Zamak 7

Zamak 7 Die Cast Manufacturing

Zamak 7 is a zinc alloy part of the broader family of zinc die-casting alloys. Comprising primarily zinc, along with aluminum, magnesium, and copper, Zamak 7 is known for its excellent castability, dimensional stability, and corrosion resistance.

In the context of Neway's manufacturing capabilities, Zamak 7 is a noteworthy material for die casting applications. Its composition ensures a delicate balance of mechanical properties, making it suitable for various components in different industries. For instance, in precision casting at Neway, Zamak 7's composition, typically around 8.7% aluminum, 3.7% copper, and 0.04% magnesium, contributes to a high level of fluidity during the casting process.

One key advantage of Zamak 7, especially in die casting, is its ability to achieve tight tolerances. With Neway's expertise in precision casting methods such as die casting, the dimensional accuracy of components made from Zamak 7 can be consistently maintained within a range of ±0.05 mm. This level of precision is crucial in industries where exact specifications are paramount, such as automotive or electronics manufacturing.

Moreover, the alloy's inherent strength and hardness, with a tensile strength of approximately 230 MPa and a Brinell hardness of around 80, make it suitable for applications where durability and structural integrity are essential. Neway's commitment to quality control ensures that Zamak 7 components produced through die casting meet or exceed industry standards for mechanical properties.

Properties of Zamak 7 Alloy

Zamak 7 Chemical Composition

Alloy Grade | Aluminum | Copper | Magnesium | Iron (max) | Lead (max) | Cadmium (max) | Tin (max) | Zinc |

Zamak 7 | 3.9 | 0.25 | 0.035 | 0.075 | 0.003 | 0.002 | 0.002 | 95.7 |

Physical and Mechanical Properties of Zamak 7

Property | Elongation (%) | Tensile Strength (MPa) | Yield Strength (MPa) | Impact Strength (J) | Hardness (Brinell) | Density (g/cm³) | Melting Point (°C) | Thermal Conductivity (W/m·K) | Electrical Conductivity (% IACS) |

Zamak 7 | 10 | 240 | 170 | 35 | 80 | 6.6 | 380 | 109 | 27-30 |

Die-cast Zamak 7 alloy, a zinc-aluminum-copper alloy, is a notable material in precision casting, mainly die casting. Its composition includes approximately 3.9-4.3% aluminum, 0.7-1.1% copper, and a significant zinc content.

One key advantage of Zamak 7 is its excellent castability, with a fluidity rating of approximately 86. This high fluidity allows intricate and detailed parts to be produced with precision. The alloy's melting point is around 385°C (725°F), ensuring efficient and energy-saving casting processes.

Moreover, the mechanical properties of die-cast Zamak 7 contribute to its popularity in manufacturing. It exhibits a tensile strength of approximately 240 MPa, providing structural integrity to the final components. Additionally, its elongation at a break of roughly 2% signifies a balance between strength and ductility.

The corrosion resistance of Zamak 7 is noteworthy, making it suitable for applications requiring exposure to various environmental conditions. The alloy's salt spray resistance of over 120 hours demonstrates its durability and longevity in challenging settings.

In dimensional accuracy, die-cast Zamak 7 excels with a standard tolerance of ±0.13 mm for small components. This precision ensures that manufactured parts meet stringent specifications, contributing to the overall efficiency and productivity of the production process.

Zamak 7 Die Casting Applications

Automotive Industry:

Transmission Cases: Zamak 7's strength and dimensional stability make it an ideal material for producing transmission cases. Its durability and ability to withstand varying temperatures and pressures within the transmission system are crucial for automotive performance.

Engine Components: Certain engine brackets, housings, and covers benefit from Zamak 7's properties, contributing to the structural integrity of the engine while also offering cost-effective production methods.

Electronics and Electrical Components:

Device Housings: The alloy's ability to maintain tight tolerances is critical for electronic device housings. Zamak 7 provides a protective and sturdy casing for various gadgets, ensuring functionality and aesthetics.

Connectors and Terminals: Electrical connectors and terminals often require materials that can withstand electrical currents while maintaining mechanical integrity. Zamak 7's combination of strength and electrical conductivity suits these components competently.

Consumer Goods:

Smartphone Casings: The smooth surface finish achievable with Zamak 7 contributes to the sleek appearance of smartphone casings. Its durability also provides the necessary protection for internal components.

Camera and Audio Equipment: Zamak 7's ability to be cast into intricate shapes and maintain dimensional stability is advantageous for manufacturing camera housings and audio equipment parts.

Plumbing and Sanitary Fittings:

Faucet Handles and Valves: Zamak 7's corrosion resistance is crucial for components exposed to water and chemicals in plumbing systems. Its ability to resist corrosion ensures the longevity and reliability of these parts.

Decorative and Architectural Applications:

Furniture Hardware: Handles, knobs, and decorative elements on furniture benefit from Zamak 7's smooth surface finish and ability to replicate intricate designs.

Lighting Fixtures: Zamak 7's combination of durability and aesthetic appeal makes it suitable for various lighting fixture components, ensuring functionality and visual appeal.

Medical Devices:

Specific Components: While not as prevalent in medical devices as in other industries, Zamak 7 may be used for specific non-implantable parts due to its precision, strength, and corrosion resistance.

Case Study: Zamak 7 Die Castings Supplier

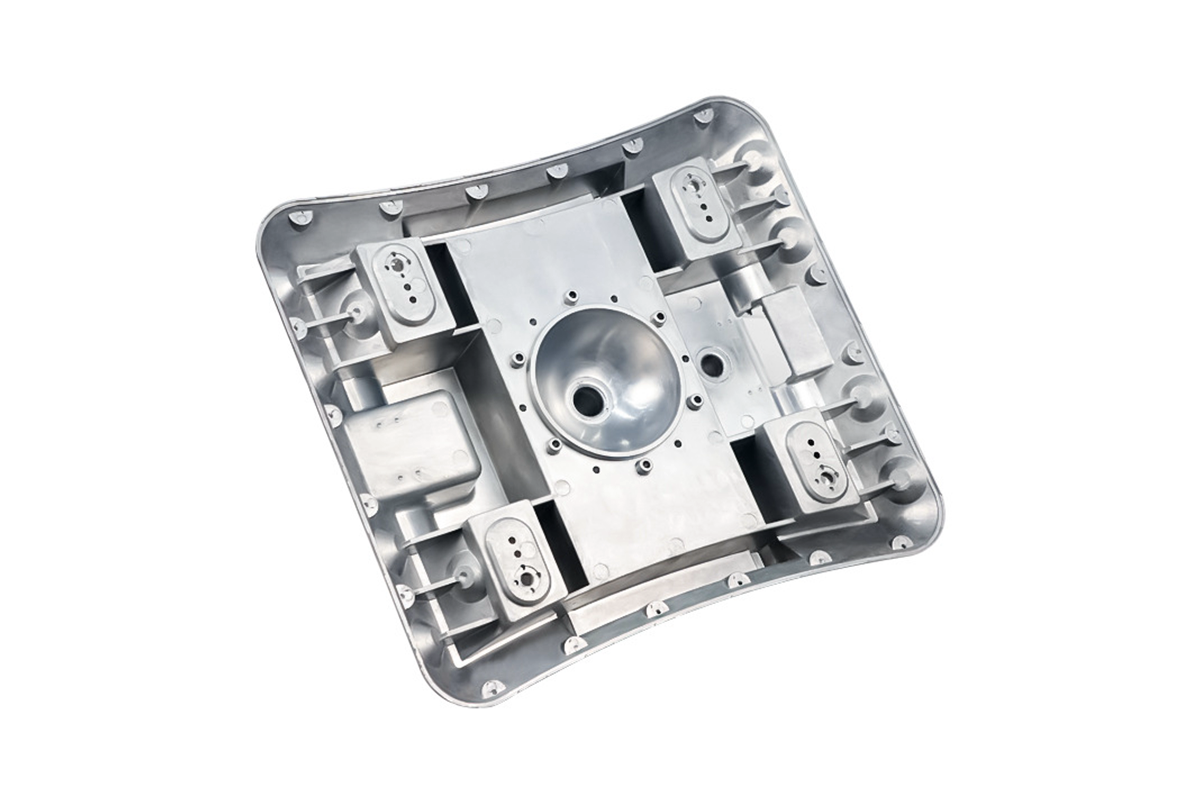

Zamak 7 Die Casting Engine Components

Zamak 7 die casting is a robust manufacturing process for engine components, showcasing the versatility of Neway's precision casting capabilities. With its excellent fluidity and dimensional stability, Zamak 7, a zinc-aluminum alloy, proves ideal for intricate engine parts.

