Die Casting Process, Materials, Molds, Pros, and Cons | Neway

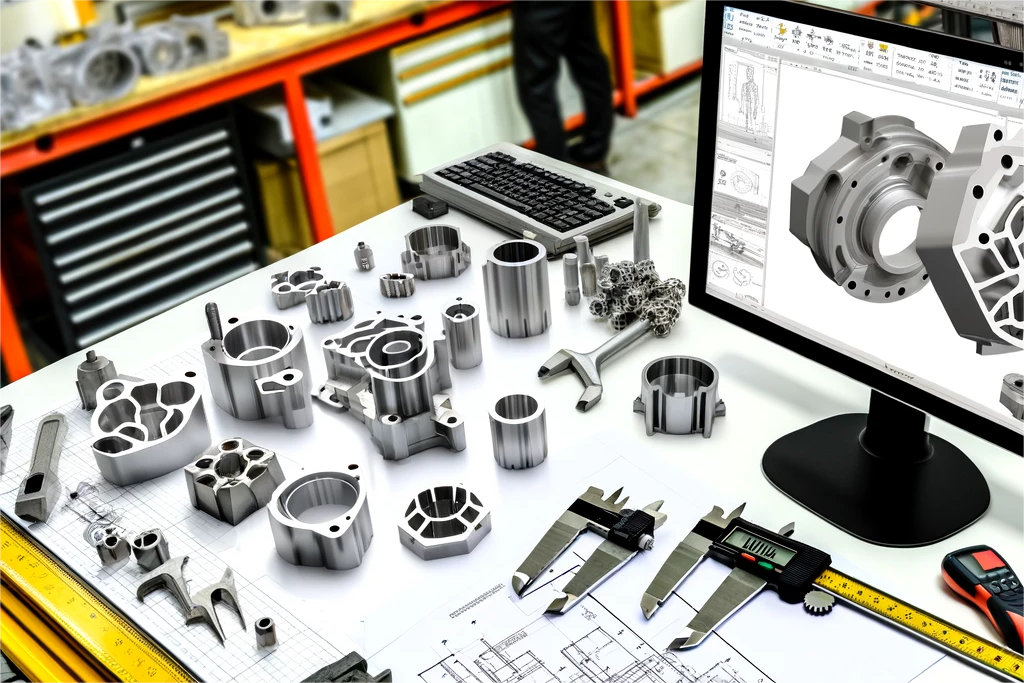

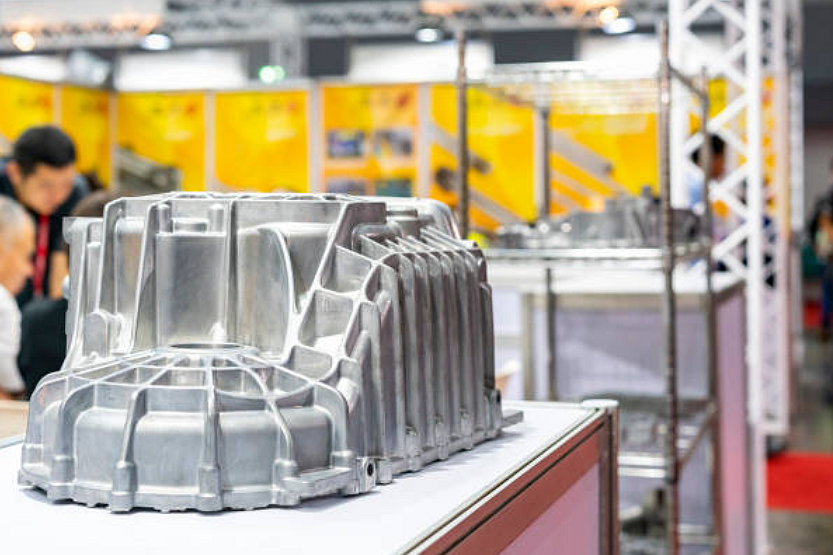

Die casting, a precision-driven and efficient metal manufacturing process, is a cornerstone in producing goods across industrial, commercial, and consumer sectors. Die-cast parts are renowned for their accuracy, making die casting a go-to process for creating complex metal components, especially in high-volume production scenarios. The die caster often works with primary materials such as aluminum, magnesium, and zinc alloys, each offering unique benefits and being suitable for specific applications. This in-depth exploration of die casting will provide valuable insights for designers and purchasers in the manufacturing industry, particularly those seeking custom die-cast parts.

Exploring the Various Types of Die Casting

Die casting is not a one-size-fits-all process. It branches into several types, each possessing unique characteristics and applications, catering to the needs of different die casters and their projects.

Hot Chamber Die Casting

This method involves melting the metal within a chamber directly attached to the die casting machine. It's typically employed for metals with lower melting points, such as zinc, magnesium, and lead alloys. It is more suitable for manufacturing small parts such as watch frames, belt buckles, and electronic cigarette cases. For a detailed comparison, see hot chamber vs. cold chamber die casting.

Cold Chamber Die Casting

In contrast to hot chamber die casting, the metal is melted in a separate furnace before being transferred to the machine. This method is slower but is used for metals with higher melting points, like aluminum die-cast alloys.

Die Casting Process Steps

Regardless of the die-casting type, the process follows a routine. Here are the steps involved:

Clamping

The initial stage involves reading the dies for casting. The two halves of the die, the cover die half and the ejector die half, are secured together—the gap between these two halves functions as the mold cavity.

Injection

In the subsequent stage, molten metal is injected into the mold cavity under high pressure. The pressure degree depends on the material type and whether it is a hot-chamber or cold-chamber die-casting machine. The pressure ensures that the material is forced into even the tiniest crevices of the mold.

Cooling

Post-injection, the molten metal begins to cool and solidify within the mold cavity. The pressure is maintained during this stage to mitigate shrinkage and ensure the metal fills the cavity.

Ejection

Once the metal has cooled and solidified, the casting is ejected. The dies are opened, and the castings are gently pushed out of the dies with ejector pins. Another shot can be prepared immediately after the ejection, enabling rapid mass manufacture of identical parts.

Trimming

The final stage of the die-casting process is the shakeout stage. This involves cutting the excess bits of metal attached to the casting, including flash from the parting line and any gates, runners, and sprues.

Understanding these steps is crucial for part designers and purchasers as it helps to plan the design and production process effectively.

Material Considerations in Die Casting

Die casting employs a variety of metals, predominantly non-ferrous, although occasionally ferrous metals can be used too. The primary die-casting materials are aluminum, magnesium, and zinc alloys, each with unique properties and applications. To explore detailed material options, refer to the materials database.

Aluminum Alloys

Aluminum die-casting alloys are lightweight and offer good dimensional stability, making them an excellent choice for complex, fine-featured parts. For example, Aluminum 360, A380, and B390 are common options, each suited for specific mechanical and thermal requirements.

Materials Selector |

|---|

Commercial: | 360 | A360 | 380 b | A380 b | 383 | 384 b | B390* | 13 | A13 | 43 | 218 |

ANSI/AA | 360.0 | A360.0 | 380.0 | A380.0 | 383.0 | 384.0 | B390.0 | 413.0 | A413.0 | C443.0 | 518.0 |

Nominal | Mg 0.5 | Mg 0.5 | Cu 3.5 | Cu 3.5 | Cu 2.5 | Cu 3.8 | Cu 4.5 | Si 12.0 | Si 12.0 | Si 5.0 | Mg 8.0 |

Comp: | Si 9.0 | Si 9.5 | Si 8.5 | Si 8.5 | Si 10.5 | Si 11.0 | Si 17.0 |

|

|

|

|

Chemical Composition

Detailed Composition | |||||||||||

Silicon Si | 9.0-10.0 | 9.0-10.0 | 7.5-9.5 | 7.5-9.5 | 9.5-11.5 | 10.5-12.0 | 16.0-18.0 | 11.0-13.0 | 11.0-13.0 | 4.5-6.0 | 0.35 |

Iron Fe | 2.0 | 1.3 | 2.0 | 1.3 | 1.3 | 1.3 | 1.3 | 2.0 | 1.3 | 2.0 | 1.8 |

Copper Cu | 0.6 | 0.6 | 3.0-4.0 | 3.0-4.0 | 2.0-3.0 | 3.0-4.5 | 4.0-5.0 | 1.0 | 1.0 | 0.6 | 0.25 |

