MIM 17-4 PH Metal Injection Molding Door Lock Hinge Manufacturer

Importance of MIM Door Lock Hinges

Metal Injection Molded (MIM) door lock hinges stand as a remarkable innovation in precision manufacturing. Their significance is underscored by their unique ability to combine intricate designs, cost-efficiency, and exceptional mechanical properties. This blend of attributes makes MIM door lock hinges indispensable in the security and durability of doors across various industries.

One of the pivotal aspects of MIM hinges is their precision. MIM technology allows for producing these hinges with incredibly tight tolerances, often reaching up to ±0.02 mm. Such precision ensures that doors close seamlessly, enhancing security and sealing against external elements. These hinges boast remarkable strength, with tensile values often exceeding 500 MPa, providing long-lasting reliability and stability.

From a cost-effective standpoint, MIM hinges shine. The MIM process minimizes material waste, with over 95% of the starting material utilized, making it an environmentally conscious choice. Additionally, MIM hinges can be manufactured in large quantities with minimal tooling costs, making them an economical choice for manufacturers. This blend of precision, strength, and cost-efficiency makes MIM door lock hinges a paramount choice for various applications, from residential to commercial doors, emphasizing their significance in the door lock parts manufacturing industry.

Understanding Metal Injection Molding

Metal Injection Molding (MIM) is a highly sophisticated manufacturing process that has revolutionized the production of intricate metal components, particularly in door lock parts manufacturing. MIM combines the principles of traditional powder metallurgy and plastic injection molding to produce complex, high-precision metal parts with remarkable efficiency and precision.

The MIM process begins with selecting fine metal powders, typically ranging from 2 to 20 micrometers in size. These powders are then mixed with a binder material to create a feedstock. This feedstock is injected into molds like plastic injection molding, where it takes the desired shape. The formed components are then subjected to a debinding process to remove the binder, leaving behind a "green" part. Subsequently, the green parts go through a sintering process, heated to high temperatures, causing the metal particles to fuse. It produces a fully dense, high-precision metal part with minimal post-processing requirements.

The benefits of MIM are manifold. It allows for producing intricate, net-shape components with minimal material waste, offering a cost-effective solution. MIM also excels in high precision, with tight tolerances often reaching ±0.1 mm. Moreover, it's highly versatile, producing many metal alloys. In the realm of door lock parts manufacturing, MIM has become synonymous with precision, efficiency, and quality, making it an indispensable process in the industry.

Advantages of Metal Injection Molding

Firstly, MIM allows for intricate and high-precision components. Door lock hinges require precise, complex geometries to ensure smooth operation and security. MIM achieves this with a precision down to a remarkable ±0.003 inches, providing a level of accuracy that traditional methods struggle to match. This results in perfectly fit hinges, enhancing the door's performance and overall security.

Moreover, MIM delivers cost-efficiency. The process significantly reduces material wastage, as nearly 98% of the metal powder is used in creating parts, reducing material costs. Additionally, MIM enables the production of multiple parts in a single cycle, reducing labor costs. This cost-effectiveness benefits manufacturers and, ultimately, consumers as well.

Lastly, MIM hinges exhibit excellent material properties. They are sturdy, corrosion-resistant, and long-lasting, crucial characteristics for door lock components. These qualities ensure the door lock's longevity and reliability, providing users peace of mind.

MIM Materials Optional for Door Lock Hinges

In the realm of MIM (Metal Injection Molding) for door lock hinges, two prominent materials take center stage: 17-4 PH stainless steel and SS304 stainless steel. These materials offer exceptional performance and durability, aligning perfectly with the rigorous demands of door lock components.

MIM-17-4PH

17-4 PH Stainless Steel, known for its high strength and corrosion resistance, is an ideal choice for door lock hinges. Its mechanical properties, with a tensile strength of approximately 1100 MPa, ensure that the hinges can withstand substantial loads and function optimally over an extended period. This level of precision, often in the range of ±0.3%, is essential for hinge components to fit perfectly within the door lock system, guaranteeing smooth operation and enhanced security.

MIM-304 Stainless Steel

SS304 Stainless Steel is another widely used material renowned for its excellent corrosion resistance in various environmental conditions. This is particularly crucial for door lock hinges, as they are constantly exposed to the elements. SS304 also offers an impressive tensile strength of about 590 MPa, ensuring the longevity and dependability of the hinges. With MIM technology, even intricate SS304 hinge designs can be manufactured precisely, maintaining the necessary tolerances for optimal functionality.

MIM Parts Sand Blasting Process

Sandblasting, a standard surface treatment method, is pivotal in manufacturing door lock parts. It involves propelling abrasive particles at high speeds to clean, etch, or roughen the surface of the metal components. Sandblasting serves several crucial purposes in the door lock parts industry.

Firstly, it ensures optimal surface cleanliness, removing contaminants and oxides that might hinder the adhesion of coatings. It leads to improved paint or plating adhesion, enhancing the overall quality and longevity of the door lock parts. Additionally, sandblasting provides an ideal surface finish for aesthetics, creating a uniform texture and improving the visual appeal of the components. The process is exact, with the ability to achieve specific roughness values to meet the desired specifications in the MIM door lock parts manufacturing. Furthermore, sandblasting also plays a role in stress relief for parts, reducing the risk of material fatigue and prolonging the life of door lock components.

MIM Case Studies

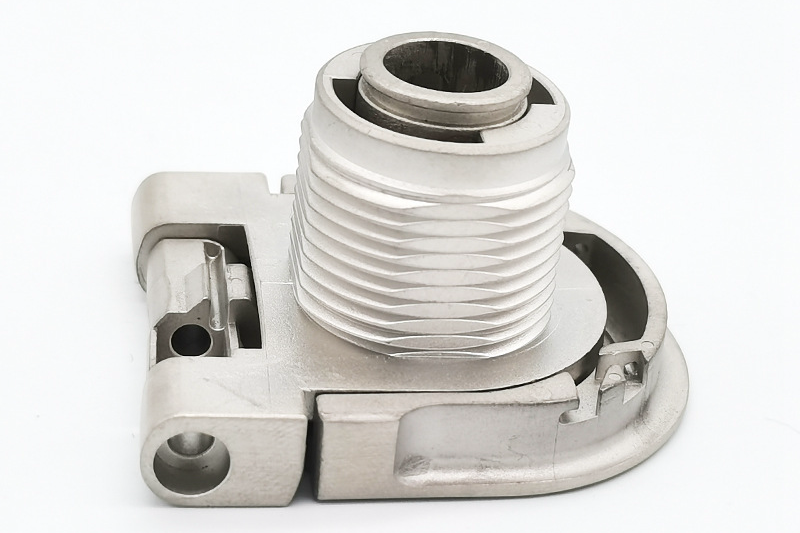

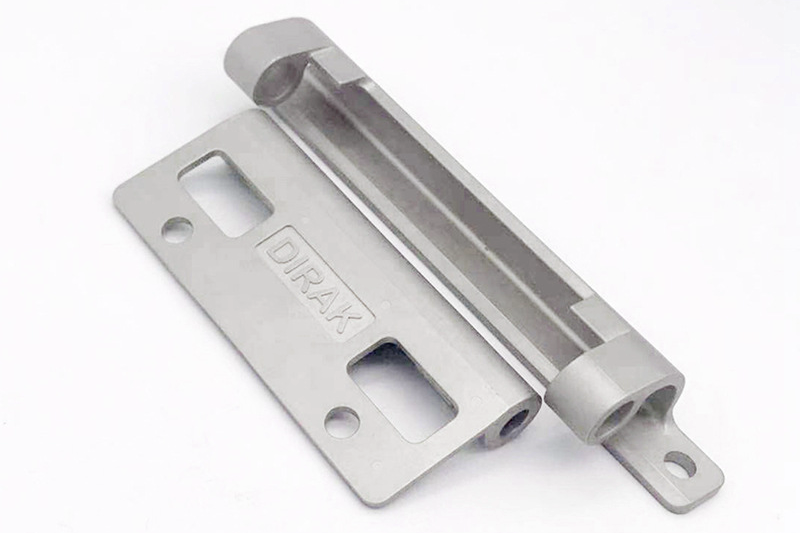

Neway's expertise in metal injection molding (MIM) extends to the intricate manufacturing of 17-4 PH stainless steel door lock hinges. This specialized process is a testament to our commitment to precision and quality. With 17-4 PH stainless steel's remarkable corrosion resistance and mechanical properties, Neway ensures that the door lock hinges provide security and endure time. Regarding material selection, 17-4 PH is the most economical, durable, and low-cost choice.

The heart of this manufacturing process lies in the MIM technique, which enables us to achieve unparalleled precision. Utilizing state-of-the-art machinery, we meticulously create the intricate geometries required for door lock hinges with tight tolerances, often reaching as high as ±0.02 mm. This level of precision ensures that the hinges function flawlessly, enhancing the overall security of the doors they are installed in.

Furthermore, Neway's commitment to quality extends beyond precision. We subject the 17-4 PH stainless steel door lock hinges to a rigorous sandblasting process, which not only refines the surface finish but also imparts a uniform texture. It not only enhances the aesthetic appeal of the hinges but also plays a pivotal role in preventing corrosion and wear, extending the product's lifespan. In addition, sandblasting creates a key surface texture that facilitates painting or powder coating, further customizing the appearance to suit the client's requirements.

Challenges And Solutions

Challenge 1: Material Selection and Composition

Neway's commitment to producing high-quality door lock hinges begins with meticulous material selection and composition. The 17-4 PH stainless steel alloy is the material of choice due to its exceptional strength and corrosion resistance. However, creating the ideal alloy composition is crucial.

Solution: Neway's Expertise in Material Formulation

Neway boasts a team of experienced engineers and metallurgists who excel in tailoring the 17-4 PH stainless steel alloy composition to meet the specific requirements of door lock hinges. It involves precise control over critical elements such as chromium, nickel, and copper percentages. For instance, maintaining approximately 15-17.5% chromium content ensures superior corrosion resistance, while the nickel content, between 3-5%, enhances the alloy's toughness. Copper is carefully controlled to promote corrosion resistance and hardening.

Challenge 2: Part Complexity and Precision

Door lock hinges are known for their intricate designs, which require high precision to ensure proper fit and functionality.

Solution: Advanced MIM Technology

Neway employs cutting-edge MIM technology, characterized by its ability to achieve exceptionally high precision levels. Tolerances as low as ±0.02 mm are routinely achieved, ensuring that every door lock hinge is manufactured with meticulous attention to detail. The MIM process allows for creating complex geometries and delicate features, ensuring that each hinge functions flawlessly.

Challenge 3: Surface Finish and Aesthetics

The visual appearance of door lock hinges is vital for practical and aesthetic reasons. Achieving a smooth, uniform surface finish can be challenging during the MIM process.

Solution: Sandblasting for Superior Finish

Neway's use of sandblasting as a surface treatment method is pivotal in addressing this challenge. Sandblasting enhances the door lock hinges' aesthetics while eliminating any surface imperfections. This process involves propelling fine abrasive particles against the surface of the hinges at high velocity. As the abrasive particles impact the surface, they remove any irregularities, creating a consistent matte finish. Sandblasting not only improves the overall look of the hinges but also ensures that they have a uniform texture, which is essential for their functional performance.

Challenge 4: Cost Efficiency and Mass Production

Balancing cost-efficiency with large-scale production is a perpetual challenge in manufacturing.

Solution: Economic Mass Production

Neway's dedication to efficiency and optimized manufacturing processes is evident in our ability to produce door lock hinges cost-effectively and in large quantities. By leveraging our expertise in MIM, we can streamline production workflows and minimize waste, ultimately reducing manufacturing costs.

This commitment to cost-efficiency extends to every production stage, from material sourcing to final finishing. The result is that Neway can offer high-quality, precision-manufactured door lock hinges at competitive prices while still adhering to the industry's stringent quality standards.

Surface Treatment Techniques

In Stainless Steel Metal Injection Molded Door Lock Hinges production, surface treatments are pivotal in enhancing functionality and aesthetics. Here, we'll delve into three significant treatment options: PVD (Physical Vapor Deposition), Polishing, and Sand Blasting, shedding light on how each method contributes to the quality of these essential components.

PVD (Physical Vapor Deposition): Elevating Durability and Aesthetics

PVD, or Physical Vapor Deposition, is a cutting-edge surface treatment technique gaining momentum in manufacturing stainless steel MIM door lock parts. This method involves depositing a thin film of material onto the surface of the stainless steel hinge, enhancing its durability and visual appeal. PVD coatings are renowned for their ability to withstand corrosion, wear, and scratching, making them a preferred choice for applications in environments with high moisture or abrasion, such as exterior door lock hardware.

One notable advantage of PVD treatment is its exceptional precision. Thickness values of PVD coatings can be as precise as 1-5 microns, ensuring a consistently even coating and minimal impact on the hinge's tolerances. This precision is especially crucial in the door lock industry, where even the slightest deviation can compromise the lock's functionality. Additionally, the variety of available PVD coating colors allows manufacturers to customize the appearance of door lock hinges, meeting functional and aesthetic requirements. By incorporating PVD-coated hinges into their products, manufacturers can offer customers enhanced durability and a visually appealing finish, further solidifying their reputation in the market.

