Fast Prototype Solutions for Consumer Electronics Development

Fast Prototype Solutions: The Key Engine Driving Innovation in Consumer Electronics

In today’s rapidly evolving consumer electronics market, the speed of product development directly determines a company’s competitiveness. At Neway, the engineering team fully recognizes the critical role of rapid prototyping throughout the product development cycle. From concept validation to functional testing, from user experience evaluation to market research, precisely manufactured prototypes enable customers to thoroughly verify their designs before committing to mass production, significantly reducing development risks and shortening time-to-market.

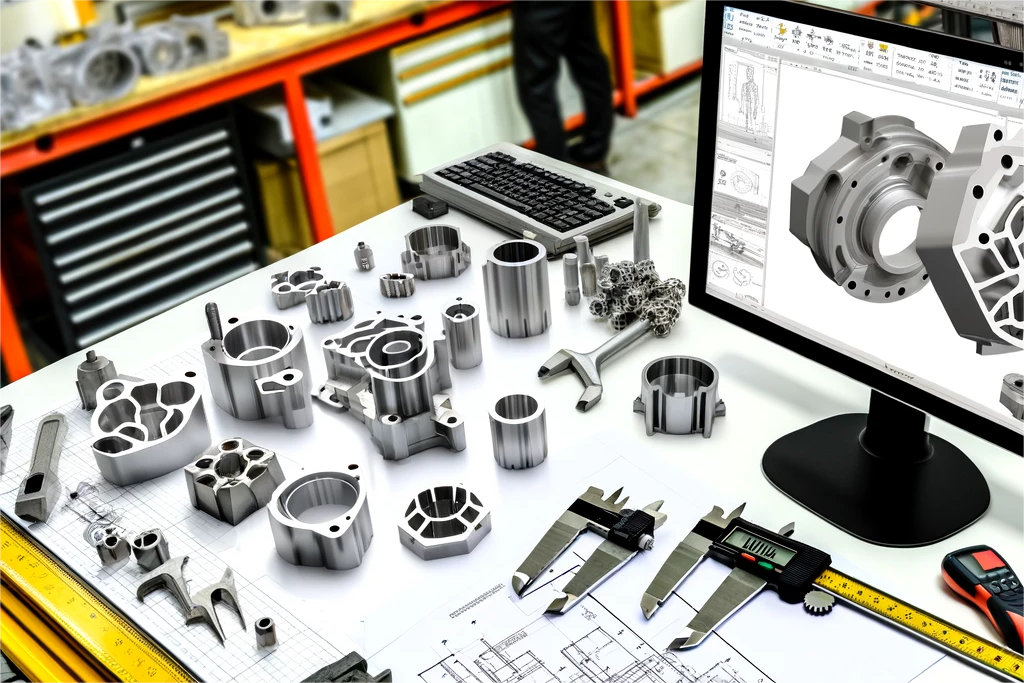

Core Manufacturing Processes for Rapid Prototyping in Consumer Electronics

3D Printing Prototypes: Unmatched Iteration Speed and Design Freedom

3D printing prototyping services provide unprecedented flexibility and speed for consumer electronics development. With multiple technologies, including SLA, SLS, and FDM, we can produce complex prototype parts within 24 hours. This approach is especially suitable for enclosures and components with internal channels, freeform surfaces, and complex assembly relationships, enabling designers to quickly validate the feasibility of their ideas. From wearable device housings to earphone bodies, 3D printing—with its exceptional capability to handle geometric complexity—has become the preferred solution at the concept design stage.

CNC Machining Prototypes: The Top Choice for High-Precision Functional Testing

When projects move into the functional verification phase, our CNC machining prototyping services deliver accuracy and performance close to that of final products. Our 5-axis machining centers can handle a broad range of materials from engineering plastics to metals, producing high-precision parts with tolerances controlled within ±0.05 mm. This process is particularly suitable for connectors, thermal management structures, and transmission components that require precise fits, ensuring prototypes meet stringent functional testing requirements.

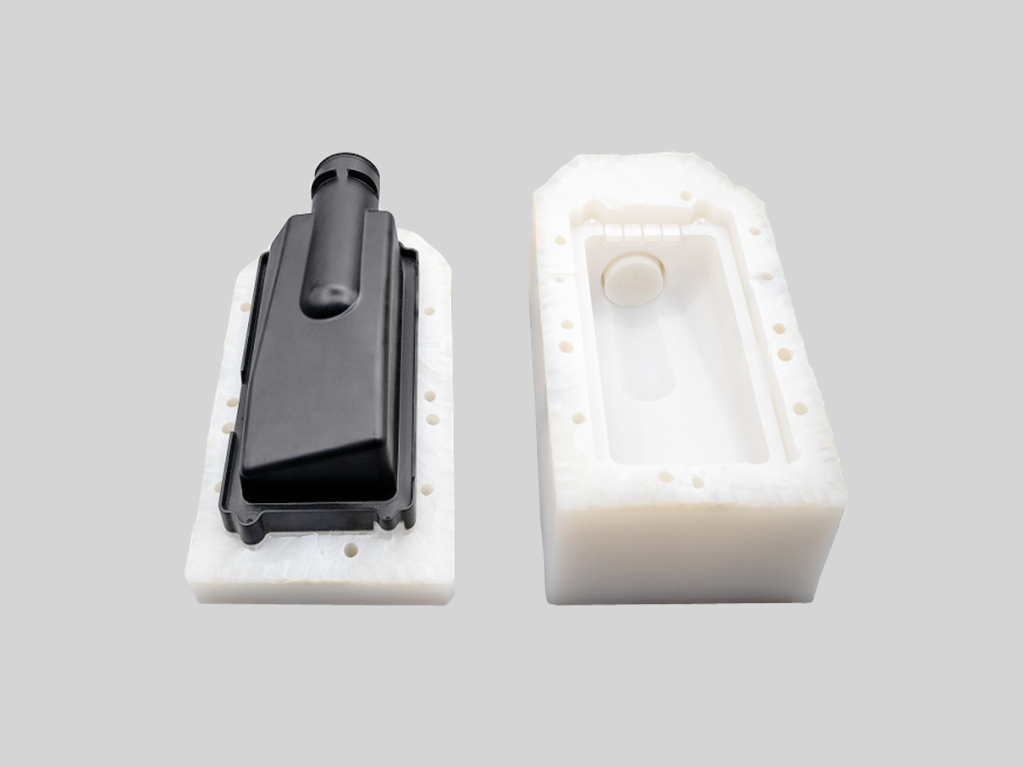

Rapid Tooling: Bridging the Gap Between Prototyping and Low-Volume Production

In the later stages of product development, our rapid molding prototyping services bridge the gap between prototyping and mass production. Using aluminum molds or soft tooling, we can deliver 50–1000 low-volume injection-molded parts within 2–3 weeks. This solution enables customers to conduct market tests and user studies while also validating mold design prior to formal production, thereby significantly reducing the risks associated with large-scale manufacturing.

Sheet Metal Rapid Prototyping: An Efficient Solution for Metal Enclosures and Structural Parts

For electronic products that require metal enclosures and structural components, our sheet metal fabrication services provide a fast-response solution. With advanced laser cutting and precision bending technologies, we can complete metal housings, shielding covers, and mounting brackets within just a few days. This process excels in applications such as router enclosures, smart home device structures, and industrial controller housings, providing customers with a cost-effective option for rapid metal prototyping.

Finishing and Post-Processing: From Rough Prototype to Final-Like Product

Finishing processes significantly enhance the visual quality and functional characteristics of prototypes, bringing them closer to the final product. Our painting services offer a wide range of colors and textures, from gloss to matte, as well as metallic effects and special finishes, to meet diverse aesthetic requirements. For parts requiring transparency or high-gloss finishes, professional polishing achieves mirror-like surfaces. Sandblasting can create uniform matte surfaces while improving tactile feel and wear resistance.

Specialized Material Selection for Consumer Electronics Prototyping

Prototype-Grade Engineering Plastics

In terms of plastic materials, ABS is one of the most widely used options in prototype production thanks to its balanced strength, toughness, and ease of processing. It is well-suited for most electronic housings. For applications requiring higher transparency and impact resistance, polycarbonate (PC) offers an excellent solution, particularly for light-transmitting covers and protective lenses.

Metals and Special Materials

Metals play an indispensable role in the manufacturing of functional prototypes. Aluminum alloys, with their superior strength-to-weight ratio and thermal conductivity, are ideal for thermal management components and lightweight structural designs. For applications requiring higher strength and corrosion resistance, stainless steel offers a reliable choice, particularly for precise structural components and connectors.

The Value of Rapid Prototyping Across Consumer Electronics Development Stages

Concept Proof and Design Validation

In the early development phase, rapid prototyping helps teams quickly transform ideas into physical models. Through direct tactile and interactive feedback, designers can evaluate a product's appearance, feel, and ergonomics, promptly identify issues, and make necessary improvements. This physical validation process goes far beyond the limitations of purely digital models, providing a solid foundation for sound design decisions.

Functional Testing and Assembly Verification

Once products move into engineering development, functional prototypes become essential tools for performance validation. Our high-precision prototype parts support a wide range of tests, including drop tests, durability tests, thermal management validation, and environmental reliability testing. Assembly verification prototypes enable engineers to verify the fit between components, optimize assembly processes, and ensure feasibility and efficiency in future mass production.

Market Testing and Investor Demonstrations

High-fidelity prototypes play a crucial role in marketing and fundraising activities. With our precisely finished and visually refined prototypes, customers can conduct professional product photography, create promotional materials, and gather real user feedback in market research. In the consumer electronics field, a well-crafted prototype often helps teams win investor confidence and lay the groundwork for project success.

Successful Case Sharing

Our technical strengths have been thoroughly proven across multiple flagship projects. In our collaboration on Huawei mobile phone accessories using metal injection molding, we leveraged rapid prototyping to help the customer complete the entire journey from concept to mass production within a very short timeframe, ensuring an on-schedule product launch.

Key Advantages of Choosing Neway for Rapid Prototyping Services

At Neway, we are committed to delivering comprehensive, high-efficiency rapid prototyping solutions. Our strengths lie not only in advanced equipment and mature process systems, but more importantly in our deep industry experience and robust engineering support. From material selection and process optimization to design recommendations and subsequent production support, our engineering team works closely with customers to ensure optimal outcomes for every prototype project. Through strict quality control and professional project management, we guarantee on-time delivery and high-quality results for every prototype.

Conclusion: Accelerate Innovation and Bring Your Consumer Electronics to Market Faster

In an increasingly competitive consumer electronics landscape, rapid prototyping has become a key driver of innovation. Choosing a professional rapid prototyping partner not only accelerates product development but also significantly reduces project risk. With comprehensive technical capabilities, extensive industry experience, and a customer-centric service philosophy, Neway has established itself as a trusted partner for many leading brands. Let us work together to quickly transform your innovative concepts into successful products.