Magnesium Mg | 0.4-0.6 | 0.4-0.6 | 0.30 f | 0.30 f | 0.10 | 0.10 | 0.45- 0.65 | 0.10 | 0.10 | 0.10 | 7.5-8.5 |

Manganese Mn | 0.35 | 0.35 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.35 | 0.35 | 0.35 | 0.35 |

Nickel Ni | 0.50 | 0.50 | 0.50 | 0.50 | 0.30 | 0.50 | 0.10 | 0.50 | 0.50 | 0.50 | 0.15 |

Zinc Zn | 0.50 | 0.50 | 3.0 | 3.0 | 3.0 | 3.0 | 1.5 | 0.50 | 0.50 | 0.50 | 0.15 |

Tin Sn | 0.15 | 0.15 | 0.35 | 0.35 | 0.15 | 0.35 | — | 0.15 | 0.15 | 0.15 | 0.15 |

Titanium Ti | — | — | — | — | — | — | 0.10 | — | — | — | — |

Others Each | — | — | — | — | — | — | 0.10 | — | — | — | — |

Total Others c | 0.25 | 0.25 | 0.50 | 0.50 | 0.50 | 0.50 | 0.20 | 0.25 | 0.25 | 0.25 | 0.25 |

Aluminum Al | Balance | Balance | Balance | Balance | Balance | Balance | Balance | Balance | Balance | Balance | Balance |

Aluminum Die Casting Alloys | |||||||||||

Commercial | 360 | A360 | 380 | A380 EF | 383 | 384 | B390* | 13 | A13 | 43 | 218 |

ANSI/AA | 360 | A360.0 | 380.0 | A380.0 | 383 E | 384.0 | B390.0 | 413 | A413.0 | C443.0 | 518.0 |

Mechanical Properties | |||||||||||

Ultimate Tensile Strength | |||||||||||

KSI | 44 | 46 | 46 | 47 | 45 | 48 | 46 | 43 | 42 | 33 | 45 |

(MPa) | 303 | 317 | 317 | 324 | 310 | 331 | 317 | 296 | 290 | 228 | 310 |

Yield Strength | |||||||||||

KSI | 25 | 24 | 23 | 23 | 22 | 24 | 36 | 21 | 19 | 14 | 28 |

(MPa) | 172 | 165 | 159 | 159 | 152 | 165 | 248 | 145 | 131 | 97 | 193 |

Elongation | |||||||||||

% in 2in. (51mm) | 2.5 | 3.5 | 3.5 | 3.5 | 3.5 | 2.5 | <1 | 2.5 | 3.5 | 9 | 5 |

Hardness b | |||||||||||

BHN | 75 | 75 | 80 | 80 | 75 | 85 | 120 | 80 | 80 | 65 | 80 |

Shear Strength | 25 | 25 | 19 | 29 | |||||||

(MPa) | 193 | 179 | 193 | 186 | — | 200 | — | 172 | 172 | 131 | 200 |

Impact Strength | |||||||||||

ftlb | — | — | 3 | — | 3 d | — | — | — | — | — | 7 |

(J) | — | — | 4 | — | 4 | — | — | — | — | — | 9 |

Fatigue Strength c | |||||||||||

KSI | 20 (MPa | 18 | 20 | 20 | 21 | 20 | 20 | 19 | 19 | 17 | 20 |

(MPa) | 138 | 124 | 138 | 138 | 145 | 138 | 138 | 131 | 131 | 117 | 138 |

Young’s Modulus | |||||||||||

psi x 106 | 10.3 | 10.3 | 10.3 | 10.3 | 10.3 | — | 11.8 | 10.3 | — | 10.3 | — |

(GPa) | -71 | 71 | 71 | 71 | 71 | — | 81 | 71 | — | 71 | — |

Physical Properties | |||||||||||

Density | |||||||||||

lb/in3 | 0.095 | 0.095 | 0.099 | 0.098 | 0.099 | 0.102 | 0.098 | 0.096 | 0.096 | 0.097 | 0.093 |

(g/cm3) | 2.63 | 2.63 | 2.74 | 2.71 | 2.74 | 2.82 | 2.71 | 2.66 | 2.66 | 2.69 | 2.57 |

Melting Range | |||||||||||

°F | 1035-1105 | 1035-1105 | 1000-1100 | 1000-1100 | 960-1080 | 960-1080 | 950-1200 | 1065-1080 | 1065-1080 | 1065-1170 | 995-1150 |

(°C) | 557-596 | 557-596 | 540-595 | 540-595 | 516-582 | 516-582 | 510-650 | 574-582 | 574-582 | 574-632 | 535-621 |

Specific Heat | |||||||||||

BTU/lb °F | 0.23 | 0.23 | 0.23 | 0.23 | — | 0.23 | — | 0.23 | 0.23 | 0.23 | — |

(J/kg °C) | 963 | 963 | 963 | 963 | — | 963 | — | 963 | 963 | 963 | — |

Coefficient of Thermal Expansion | |||||||||||

u in/in°F | 12.2 | 12.1 | 11.7 | 11.6 | 10 | 11.3 | 11.9 | 12.2 | 13.4 | ||

(u m/m°K) | 22 | 21.8 | 21.1 | 21 | 18 | 20.4 | 21.6 | 22 | 24.1 | ||

Thermal Conductivity | |||||||||||

BTU/ft hr°F | 65.3 | 65.3 | 55.6 | 55.6 | 55.6 | 55.6 | 77.4 | 70.1 | 70.1 | 82.2 | 55.6 |

(W/m °K) | 113 | 113 | 96.2 | 96.2 | 96.2 | 96.2 | 134 | 121 | 121 | 142 | 96.2 |

Electrical Conductivity | |||||||||||

% IACS | 30 | 29 | 27 | 23 | 23 | 22 | 27 | 31 | 31 | 37 | 24 |

Poisson’s Ratio | 0.33 | 0.33 | 0.33 | 0.33 | 0.33 | — | — | — | — | 0.33 | — |

Zinc and Za Alloys

Zinc alloys are the most manufacturer-friendly of die-casting materials and offer benefits like impact strength, flexibility, and suitability for plating. Due to their castability, they also result in minimal die wear. Learn more about zinc die casting materials.

Copper Alloys

Copper alloys exhibit high strength, hardness, corrosion resistance, and excellent dimensional stability. See also copper alloy casting services.

Magnesium Alloys

Magnesium is even lighter than aluminum, with the advantage of being highly machinable. It is suitable for cast parts requiring additional details or machined surface finishing.

Geometry in Die Casting Design

Designing for die casting requires understanding several principles and considerations to ensure the final part meets the desired specifications and quality. Here are some key aspects:

Parting Line

The parting line is where the two halves of the die meet. The parting line's location can affect the die's complexity and the appearance of the final casting.

Draft

The draft is a slight angle incorporated into the walls of the part that are parallel to the opening direction of the die. This allows for easier ejection of the part from the die.

Fillet Radii

Fillets are the rounded corners and edges of the part. They help reduce stress concentration and improve the molten metal's flow.

Bosses

Bosses have raised portions of the design for mounting and other functional purposes. They should be connected to walls or ribs for better support and cooling.

Ribs

Ribs are thin, flat sections of the part that add strength and rigidity. They also help in improving the flow of the molten metal and cooling.

Holes and Windows

Holes and windows are openings in a part. Their size and location can affect the molten metal's flow and the part's strength.

Tolerances in Die Casting

Die casting can achieve high precision and tight tolerances. However, the achievable tolerances can vary based on factors such as the type of material, the design of the part, and the specific die casting process used. For typical tolerances and quality standards, check out die casting process standards.

Linear Dimensions

These are the straight-line measurements of the part. They can be affected by factors such as the material's shrinkage and the die's thermal expansion.

Flatness

Flatness measures a surface's deviation from being perfectly flat. It can be affected by factors such as the cooling rate and the part's design.

Roundness

Roundness is the measure of how closely the shape of an object approaches that of a perfect circle. It can be affected by factors such as the flow of the molten metal and the cooling rate.

Surface Finishes in Die Casting

What are the surface finishes of die castings, and how do we achieve them? The surface finish of a die-cast part can be influenced by the type of material, the design of the part, and the specific die-casting process used. Several types of surface finishes can be achieved. For an overview of finishing options, see metal part surface finishes and anodizing process.

As Die-Cast Finishes

These are the finishes that are achieved directly from the die-casting process. They can vary based on the material type and the die's condition.

Machining Finishes

These are finishes achieved through mechanical processes such as grinding, polishing, blasting, and buffing.

Chemical Finishes

These are finishes achieved through chemical processes such as etching, anodizing, and plating.

Powder Coating

These finishes involve applying paint or powder to the part's surface.

These are specialized finishes that can provide unique aesthetic or functional properties to the part.

Weighing the Pros and Cons of Die Casting

Die casting offers several advantages, making it a preferred choice for the mass production of complex parts. However, it also has certain limitations that need to be considered. For a detailed comparison, read die casting vs. sand casting and die casting vs. investment casting.

Multi-Slide and Conventional Die Casting

Multi-slide die casting uses multiple slides in the tooling, allowing for complex and intricate parts to be produced. Conventional die casting, on the other hand, uses a simpler tooling setup and is more suited for simpler parts.

Benefits of Multi-Slide Tooling

Multi-slide tooling allows for producing complex parts with high precision and excellent surface finish. It also offers faster cycle times, leading to higher productivity.

Benefits of Conventional Tooling

Conventional tooling is more straightforward and less expensive. It suits more significant parts and materials requiring slower injection speeds.

Die Casting Vs. Investment Casting

While die casting is ideal for the high-volume production of complex parts, investment casting allows for the production of parts with intricate details and an excellent surface finish. However, investment casting is slower and more expensive.

Die Casting Vs. Sand Casting

Die casting offers higher precision, a better surface finish, and faster production times than sand casting. However, sand casting is more flexible regarding design changes and more suited for significant parts.

Cost Considerations in Die Casting

Several factors can affect the cost of die casting. Understanding these factors can help in making cost-effective decisions. For guidance on cost analysis, visit die casting cost calculation.

Die Casting Material Selection: The type of material used can significantly affect the cost. Materials with higher melting points require more energy and can wear out the die faster.

- Production Cost: The cost includes melting the material, operating the die casting machine, and labor costs.

- Mold Cost: The cost of the mold can be significant, especially for complex parts. However, the mold can be used for many parts, spreading the cost over the production run.

- Secondary Operations Cost: Any secondary operations, such as machining, surface finishing, and assembly, can add to the cost.

- Finishing Cost: The cost of the final finishing operations, such as painting, plating, or coating, can also add to the cost.

- How to Reduce Die-Cast Cost: Cost can be reduced by optimizing the part design, selecting the most suitable material, minimizing secondary operations, and optimizing the production process.

Applications of Die Casting Across Industries

Die casting is used in many industries due to its ability to produce complex parts with high precision and an excellent surface finish. Notable industries include automotive, aerospace, medical devices, consumer electronics, and energy. Each sector utilizes die casting for its unique combination of quality, precision, and efficiency.

A Versatile and Efficient Manufacturing Process

Die casting, with its ability to produce complex parts with high precision and excellent surface finish, is a versatile and efficient manufacturing process. Whether it's aluminum die casting, zinc alloys, or other materials, die casting offers a range of benefits that make it a preferred choice for many industries. For more details on how to start your custom project, see custom parts manufacturing service.

Die casting is crucial for producing high-quality automotive, electronics, aerospace, medical, and construction parts. With advancements in technology and materials, the potential applications of die casting are continually expanding.

For purchasers and designers seeking custom die-cast parts, understanding the intricacies of die casting – from the process and materials to design considerations, tolerances, surface finishes, and cost factors – is essential. This knowledge will enable them to make informed decisions and leverage the benefits of die casting to meet their specific requirements.

I hope you found this in-depth exploration of die casting informative and valuable. Please let me know if you have any specific requests or would like changes to the above content.