Housings: Housing components for electronic sensors.

X-ray Device Components: Ensuring precision in medical and industrial X-ray equipment.

Typical Properties of MIM W-Ni-Fe

MIM W-Ni-Fe Chemical Composition

Element | Tungsten (W) | Nickel (Ni) | Iron (Fe) |

|---|---|---|---|

Composition (%) | 88.0 | 7.0 | 5.0 |

MIM W-Ni-Fe Physics and Mechanical Properties

Property | Tensile Strength (MPa) | Yield Strength (MPa) | Impact Strength (J/cm²) | Hardness (HRC) | Young's Modulus (GPa) | Poisson's Ratio | Elongation (%) | Density (g/cm³) |

|---|---|---|---|---|---|---|---|---|

Typical Values | 800 | 600 | 2.5 | 30 | 320 | 0.28 | 6 | 17.5 |

MIM W-Ni-Fe Injection Molding Applications

MIM W-Ni-Fe Injection Molding Electrical Contacts

MIM W-Ni-Fe (Tungsten-Nickel-Iron) electrical contacts are precision components extensively used in the electronics industry. These contacts are renowned for their exceptional electrical conductivity, high density, and reliability. Their popularity arises from their ability to ensure efficient current flow and signal transmission, which is crucial for electronic devices. Due to the specific composition of tungsten, nickel, and iron, these contacts exhibit low resistivity, making them ideal for connectors, switches, and electrical components where minimal energy loss is paramount.

Furthermore, MIM W-Ni-Fe electrical contacts are favored for their robustness, longevity, and resistance to wear and corrosion. These qualities align perfectly with the demanding requirements of the electronics sector, ensuring stable and enduring connections in devices such as smartphones, computers, and aerospace equipment.

MIM W-Ni-Fe Injection Molding Radiation Shieldings

MIM W-Ni-Fe (Tungsten-Nickel-Iron) radiation shielding components are vital in the electronics industry due to their exceptional ability to protect sensitive electronic equipment from harmful radiation. These components effectively leverage tungsten's high density and radiation-absorbing properties to shield devices from X-rays and other ionizing radiation. Their popularity in the electronics sector stems from their capacity to ensure the integrity and functionality of electronic devices, preventing radiation-induced damage that could compromise performance or pose health risks to users.

The MIM W-Ni-Fe radiation shielding's precision and reliability make it indispensable in medical and dental equipment, such as X-ray machines and nuclear industry applications. Its robust composition guarantees superior radiation absorption and ensures longevity and resistance to wear, contributing to the safety and longevity of electronics in critical industries.

MIM W-Ni-Fe Injection Molding Connector Pins

MIM W-Ni-Fe (Tungsten-Nickel-Iron) connector pins are indispensable components in the electronics industry and are known for their reliability and conductivity. These precision-crafted pins are favored for their exceptional electrical conductivity, low resistivity, and high-density properties. They excel in maintaining stable and efficient electrical connections within electronic devices, ensuring minimal energy loss during signal transmission.

The MIM W-Ni-Fe connector pins are highly durable and resistant to wear and corrosion, making them ideal for connectors in various electronic applications. Their robust construction ensures long-lasting and secure connections in smartphones, computers, and aerospace equipment.

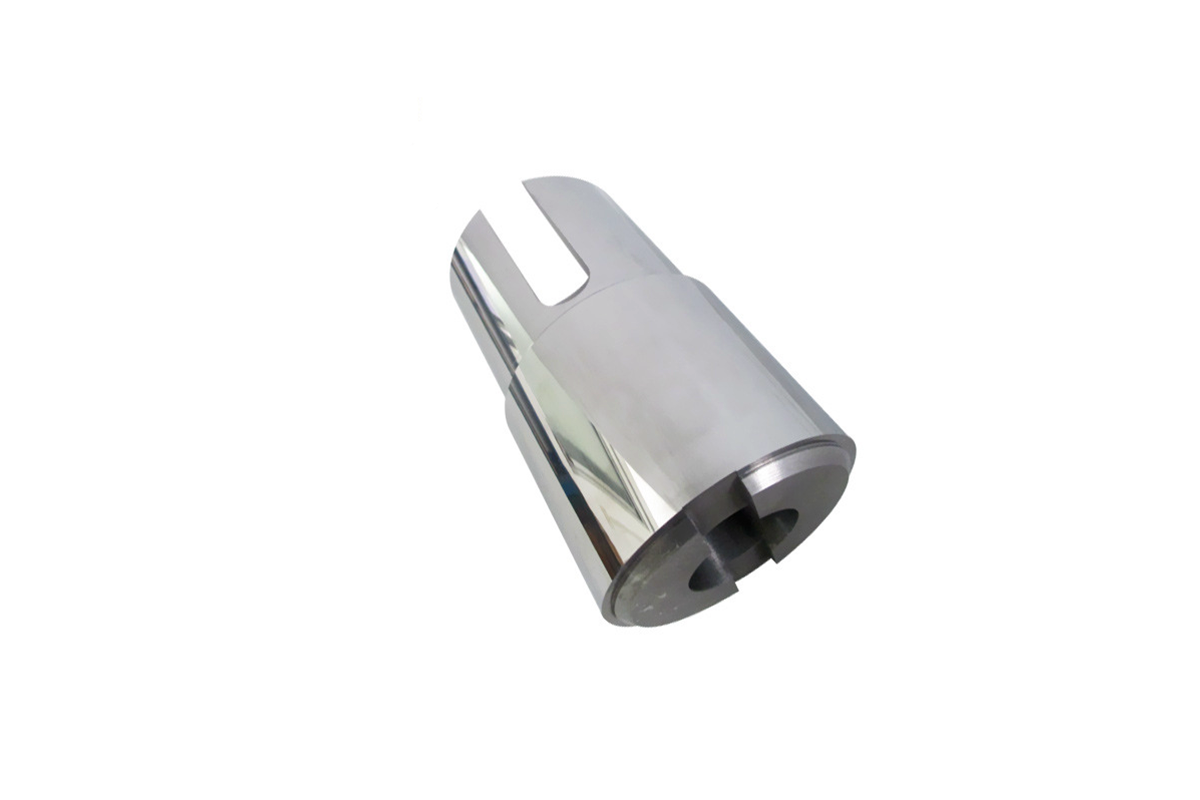

MIM W-Ni-Fe Injection Molding Sensor Housings

MIM W-Ni-Fe (Tungsten-Nickel-Iron) sensor housings are critical components in the electronics industry, prized for their unique combination of properties. These housings provide robust protection for sensitive sensors, shielding them from environmental factors and electromagnetic interference. Their popularity in electronics stems from their exceptional durability, resistance to wear, and high-density characteristics, ensuring that sensors remain functional in challenging conditions.

MIM W-Ni-Fe sensor housings are renowned for maintaining sensor precision by minimizing signal interference. It is especially crucial in aerospace, automotive, and telecommunications applications, where precise sensor readings are imperative.

Industry Solution Case Study

Custom parts manufacturing is crucial across diverse industries, and Neway excels in meeting their unique demands. Neway mainly provides customized parts in Aerospace, Medical Devices, Automotive, Telecommunication, Consumer Electronics, Lighting, E-Mobility, Power Tools, Energy, and Locking System Parts Manufacturing. Neway's precision and versatility make it a top choice for custom parts manufacturing across these industries, aligning seamlessly with their specific needs.

Try Neway Prototyping Service For Free

Neway provides free Consultative Design and rapid prototyping services for valid projects for free.

1. CNC Machining Prototyping Service

Correctly fill in your information and send it to our engineer to get free service.