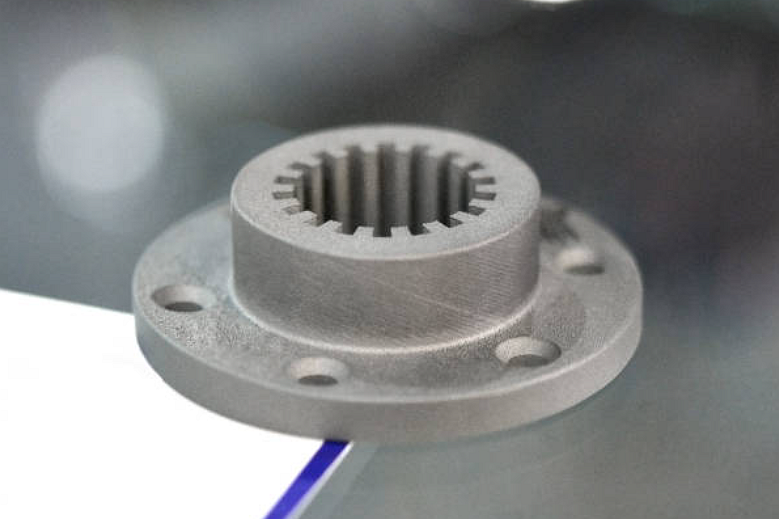

Metal Injection Molding Materials | Stainless Steel 17-4 PH

Description

Type 630, also known as 17-4, is a martensitic precipitation hardening stainless steel that has gained significant attention in metal injection molding due to its unique combination of high hardness and strength after suitable heat treatment. This blog post aims to provide a comprehensive overview of 17-4 PH, its specifications, heat treatment process, welding considerations, and mechanical properties. Understanding these aspects is crucial for part designers and purchasers who have procurement needs for MIM parts.

What is Type 17-4 PH?

17-4PH stainless steel is a grade of stainless steel known for its high hardness and strength after suitable heat treatment. It also has similar corrosion and heat resistance to Grade 304.

This grade of stainless steel is generally supplied in the solution-treated condition, making it machinable. It can then be age-hardened to achieve relatively high strengths. This aging treatment is so low in temperature that there is no significant distortion, making these grades well-suited to producing long shafts, which require no re-straightening after heat treatment.

17-4 PH has found its place in various industries due to its unique properties. It has been used for boat shafting in fresh water and seawater with the addition of cathodic protection. It is also highly resistant to stress corrosion cracking if aged at 550°C or higher.

The 17-4 PH stainless steel commonly used in metal injection molding has the following states:

MIM-17-4 PH (as-sintered)

MIM-17-4 PH (Heat treated)

MIM-17-4 PH (H900)

MIM-17-4 PH (H1100)

Specifications of 17-4 PH

17-4 PH has a specific chemical composition that contributes to its unique properties. Here's a table showing its composition:

Element | Percentage |

Carbon (C) | Max 0.07% |

Manganese (Mn) | Max 1.00% |

Silicon (Si) | Max 1.00% |

Phosphorus (P) | Max 0.040% |

Sulphur (S) | Max 0.030% |

Chromium (Cr) | 15.0 - 17.5% |

Nickel (Ni) | 3.0 - 5.0% |

Copper (Cu) | 3.0 - 5.0% |

Niobium + Tantalum (Nb+Ta) | 0.15 - 0.45% |

The physical properties of 17-4 PH also play a significant role in its applications. Here are some of its physical properties:

Property | Value |

Density | 7750 kg/m3 |

Elastic Modulus | 196 GPa |

Mean Coefficient of Thermal Expansion (0-100℃) | 10.8 ㎛/m/℃ |

Thermal Conductivity at 100 ℃ | 18.4 W/m.K |

Specific Heat (0-100 ℃ ) | 460 J/kg.K |

Electrical Resistivity | 800 nΩ.m |

Heat Treatment and Hardening of 17-4 PH

The 17-4 PH heat treatment process involves solution treatment and hardening. The solution treatment, also known as Condition A, involves heating at 1040°C for ½ hour and cooling to 30°C maximum in air. Oil quenching may be used for small non-intricate sections.

The hardening process, also known as aging, is a single low-temperature treatment employed to achieve the required properties. This treatment results in no distortion and only superficial discoloration. A slight decrease in size (shrinkage) takes place during the hardening; this is approximately 0.05% for Condition H900 and 0.10% for H1150.

Welding and Workability of 17-4 PH

All standard methods can successfully weld 17-4 PH. Preheating is not necessary, which simplifies the welding process. Properties comparable to those of the parent metal may be achieved in the weld metal by post-weld heat treatment. However, as with other high-strength steels, precautions should be taken in design and welding procedures to avoid the concentration of weldment stresses.

Regarding workability, 17-4 PH is usually supplied in the solution-treated condition, in which it can be machined. Its machinability is similar to Grade 304, making it a versatile material for various applications.

Mechanical Properties of 17-4 PH

17-4 PH exhibits impressive mechanical properties after solution treatment and age hardening. Here are some of the typical mechanical properties achieved:

Condition | Hardening Temp (℃) | Time (h) | Tensile Strength (MPa) | Yield Strength 0.2% Proof (MPa) | Elongation (% in 50mm) | Rockwell C (HR C) | Brinell (HB) |

H900 | 480 | 1 | 1310 | 1170 | 10 | 40 | 388 |

H925 | 495 | 4 | 1170 | 1070 | 10 | 38 | 375 |

H1025 | 550 | 4 | 1070 | 1000 | 12 | 35 | 331 |

H1075 | 580 | 4 | 1000 | 860 | 13 | 32 | 311 |

H1100 | 595 | 4 | 965 | 795 | 14 | 31 | 302 |

H1150 | 620 | 4 | 930 | 725 | 16 | 28 | 277 |

These properties make 17-4 PH suitable for applications where high strength or hardness is needed in conjunction with some corrosion resistance.

Conclusion

17-4PH is a versatile stainless steel grade that offers a unique combination of high hardness and strength after suitable heat treatment. Its corrosion and heat resistance, similar to Grade 304, make it valuable in various industries.

The specifications of 17-4 PH, including its chemical composition and physical properties, contribute to its unique characteristics. The heat treatment process, involving solution treatment and hardening, further enhances its mechanical properties without causing significant distortion.

17-4 PH can be successfully welded using all standard methods, and its machinability is similar to Grade 304. Its impressive mechanical properties, including tensile strength, yield strength, elongation, and hardness, make it suitable for applications requiring high strength or hardness in conjunction with some corrosion resistance.

The prospects for 17-4 PH are promising, given its unique properties and wide range of applications. Whether you're a part designer or a purchaser with procurement needs for MIM parts, understanding the properties and applications of 17-4 PH can help you make informed decisions.