B390

What Is Cast Aluminum B390?

Cast aluminum alloy B390 is a high-strength material known for its excellent casting properties and mechanical performance. B390 is a favored choice in precision casting, especially in die-casting processes. Neway, being a custom parts manufacturer, leverages the advantages of B390 in its precision casting operations.

The B390 alloy primarily comprises aluminum and alloying elements, contributing to its remarkable properties. It exhibits good corrosion resistance, making it suitable for applications where exposure to various environmental conditions is a concern. Additionally, B390 offers enhanced thermal conductivity, an essential characteristic in components where heat dissipation is crucial.

In the die-casting method, B390 proves advantageous due to its fluidity during the molten stage, allowing intricate details to be captured in the cast parts. Neway's utilization of B390 in die casting aligns with its commitment to delivering high-quality, custom metal parts with precision and durability.

The versatility of B390 extends its applications across different industries, from automotive components to electronic housings. Neway's expertise in incorporating B390 into its precision casting processes positions it as a reliable supplier for clients seeking custom parts focusing on performance and longevity.

For instance, Neway has successfully applied B390 to produce intricate automotive components, showcasing the alloy's ability to meet stringent industry standards. It underscores Neway's proficiency in precision casting and highlights the superior characteristics of B390 alloy in demanding applications.

Key Features And Applications of Aluminum B390 Castings

Aluminum alloy B390, renowned for its exceptional casting properties, boasts critical features that make it a preferred choice in precision casting, particularly in methods like die casting. Neway, a leading custom parts manufacturer, leverages these features to deliver top-notch components tailored to client specifications.

Key Features of Aluminum B390 in Casting:

High Strength:

B390 exhibits excellent mechanical strength, making it suitable for applications where robustness is paramount. This feature ensures that cast parts maintain structural integrity under various operational conditions.

Corrosion Resistance:

The alloy's corrosion resistance is a crucial advantage, especially in environments where exposure to moisture or aggressive substances is a concern. This feature enhances the longevity of cast components.

Thermal Conductivity:

B390 demonstrates superior thermal conductivity, allowing for efficient heat dissipation. It makes it an ideal choice for components in applications where thermal management is essential, such as electronic housings.

Fluidity in Casting:

During the molten stage, B390 exhibits good fluidity, enabling the capture of intricate details in the casting process. It is particularly advantageous in die casting, where complex shapes and fine details are standard requirements.

Versatility:

The versatility of B390 extends its applications across diverse industries, including automotive, electronics, and more. Its adaptability makes it a go-to choice for various custom part manufacturing needs.

Applications of Aluminum B390 in Casting:

Automotive Components:

Neway employs B390 in producing automotive components, taking advantage of its high strength and lightweight characteristics. It includes parts like engine components, transmission housings, and structural elements.

Electronics Housings:

Given its excellent thermal conductivity and corrosion resistance, B390 is utilized in casting electronic housings. It ensures effective heat dissipation and protection of sensitive electronic components.

Industrial Machinery:

B390 finds applications in casting parts for industrial machinery, where durability and performance are critical. It includes components like gear housings and structural elements.

Consumer Goods:

The versatility of B390 allows for its use in casting various consumer goods, ranging from kitchen appliances to recreational equipment. Its combination of strength and corrosion resistance enhances the reliability of these products.

In summary, Aluminum B390's essential features, including high strength, corrosion resistance, thermal conductivity, fluidity in casting, and versatility, make it an excellent choice for precision casting. Neway's expertise in leveraging these features ensures the delivery of custom parts that meet stringent quality standards across diverse industries.

Properties of Aluminum B390 Alloys

Chemical Comparison of Aluminum B390

Aluminum (Al) | Copper (Cu) | Magnesium (Mg) | Zinc (Zn) | Silicon (Si) | Iron (Fe) |

|---|---|---|---|---|---|

90.0 | 3.5 | 0.5 | 3.5 | 0.9 | 0.5 |

Function of Chemical Components

Each chemical component in Aluminum Alloy B390 serves a specific purpose in shaping the alloy's properties. The combination of aluminum with carefully controlled amounts of copper, magnesium, zinc, silicon, and iron results in a material with a balanced blend of strength, lightweight characteristics, corrosion resistance, and casting performance. Neway leverages this well-defined composition as a custom parts manufacturer to ensure that B390 meets the stringent requirements of precision casting applications in various industries.

Aluminum (Al):

Function: Aluminum is the primary constituent and contributes to the alloy's strength, lightweight nature, and corrosion resistance. It is the crucial element that defines the essential characteristics of the alloy.

Copper (Cu):

Function: Copper enhances the alloy's strength and hardness. It also improves wear resistance and facilitates better machinability. However, excessive copper content can lead to reduced corrosion resistance.

Magnesium (Mg):

Function: Magnesium is added to increase the alloy's strength and contributes to precipitation hardening in conjunction with copper. It also enhances the alloy's response to heat treatment.

Zinc (Zn):

Function: Zinc primarily contributes to the alloy's strength and hardness. It also improves casting fluidity, aiding manufacturing by ensuring the alloy can fill intricate molds effectively.

Silicon (Si):

Function: Silicon enhances the fluidity of the molten alloy during the casting process. It helps achieve detailed and intricate castings by reducing the viscosity of the molten metal. Silicon also contributes to the alloy's strength.

Iron (Fe):

Function: Iron is a common impurity in aluminum alloys, and its content is carefully controlled. Excessive iron can adversely affect the alloy's mechanical properties. Controlling iron levels is crucial for maintaining the desired characteristics of B390.

Physical and Mechanical Properties

Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (Brinell) | Shear Strength (MPa) | Impact Strength (J) | Fatigue Strength (MPa) | Thermal Conductivity (W/m·K) | Density (g/cm³) | Melting Range (°C) |

|---|---|---|---|---|---|---|---|---|

360 | 240 | 95 | 230 | 10 | 120 | 170 | 2.74 | 570-640 |

Typical Applications of Aluminum B390 Castings

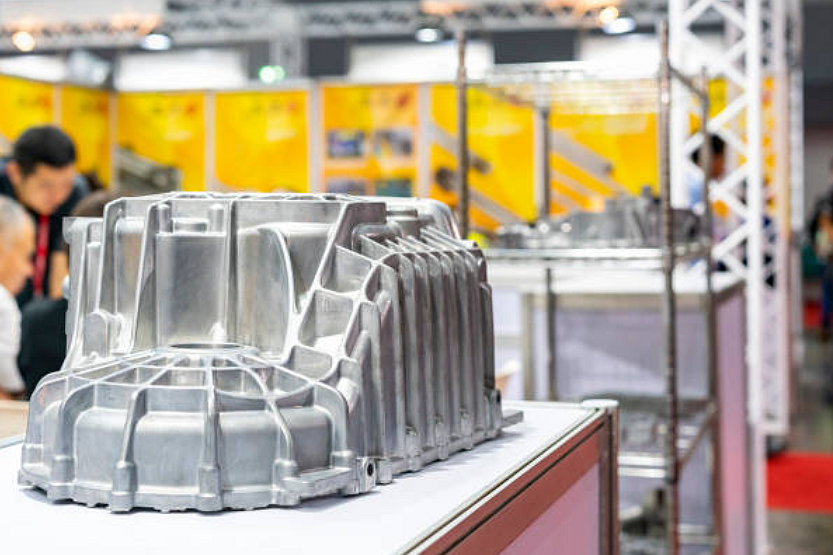

Aluminum B390 Die Casting Structural Elements

Aluminum Alloy B390 is an excellent choice for die-casting structural elements owing to its well-balanced mechanical properties. With a high tensile strength of 360 MPa and a yield strength of 240 MPa, B390 provides the necessary structural integrity to withstand substantial loads and resist deformation, ensuring the longevity of components subjected to mechanical stresses. Its Brinell hardness 95 enhances wear resistance, making it well-suited for structural elements that may encounter surface abrasion over time.

The alloy's ability to maintain shear strength at 230 MPa is crucial for stability under parallel forces, while an impact strength of 10 Joules ensures resilience against sudden impacts or dynamic loads. B390 further exhibits a fatigue strength of 120 MPa, indicating durability against repeated loading, a common consideration for long-term performance in structural applications. Moreover, its thermal conductivity of 170 W/m·K facilitates efficient heat dissipation, an essential feature for components exposed to temperature variations.

In addition to its mechanical properties, B390's moderate density of 2.74 g/cm³ adds to its appeal for die-casting structural elements, contributing to lightweight designs without compromising strength. Neway's utilization of Aluminum Alloy B390 in die casting aligns with the alloy's versatile and comprehensive properties, ensuring that the structural elements produced meet the demanding standards of diverse industries.

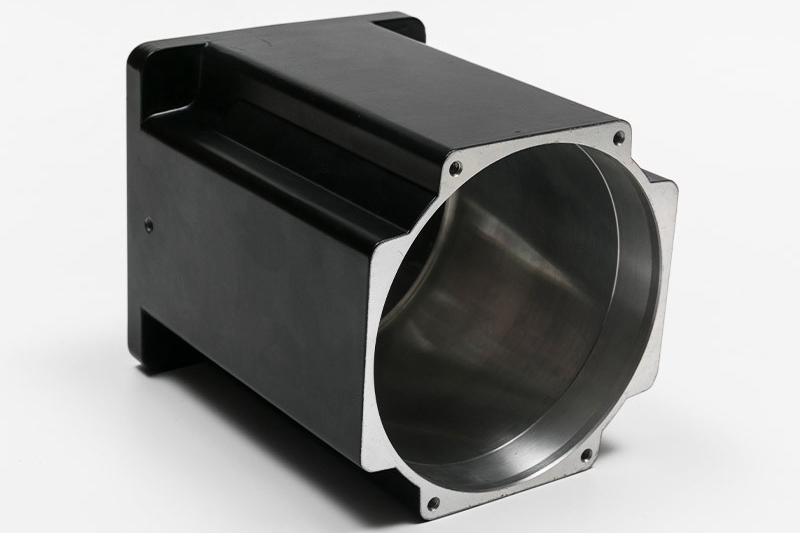

Aluminum B390 Die Casting Electronics Housings

Aluminum alloy B390 is an ideal choice for die-cast electronics housings due to its lightweight nature, excellent thermal conductivity, and corrosion resistance. With a 2.74 g/cm³ density, B390 ensures that electronic housings remain lightweight, facilitating the design of portable and sleek devices. This characteristic is particularly advantageous in the electronics industry, where minimizing weight without compromising structural integrity is crucial.

The alloy's remarkable thermal conductivity, measured at 170 W/m·K, is crucial for effective heat dissipation in electronics housings. As electronic components generate heat during operation, B390 facilitates the efficient transfer of heat away from sensitive parts, preventing overheating and ensuring optimal performance and longevity of electronic devices. This feature is especially vital in applications like smartphones, computers, and other electronic gadgets where thermal management is critical.

Furthermore, B390's corrosion resistance protects electronics in humid or corrosive environments. The alloy's resistance to corrosion ensures the durability of the housing, safeguarding the internal electronics from environmental factors that could compromise their functionality. Neway's use of Aluminum Alloy B390 in die-casting electronics housings reflects a strategic choice that aligns with the specific requirements of the electronics industry, ensuring the production of reliable and high-performance electronic devices.

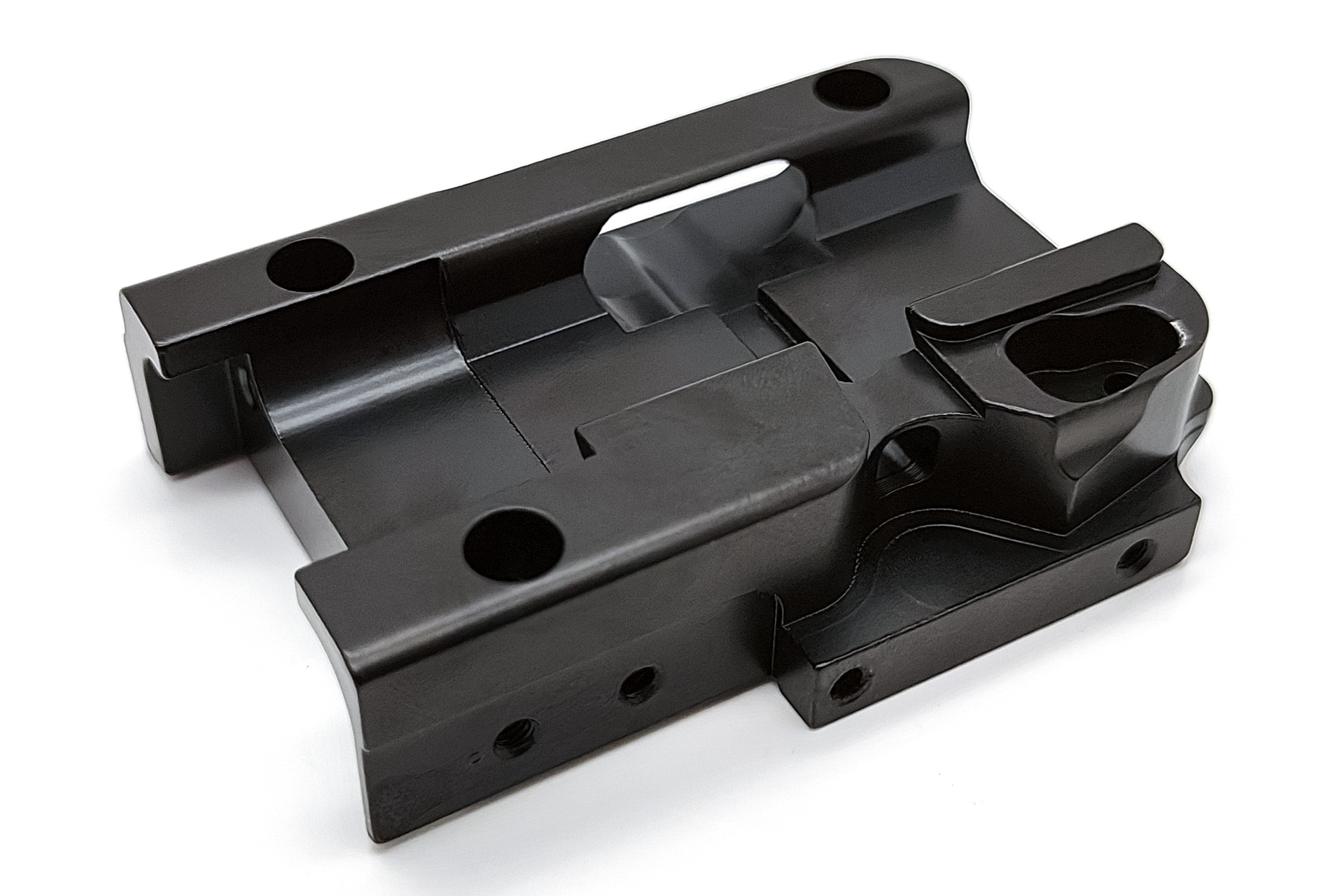

Aluminum B390 Die Casting Industrial Machinery Parts

Aluminum Alloy B390 emerges as a favorable material for die-casting industrial machinery parts, showcasing a well-balanced set of mechanical properties that meet the rigorous demands of heavy-duty applications. With a tensile strength of 360 MPa and a yield strength of 240 MPa, B390 provides the structural robustness required in industrial machinery components subjected to substantial loads and forces. It ensures the integrity and durability of the die-cast parts, contributing to the overall reliability of the machinery.

In addition to its strength, B390 exhibits a shear strength of 230 MPa, making it well-suited for components experiencing forces parallel to their surfaces, a common scenario in industrial machinery. The alloy's excellent thermal conductivity at 170 W/m·K is beneficial in dissipating heat generated during machinery operation, preventing overheating and contributing to the overall efficiency and performance of the equipment.

Moreover, the corrosion resistance of B390 adds to its suitability for industrial applications where exposure to harsh environments is prevalent. This corrosion resistance ensures a prolonged lifespan for die-cast machinery parts, reducing the need for frequent replacements and maintenance. Neway's choice of Aluminum Alloy B390 for die-casting industrial machinery parts underscores the alloy's ability to meet the stringent requirements of durability, strength, and performance in the demanding industrial sector.

Aluminum B390 Die Casting Consumer Goods Accessories

Aluminum Alloy B390 is an excellent choice for die-casting consumer goods accessories, providing lightweight design, durability, and versatility. With a 2.74 g/cm³ density, B390 creates lightweight accessories, making it an ideal material for consumer electronics, kitchen appliances, and recreational equipment. This lightweight characteristic enhances the overall user experience, especially in handheld or frequently manipulated accessories.

The alloy's superior corrosion resistance ensures the longevity and aesthetic appeal of consumer goods accessories, making it well-suited for items that may be exposed to varying environmental conditions. Whether used in kitchen gadgets or outdoor equipment, B390's resistance to corrosion safeguards the appearance and functionality of accessories over time, contributing to consumer satisfaction and product reliability.

Additionally, the versatility of B390 allows for intricate and detailed designs in die casting, enabling the production of aesthetically pleasing consumer goods accessories. The alloy's ability to capture fine details in the casting process makes it suitable for creating visually appealing and ergonomic designs. Neway's utilization of Aluminum Alloy B390 in die casting aligns with the diverse needs of the consumer goods industry, where the combination of functionality, durability, and design aesthetics is paramount.

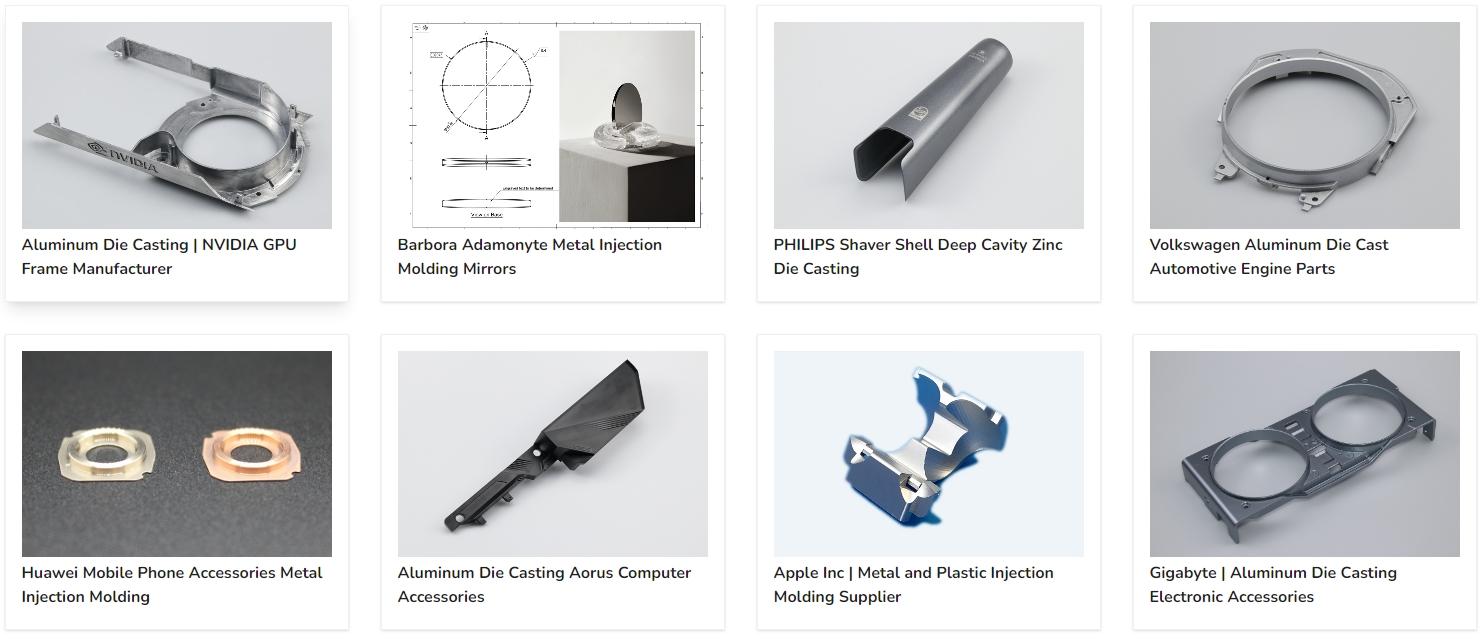

Brand Case Study

Neway has served many world-renowned companies, using its strong manufacturing capabilities and complete quality control system to provide further market competitiveness and quality assurance for major brands.

Neway Custom Manufacturing Capability

Neway has gradually improved the production system of basic hardware, plastic, and ceramic non-standard parts after 30 years of growth from the original CNC workshop. As well as polishing, PVD, and simple assembly lines. Provide one-stop, non-standard manufacturing services to our customers.