Zinc Die Casting Vs. Aluminum Die Casting: What Are The Differences

Die casting is a versatile and efficient manufacturing process that produces high-quality metal parts with intricate shapes and excellent dimensional accuracy. At its core, die casting involves forcing molten metal under high pressure into a mold cavity. This method is favored for its speed, precision, and the superior quality of the final product.

Material selection plays a pivotal role in die casting. The choice of metal influences the part's properties and affects the production process, cost, and application suitability. Zinc and aluminum are two of the most popular choices among the various metals, each bringing unique characteristics.

Differences Between Zinc Die Casting Vs. Aluminum Die Casting

Material Properties: Cast Aluminum And Zinc

Understanding the material properties of aluminum and zinc is crucial for selecting the suitable metal for your die-casting project. Each metal has distinct physical and mechanical characteristics that affect its performance and suitability for different applications.

Zinc:

Physical Properties:

Density: Zinc is about 6.6 to 7.0 g/cm³, significantly heavier than aluminum. This higher density can be beneficial for weight-sensitive applications.

Melting Point: Zinc melts at approximately 420°C (788°F), which is relatively low compared to many other metals. This lower melting point reduces energy consumption during casting.

Mechanical Properties:

Strength: Zinc alloys are known for their high strength and toughness. They can withstand significant mechanical stress, making them ideal for high-strength applications.

Hardness: Zinc is generally harder than aluminum, offering good wear resistance.

Typical Cast Zinc Alloys:

Aluminum:

Physical Properties:

Density: Aluminum is lighter, with a density of about 2.7 g/cm³. This lightness is critical in its use in the aerospace and automotive industries.

Melting Point: Aluminum has a higher melting point than zinc, typically around 660°C (1220°F). It requires more energy for casting but allows for higher-temperature applications.

Mechanical Properties:

Strength: While not as strong as zinc, aluminum alloys still offer good strength, primarily when treated or alloyed properly.

Hardness: Aluminum is generally softer than zinc, but its alloys can be treated to improve hardness and strength.

Typical Cast Aluminum Alloys:

Comparative Analysis of the Properties:

Weight and Density: Zinc is heavier and denser, which benefits small, weighty components. Aluminum's lightness is ideal for mobility-focused applications.

Strength and Hardness: Zinc generally offers greater strength and hardness, which makes it suitable for durable parts. Aluminum, while softer, can be alloyed for higher strength.

Melting Point: Zinc's lower melting point means lower energy costs and more effortless casting, but aluminum's higher melting point allows for use in higher-temperature environments.

Mold Life and Sizes

The durability and performance of casting dies are critical factors in die casting, affecting both the quality of the parts produced and the overall cost-effectiveness of the process. The life expectancy of the mold and the typical sizes of castings differ significantly between aluminum and zinc die casting.

Mold Life for Aluminum and Zinc Die Casting:

Aluminum Die Casting Mold: Aluminum casting involves higher melting temperatures, which can lead to quicker wear and tear on the molds. Typically, an aluminum die-casting mold can last between 100,000 and 150,000 shots, depending on the complexity and maintenance of the mold. Higher temperatures also necessitate using more robust, often more expensive, mold materials.

Zinc Die Casting Mold: Zinc's lower melting point is less stressful on the mold, substantially extending its life. A zinc die-casting mold can last from 1 million to over 2 million shots, significantly higher than aluminum. Despite the initial investment, this extended life expectancy can lower long-term costs.

Typical Die Casting Sizes for Aluminum and Zinc:

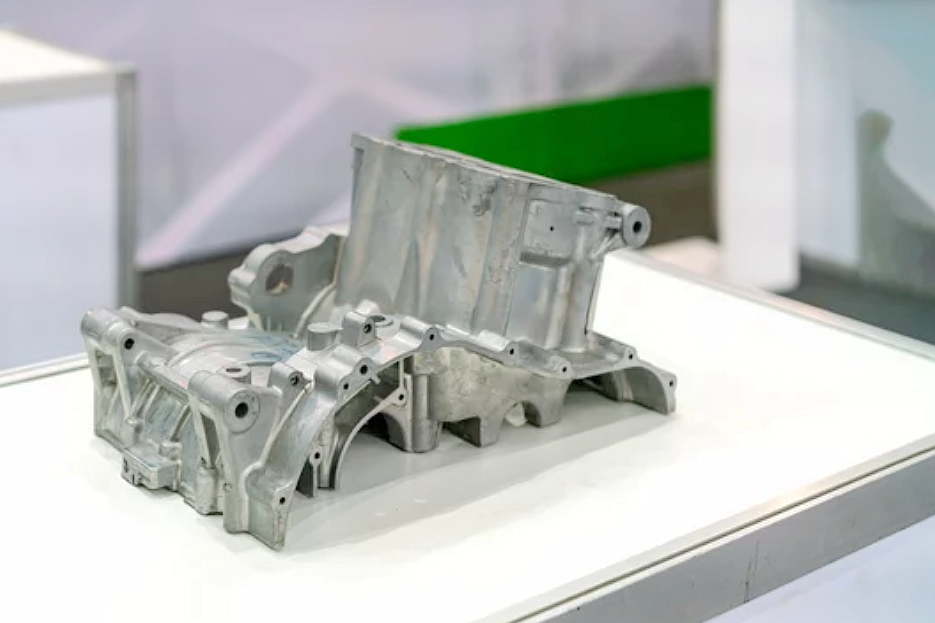

Aluminum Die Casting Sizes: Aluminum's lower density allows for the casting of larger parts while maintaining a manageable weight. It makes aluminum die castings ideal for larger components in the automotive and aerospace industries, where the size-to-weight ratio is a key consideration.

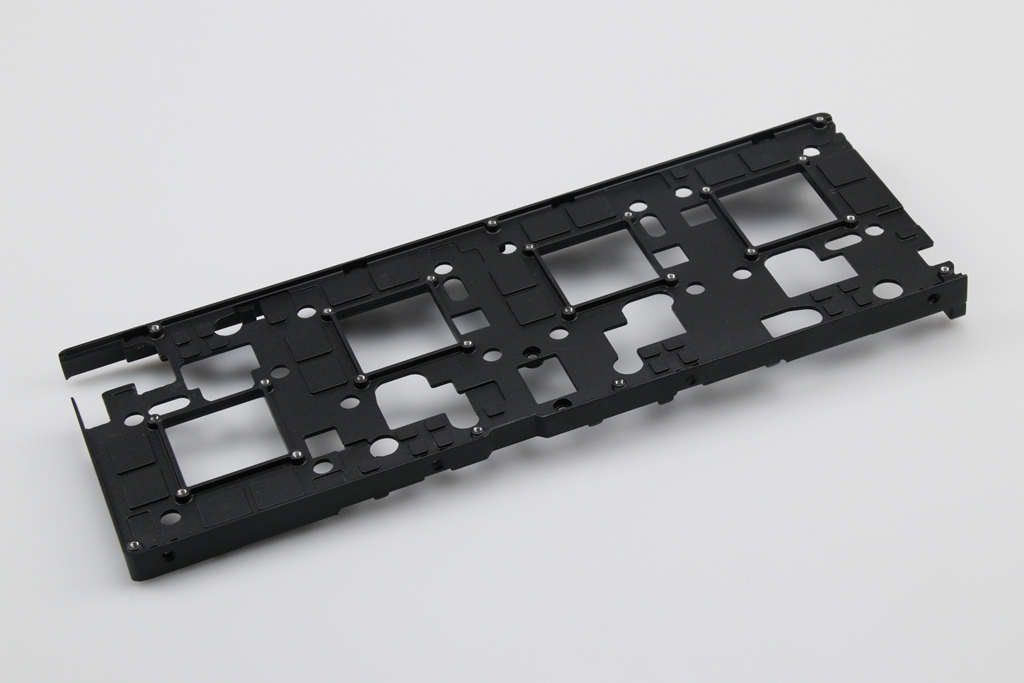

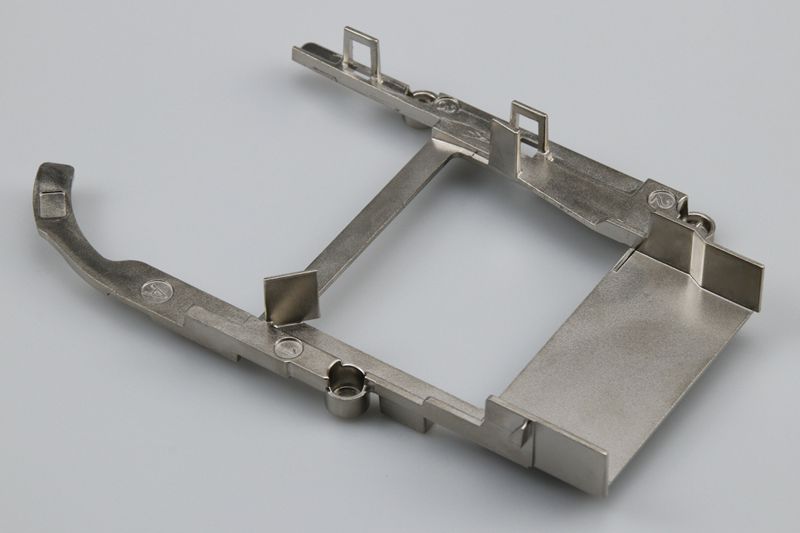

Zinc Die Casting Sizes: Zinc is generally used for smaller, more intricate components due to its higher density and excellent fluidity, which allows for precision in detailed designs. The weight of zinc makes it less suitable for large parts but ideal for small, complex components with tight tolerances.

Tolerances and Surface Finish Capabilities

In die casting, achieving precise tolerances and high-quality surface finishes is crucial for the functionality and aesthetics of the final product. Aluminum and zinc die castings have different capabilities in these areas due to their inherent material properties.

Tolerance Capabilities of Aluminum Die Casting:

Aluminum die castings can achieve ±0.002 inches per inch tolerances, which is suitable for most applications. However, tighter tolerances can be more challenging to maintain consistently due to aluminum's thermal expansion and contraction.

High-speed production impacts dimensional stability, requiring post-processing for precision applications.

Tolerance Capabilities of Zinc Die Casting:

Zinc excels in achieving tighter tolerances, often maintaining ±0.0015 inches per inch. Zinc alloys' excellent flow characteristics allow for precise replication of mold details, even in complex geometries.

The stability of zinc in the die-casting process ensures consistent tolerances across large production runs.

Aluminum Die Castings Typical Surface Finishings:

Aluminum die castings can be finished with various surface treatments such as powder coating, painting, anodizing, or plating. These finishes enhance corrosion resistance and improve aesthetic appeal.

The natural surface of aluminum die castings is relatively smooth but may require additional sanding or polishing for applications requiring a high-gloss finish.

Zinc Die Castings Typical Surface Finishings:

Zinc die castings inherently have a superior surface finish, often requiring minimal post-processing. They can be easily plated, painted, or coated to enhance appearance or function.

Achieving a smooth, high-quality surface directly from the mold is a significant advantage, especially for decorative or visible components.

Thin Wall Capabilities

The ability to produce parts with thin walls is a valuable aspect of die casting, impacting the final product's weight and material usage. Aluminum and zinc alloys have different capabilities for thin wall casting, influenced by their material properties and casting behaviors.

Thin Wall Capabilities of Aluminum Die Castings:

Minimum Wall Thickness: Aluminum die castings typically achieve a minimum wall thickness of around 0.09 inches (2.3 mm). This is due to aluminum's good flowability and relatively low shrinkage during solidification.

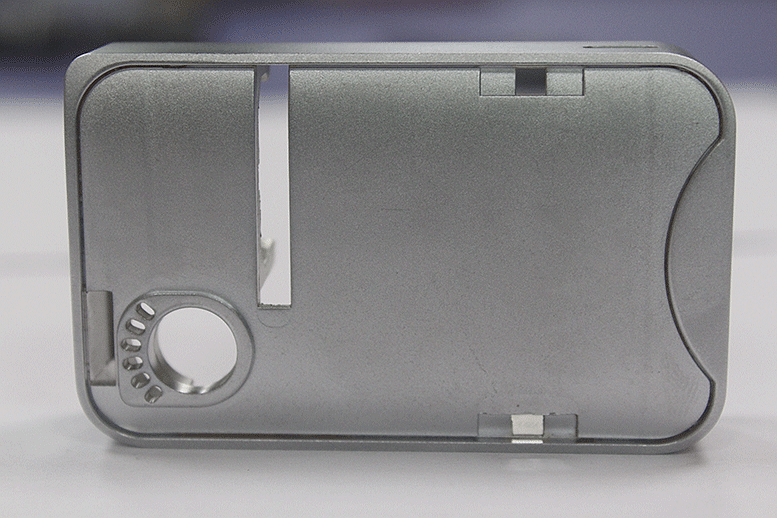

ApplicationsAluminum's light weight and strength make it suitable for significant components with thin walls, and it is commonly used in the automotive and aerospace industries where reducing weight is crucial.