Polishing: Aesthetic Excellence with a Smooth Touch

Polishing is a surface treatment option focusing on refining the aesthetic aspect of stainless steel metal injection molded door lock hinges. This process involves the removal of imperfections, such as burrs and irregularities, from the surface of the hinge, resulting in a sleek and smooth finish. Polishing not only contributes to the visual appeal of the hinge but also ensures that there are no sharp edges or rough surfaces that could cause injuries during installation or regular use.

The precision in polishing can be measured in terms of surface roughness. A typical stainless steel hinge might have an initial roughness of Ra 0.6 - 0.8 microns. After a high-precision polishing process, this roughness can be reduced to an impressive Ra 0.1 - 0.2 microns or even lower. This level of precision guarantees that the hinge's surface is visually appealing and safe to handle.

Manufacturers that opt for polishing demonstrate a commitment to producing high-quality door lock components, emphasizing the importance of user experience and aesthetics. Such attention to detail sets them apart in a competitive market, making their products highly sought after by customers who value functionality and design.

Sand Blasting: Enhancing Texture and Durability

Sandblasting is a versatile surface treatment method that enhances the texture and durability of stainless steel metal injection molded door lock hinges. In this process, abrasive particles are directed at the hinge's surface at high velocity, creating a unique texture while removing contaminants and imperfections. Sandblasting is an excellent choice when manufacturers aim to provide their customers with door lock hinges that offer enhanced grip, particularly in applications where a non-slip surface is crucial.

The precision in sandblasting can be measured by controlling variables such as pressure, distance, and the type of abrasive material used. By adjusting these factors, manufacturers can achieve varying degrees of surface texture, ensuring that the end product meets specific functional requirements. Moreover, sandblasting improves the adhesion of subsequent coatings or treatments, enhancing the overall durability of the hinge.

Manufacturers incorporating sandblasted stainless steel door lock hinges into their product lines are attuned to the practical needs of their customers. By prioritizing texture and durability, they ensure their hinges look appealing and perform exceptionally well in various door lock applications.

Neway's Expertise In Manufacturing

Neway, as a leading player in the realm of Metal Injection Molding (MIM), distinguishes itself through its remarkable expertise in MIM production, meticulous surface treatment, stringent quality control, and unwavering commitment to customer satisfaction.

Metal Injection Molding (MIM) Expertise: Precision Meets Innovation

Neway has carved a niche in the MIM industry by being at the forefront of innovation and precision. Our engineers and production experts leverage their extensive knowledge to create complex and high-precision parts that meet the exacting demands of modern industries. We excel in producing MIM components, especially in applications such as door lock parts. Our expertise in MIM extends from material selection to tool design and process optimization, ensuring that the parts we produce exhibit exceptional strength and dimensional accuracy. This precision is paramount, particularly in the realm of door lock parts, where even the slightest deviation can affect the performance and safety of the lock.

Surface Treatment Excellence: Aesthetic and Functional Enhancement

Neway understands that the surface treatment of MIM components is not just about visual appeal but also functionality. Our commitment to excellence in surface treatment is reflected in our ability to provide diverse options, including PVD coatings, polishing, and sandblasting. These treatments enhance the appearance of MIM components and contribute to their durability and usability. It is especially relevant in manufacturing door lock parts, where the hinges and latches must look good, withstand the test of time, and ensure security.

Rigorous Quality Control: Uncompromising Precision

At Neway, quality control is more than just a process; it's a culture. We employ state-of-the-art inspection and testing equipment to ensure that every MIM component, including those used in door lock parts, meets the highest standards. Our rigorous quality control protocols cover every aspect of production, from material composition to final inspection. By adhering to these strict quality control measures, we guarantee that our MIM components are free from defects and consistently perform to the satisfaction of our customers.

Customer Focus: Your Success, Our Priority

Neway's customer-centric approach is a cornerstone of our success. We recognize that our customers are at the heart of our business and we go the extra mile to meet their specific requirements. In the realm of door lock parts, this means collaborating closely with our customers to understand their unique needs and delivering tailored solutions. Our commitment to customer satisfaction extends beyond product quality, including responsive communication, on-time delivery, and flexible production capabilities.

More MIM Materials Optional

Neway has a comprehensive selection of metal injection molding materials. We have a mature metal powder supply chain. At the same time, we can configure the powders according to specific MIM part requirements.

Common MIM Materials We Use: