MIM Ti-15Mo-5Zr-3Al (Grade 21)

Ti-15Mo-5Zr-3Al (Grade 21) Titanium Injection Moulding

Ti-15Mo-5Zr-3Al (Grade 21) Metal Injected Parts

Ti-15Mo-5Zr-3Al, commonly known as Grade 21, demonstrates exceptional characteristics when utilized in metal injection molding (MIM) processes. Its distinctive properties make it an excellent choice for manufacturing metal-injected parts, particularly in industries like Consumer Electronics, Telecommunication, Lighting Solutions, Power Tools, and Locking systems. One of its standout features is its remarkable strength-to-weight ratio, with a tensile strength approaching 800 MPa. This makes Grade 21 a preferred material for crafting robust components, ensuring structural integrity and reliability, especially in demanding applications such as power tools and locking systems.

Furthermore, Grade 21 offers impressive corrosion resistance, a vital attribute in environments prone to chemical exposure. This feature enhances the longevity of metal-injected parts, making them well-suited for various applications across industries. The material's exceptional precision and dimensional stability, with precision values often measured within microns, make it ideal for crafting intricate components found in telecommunication devices and lighting solutions.

Typical Properties Of MIM Ti-15Mo-5Zr-3Al (Grade 21)

Chemical Composition Of Ti-15Mo-5Zr-3Al (Grade 21)

Element | Titanium (Ti) | Molybdenum (Mo) | Zirconium (Zr) | Aluminum (Al) |

|---|---|---|---|---|

Composition (Percentage by Weight) | 84.0% | 15.0% | 5.0% | 3.0% |

MIM Ti-15Mo-5Zr-3Al (Grade 21) Physics and Mechanical Properties

Property | Status | Tensile Strength (MPa) | Yield Strength (MPa) | Impact Strength (J) | Hardness (HRC) | Young's Modulus (GPa) | Poisson's Ratio | Elongation (%) | Density (g/cm³) |

|---|---|---|---|---|---|---|---|---|---|

Typical Values | As Sintered | 800 | 750 | 25 | 32 | 103 | 0.34 | 10 | 4.47 |

Applications and Benefits of Ti-15Mo-5Zr-3Al (Grade 21) Injection Molding Parts

Ti-15Mo-5Zr-3Al (Grade 21) Metal Injected Offshore Parts

Ti-15Mo-5Zr-3Al (Grade 21) metal-injected parts find valuable offshore applications due to their exceptional properties. In offshore environments, where components must withstand harsh conditions such as saltwater exposure and high mechanical stress, Grade 21 exhibits its prowess. These components can be employed in offshore drilling equipment, underwater vehicles, and subsea infrastructure.

For instance, Grade 21's corrosion resistance ensures longevity in saltwater environments, making it ideal for manufacturing components in subsea pipelines and offshore platform structures. Its high tensile strength and impact resistance further contribute to the durability of critical offshore equipment, enhancing safety and reliability.

Ti-15Mo-5Zr-3Al (Grade 21) Metal Injected Power Tool Parts

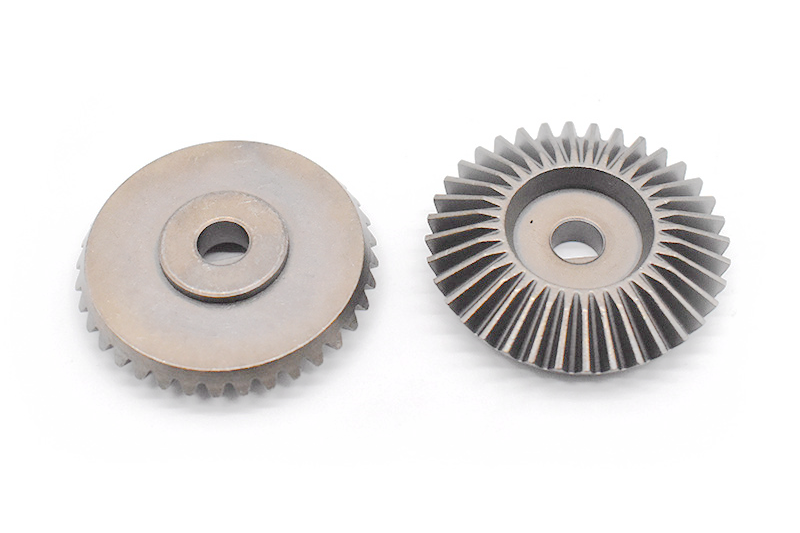

Ti-15Mo-5Zr-3Al (Grade 21) metal-injected parts offer remarkable advantages in power tools, enhancing their performance, longevity, and precision. These components can be found in various power tools, such as drills, saws, and grinders, where robustness and precision are paramount. Grade 21's high tensile strength, superior wear resistance, and excellent dimensional stability make it ideal for power tools' critical parts like gears, shafts, and housings.

One of the key benefits of using Grade 21 in power tools is its exceptional strength-to-weight ratio. It allows for the creation of lighter yet incredibly durable components, reducing the overall weight of power tools while maintaining their ruggedness. Additionally, Grade 21's resistance to wear and abrasion ensures the longevity of these components, reducing maintenance needs and enhancing the reliability of power tools. The precision and dimensional stability of Grade 21 parts also contribute to the accuracy and consistency of power tool operations, making it a top choice for manufacturers in the Power Tools industry.

Ti-15Mo-5Zr-3Al (Grade 21) Metal Injected Locking Systems Parts

Ti-15Mo-5Zr-3Al (Grade 21) metal-injected parts play a pivotal role in enhancing the performance and reliability of locking systems across various industries. Grade 21 components are prized for their exceptional strength, precision, and corrosion resistance in consumer electronics, automotive, or aerospace.

In the automotive sector, Grade 21 is employed in lock mechanisms, ensuring the security of vehicles. Its high tensile strength and wear resistance make it ideal for crafting durable locking components, providing peace of mind to vehicle owners. In the aerospace industry, where precision is paramount, Grade 21's dimensional stability and resistance to corrosion are essential for locking systems in aircraft doors and compartments. Moreover, in consumer electronics and security applications, Grade 21's robustness and corrosion resistance contribute to the longevity and reliability of locking systems in electronic devices and secure access control systems.

Ti-15Mo-5Zr-3Al (Grade 21) Metal Injected Telecommunication Devices Parts

Ti-15Mo-5Zr-3Al (Grade 21) metal-injected parts contribute to the reliability and performance of critical components in this industry. Telecommunication devices demand precision, durability, and resistance to environmental factors, making Grade 21 an excellent choice.

Grade 21's exceptional dimensional stability and precision are vital in producing connectors and housings for telecommunication devices. These components must maintain precise alignment and withstand the rigors of daily use. Additionally, Grade 21's resistance to corrosion ensures the longevity of components exposed to various environmental conditions, including outdoor installations and data centers. Its high tensile strength makes it suitable for manufacturing structural elements within telecommunication infrastructure, such as antenna mounts and support brackets.

More MIM Materials Optional

Neway has a comprehensive selection of metal injection molding materials. We have a mature metal powder supply chain. At the same time, we can configure the powders according to specific MIM part requirements.

Common MIM Materials We Use: