MIM-Fe-50Ni

Magnetic Alloy MIM-Fe-50Ni Injection Molding

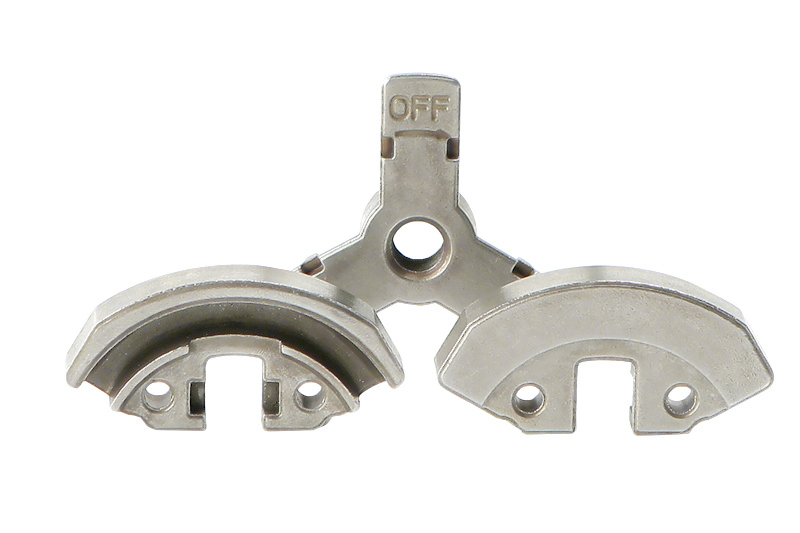

MIM-Fe-50Ni Magnetic Alloy Injection Molding Parts

MIM-Fe-50Ni Magnetic Alloy Injection Molding Parts possess remarkable properties, making them a preferred choice in various industries, including Consumer Electronics and Telecommunication. These parts exhibit exceptional magnetic permeability, ensuring efficient magnetic field conduction. Their high precision, with tolerances as low as ±0.02 mm, guarantees accurate dimensions critical for intricate applications in electronics. Furthermore, their corrosion resistance, backed by rigorous testing, ensures longevity even in harsh environmental conditions.

In addition to their precision and corrosion resistance, MIM-Fe-50Ni parts are lightweight, contributing to the overall weight reduction of electronic devices. This alloy's unique composition, with a 50% nickel content, enhances its magnetic properties while maintaining mechanical strength.

Typical Applications:

Miniaturized Transformers

RFID Antennas

Sensor Housings

Telecommunication Components

Power Supply Modules

Typical Properties Of MIM-Fe-50Ni

Chemical Composition Of MIM-Fe-50Ni

Composition (%) | Iron (Fe) | Nickel (Ni) |

|---|---|---|

MIM-Fe-50Ni | 50.0 | 50.0 |

MIM-Fe-50Ni Magnetic Alloy Physics and Mechanical Properties

Property | Status | Tensile Strength (MPa) | Yield Strength (MPa) | Impact Strength (J) | Hardness (HRC) | Young's Modulus (GPa) | Poisson's Ratio | Elongation (%) | Density (g/cm³) |

|---|---|---|---|---|---|---|---|---|---|

Typical Values | As Sintered | 450 | 350 | 12 | 45 | 150 | 0.3 | 5 | 7.8 |

Applications of MIM-Fe-50Ni Magnetic Alloy Injection Molding Parts

MIM-Fe-50Ni Magnetic Alloy Injection Moulding Miniaturized Transformers

MIM-Fe-50Ni Magnetic Alloy Injection Molding Parts are ideally suited for miniaturized transformers due to their exceptional properties. Firstly, these parts offer a high level of magnetic permeability, which is crucial for efficient energy transfer in transformers. Their ability to concentrate magnetic flux enables these transformers to maintain optimal performance despite their compact size, making them ideal for applications in consumer electronics where space is limited.

Secondly, the precision achievable with MIM-Fe-50Ni parts ensures that the transformer's core components are manufactured with extremely tight tolerances, as low as ±0.02 mm. This precision is vital in miniaturized transformers, as any dimensional variations can lead to inefficiencies or failure.

MIM-Fe-50Ni Magnetic Alloy Injection Moulding RFID Antennas

MIM-Fe-50Ni Magnetic Alloy Injection Molding Parts are well-suited for applications in Radio-Frequency Identification (RFID) antennas, offering a combination of properties that enhance their performance in this critical technology. Firstly, these parts exhibit precise dimensions, with tolerances as low as ±0.02 mm. In RFID antennas, where the accuracy of the antenna's geometry directly impacts signal transmission and reception, the precision of MIM-Fe-50Ni parts ensures reliable data communication, enhancing the overall effectiveness of RFID systems.

Secondly, the high magnetic permeability of MIM-Fe-50Ni plays a pivotal role in RFID applications. This property facilitates efficient magnetic field conduction, which is vital for the operation of RFID systems. It ensures the antenna can send and receive signals effectively, even in challenging environments with metallic interference. Moreover, MIM-Fe-50Ni's corrosion resistance ensures the long-term durability of RFID antennas, a crucial factor for their reliability in various applications, including access control, logistics, and asset tracking.

MIM-Fe-50Ni Magnetic Alloy Injection Moulding Sensor Housings

Firstly, the precise manufacturing capabilities of MIM technology ensure that sensor housing components meet the stringent requirements of these industries. The material's high precision, with tolerances as low as ±0.02mm, guarantees a snug fit for sensitive sensor elements, enhancing overall performance and accuracy. Additionally, the alloy's superior magnetic properties enable efficient shielding against external electromagnetic interference, a critical factor in ensuring the reliability of electronic devices in these sectors.

Furthermore, MIM-Fe-50Ni components boast outstanding corrosion resistance, making them suitable for outdoor and rugged environments. They excel in applications like mobile phone sensor housings, where exposure to moisture and contaminants is daily. Their lightweight yet durable nature also contributes to improved product durability, meeting the demands of the highly competitive Consumer Electronics and Telecommunication markets.

MIM-Fe-50Ni Magnetic Alloy Injection Moulding Telecommunication Components

First and foremost, the exceptional precision achievable with MIM technology ensures that these components meet the demanding standards of the Telecommunication sector. With tolerances as low as ±0.02mm, MIM-Fe-50Ni parts guarantee a tight fit and precise alignment in devices like connectors and switches, which are crucial for reliable signal transmission. This level of precision directly contributes to reduced signal loss and improved overall network performance.

Moreover, the magnetic properties of MIM-Fe-50Ni make it an ideal choice for Telecommunication applications. These components can be used in antennas, connectors, and waveguides, where their high magnetic permeability and excellent electromagnetic shielding properties ensure minimal interference and signal degradation. Furthermore, the alloy's resistance to corrosion and harsh environmental conditions ensures the longevity of Telecommunication equipment, making it a cost-effective solution for the industry.

Industries We Cover In Metal Injection Molding

As an experienced metal injection molding manufacturer, Neway is involved in many industries and trusted by big brand companies.

The industries we cover include: