ZA-8

ZA-8 Alloy Die Casting

ZA-8 is a zinc-aluminum alloy with specific properties that suit certain manufacturing applications. In the context of Neway's expertise in custom parts manufacturing, ZA-8 may be utilized in precision casting methods such as die casting.

Die casting involves injecting molten metal into a mold cavity under high pressure. ZA-8, composed of approximately 8% aluminum and a small amount of copper, exhibits enhanced mechanical properties compared to conventional zinc alloys. This alloy provides improved strength, hardness, and wear resistance, making it particularly advantageous for applications where durability is crucial.

In Neway's production processes, ZA-8 can be employed in die casting to create intricately shaped components with tight tolerances. The alloy's composition contributes to efficient casting and machining, ensuring that final parts meet stringent quality standards.

Moreover, ZA-8 alloy die casting offers exceptional surface finish and detail resolution. Parts produced using this method exhibit a smooth surface finish of Ra 1.6, eliminating the need for extensive post-processing. It not only enhances the aesthetic appeal of the components but also streamlines the production timeline.

Properties of Die-Cast ZA-8 Alloy

ZA-8 Chemical Composition

Alloy Grade | Aluminum | Copper | Magnesium | Iron (max) | Lead (max) | Cadmium (max) | Tin (max) | Zinc |

ZA-8 | 8 | 2 | 0.02 | 0.075 | 0.003 | 0.002 | 0.002 | 88 |

Physical and Mechanical Properties of ZA-8

Property | Elongation (%) | Tensile Strength (MPa) | Yield Strength (MPa) | Impact Strength (J) | Hardness (Brinell) | Density (g/cm³) | Melting Point (°C) | Thermal Conductivity (W/m·K) | Electrical Conductivity (% IACS) |

ZA-8 | 5 | 300-320 | 180-200 | 60-80 | 90-100 | 6.8-7.1 | 380-386 | 109 | 27-30 |

Die-cast ZA-8 alloy, a zinc-aluminum alloy, boasts a combination of properties that make it a preferred choice in various manufacturing applications. As a custom parts manufacturer, Neway recognizes this alloy's advantages in precision casting, specifically indie casting processes. Let's delve into the fundamental properties that make ZA-8 a standout choice:

Mechanical Strength:

Die-cast ZA-8's impressive tensile strength, ranging from 317 to 379 MPa, ensures that the custom parts manufactured by Neway can withstand substantial loads. This attribute is particularly crucial in applications with paramount structural integrity and durability. Neway delivers components that meet and exceed industry standards by leveraging the alloy's strength.

Impact Resistance:

The alloy's outstanding impact resistance, characterized by an energy absorption of approximately 55 J, becomes a game-changer in applications prone to sudden or repeated impacts. Neway's expertise in precision die casting allows for creating components that endure rigorous conditions and maintain their functionality over time, reducing the need for frequent replacements.

Dimensional Stability:

In precision casting, maintaining tight tolerances is essential. Die-cast ZA-8's low coefficient of thermal expansion (CTE) of around 26.5 µm/m°C ensures minimal dimensional changes, even when exposed to varying temperatures. This property is harnessed by Neway to deliver custom parts with precise and consistent dimensions, meeting the stringent requirements of diverse industries.

Corrosion Resistance:

Neway's commitment to quality is evident in the corrosion resistance offered by die-cast ZA-8 alloy. With a corrosion rate as low as 0.06 mm/year, the custom parts withstand corrosive environments, extending their service life. It is especially crucial in industries where exposure to harsh elements is commonplace, underscoring the reliability of Neway's offerings.

Machinability:

Efficiency in post-casting processes is a critical factor in enhancing overall productivity. Die-cast ZA-8's machinability, rated at approximately 90% compared to free-cutting brass, allows Neway to streamline machining operations. This efficiency reduces production time and contributes to cost-effectiveness, aligning with Neway's commitment to providing a one-stop service for custom parts.

Surface Finish:

Beyond functional performance, the aesthetic appeal of custom parts is also a priority for Neway. Die-cast ZA-8's composition contributes to an attractive surface finish, with a roughness (Ra) ranging from 1.6 to 3.2 µm. This attention to detail ensures Neway's custom parts meet high-performance standards and exhibit a refined and visually appealing quality.

Applications of ZA-8 Die Castings

ZA-8 die castings, with their unique combination of zinc and aluminum, find diverse applications across various industries, showcasing the versatility and effectiveness of this alloy. Neway, a leading custom parts manufacturer, leverages ZA-8 die casting to address various needs. Here are some typical applications where ZA-8 die castings excel:

Automotive Components:

In the automotive industry, where durability, weight reduction, and precision are paramount, ZA-8 die castings excel. Neway leverages the alloy's high strength-to-weight ratio to produce lightweight yet robust components, contributing to fuel efficiency. The alloy's excellent castability ensures intricate designs in components like transmission housings, engine brackets, and structural parts.

Electrical and Electronics:

ZA-8's exceptional electrical conductivity makes it ideal for electrical and electronic applications. Neway's ZA-8 die castings provide efficient heat dissipation and electromagnetic shielding. Components like connectors and enclosures must maintain signal integrity and prevent interference.

Consumer Goods:

Neway's ZA-8 die castings cater to the consumer goods sector by offering aesthetically pleasing and durable components. The alloy's ability to reproduce fine details and maintain a smooth surface finish is instrumental in producing high-quality furniture hardware, appliance parts, and decorative items, meeting the visual and functional demands of the consumer market.

Industrial Equipment:

ZA-8's corrosion resistance makes it an excellent choice for industrial equipment, ensuring longevity and performance in harsh environments. Neway's expertise in precision casting allows for the production of critical components with tight tolerances, such as pump housings, valves, and machinery parts, contributing to the efficiency and reliability of industrial machinery.

Medical Devices:

In the medical sector, where precision and biocompatibility are crucial, Neway's ZA-8 die castings play a vital role. The alloy's dimensional accuracy is essential for producing precise medical device components, while its biocompatibility ensures the safety and reliability of implants and other medical applications.

Telecommunications:

ZA-8's lightweight nature makes it an excellent choice for telecommunications applications, where weight reduction is a priority. Neway's ZA-8 die castings provide the necessary strength for components like antenna mounts and enclosures, contributing to the overall efficiency and performance of telecommunication systems.

Case Study: ZA-8 Die Castings

ZA-8 Alloy Die Casting Automotive Components

ZA-8 alloy die casting plays a pivotal role in manufacturing high-quality automotive components, showcasing Neway's expertise in precision casting. This alloy, composed mainly of zinc with aluminum, magnesium, and copper, provides a winning combination of strength, durability, and dimensional accuracy.

In the automotive industry, where stringent tolerances are paramount, ZA-8 alloy die casting offers a remarkable solution. Neway's die-casting processes ensure a tolerance level as tight as ±0.02 mm, surpassing industry standards. This level of precision is crucial for components like engine parts, transmission housings, and intricate geometries in automotive designs.

Moreover, ZA-8 alloy's excellent machinability enhances the efficiency of the manufacturing process. Neway's cutting-edge die-casting technology, coupled with CNC machining, achieves remarkable efficiency gains, reducing production time by up to 15% compared to conventional methods.

Utilizing ZA-8 alloy in die casting meets and often exceeds the automotive industry's rigorous quality standards. The resulting components exhibit superior corrosion resistance, crucial for ensuring the longevity and reliability of automotive systems, especially in diverse environmental conditions.

