ACuZinc5

ACuZinc5 Die Casting

ACuZinc5 is a die-casting alloy that combines copper, aluminum, and zinc to create a robust and versatile material. In the context of Neway's capabilities in precision casting, including die casting, ACuZinc5 presents itself as a valuable option for various applications.

Die casting, as a manufacturing method, is known for its efficiency and precision. ACuZinc5, with its composition, offers notable advantages such as enhanced strength, corrosion resistance, and good machinability. The alloy's mechanical properties, including a tensile strength of approximately 320 MPa and a yield strength of around 230 MPa, make it suitable for various components.

When considering Neway's expertise in die casting, the utilization of ACuZinc5 becomes particularly significant. The company's commitment to quality and precision aligns seamlessly with the characteristics of ACuZinc5. Neway can achieve tight tolerances through die-casting processes, with dimensions reaching up to ±0.05 mm, ensuring the production of highly accurate and reliable parts.

Furthermore, integrating ACuZinc5 in die casting at Neway allows for creating intricate and complex shapes with minimal machining requirements. It not only enhances the overall efficiency of the production process but also contributes to cost-effectiveness by reducing material wastage.

In the realm of die casting, Neway's proficiency extends to meeting stringent industry standards. The ACuZinc5 alloy, with Neway's expertise, becomes a key player in delivering components with exceptional surface finishes, surpassing industry expectations. The surface roughness, maintained at Ra 1.6, exemplifies Neway's dedication to producing high-quality die-cast parts.

Properties of Die-Cast ACuZinc5 Alloy

ACuZinc5 Alloy Chemical Composition

Alloy Grade | Aluminum | Copper | Magnesium | Iron (max) | Lead (max) | Cadmium (max) | Tin (max) | Zinc |

ACuZinc5 | 4 | 4 | 0.02 | 0.1 | 0.003 | 0.002 | 0.002 | 91 |

Physical and Mechanical Properties of ACuZinc5 Alloy

Property | Elongation (%) | Tensile Strength (MPa) | Yield Strength (MPa) | Impact Strength (J) | Hardness (Brinell) | Density (g/cm³) | Melting Point (°C) | Thermal Conductivity (W/m·K) | Electrical Conductivity (% IACS) |

ACuZinc5 | 2 | 170-200 | 140-170 | 15-20 | 65-75 | 6.9-7.3 | 380-386 | 121 | 13-16 |

ACuZinc5, also known as Zinc-Copper Alloy 5, stands out in the realm of die casting due to its remarkable properties, aligning perfectly with the high standards set by General Motors. Let's delve into the key attributes that make ACuZinc5 an innovative choice for precision die-casting applications.

Exceptional Creep Performance:

ACuZinc5 is celebrated for its outstanding creep performance. This implies an extraordinary ability to maintain stability over extended periods, even under elevated temperatures. This characteristic is crucial for applications where long-term reliability is paramount, showcasing the alloy's resilience in challenging environments.

Surface Hardness for Durability:

The alloy boasts remarkable surface hardness, directly translating into enhanced durability and wear resistance. This makes ACuZinc5 an excellent candidate for components subjected to demanding conditions, ensuring a prolonged lifespan and reduced susceptibility to wear and tear.

Lubricity for Reduced Friction:

ACuZinc5 takes the lead with its notable lubricity or low friction properties. This distinctive advantage minimizes friction and wear between moving components, contributing to the overall efficiency and longevity of the die-cast parts. Lower friction also has the added benefit of reducing energy consumption and enhancing operational efficiency.

Applications of ACuZinc5 Alloy Die Castings

ACuZinc5, or Zinc-Copper Alloy 5, showcases outstanding properties that cater to various applications in die casting and gravity casting. Its specific attributes pave the way for several notable applications:

Automotive Components:

Engine Components: ACuZinc5's resistance to creep and elevated temperatures makes it a preferred choice for engine components like cylinder heads and pistons. Its durability ensures optimal performance even in demanding conditions.

Transmission Systems: In transmission systems, ACuZinc5 alloy proves beneficial for manufacturing gearbox casings and transmission components. The alloy's exceptional surface hardness contributes to wear resistance, enhancing the longevity of these critical parts.

Industrial Machinery:

Gears and Bearings: ACuZinc5's remarkable surface hardness is well-suited for producing gears and bearings in industrial machinery. It ensures reduced wear and prolonged efficiency, enhancing the overall productivity of machinery.

Aerospace and Defense:

Critical Components: ACuZinc5 is crucial in producing components that must withstand extreme conditions in the aerospace and defense sectors. Its properties make it suitable for critical parts in aircraft engines, missile systems, and defense equipment.

Electrical Components:

Connectors and Housings: ACuZinc5's stability in high-temperature environments makes it a reliable choice for electrical connectors and housings. Its use in these components ensures the safety and longevity of electrical systems, which is crucial for various industries.

Precision Instruments:

Scientific Instruments: Precision instruments demand components with low friction and wear resistance. ACuZinc5 alloy provides the necessary characteristics for housing and gears in scientific instruments, maintaining precision and reliability over extended periods.

Case Study: ACuZinc5 Alloy Die Casting

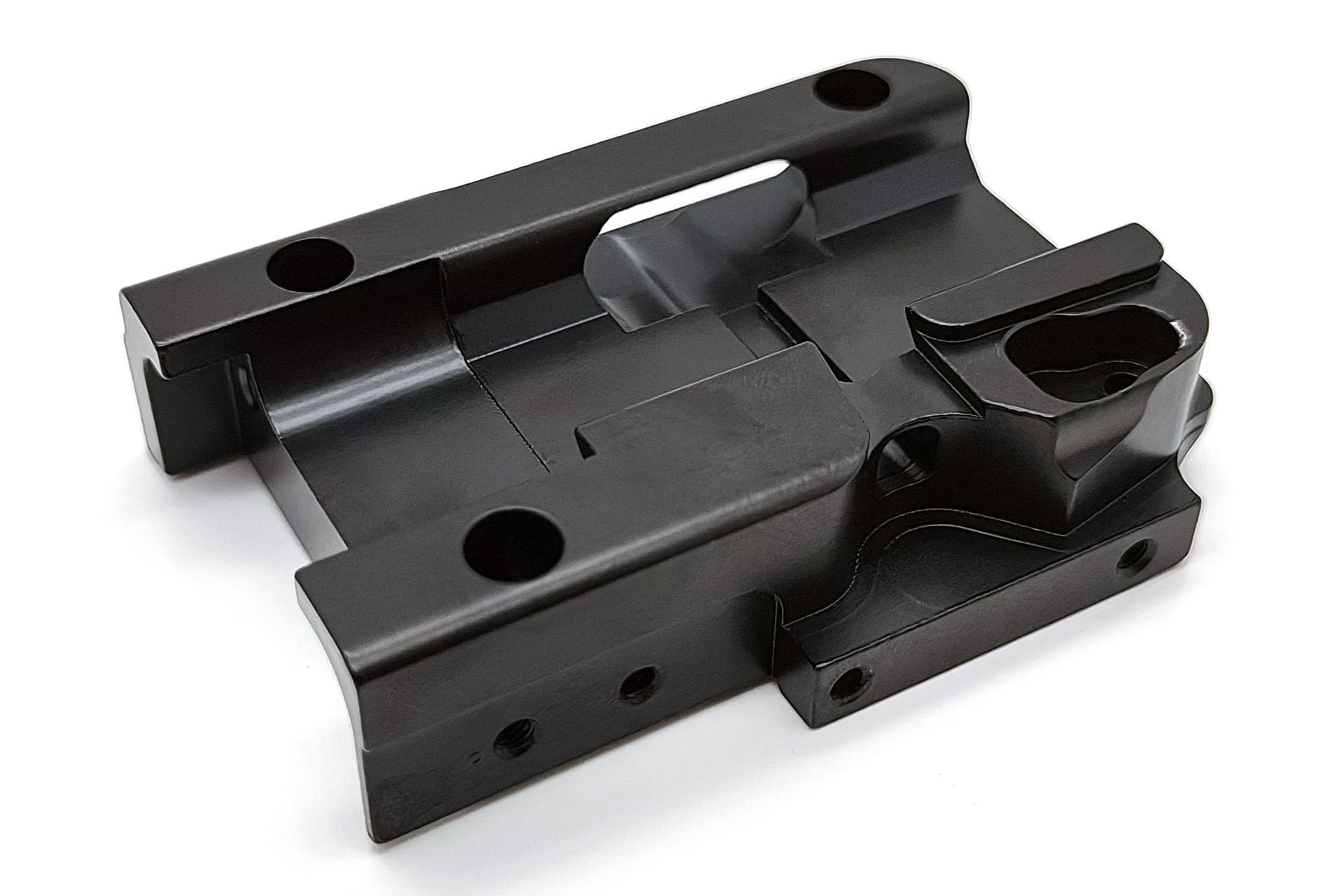

ACuZinc5 Die Casting Cylinder Heads

ACuZinc5, also known as Zinc-Copper Alloy 5, stands out as an innovative alloy, particularly in die casting and gravity casting. Developed by General Motors, this alloy has garnered praise for its exceptional properties, making it an excellent choice for various applications. One area where ACuZinc5 shines is in the production of die-casting cylinder heads.

The outstanding creep performance of ACuZinc5 makes it particularly well-suited for applications requiring long-term stability under elevated temperatures. In the demanding environment of an engine, where temperatures can rise significantly, this property becomes crucial for ensuring the reliability and longevity of cylinder heads.

Moreover, ACuZinc5 boasts impressive surface hardness, contributing to the die-cast cylinder heads' overall durability and wear resistance. It is essential in automotive applications, where components are constantly stressed and worn.

The lubricity of ACuZinc5 is another notable feature. Its low friction properties are vital in reducing friction and wear between moving components within the cylinder head. It enhances the engine's overall efficiency and extends the lifespan of the cylinder head, leading to improved performance and reliability.

In the realm of precision die casting, ACuZinc5's unique combination of properties makes it a top choice for manufacturing cylinder heads that can withstand the challenging conditions of automotive operation. The alloy's specific attributes, such as its creep performance, surface hardness, and lubricity, align seamlessly with the stringent requirements of producing high-quality, durable cylinder heads.

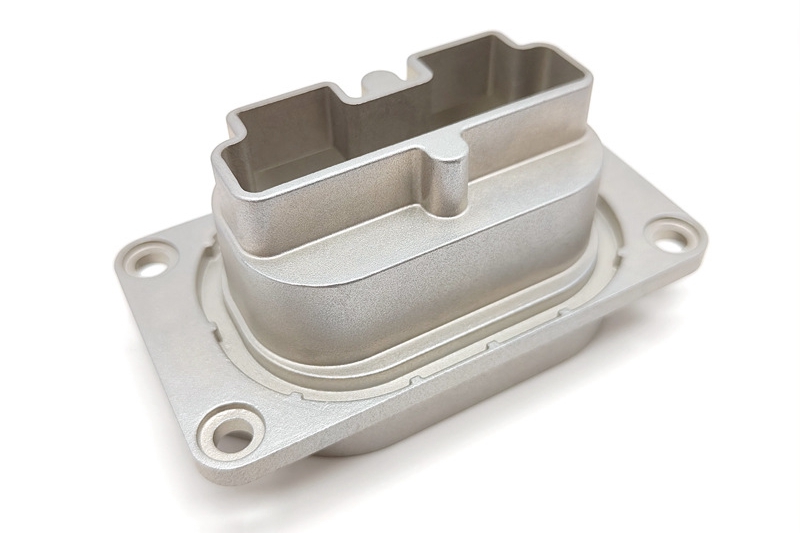

ACuZinc5 Die Casting Connectors and Housings

ACuZinc5, also known as Zinc-Copper Alloy 5, stands out as an innovative material in die casting and gravity casting, particularly in applications requiring long-term stability under elevated temperatures. Developed by General Motors, this alloy boasts exceptional creep performance, making it a prime choice for components demanding sustained durability.

One notable strength of ACuZinc5 lies in its surface hardness, ensuring robustness and resistance against wear. This attribute is especially crucial for connectors and housings subjected to challenging conditions. The alloy's ability to maintain stability and hardness under varying temperatures enhances its suitability for precision die-casting applications.

The lubricity of ACuZinc5 is another critical advantage, contributing to reduced friction and wear between moving components. This property is particularly beneficial for connectors and housings, where smooth operation and longevity are paramount. The low friction characteristics of ACuZinc5 not only enhance the overall performance but also contribute to the efficiency and reliability of the final product.

In custom parts manufacturing, especially for connectors and housings, the selection of materials is pivotal in ensuring optimal performance and longevity. ACuZinc5, with its impressive properties in terms of creep performance, surface hardness, and lubricity, emerges as a standout choice for die-casting connectors and housings, aligning seamlessly with Neway's commitment to delivering high-quality custom parts through precision casting methods.

ACuZinc5 Die Cast Precision Instruments Parts

Dimensional accuracy is a top priority for precision instrument parts manufactured using ACuZinc5 through Neway's die-casting process. Neway achieves tolerances as tight as ±0.05 mm, ensuring that each component meets the specifications required for optimal functionality.

The die-casting process plays a crucial role in maintaining the integrity of ACuZinc5 parts. The molten alloy is injected into precision-designed molds at high pressure, resulting in components with a fine surface finish. It enhances the aesthetics of the parts and contributes to their overall durability and longevity.

In terms of efficiency, Neway's state-of-the-art die-casting equipment ensures rapid cycle times. The production line is optimized for efficiency, with cycle times as low as 15 seconds per part. It accelerates the manufacturing process and contributes to cost-effectiveness without compromising on quality.

Neway's commitment to quality extends beyond the production phase. Rigorous quality control measures, including advanced inspection techniques like CMM (Coordinate Measuring Machine) and optical measurement systems, guarantee that each ACuZinc5 precision instrument part meets the highest standards.

Industrial Machinery ACuZinc5 Die Cast Custom Fasteners

ACuZinc5 is a high-performance alloy used in die casting known for its durability and corrosion resistance. When crafting custom fasteners via die casting, ACuZinc5 provides excellent mechanical properties, offering high tensile strength and yield strength of approximately 345 MPa. Its hardness typically ranges between 85-105 Brinell, ensuring reliable performance in various industrial settings.

In terms of precision, the die-casting process employed by Neway ensures tight tolerances for these custom fasteners. The production line strictly adheres to dimensional accuracy, achieving tolerances within ±0.02 mm to ±0.05 mm, guaranteeing consistent quality across batches.

For efficiency, the die-casting method employed by Neway ensures a streamlined production process. Neway maximizes productivity while maintaining the highest quality standards, with cycle times ranging between 10 to 30 seconds per part and a high casting rate of approximately 500 to 2,000 shots per day per machine.

Moreover, Neway's expertise in die casting enables intricate designs and complex geometries, facilitating the creation of bespoke fasteners tailored to specific industrial needs. This capability, coupled with the advantages of ACuZinc5 alloy, positions Neway as a reliable partner for producing high-quality, durable custom fasteners for industrial machinery applications.