MIM-430L

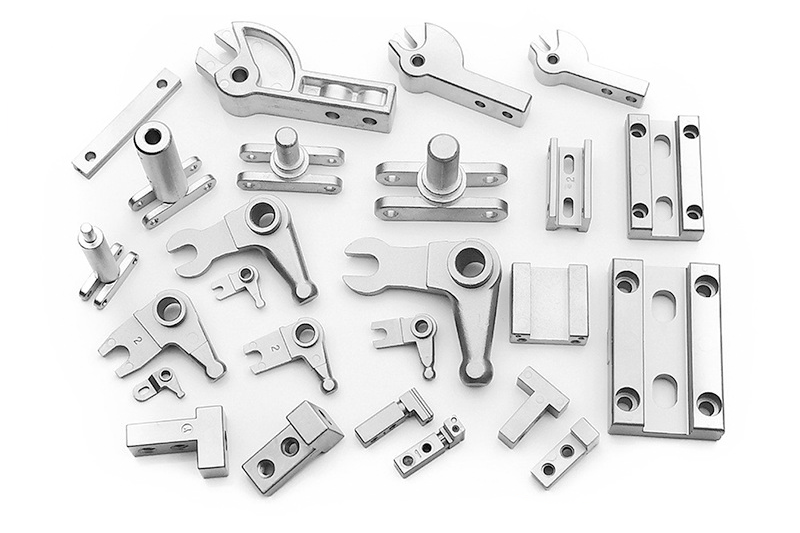

MIM-430L Metal Injection Molding service

MIM-430L is a low alloy steel with a composition designed for optimal performance in various industrial applications. This specialized alloy primarily consists of iron (Fe), manganese (Mn), nickel (Ni), chromium (Cr), and molybdenum (Mo), with precise percentages tailored to achieve its remarkable properties.

MIM-430L is characterized by its excellent corrosion resistance, making it well-suited for environments where exposure to moisture, chemicals, or corrosive substances is a concern.

Furthermore, MIM-430L exhibits commendable mechanical properties, including high tensile strength and flexibility. This combination of corrosion resistance and mechanical strength positions MIM-430L as an ideal material for components in industries such as automotive, aerospace, medical devices, and marine applications.

Key Features and Applications of MIM-430L

Key Features | Applications |

|---|---|

Excellent corrosion resistance | Marine components |

High tensile strength | Aerospace parts |

Good ductility | Medical devices |

Versatile material for complex shapes | Automotive components |

Precision achievable through MIM | Chemical processing equipment |

Resistance to moisture and chemicals | Oil and gas industry components |

Tailored alloy composition for performance | Electronics and telecommunications components |

Long-lasting and reliable performance | Consumer goods |

MIM-430L Low Alloy Steel Typical Properties

MIM-430L Chemical Composition

Iron (Fe) | Manganese (Mn) | Nickel (Ni) | Chromium (Cr) | Molybdenum (Mo) | Carbon (C) | Silicon (Si) | Phosphorus (P) | Sulfur (S) |

|---|---|---|---|---|---|---|---|---|

80.0% | 1.2% | 3.0% | 16.0% | 2.0% | 0.03% | 0.5% | 0.035% | 0.02% |

MIM-430L Physics and Mechanical Properties

Status | Tensile Strength (MPa) | Yield Strength (MPa) | Impact Strength (J) | Hardness (HRC) | Young's Modulus (GPa) | Poisson's Ratio | Elongation (%) | Density (g/cm³) |

|---|---|---|---|---|---|---|---|---|

As Sintered | 620 - 700 | 500 - 580 | 25 - 45 | 20 - 30 | 200 | 0.30 | 10 - 15 | 7.9 |

Other Excellent Properties of MIM-430L

Corrosion Resistance

MIM-430L parts exhibit excellent corrosion resistance, particularly in environments where exposure to moisture, chemicals, or mild corrosive substances is a concern. This property is attributed to the alloy's composition, including chromium and nickel elements. These elements form a protective oxide layer on the surface of the parts, effectively shielding them from corrosion and rust. While MIM-430L may not offer the same level of corrosion resistance as stainless steel, its ability to withstand moderate corrosive conditions makes it highly suitable for applications where protection against corrosion is essential but does not require more expensive, highly corrosion-resistant materials.

Applications requiring corrosion-resistant MIM-430L parts include marine components, where exposure to saltwater and moisture is prevalent, and chemical processing equipment.

Machinability

The machinability of MIM-430L parts is generally considered moderate. While MIM components are renowned for their intricate shapes and precision, machining may still be required in specific applications. The alloy's composition, including chromium and molybdenum, can influence machinability, often requiring slower cutting speeds and specialized tooling.

Applications requiring machinability for MIM-430L parts include aerospace components, where precise finishing or modification of complex shapes may be necessary to meet stringent industry standards. Additionally, specific medical devices and instrumentation may require machining for customizations or precise fittings.

Dimensional Accuracy

The dimensional accuracy of MIM-430L parts is a key highlight, as the Metal Injection Molding (MIM) process enables the production of exact components. MIM-430L parts adhere closely to specified tolerances, faithfully replicating intricate and complex geometries.

Applications requiring exceptional dimensional accuracy for MIM-430L parts include medical instruments like surgical tools, where precision is crucial for patient safety and effective procedures. Additionally, in aerospace applications, where components must fit seamlessly and reliably within complex systems, MIM-430L's dimensional accuracy ensures consistent and dependable performance.

Magnetic Properties

MIM-430L parts exhibit notable ferromagnetic properties due to their composition, making them susceptible to magnetic fields. This magnetic characteristic is advantageous in applications requiring components to interact with or respond to magnetic forces. In industries like electronics, MIM-430L parts can be used in electromagnetic devices, sensors, and actuators where magnetic properties are integral for proper functioning.

Applications requiring magnetic properties in MIM-430L parts include electromagnetic coils, magnetic sensors, and actuators, where precise control of magnetic fields is necessary for functionality and performance. In sensors, for instance, MIM-430L's magnetic properties can be leveraged to detect changes in magnetic fields, making it valuable in various industries, including automotive, for sensor applications related to position, speed, or alignment.

Try Neway For Free

Neway provides free Consultative Design and rapid prototyping services for valid projects for free.

1. CNC Machining Prototyping Service

Correctly fill in your information and send it to our engineer to get free service.