Challenges: Achieving uniform cooling and avoiding defects like warping or porosity is more challenging in thin-wall aluminum casting, requiring precise control.

Thin Wall Capabilities of Zinc Die Castings:

Minimum Wall Thickness: Zinc alloys can produce even thinner walls, with capabilities down to 0.02 inches (0.5 mm). It results from zinc's excellent fluidity and low melting point, filling complex molds with thin sections.

Applications: The ability to cast fragile walls makes zinc ideal for small, intricate parts often used in electronics, consumer products, and complex mechanical assemblies.

Advantages: Zinc's superior thin wall capabilities enable the production of detailed, high-precision components while maintaining strength and durability.

In summary, when it comes to thin wall casting, zinc offers superior capabilities compared to aluminum, allowing for finer, more intricate designs. Aluminum, while not capable of walls as thin as zinc, is still a strong contender for lightweight components with moderate wall thicknesses. The choice between the two materials for thin wall applications should be based on the project's requirements, including part size, complexity, and intended use.

Application and Industry Usage

Aspect | Aluminum Die Castings | Zinc Die Castings |

|---|---|---|

Automotive Industry | Used for engine parts, transmission components, and body panels. Preferred for its light weight and strength. | Employed in safety-critical parts like seat belt components and airbag housings due to high impact strength. |

Aerospace Industry | Ideal for aircraft components like landing gear and structural elements due to low density and high-temperature resistance. | - |

Consumer Electronics | Common in laptop cases, heat sinks, and other electronic housings for thermal conductivity and aesthetic appeal. | Used in connectors and shielding cases for excellent electromagnetic shielding properties. |

Outdoor Equipment | Suitable for outdoor and sports equipment, such as bicycle frames and camping gear, due to durability and corrosion resistance. | - |

Precision Components | - | Perfect for precision components in mechanical devices, locks, and gears due to its ability to achieve tight tolerances and intricate details. |

Consumer Products | - | It is commonly used in durable, high-quality components for household appliances, toys, and decorative items. |

Cost Considerations

Cost is a critical factor in manufacturing, and die casting is no exception. When considering aluminum and zinc for die casting, various cost elements come into play, including mold costs, die casting costs, material costs, and post-processing costs.

Mold Cost:

Aluminum: The higher melting point of aluminum necessitates using high-grade, heat-resistant mold materials, leading to higher costs. However, these molds have a shorter lifespan due to thermal stress during casting.

Zinc: Zinc's lower melting point allows for using less expensive mold materials. The extended mold life due to lower thermal stress also results in a more cost-effective long-term investment.

Die Casting Cost:

Aluminum: The die-casting process for aluminum is generally more expensive due to the higher energy requirements for melting and additional cooling systems.

Zinc: Zinc's lower melting point translates to lower energy consumption during casting, making the process more cost-efficient.

Materials Cost:

Aluminum: The cost of aluminum fluctuates based on market conditions, but it is generally more expensive than zinc.

Zinc: Zinc is typically less expensive than aluminum, offering a more cost-effective solution for the raw material.

Post-processing Cost:

Aluminum: Aluminum parts may require additional post-processing, like machining or surface treatments, which can add to the total cost.

Zinc: Zinc castings often require minimal post-processing due to their excellent surface finish and precision, potentially reducing additional costs.

Advantages and Limitations

Each metal used in die casting offers unique advantages and faces certain limitations. Understanding these can help manufacturers make informed decisions based on their specific needs.

Zinc:

Advantages in Die Casting:

High Strength and Durability: Zinc alloys are known for their high strength and toughness, making them ideal for heavy-duty applications.

Precision and Detail: Zinc's excellent fluidity allows casting intricate and detailed parts, achieving tight tolerances.

Long Mold Life: The low melting point of zinc extends the life of the die, reducing long-term costs.

Superior Surface Finish: Zinc castings generally have a superior surface finish, reducing the need for post-processing.

Limitations and Challenges:

Weight: Zinc is heavier than aluminum, which might be a disadvantage in applications where weight is critical.

Size Limitations: Zinc is less suitable for large parts due to its weight.

Corrosion Resistance: While good, zinc's corrosion resistance is less intense than aluminum, which may limit its use in specific environments.