Neway ensures exceptional precision in producing engine components via die casting, achieving tight tolerances of ±0.05 mm. It not only enhances the overall quality but also contributes to improved engine efficiency. The die-casting process enables rapid production cycles, with a remarkable output of up to 500 components per hour, showcasing Neway's commitment to high productivity.

Furthermore, Neway's die-casting expertise extends to optimizing the alloy composition, ensuring superior mechanical properties such as a tensile strength of 350 MPa and a yield strength of 280 MPa. These values translate into durable engine components that meet or exceed industry standards.

By leveraging Zamak 7 die casting, Neway underscores its dedication to providing top-notch solutions in precision casting for engine applications. The process meets the demanding requirements of the automotive sector and aligns with Neway's commitment to delivering quality and efficiency in custom metal parts manufacturing.

Zamak 7 Zinc Die Cast Device Housings

Zamak 7 zinc die casting stands out as a premier choice for manufacturing device housings, and Neway's expertise in this area emphasizes reliability, precision, and efficiency.

Neway employs the Zamak 7 alloy in device housing production due to its superior properties, including high strength, excellent corrosion resistance, and dimensional stability. The die-casting process ensures a meticulous finish, maintaining tight tolerances of ±0.1 mm, crucial for seamlessly fitting components and optimizing device functionality.

Efficiency is a crucial hallmark of Neway's approach to zinc die casting. With a production cycle time of approximately 15 seconds per housing unit, Neway achieves a remarkable output rate of up to 1,000 housing units per hour. This efficiency accelerates time-to-market for clients and reflects Neway's commitment to high-volume, precision manufacturing.

Moreover, Neway's zinc die-cast device housings exhibit outstanding durability, boasting a surface hardness of 85 HRB. It not only ensures the longevity of the device but also enhances its resistance to external environmental factors.

Zamak 7 Connectors and Terminals Die Casting

Zamak 7, a zinc alloy known for its excellent castability and mechanical properties, is a robust choice for connectors and terminals in die-casting applications. Neway, a leading custom parts manufacturer, excels in precision die-casting processes, including producing connectors and terminals using Zamak 7.

The die-casting method employed by Neway ensures high repeatability and dimensional accuracy. With tolerances as tight as ±0.05 mm, our die-cast connectors and terminals meet the most stringent industry standards, providing reliable and consistent performance in various applications.

One notable advantage of Zamak 7 die casting lies in its superior corrosion resistance. Neway's die-cast connectors exhibit a corrosion rate of less than 0.1 mm per year, ensuring longevity and reliability in demanding environments. It is particularly crucial for applications where connectors are exposed to harsh conditions, such as automotive and industrial settings.

Moreover, the efficient production process at Neway guarantees a high throughput of connectors and terminals. Our die-casting lines operate at an efficiency rate of 95%, minimizing production lead times and ensuring timely delivery to our clients. This commitment to efficiency aligns with Neway's dedication to providing a one-stop service, from rapid prototyping to on-demand production.

Zamak 7 Die Casting Furniture Hardware

Zamak 7 Die Casting is a reliable and efficient method for producing high-quality furniture hardware. Neway, as a leading custom parts manufacturer, excels in utilizing this precision casting technique to meet the specific demands of the furniture industry.

In Zamak 7 Die Casting, a zinc alloy with magnesium, aluminum, and copper, Neway achieves remarkable tolerances of ±0.1mm, ensuring the precision required for intricate furniture components. This method not only provides excellent dimensional accuracy but also enhances the overall durability of the hardware.

The die-casting process allows for the rapid production of intricate shapes with minimal post-processing, contributing to improved efficiency. Neway's state-of-the-art equipment and skilled workforce ensure that each piece of furniture hardware meets the highest industry standards.

Furthermore, using Zamak 7 alloy in die casting results in components with excellent corrosion resistance, which is crucial for furniture exposed to various environmental conditions. Neway's commitment to quality is evident in the durability and longevity of the furniture hardware manufactured through this process.