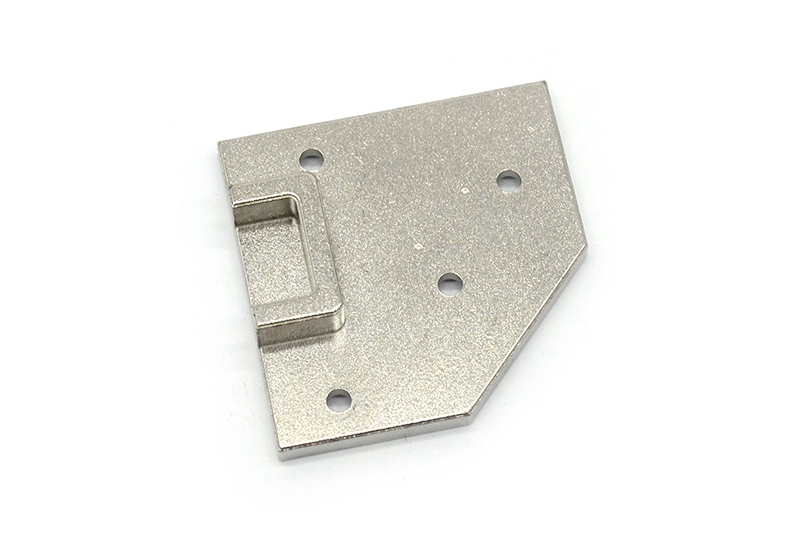

MIM-8620

MIM-8620 Metal Injection Molding service

MIM-8620 is a remarkable low alloy steel renowned for its outstanding properties and versatile applications in metal injection molding (MIM). Composed primarily of iron (Fe), it incorporates alloying elements like nickel (Ni), chromium (Cr), and molybdenum (Mo) to attain its unique characteristics.

One of MIM-8620's distinctive attributes is its ability to achieve precision and fine-grained microstructures through the MIM process. This makes it highly suitable for applications requiring intricate designs, precise dimensional control, and durability under challenging conditions.

Whether in gears, shafts, or critical mechanical components, MIM-8620 low alloy steel offers a cost-effective solution without compromising quality and performance, making it an invaluable material for various engineering applications.

Key Features and Applications of MIM-8620

Key Features of MIM-8620 | Applications |

|---|---|

Exceptional Strength | Automotive Parts |

High Toughness | Aerospace Components |

Outstanding Wear Resistance | Industrial Machinery Components |

Precise Dimensional Control | Gears and Bearings |

Fine-Grained Microstructure | Medical Instruments |

Excellent Machinability | Tooling and Dies |

Cost-Effective Production | Precision Engineering |

MIM-8620 Low Alloy Steel Typical Properties

MIM-8620 Chemical Composition

Carbon (C) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Silicon (Si) | Nickel (Ni) | Chromium (Cr) | Molybdenum (Mo) | Iron (Fe) |

|---|---|---|---|---|---|---|---|---|

0.18 | 0.70 | 0.010 | 0.010 | 0.25 | 0.50 | 0.70 | 0.20 | Balance |

MIM-8620 Physics and Mechanical Properties

Property | Status | Tensile Strength (MPa) | Yield Strength (MPa) | Impact Strength (J) | Hardness (HRC) | Young's Modulus (GPa) | Poisson's Ratio | Elongation (%) | Density (g/cm³) |

|---|---|---|---|---|---|---|---|---|---|

MIM-8620 | Heat Treated | 700 | 600 | 15 | 45 | 200 | 0.29 | 10 | 7.8 |

Other Excellent Properties of MIM-8620

Weldability

MIM-8620 parts exhibit good weldability. This characteristic arises from the low alloy composition and microstructure of MIM-8620 steel. MIM-8620 readily fuses with compatible materials during welding, forming solid and reliable joints. Standard welding techniques such as arc welding, MIG (Metal Inert Gas) welding, and TIG (Tungsten Inert Gas) welding can be easily employed.

Notably, the automotive sector benefits from the weldability of MIM-8620 parts, especially for assembling drivetrain components, suspension systems, and chassis elements. In aerospace, precision welding of MIM-8620 parts ensures the structural integrity of critical components like landing gear assemblies and engine mounts.

Magnetic

MIM-8620 parts can exhibit magnetic properties depending on their specific alloy composition and processing. The magnetic behavior of MIM-8620 is influenced by factors such as its chemical composition, heat treatment, and microstructure.

MIM-8620 components with magnetic characteristics can be used in the automotive industry in sensor systems. These sensors may require controlled magnetic responses to detect and measure parameters like speed, position, or fluid levels. In industrial settings, MIM-8620's magnetic properties find applications in magnetic actuators used in control systems, where precise and predictable responses to magnetic fields are essential for controlling valves, switches, or other mechanical actions.

Heat Resistance

MIM-8620 parts exhibit commendable heat resistance, allowing them to maintain structural integrity and performance even when exposed to elevated temperatures. Depending on specific processing and heat treatment, MIM-8620 can withstand temperatures well above 300°C (572°F).

Applications necessitating heat resistance in MIM-8620 MIM parts are widespread. In the automotive industry, components within exhaust systems are subjected to extreme temperatures due to exhaust gases. MIM-8620's heat resistance allows it to maintain its structural integrity and functionality in these conditions, contributing to the durability and efficiency of exhaust system components.

Electrical Conductivity

The electrical conductivity of MIM-8620 parts can vary depending on their specific alloy composition. MIM-8620 exhibits good electrical conductivity in some formulations, allowing for the efficient flow of electrical current.

Applications requiring electrical conductivity in MIM-8620 MIM parts are typically found in the electrical and electronics industries. Electrical connectors and contact components used in telecommunications, consumer electronics, and power distribution systems often demand materials with reliable electrical conductivity. MIM-8620's ability to facilitate efficient energy transfer through electrical contacts makes it suitable for these applications, ensuring minimal energy loss and reliable performance in various electrical systems.

Try Neway For Free

Neway provides free Consultative Design and rapid prototyping services for valid projects for free.

1. CNC Machining Prototyping Service

Correctly fill in your information and send it to our engineer to get free service.