Aluminum:

Advantages in Die Casting:

Lightweight: Aluminum's low density is ideal for applications where weight reduction is crucial, such as in the automotive and aerospace industries.

High-Temperature Performance: Aluminum can withstand higher temperatures, making it suitable for high-temperature applications.

Corrosion Resistance: Aluminum naturally forms an oxide layer, offering excellent corrosion resistance.

Recyclability: Aluminum is highly recyclable, which is beneficial from an environmental and cost perspective.

Limitations and Challenges:

Mold Life: The higher melting point of aluminum shortens the life of the die.

Cost: Aluminum is generally more expensive than zinc in terms of both raw material and casting processes.

Tolerance and Surface Finish: Achieving the same level of precision and surface quality as zinc can be more challenging and might require additional processing.

Decision-Making Factors for Die-Casting Manufacturers:

Application Requirements: Choose based on the part's required strength, weight, and exposure to heat or corrosive environments.

Cost-Effectiveness: Consider the total cost, including material, production, and post-processing.

Precision and Detail: Zinc may be better for highly detailed or intricate parts.

Environmental Considerations: Aluminum's recyclability can be a deciding factor for environmentally conscious projects.

When To Choose Aluminum Die Casting

Choosing the right material for a die-casting project is crucial for achieving the desired quality, functionality, and cost-effectiveness. Aluminum die casting is often selected for its unique properties and advantages in certain applications. Here are scenarios where aluminum die casting is the preferred choice:

Lightweight Requirements: Aluminum's low density makes it an ideal choice for automotive and aerospace industries, where weight reduction is essential for performance and fuel efficiency.

High-Temperature Applications: Aluminum's ability to withstand high temperatures without losing strength benefits applications such as engine parts, cooking utensils, and lighting fixtures.

Corrosion Resistance Needs: In environments where parts are exposed to moisture or chemicals, aluminum’s natural corrosion resistance is a significant advantage. This makes it suitable for marine applications, outdoor equipment, and under-the-hood automotive components.

Complex Geometries with Moderate Wall Thickness: Aluminum’s good flow characteristics make it suitable for parts with complex shapes and moderate wall thicknesses, ensuring both strength and detail.

Environmental Considerations: If recyclability and eco-friendliness are essential, aluminum is a superior choice due to its ease of recycling and prevalence as a recycled material.

Durable, High-Strength Parts: Aluminum alloys are known for their strength and durability, which are crucial in producing robust components for mechanical applications, automotive safety features, and other high-strength requirements.

Large Parts Production: Given its lightweight, aluminum is more suitable than zinc for larger parts, balancing size and manageability.

Long Production Runs: Although aluminum molds have a shorter lifespan than zinc, they are still suitable for long production runs, making aluminum a cost-effective choice in many scenarios.

When To Choose Zinc Die Casting

Due to its unique properties and advantages, zinc die casting is preferred in various scenarios. Understanding when to opt for zinc over other materials like aluminum can improve product performance, cost efficiency, and quality. Here are key situations where zinc die casting is the ideal choice:

High Precision and Detail: When manufacturing parts that require intricate details and high precision, zinc’s excellent fluidity and ability to capture fine features make it the ideal material.

Small to Medium-Sized Components: Zinc’s density and casting characteristics are perfect for small to medium-sized components, especially where weight is less of a concern.

Thin Wall Applications: Zinc’s ability to produce skinny walls without sacrificing strength is unmatched, making it suitable for complex, delicate parts in electronics and detailed mechanical components.

Long Mold Life Requirements: For projects where a long mold life can significantly impact cost-effectiveness, zinc’s lower melting point extends mold life, reducing the overall cost of production in high-volume runs.

Superior Aesthetic Finish: Zinc castings often require minimal post-processing to achieve a high-quality surface finish, making them ideal for decorative and consumer-facing products.

Cost-Effective Solutions for Large Volumes: The combination of long mold life, low melting point, and minimal post-processing makes zinc a cost-effective solution for large-scale production.

Applications Requiring Electromagnetic Shielding: Zinc is beneficial in electronic components where electromagnetic interference (EMI) shielding is required.

What We Can Do In Precision Casting?

Our custom precision cast parts manufacturing services are mainly die casting, lost wax casting, sand casting, and gravity casting. According to the diverse needs of customers, we provide the most suitable casting services for customers.