MIM-M4

MIM-M4 Tool Steel Injection Molding

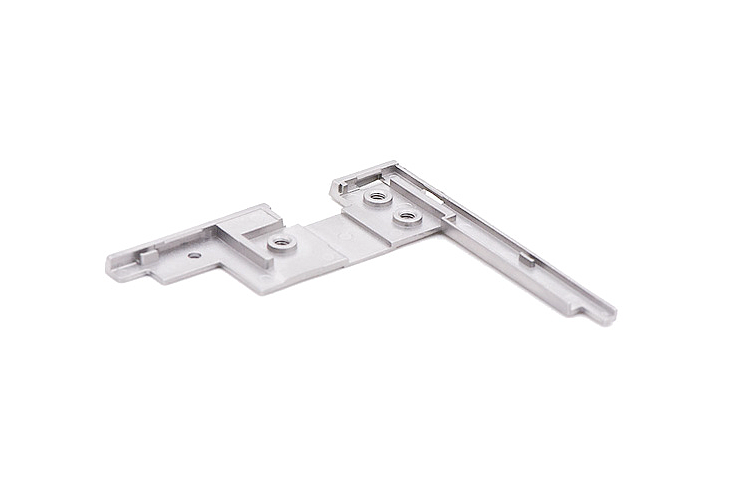

M4 Tool Steel Injection Moulded Parts

M4 Tool Steel Injection Moulded Parts possess distinctive properties, making them a preferred choice in various industries, including Consumer Electronics and Power Tools. First and foremost, M4 Tool Steel boasts exceptional hardness, with a Rockwell hardness of around 62-64 HRC. This remarkable hardness ensures long-lasting performance, even in high-wear environments, such as cutting tools or intricate mechanical components in power tools.

Additionally, M4 Tool Steel parts exhibit remarkable dimensional stability and precision, with tolerance levels reaching as low as ±0.005 mm. Furthermore, M4 Tool Steel's high thermal conductivity aids in efficient heat dissipation, making it well-suited for components in power tools that undergo substantial thermal stress during operation.

Typical Applications:

Battery Brackets

Laptop Hinges

Tool Holder Components

Motor Casing Components

Grinding Tool Components

Typical Properties Of MIM-M4 Tool Steel

Chemical Composition Of MIM-M4 Tool Steel

Element | Carbon (C) | Chromium (Cr) | Vanadium (V) | Tungsten (W) | Manganese (Mn) | Silicon (Si) | Phosphorus (P) | Sulfur (S) | Iron (Fe) |

|---|---|---|---|---|---|---|---|---|---|

Composition | 1.05% | 4.15% | 4.25% | 6.25% | 0.35% | 0.30% | 0.03% | 0.03% | Balance |

MIM-M4 Tool Steel Physics and Mechanical Properties

Property | Status | Tensile Strength (MPa) | Yield Strength (MPa) | Impact Strength (J) | Hardness (HRC) | Young's Modulus (GPa) | Poisson's Ratio | Elongation (%) | Density (g/cm³) |

|---|---|---|---|---|---|---|---|---|---|

Typical Value | As Sintered | 875 | 725 | 20 | 63 | 210 | 0.28 | 3 | 7.8 |

Applications of M4 Tool Steel Injection Moulded Parts

M4 Tool Steel Injection Moulded Battery Brackets

Due to their unique properties, M4 Tool Steel Injection Moulded Parts are an excellent choice for battery brackets in the automotive and consumer electronics industries. Firstly, their exceptional hardness and dimensional stability ensure that the battery brackets can securely hold and protect the cells in demanding conditions.

Secondly, M4 Tool Steel's high thermal conductivity benefits battery applications. It aids in efficient heat dissipation, which is crucial for managing temperature fluctuations within the battery pack, ensuring optimal performance, and prolonging the battery's lifespan. These characteristics make M4 Tool Steel Injection Moulded Parts a reliable and efficient choice for battery brackets, contributing to the overall efficiency and safety of battery systems in electric vehicles and electronic devices.

M4 Tool Steel Injection Moulded Laptop Hinges

M4 Tool Steel Injection Moulded Parts are an ideal choice for laptop hinges, offering a blend of strength and precision crucial for this critical component. Their outstanding hardness, typically in the range of 63-64 HRC, ensures the hinges can withstand the repeated opening and closing of the laptop lid without deformation or wear. This durability is essential to maintain the long-term functionality and reliability of the laptop.

Furthermore, M4 Tool Steel's exceptional dimensional stability and high Young's Modulus make it suitable for precise engineering. Laptop hinges demand tight tolerances and minimal play to provide a smooth and consistent user experience. M4 Tool Steel meets these requirements by retaining its shape and resisting flexing even under the stresses of daily use. Additionally, its resistance to corrosion and wear further extends the lifespan of laptop hinges, making M4 Tool Steel Injection Moulded Parts a robust choice for this crucial laptop component.

M4 Tool Steel Injection Moulded Tool Holder Components

M4 Tool Steel Injection Moulded Parts are a superior choice for tool holder components in various industries, particularly power tools. One key advantage is their exceptional hardness, typically between 63-64 HRC. This hardness ensures that tool holder components can securely grip cutting tools, even in high-speed machining applications, without excessive wear or deformation.

Moreover, M4 Tool Steel's remarkable dimensional stability and precision are vital for tool holder components. These parts must maintain tight tolerances to ensure proper tool positioning and alignment during machining operations. M4 Tool Steel excels in this regard, providing the required accuracy and reliability, resulting in precise and efficient machining processes. Additionally, its resistance to thermal deformation and excellent thermal conductivity make it a preferred material for tool holders, allowing for effective heat dissipation and reducing the risk of tool overheating during operation.

M4 Tool Steel Injection Moulded Motor Casing Components

M4 Tool Steel Injection Moulded Parts are a superb choice for motor casing components in various industries, particularly automotive and power tools. Their outstanding combination of properties makes them highly suitable for this critical application. Firstly, M4 Tool Steel's exceptional hardness, typically 63 to 64 HRC, ensures that motor casing components can withstand the mechanical stresses and vibrations associated with motor operation.

Secondly, M4 Tool Steel's remarkable dimensional stability and precision are essential for motor casing components, which often require tight tolerances to ensure proper fit and alignment within the motor assembly. The high precision and resistance to deformation of M4 Tool Steel ensure that these components maintain their integrity and functionality over extended periods of use. Additionally, its excellent thermal conductivity aids in efficient heat dissipation, a critical factor in motor operation, as it helps prevent overheating and ensures optimal performance.

Brand Case Study

Neway has served many world-renowned companies, using its strong manufacturing capabilities and complete quality control system to provide further market competitiveness and quality assurance for major brands.

More MIM Materials Optional

Neway has a comprehensive selection of metal injection molding materials. We have a mature metal powder supply chain. At the same time, we can configure the powders according to specific MIM part requirements.

Common MIM Materials We Use: