MIM Ti-10V-2Fe-3Al (Grade 20)

Ti-10V-2Fe-3Al (Grade 20) Titanium Injection Moulding

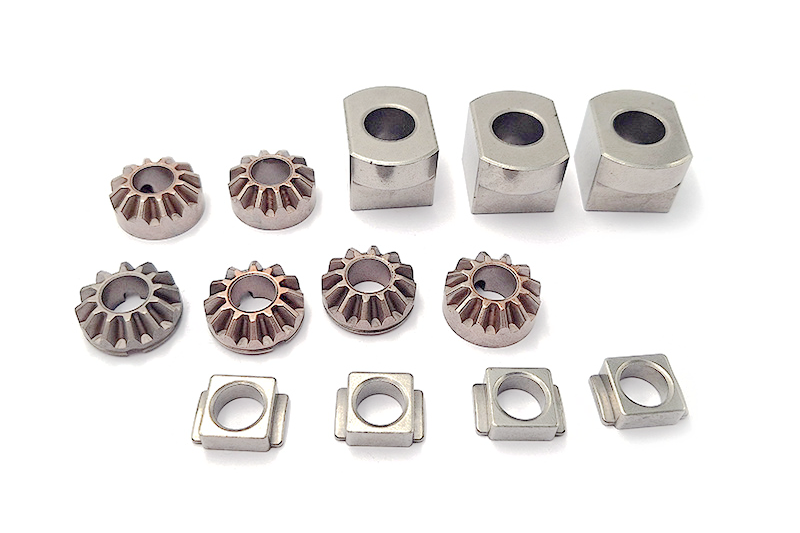

Ti-10V-2Fe-3Al (Grade 20) MIM Sintered Parts

Ti-10V-2Fe-3Al, known as Titanium Grade 20, exhibits exceptional properties when employed in metal injection molding (MIM) processes. In MIM applications, Grade 20's specific properties shine, as it offers exceptional precision with a typical dimensional accuracy of up to ±0.5%, ensuring that intricate components are manufactured with minimal variance.

Moreover, Grade 20's corrosion resistance is vital in applications such as Lighting Solutions, ensuring long-lasting and reliable performance, even in harsh environments. Its high modulus of elasticity, typically around 107 GPa, makes it a preferred material for components in Power Tools, enhancing their durability and structural integrity. In summary, Ti-10V-2Fe-3Al (Grade 20) is a versatile material for MIM, excelling in precision, strength, and corrosion resistance, making it an excellent choice across a spectrum of industries, including Consumer Electronics, Telecommunication, Lighting Solutions, and Power Tools.

Typical Properties Of MIM Ti-10V-2Fe-3Al (Grade 20)

Chemical Composition Of MIM Ti-10V-2Fe-3Al (Grade 20)

Element | Titanium (Ti) | Vanadium (V) | Iron (Fe) | Aluminum (Al) |

|---|---|---|---|---|

Composition (Weight %) | 87.5 | 10.0 | 2.0 | 3.0 |

MIM Ti-10V-2Fe-3Al (Grade 20) Physics and Mechanical Properties

Property | Status | Tensile Strength (MPa) | Yield Strength (MPa) | Impact Strength (J) | Hardness (HRC) | Young's Modulus (GPa) | Poisson's Ratio | Elongation (%) | Density (g/cm³) |

|---|---|---|---|---|---|---|---|---|---|

Typical Value | As Sintered | 950 | 860 | 12 | 28 | 108 | 0.35 | 10 | 4.51 |

Applications and Benefits of Ti-10V-2Fe-3Al (Grade 20) MIM Sintered Parts

Titanium Ti-10V-2Fe-3Al (Grade 20) MIM Sintered Power Tool Parts

Ti-10V-2Fe-3Al (Grade 20) sintered parts, manufactured through Metal Injection Molding (MIM), help produce power tool components. A key component where Grade 20 shines is creating durable, high-strength cutting blades. The material's exceptional tensile and yield strength, typically around 950 MPa and 860 MPa, respectively, make it ideal for withstanding the mechanical stresses encountered during cutting and machining operations. These blades maintain their sharpness for longer durations, contributing to the longevity of the power tools.

Another vital application lies in the development of robust tool holders and chucks. Grade 20's high Young's Modulus of approximately 108 GPa ensures that these components maintain structural integrity even under demanding conditions, providing the clamping force and stability required for precise and efficient power tool operation.

Titanium Ti-10V-2Fe-3Al (Grade 20) MIM Sintered Consumer Electronic Parts

Titanium Ti-10V-2Fe-3Al (Grade 20) MIM sintered parts exhibit their versatility and excellence in manufacturing various consumer electronic components. One critical application is in the production of precision connectors. The material's exceptional dimensional accuracy, with a typical tolerance of up to ±0.5%, ensures that connectors fit seamlessly, enhancing the reliability of electronic devices. Grade 20's precision plays a crucial role in maintaining uninterrupted data transmission, whether it's USB or intricate internal circuitry connectors.

Additionally, Grade 20 finds use in housing and enclosures for consumer electronic devices. Its high corrosion resistance ensures these casings remain resilient even in harsh environments, protecting delicate electronic components. Furthermore, the material's high Young's Modulus, typically around 108 GPa, contributes to the structural integrity of these housings, safeguarding the internal electronics.

Titanium Ti-10V-2Fe-3Al (Grade 20) MIM Sintered E-mobility Parts

In E-mobility, applying Titanium Ti-10V-2Fe-3Al (Grade 20) MIM sintered parts is instrumental in several critical components. One prominent use is in developing electric vehicle (EV) motor components. Grade 20's high tensile strength, typically around 950 MPa, and impressive Young's Modulus of approximately 108 GPa ensure that motor parts, such as rotor cores and stators, can withstand the rigors of high-speed rotation and maintain their structural integrity, contributing to the overall efficiency and reliability of electric motors in EVs.

Moreover, Grade 20 plays a significant role in producing battery terminals and connectors. Its precision and low dimensional variation, with typical tolerances of up to ±0.5%, are crucial in ensuring reliable electrical connections within the battery system. The material's corrosion resistance further enhances the durability of these components, which is essential for the longevity and safety of E-mobility solutions.

Titanium Ti-10V-2Fe-3Al (Grade 20) MIM Sintered Energy Industry Fasteners

In the energy industry, applying Titanium Ti-10V-2Fe-3Al (Grade 20) MIM sintered parts creates high-strength bolts and fasteners in power generation equipment, such as gas turbines and wind turbines. Grade 20's exceptional tensile strength, typically around 950 MPa, and impressive Young's Modulus of approximately 108 GPa ensure that these fasteners can securely hold together critical components, even in high-stress environments.

Furthermore, Grade 20's corrosion resistance is vital in energy applications, especially in offshore wind farms and power plants where exposure to harsh weather conditions is expected. These fasteners maintain their integrity over time, reducing the need for frequent maintenance and replacements.

More MIM Titanium Alloy Optional

MIM FAQs

1. What is metal injection molding used for?

2. What are the factors affecting the tolerance of MIM parts?

3. Which materials are suitable for metal injection molding?

4. What Is The Shrinkage of Metal Injection Molding?

5. 10 Reasons Why MIM Metal Powders Are More Expensive Than Common Bulk Metal Materials?

6. What Are The Applications of Thin-Walled MIM Parts Across Industries?