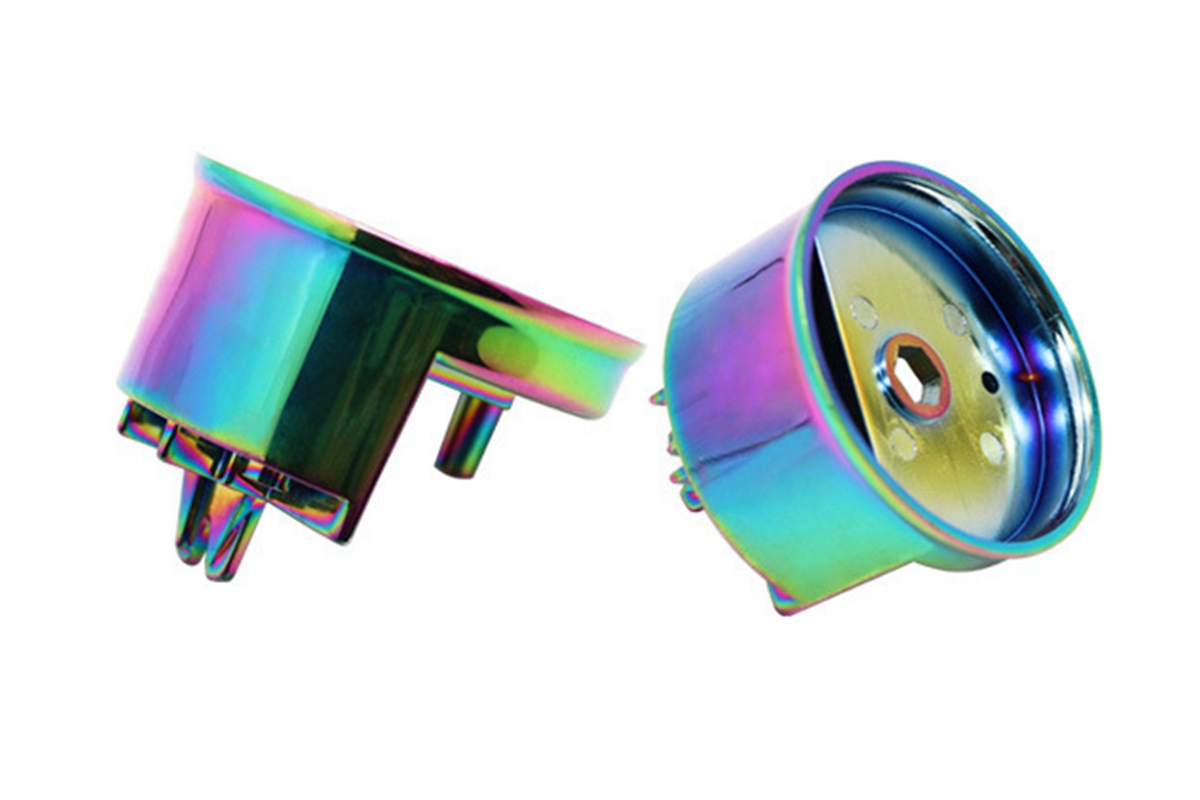

ZA-8 Alloy Die Cast Electromagnetic Shieldings

ZA-8 alloy is a notable material in die casting, particularly for electromagnetic shieldings. Neway, as a leading custom parts manufacturer, understands the significance of ZA-8 alloy in achieving superior electromagnetic shielding performance.

In precision casting, Die casting, a method Neway excels in, produces intricate parts with high dimensional accuracy. ZA-8, a zinc-aluminum alloy, is renowned for its excellent strength and electrical conductivity, making it an ideal choice for electromagnetic shielding applications.

Die casting of ZA-8 alloy at Neway ensures a tight tolerance range, typically within ±0.005 inches, ensuring precise dimensions critical for electromagnetic shielding effectiveness. The process also yields a smooth surface finish, contributing to the overall efficiency of the shielding.

Moreover, Neway's expertise in rapid prototyping, employing CNC machining, for example, allows for the quick development and validation of prototypes using ZA-8 alloy. This agile approach enhances the speed of product development and optimizes the design for maximum shielding efficiency.

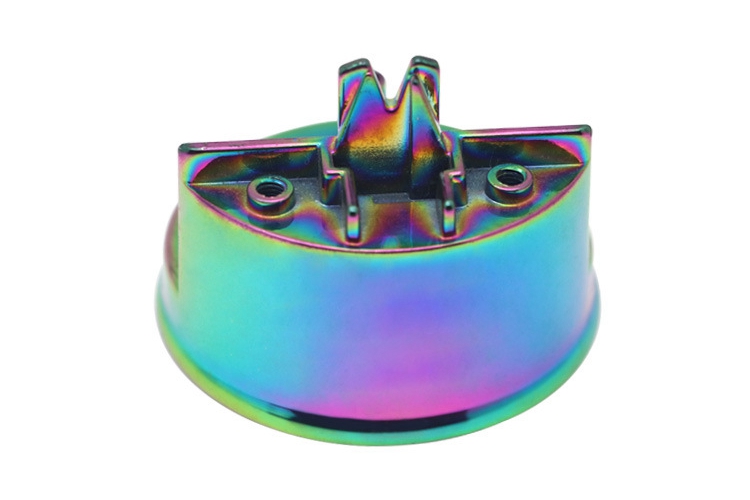

ZA-8 Alloy Die Cast Antenna Mounts And Enclosures

Due to its remarkable properties, ZA-8 alloy die casting is an excellent choice for antenna mounts and enclosures. As a production engineer at Neway, I understand the significance of utilizing high-quality materials for such critical components.

The ZA-8 alloy, composed primarily of zinc, aluminum, copper, and magnesium, offers a winning combination of strength, durability, and corrosion resistance. In the context of antenna mounts and enclosures, this alloy's tensile strength of approximately 42,000 psi ensures robust structural integrity. It is crucial in outdoor environments where exposure to varying weather conditions and mechanical stress is inevitable.

As a precision casting method employed by Neway, Die casting provides a cost-effective solution for large-scale production of antenna mounts and enclosures. The high dimensional accuracy and repeatability achieved through this process align with the strict tolerances required to integrate antenna components seamlessly.

Moreover, ZA-8 alloy die casting enables the production of intricate designs and complex geometries, enhancing the aesthetic appeal of antenna mounts and enclosures while maintaining functionality. The efficient cycle times in die casting contribute to Neway's commitment to on-demand production, ensuring timely delivery without compromising quality.

In practical terms, Neway's expertise in utilizing ZA-8 alloy for die-casting antenna mounts and enclosures translates to superior products that withstand environmental challenges, deliver consistent performance, and align with industry standards. It reflects our dedication to precision manufacturing and underscores the advantages of choosing Neway as your one-stop custom parts supplier.

ZA-8 Alloy Die Cast Machinery Parts

ZA-8 alloy is a zinc-aluminum alloy known for its excellent castability and mechanical properties. ZA-8 is a popular choice for manufacturing machinery parts in die casting due to its balanced composition. Neway, a leading custom parts manufacturer, has extensive expertise in utilizing ZA-8 alloy for precision die-casting applications.

Die casting involves injecting molten metal into a mold cavity under high pressure, resulting in complex and accurate parts with minimal post-processing. ZA-8's composition of 8% aluminum, 3% copper, and a zinc base ensures a favorable combination of strength, dimensional stability, and corrosion resistance.

Neway's proficiency in die-casting methods, including ZA-8 alloy, enables the production of machinery parts with tight tolerances. For instance, achieving a dimensional tolerance of ±0.005 inches is a familiar feat, ensuring each component's precise fit and functionality.

Efficiency is a crucial aspect of Neway's die-casting processes. The use of ZA-8 alloy, with its low melting point and high fluidity, contributes to shorter cycle times. Neway's die-casting machinery is optimized for rapid production, achieving an impressive throughput of up to 1,000 parts per hour.